Patents

Literature

35results about How to "Improve thermal crack resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Improved composite high-chromium iron-cast roller

It is a type of complex high-chromium green roll with strong oxidation resistance and wearable property. Components of its working lining are as follows: 2.5-3.0% C,0.5-1.2% Si,0.6-1.2% Mn,1.0-1.5% Ni,12-20% Cr,0.5-3.5 % Mo,0.05-0.5% V,0.2-1.5% W,0.03-0.3% Al, 0.03-0.1% N ,P <=0.04%,S <=0.04%,iron and impurity the rest. Advantages of this kind of green roll are as follows: wear-resisting property was improved by 50% ,mm rolling quantity increased by 30%,its life-span and rolling output were doubled, draw resistent intensity was reinforced and rigidity asymmetry was lowered effectively.

Owner:JIANGSU GONGCHANG ROLL

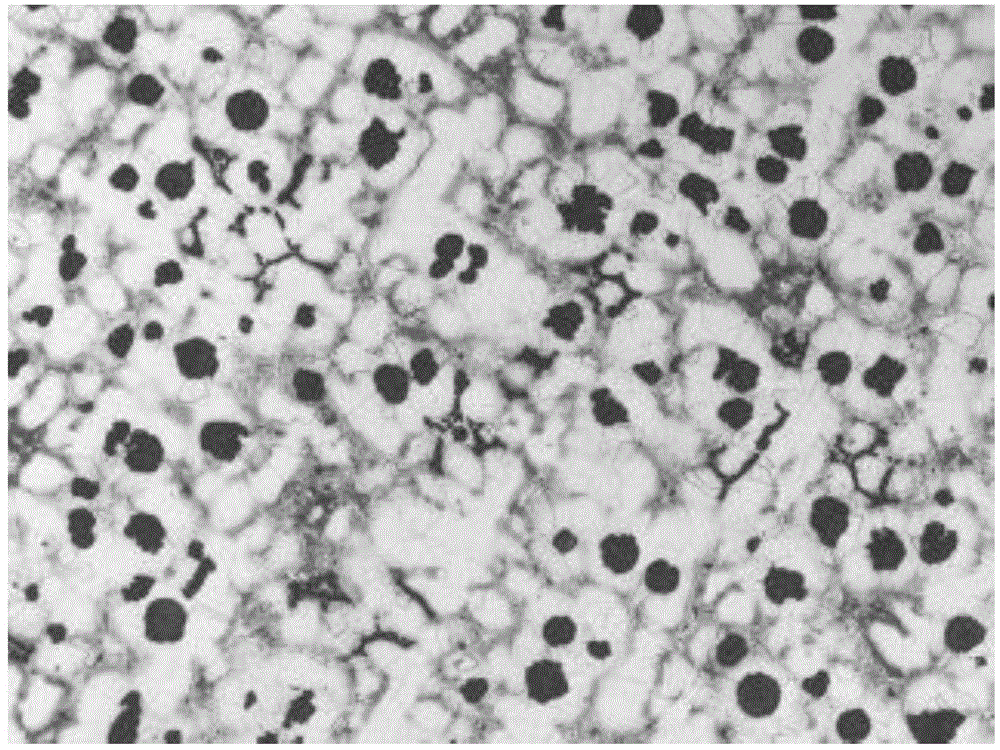

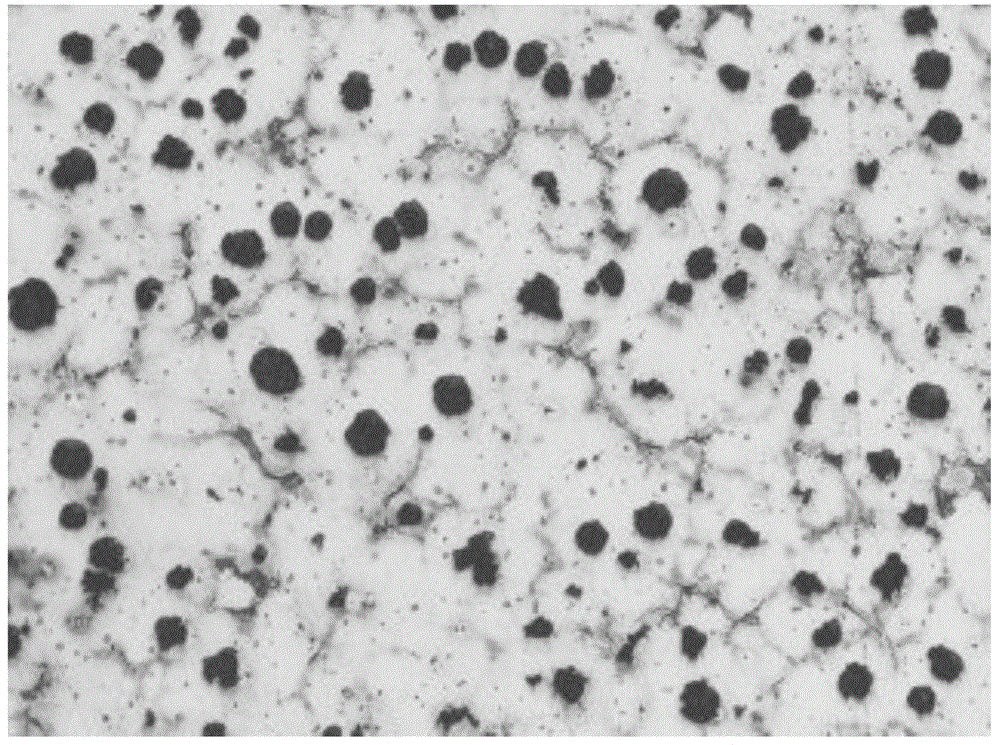

Bainite steel wheel for high-tenacity rail transit and manufacture method thereof

ActiveCN106048430AImprove toughnessLow notch sensitivityFurnace typesHeat treatment furnacesRare earthCarbide

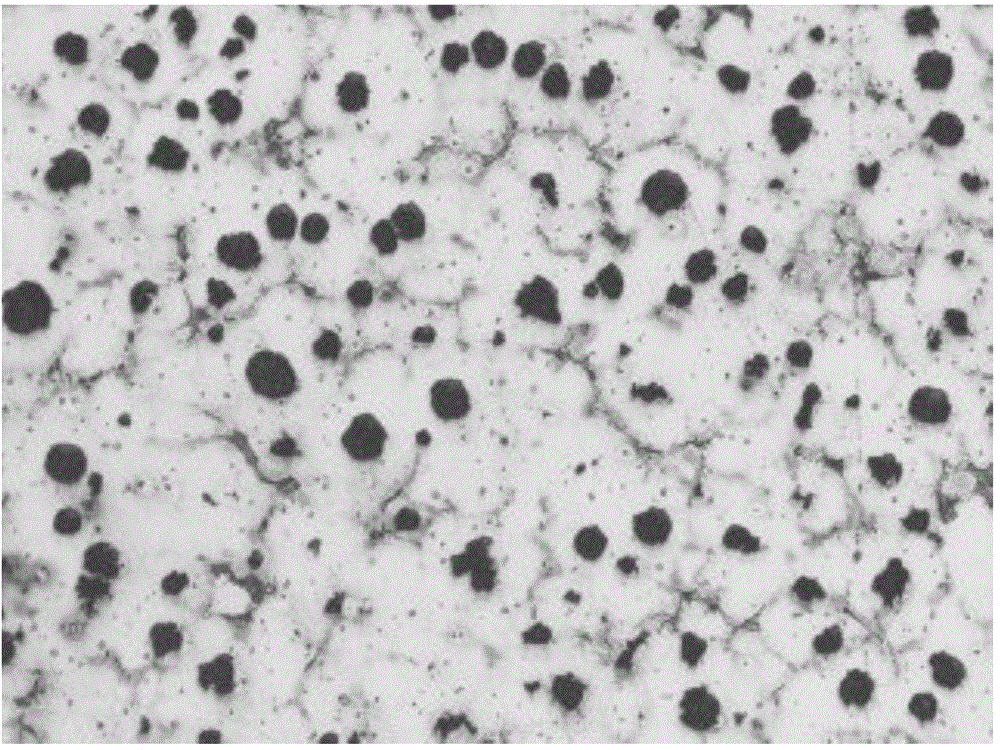

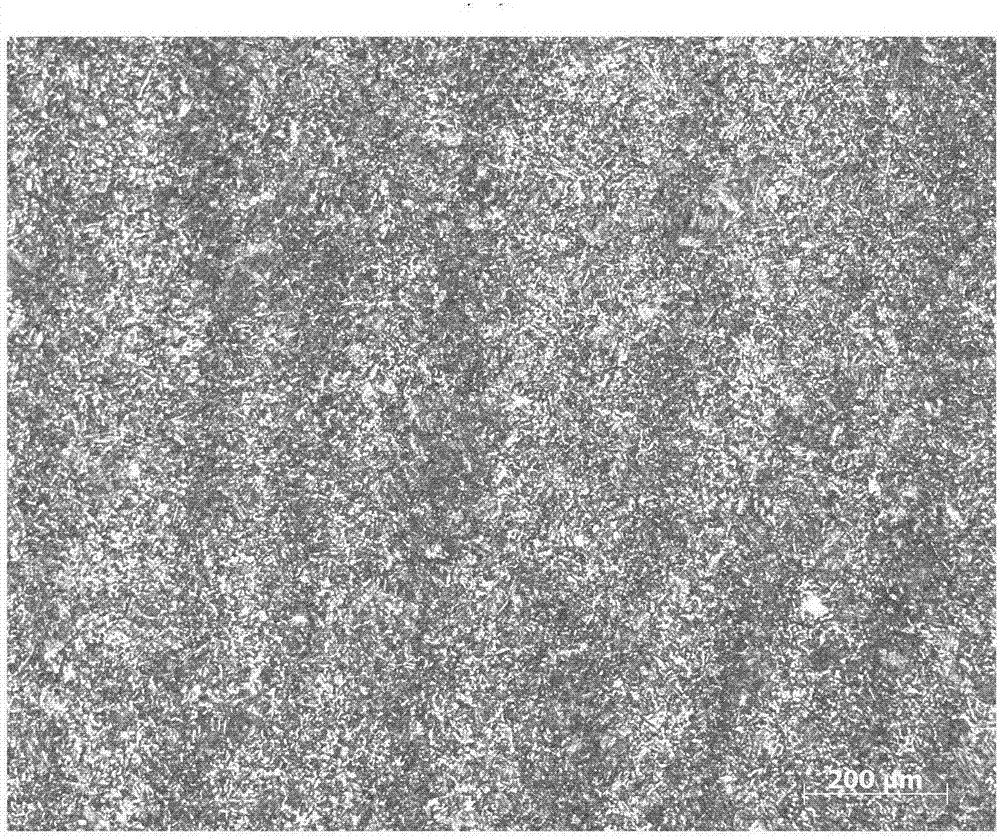

The invention provides a bainite steel wheel for high-tenacity rail transit and a manufacture method thereof. The bainite steel wheel comprises 0.10-0.40% of C, 1.00-2.00% of Si, 1.00-2.50% of Mn, 0.20-1.00% of Ni, 0.001-0.040% of RE, smaller than or equal to 0.020% of P, smaller than or equal to 0.020% of S and the balance of Fe and unavoidable residual elements, wherein Si plus Ni is larger than or equal to 1.50% and smaller than or equal to 2.50%, and Si plus Mn is larger than or equal to 2.00% and smaller than or equal to 4.00%. Compared with the prior art, the bainite steel wheel has the advantages that through a heat treatment technology, a rim of the wheel has a non-carbide bainite structure; spokes and a hub have metallographic structures taking granular bainites and supersaturated ferrites as main components; the wheel has high comprehensive mechanical properties, such as yield strength, tenacity and low-temperature tenacity; and besides, the cost is reduced, the service life of the wheel is prolonged, and comprehensive benefits are increased.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

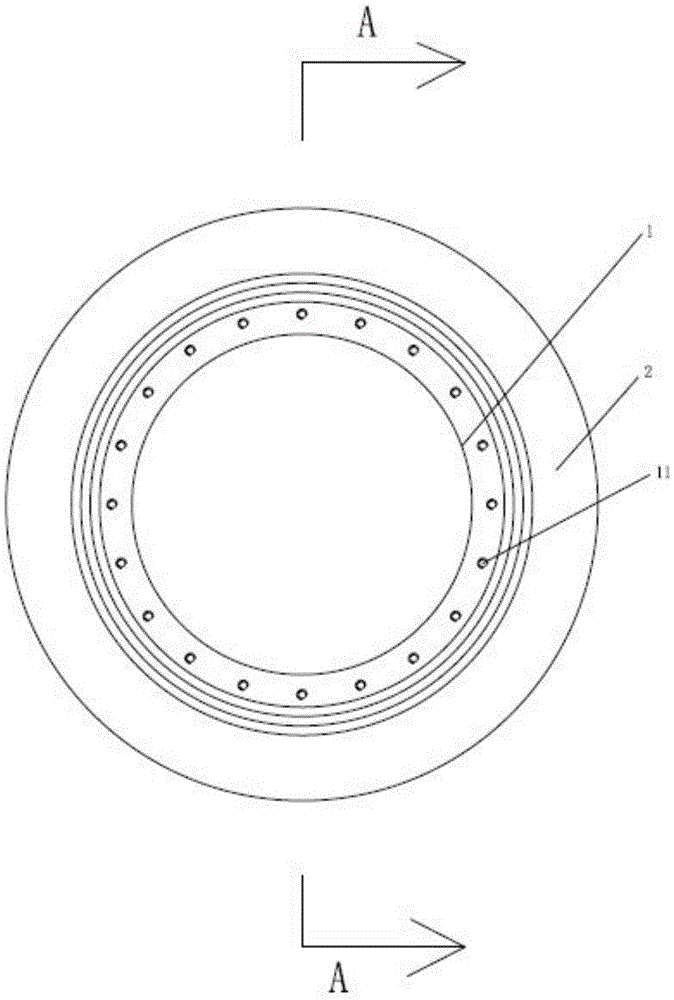

Centrifugal metal roll ring and manufacturing process thereof

ActiveCN105463308AImprove surface qualityEnhanced and improved surface qualityFurnace typesHeat treatment furnacesChemical compositionCrack resistance

The invention discloses a centrifugal metal roll ring and a manufacturing process thereof. The centrifugal metal roll ring comprises an inner layer and an outer layer which are made of different materials. The inner layer comprises 0.80%-1.2% of C, 1.00%-2.00% of Si, 0.50%-1.50% of Mn, not larger than 0.03 of P, 0.20%-1.00% of Ni, not larger than 0.20% of Mo, not smaller than 0.04% of Mg and the balance Fe. The outer layer comprises 2.00%-3.00% of C, 0.50%-1.50% of Si, 0.80%-1.50% of Mn, not larger than 0.10% of P, not larger than 0.03% of S, 12.00%-18.00% of Cr, not smaller than 0.50% of Ni, 0.20%-1.50% of Mo and the balance Fe. Compared with high-chromium cast iron and a high-carbon semi-steel roll ring which are obtained through inblock casting and centrifugal casting, by the adoption of the centrifugal metal roll ring, precious metal is saved, production cost is lowered by 18% to 22%, the roll ring is easy to cut, and the matrix organization, impact toughness, wear resistance and heat crack resistance can be improved greatly.

Owner:江苏凯达重工股份有限公司

Thermal cracking resistant hard sand

InactiveCN101941047AImprove adhesion and heat resistanceImprove thermal crack resistanceFoundry mouldsFoundry coresFuranOxide

The invention discloses thermal cracking resistant hard sand, which comprises raw sand, adhesive, curing agent, coupling agent and lubricating agent, wherein the using amount of the curing agent is 30 to 50 percent based on the using amount of the adhesive, the using amount of the coupling agent is 0.2 to 0.4 percent based on the using amount of the adhesive, the using amount of the adhesive is 2 to 5 percent based on the using amount of the raw sand, and the using amount of the lubricating agent is 1 to 3 percent based on the using amount of the raw sand; the adhesive consists of the following components in part by weight: 60 to 70 parts of furan resin, 20 to 30 parts of phenolic resin and 5 to 15 parts of tricresyl phosphate; and the raw sand comprises return sand, quartz sand, silica sand and ferric oxide powder. The thermal cracking resistant hard sand has the advantages of low brittleness, cracking resistance and low cost.

Owner:WUJIANG HYDRAULIC COMPONENTS FOUNDRY

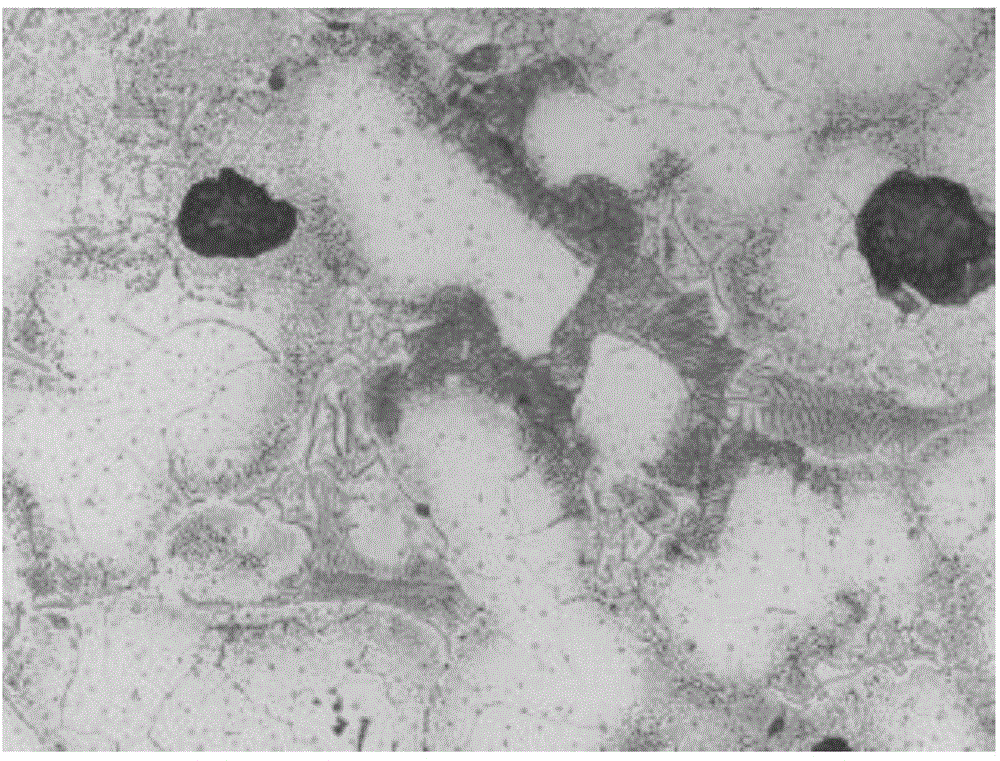

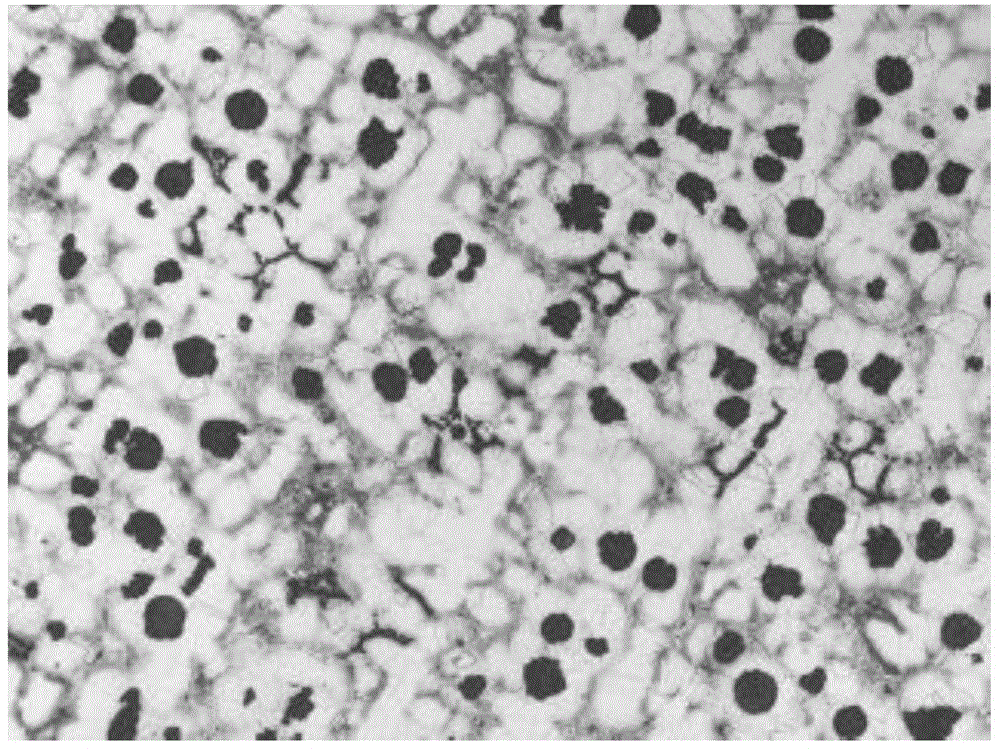

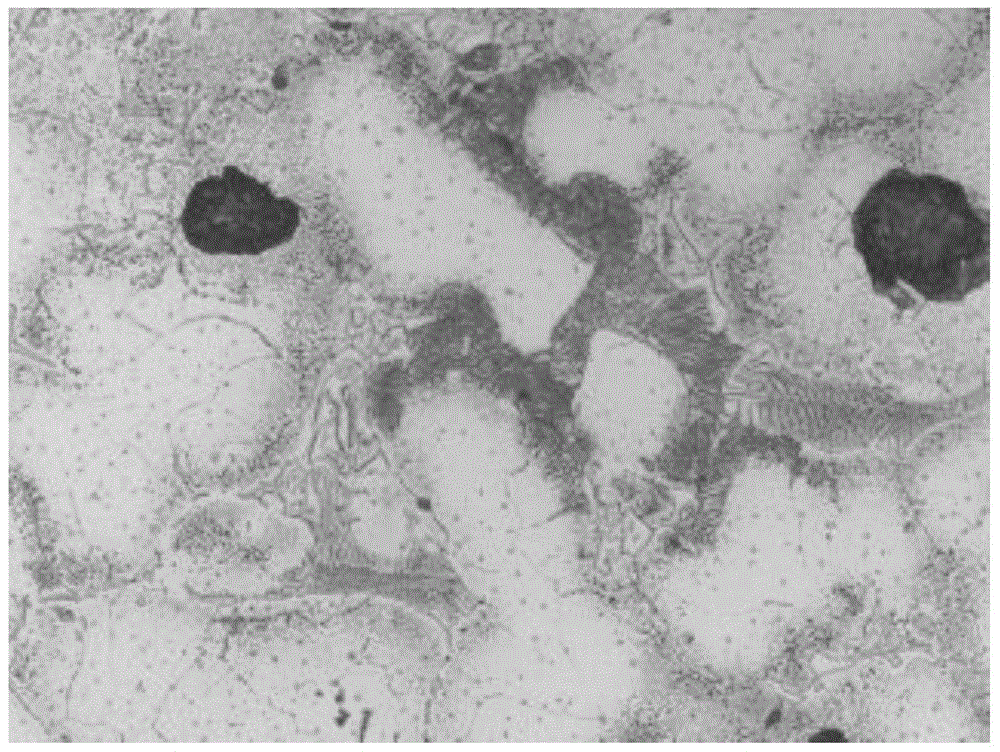

Heat-resisting spheroidal graphite cast iron and preparation method thereof

ActiveCN103820700AImprove heat resistanceImprove high temperature oxidation resistanceThermal fatigueAlloy

The invention relates to heat-resisting spheroidal graphite cast iron and a preparation method thereof. The preparation method comprises the following steps: smelting alloy, wherein the alloy comprises the following ingredients by mass: 2.7-3.5% of C, 4.0-5.0% of Si, 1.5-3.5% of W, 0.02-0.05% of Mg, 0.1-0.5% of V, Re being less than 0.03%, 0.15-0.6% of Mo, 0.05-1.0% of Mn, 0 to 0.03% of P, 0 to 0.02% of S, and the balance of iron and unavoidable impurities, discharging molten iron, inoculating the molten iron, spheroidizing, and casting. The heat-resisting spheroidal graphite cast iron prepared by the preparation method is of excellent high-temperature oxidation resistance, high-temperature anti-cracking property and thermal fatigue performance, and is good in mechanical property, low in production cost, and suitable for producing parts of an engine emission system.

Owner:CRRC QISHUYAN INSTITUTE CO LTD +1

Forged steel rubber and plastic calendar roller and heat treatment method thereof

ActiveCN105568135AStrong thermal cracking resistanceGuaranteed processing effectHeating timeMedium frequency

The invention discloses a forged steel rubber and plastic calendar roller and a heat treatment method thereof. The roller comprises, by weight percentage, 0.50%-0.75% of C, 0.40%-0.80% of Si, 0.60%-0.90% of Mn, not larger than 0.025% of P, not larger than 0.025% of S, 2.50%-3.50% of Cr, 0.30%-0.50% of Mo, 0.05%-0.15% of V and the balance Fe and inevitable impurities. According to the forged steel rubber and plastic calendar roller and the heat treatment method, the medium-frequency induction quenching technology is adopted, the heating speed is high, the quenching temperature is high, and weer and more even textures are obtained on the surface of the roller; and meanwhile, in cooperation with the movement speed during roller quenching, the heating time is controlled to obtain the shallow quenching layer thickness, and the machining performance of an inner layer is guaranteed.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

Sulfuric acid resistant pure austenitic stainless steel welding rod with high nickel-copper content and low hot cracking sensitivity and preparation method

ActiveCN109570824ANot prone to redness and crackingGood slag removalWelding/cutting media/materialsSoldering mediaNiobiumManganese

The invention discloses a pure austenitic stainless steel welding rod with high nickel-copper content and low hot cracking sensitivity. The sulfuric acid resistant pure austenitic stainless steel welding rod with high nickel-copper content and low hot cracking sensitivity is composed of a nickel-chromium-molybdenum-copper-iron alloy welding core and a coating which covers the surface of the welding core, wherein the coating is prepared from the components in parts by weight: 7-13 parts of rutile powder,4-8 parts of marble powder, 1.0-4.0 parts of fluorite powder 1.5-4.0 parts of mica powder, 1.5-3.0 parts of potassium feldspar powder, 2-3 parts of electrolytic manganese, 0.25-0.6 parts of niobium powder, 1.0-2.0 parts of metal chromium powder, 0.2-0.6 parts of molybdenum iron powder, 0.1-0.5 parts of sodium carbonate and 0.1-0.5 parts of sodium alginate. Compared with existing welding rods, the sulfuric acid resistant pure austenitic stainless steel welding rod with high nickel-coppercontent and low hot cracking sensitivity has excellent mechanical properties of deposited metal, high hot cracking resistance and excellent intergranular corrosion resistance.

Owner:ATLANTIC CHINA WELDING CONSUMABLES

Vertical roll collar used for head of high speed heavy rail and manufacturing technique thereof

InactiveCN107841683AImprove wear resistanceIncrease rolling outputFurnace typesHeat treatment furnacesSlagChemical composition

The invention discloses a vertical roll collar used for the head of a high speed heavy rail and a manufacturing technique thereof. The technique comprises the following steps that step I, the chemicalcomponents of the vertical roll collar are determined: 2.55-2.95% of C, 0.50-1.0% of Si, 0.35-0.65% of Mn, 3.5-3.85% of Cr, more than or equal to 0.35% of Ni, 1.6-1.95% of Mo, 9.0-9.5% of V, more than or equal to 0.3% of Co, less than or equal to 0.030% of P, less than or equal to 0.025% of S, less than or equal to 0.03% of Al, more than or equal to 0.15% of Re and the balance of Fe and inevitable impurities; step II, centrifugal casting is performed, namely smelting is performed through an electric arc furnace, so that the chemical components of molten steel meet requirement; and before steel tapping, aluminum blocks and glass slags are used for deoxidation and anti-oxidation; step III, a blank is subjected to thermal unpacking at 450-550 DEG C; then the blank enters a thermal treatmentfurnace for annealing immediately; the blank is subjected to thermal treatment after coarse machining; and then the blank is inspected to obtain a qualified high-vanadium high-speed steel product. Thevertical roll collar is made of the high-vanadium high-speed steel, so that the abrasion resistance and heat-cracking resistance of a roll are improved.

Owner:江苏凯达重工股份有限公司

Submerged arc welding flux-cored wire and preparation method thereof

ActiveCN109434321AImprove crack resistanceImprove thermal crack resistanceWelding/cutting media/materialsSoldering mediaCrack resistanceSlag

The invention provides a submerged arc welding flux-cored wire which comprises a steel belt and a flux core. Chemical components of the steel belt comprise, by weight, smaller than or equal to 0.02% of C, 0.2-1.2% of Mn, 0.3-1.8% of Si, 22-28% of Cr, 2-8% of W, 0.2-0.4% of Cu, 0.1-0.3% of V, smaller than or equal to 0.005% of S, smaller than or equal to 0.006% of P and the balance Fe. The components of the flux core comprise, by weight, 20-35% of marble, 15-28% of fluorite, 7-12% of mica, 6-14% of titanium dioxide, 2-8% of ferrovanadium, 2-6% of silicon iron, 2-12% of ferrotitanium, 13-17% offerro-boron, 2-8% of ferro-molybdenum, 3-12% of graphite and the balance chromium iron. By the adoption of the welding wire, while the hardness of overlaid metal can be improved, toughness and crack resistance of the metal are improved, the two aspects of metallurgy and the technology are improved, the high toughness and crack resistance of the overlaid high-hardness metal are improved, meanwhile,the good welding technology performance is ensured, slag removal is easy, splashing is avoided, the hardness is high, and the wear resistance is excellent.

Owner:江苏佳腾新材料有限公司

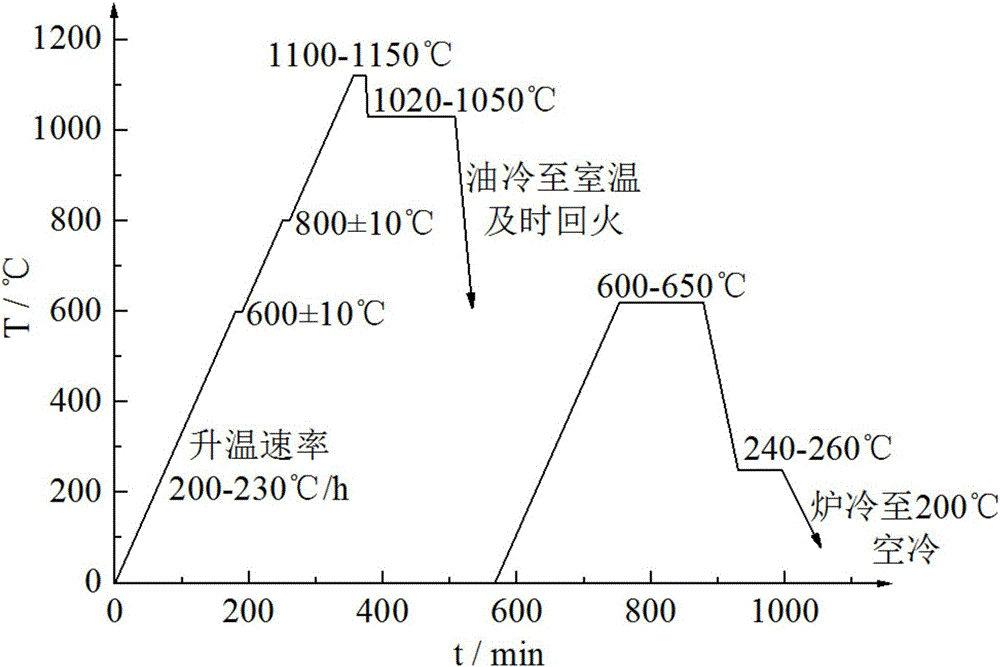

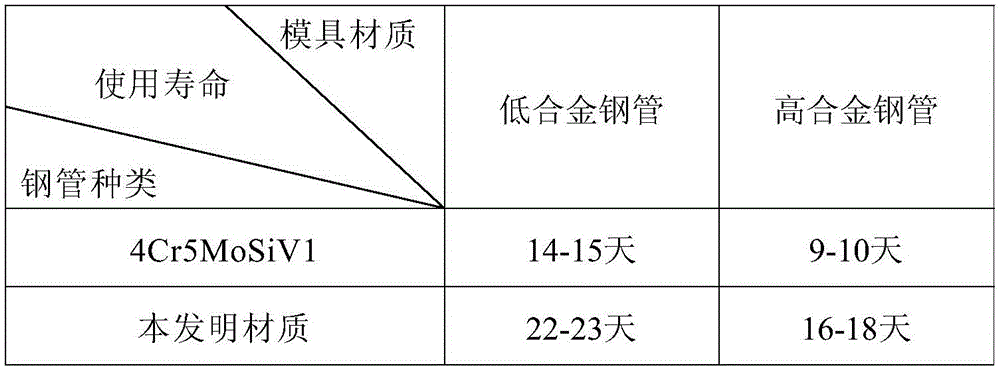

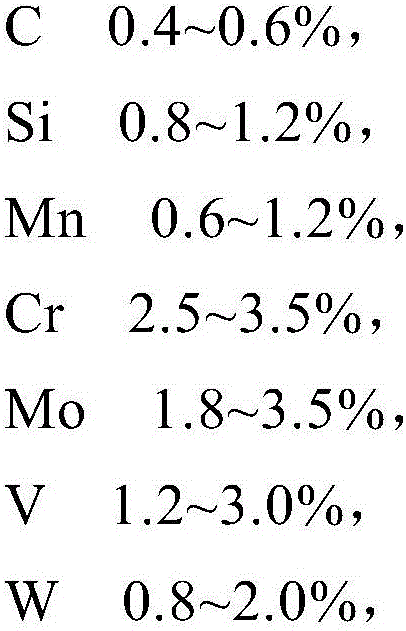

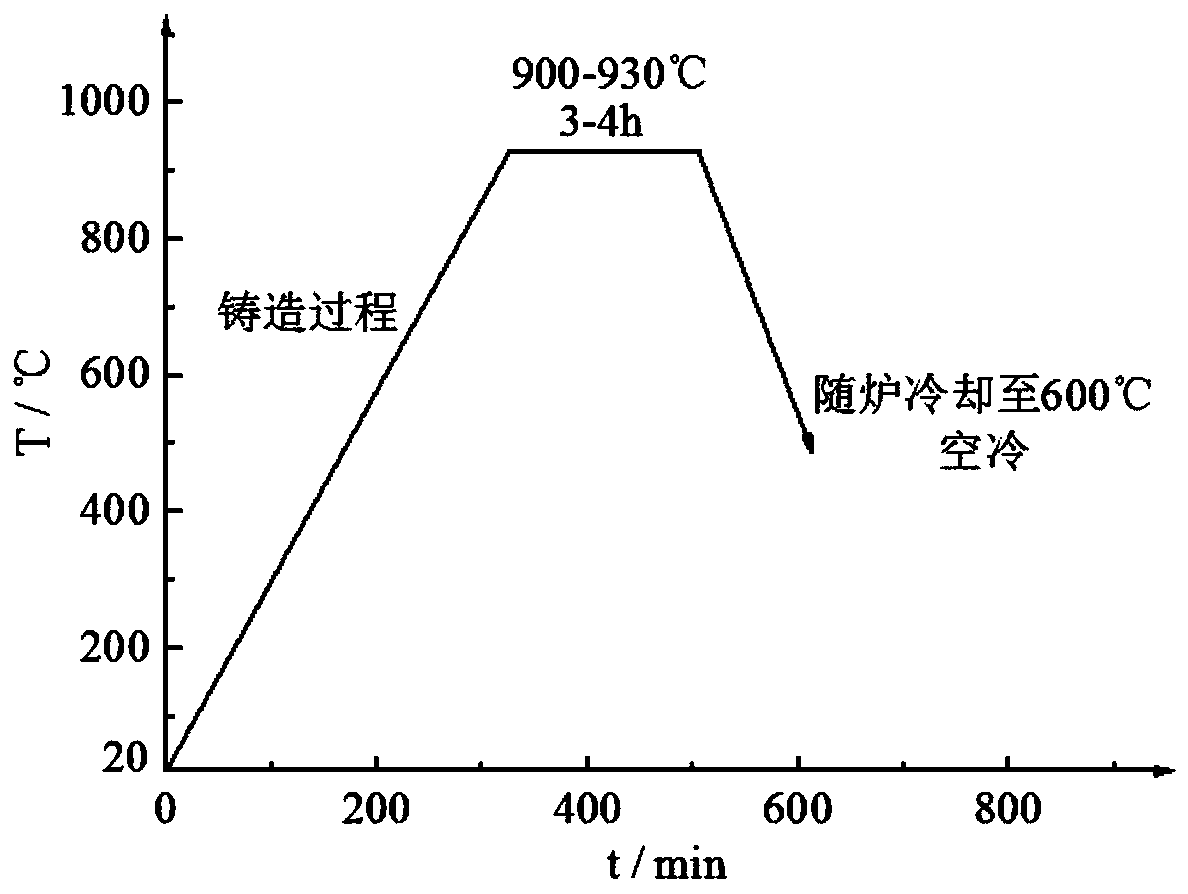

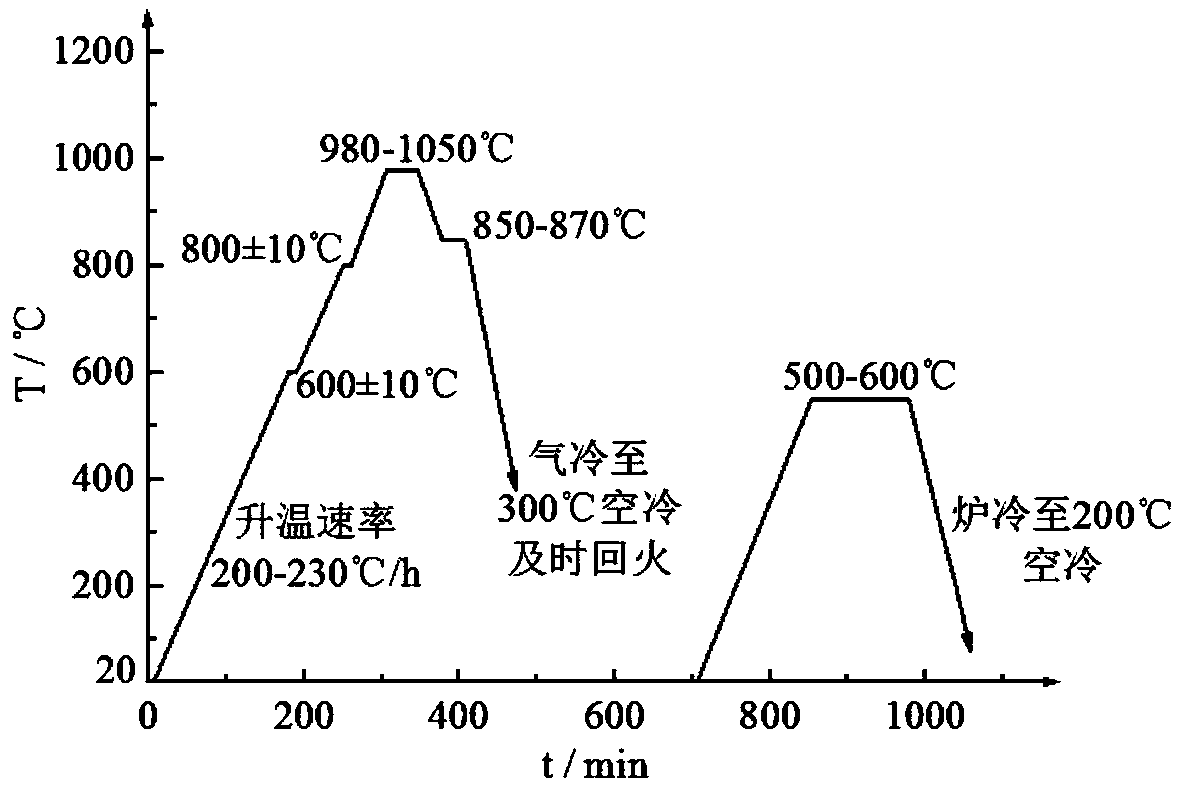

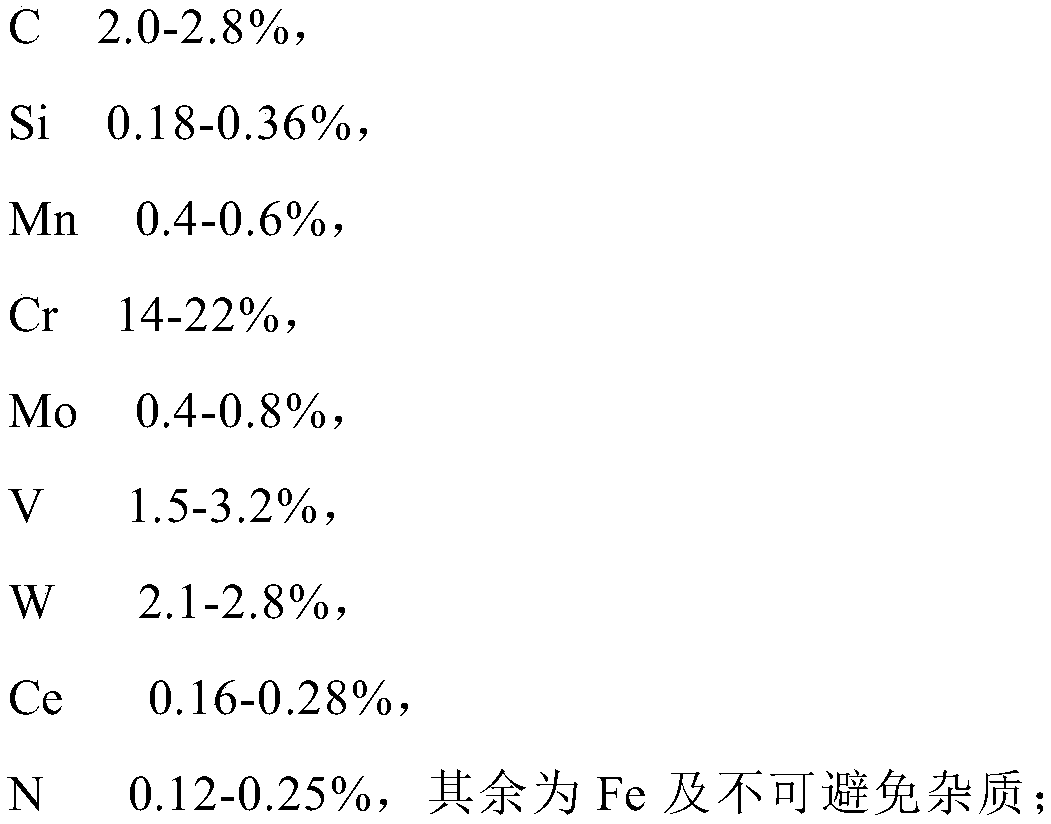

Seamless steel pipe thickening mould material with long service life and heat treatment technology thereof

ActiveCN106834928ARaise room temperatureImprove mechanical propertiesChemical compositionMechanical property

The invention relates to a seamless steel pipe thickening mould material with long service life and a heat treatment technology thereof. The seamless steel pipe thickening mould material comprises the following chemical ingredients in percentage by weight: 0.4-0.6% of C, 0.8-1.2% of Si, 0.6-1.2% of Mn, 2.5-3.5% of Cr, 1.8-3.5% of Mo, 1.2-3.0% of V, 0.8-2.0% of W, 0.35-0.6% of Nb and balance of Fe and inevitable impurities; the following relation formulas need to be met: C=0.03Mn+0.015Cr+0.16V+0.2Nb, and (V+Mo+W / 2)=3.4-5.7wt.%. The seamless steel pipe thickening mould material has the advantages that on the basis of a 4Cr5MoSiV1 material, by comprehensively adjusting composition proportion and designing a reasonable heat treatment technology, a thickening mould meeting mechanical property requirements such as resistance to heat crack is developed, so that abnormal fracture failure of the thickening mould is avoided, and service life of the thickening mould is prolonged.

Owner:BAOSHAN IRON & STEEL CO LTD

Low zinc hot dipping aluminium alloy plating material containing Ca multi-combination metamorphism

InactiveCN103131986ALower eutectic temperatureIncrease wetting and fusion abilityHot-dipping/immersion processesExtensibilityLiquid viscosity

The invention discloses low zinc hot dipping aluminium alloy plating material containing Ca multi-combination metamorphism. The composition of alloy comprises, by element weight, 10%-13% of Zn, 5.0% of alloy enhancer Cu, 0.03 % of polarization metamorphic agent Ca, 0.2 % of solvent passivator Mo and 0.5% of rare earth addition, and the rest of the composition of the alloy are A1 and micro impurities which are unavoidable. The low zinc hot dipping aluminium alloy plating material containing the Ca multi-combination metamorphism solves the problems that due to dissolution of iron in a hot dipping plating process, zinc liquid viscosity is enabled to be increased and the capability of the surface of an infiltrating steel matrix is reduced, the thickness of a zinc layer is obviously increased due to the fact that iron content in zinc liquid is increased, and therefore ductility and the appearance of the a plating layer are enabled to be poor, and other problems are solved too. The aluminium alloy plating material for hot dipping is obtained, wherein the aluminium alloy plating material for hot dipping is good in matrix wettability, strong in binding force, high in strength, good in extensibility, high temperature-resistance, thin in plating layer, and strong in corrosion resistance.

Owner:贵州铝厂有限责任公司

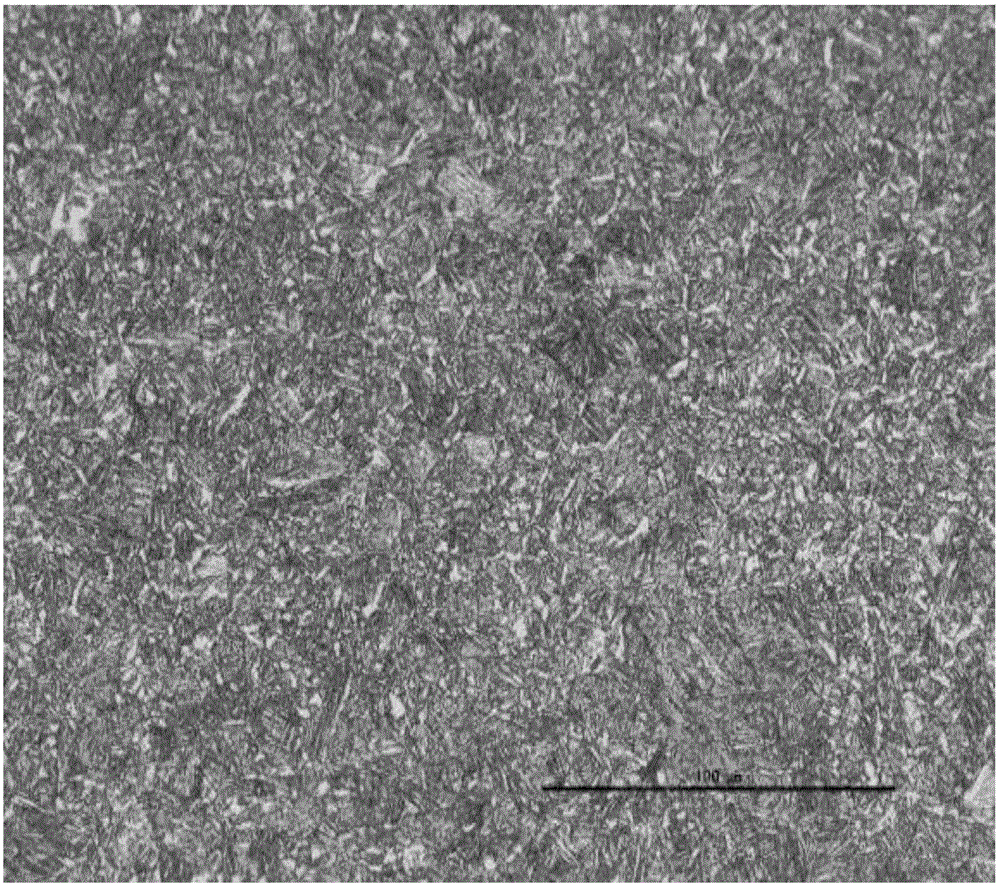

GVTi wear-resistant type semisteel roller and preparation method thereof

InactiveCN110343956AImprove thermal crack resistanceIncreased roll strengthFurnace typesHeat treatment furnacesHardnessTitanium alloy

Owner:宜兴市国昌轧辊有限公司

Low-cost and high-wear-resistant stretch reducing roller and heat treatment process thereof

ActiveCN111101077ARaise room temperatureImprove mechanical propertiesFurnace typesHeat treatment furnacesMechanical engineeringMaterials science

The invention provides a low-cost and high-wear-resistant stretch reducing roller and a heat treatment process thereof. According to the obtained low-cost and high-wear-resistant stretch reducing roller, the normal-temperature hardness is more than 50 HRC, and the tensile strength is more than 700 MPa; and the problems of high consumption, prone roll breaking in case of large hole diameter and prone annular rolling mark on the roll surface in the rolling process of a current stretch reducing roller are solved.

Owner:BAOSHAN IRON & STEEL CO LTD

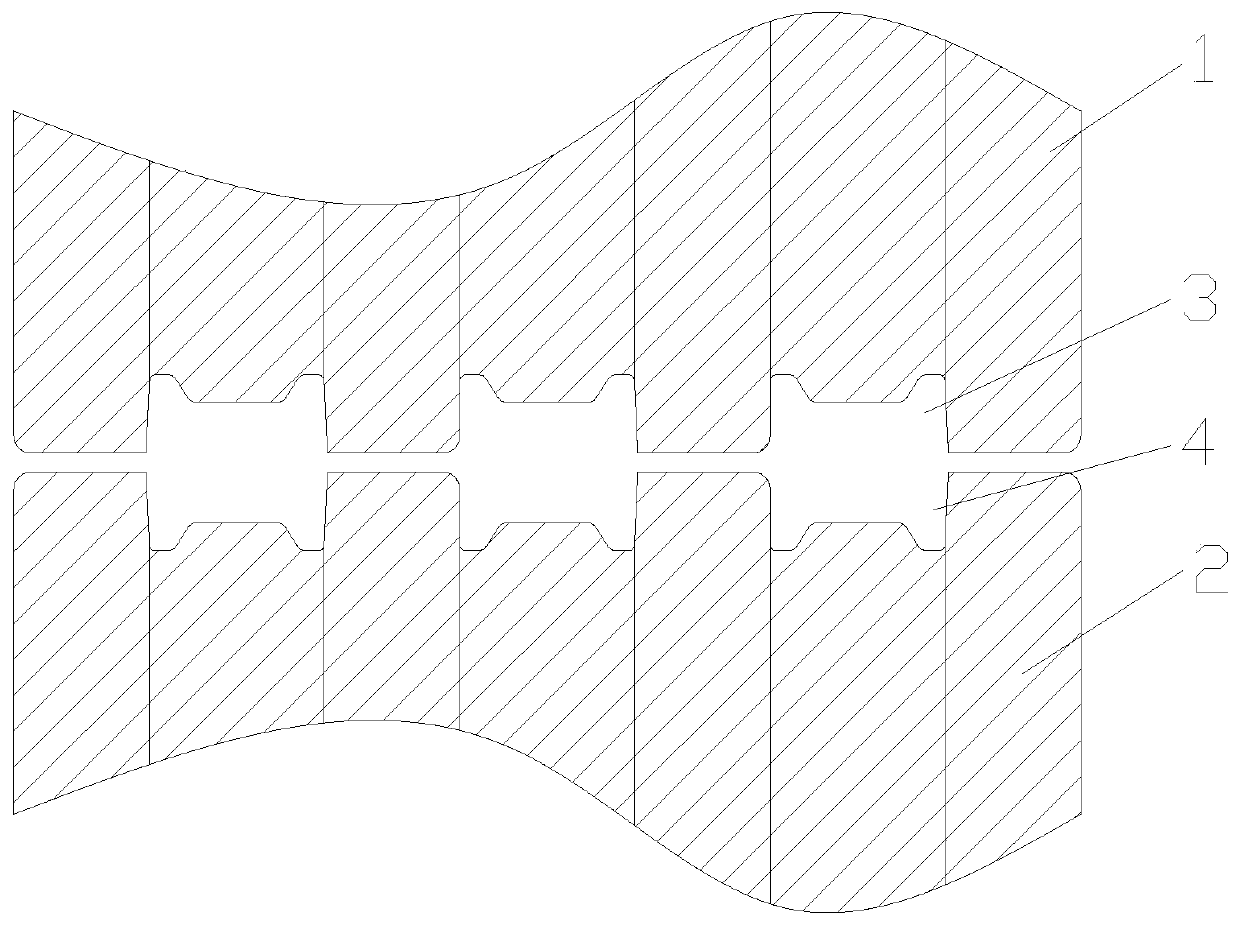

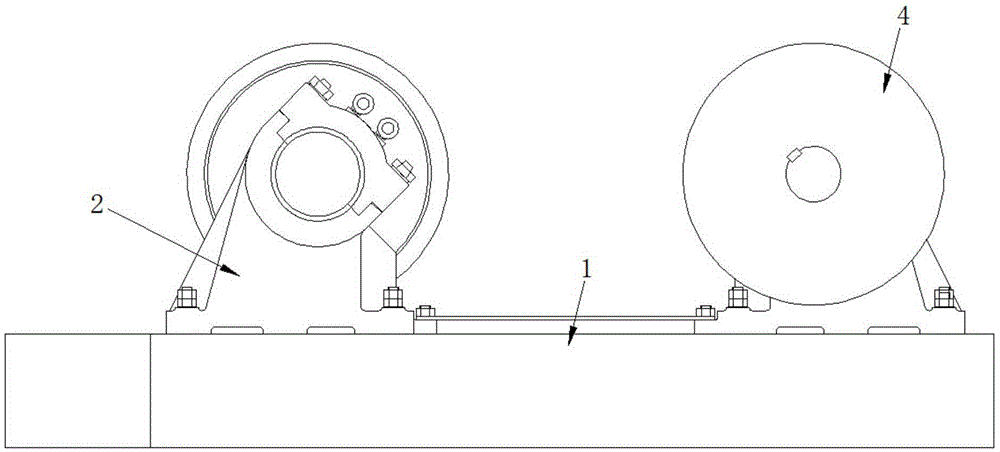

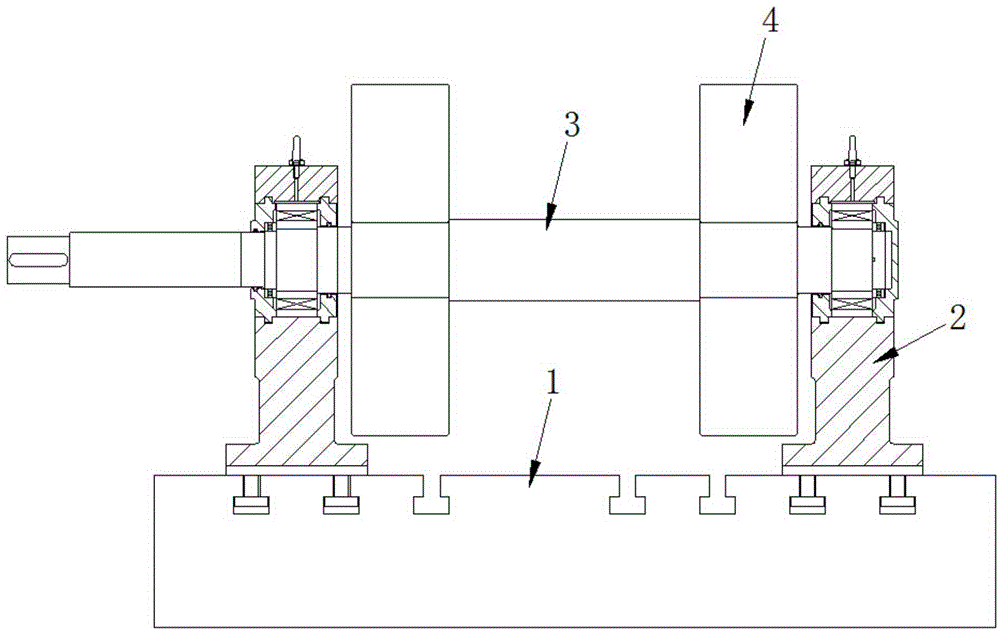

Nickel-molybdenum-vanadium alloy semi-steel roll used for section mill S-shaped rack

PendingCN110257711ASimple structureReasonable processing technologyRollsElectric furnaceWear resistanceToughness

The invention relates to the technical field of rolls, in particular to a nickel-molybdenum-vanadium alloy semi-steel roll used for a section mill S-shaped rack. The nickel-molybdenum-vanadium alloy semi-steel roll is provided with an upper roll and a lower roll which are arranged in parallel in the up-down direction, and multiple first ring-shaped opening grooves are formed in the upper roll in the length direction. Multiple second ring-shaped opening grooves are formed in the positions, opposite to the first ring-shaped opening grooves, of the lower roll. The first ring-shaped opening grooves and the second ring-shaped opening grooves are subjected to die combining to form rolled H profile steel. The nickel-molybdenum-vanadium alloy semi-steel roll used for the section mill S-shaped rack is simple in structure and reasonable in machining technology, the wear resistance, the hardness fall, the impact extrusion toughness, the heat crack resisting performance and plasticity of the roll can be obviously improved, and therefore the service life of the overall roll is prolonged, and the roll machining efficiency is improved.

Owner:常州市中宇合金轧辊厂

Al-Cu-Sr-RE-Ge aluminium alloy wire for power cable and preparation method thereof

InactiveCN110923529AHigh tensile strengthHigh yield strengthApparatus for heat treatmentConductive materialPower cableThermal insulation

The invention provides an Al-Cu-Sr-RE-Ge aluminium alloy wire for a power cable and a preparation method thereof. The Al-Cu-Sr-RE-Ge aluminium alloy wire comprises the following components: 0.4-0.8wt%of Cu, 0.15-0.36wt% of Sr, 0.12-0.32wt% of RE, 0.13-0.28wt% of Ge, 0.11-0.18wt% of Si, 0.02-0.09wt% of Co, 0.03-0.07wt% of Ca, 0.01-0.05wt% of Cr and the balance of Al and unavoidable impurities. Thepreparation method comprises the following steps: 1, smelting and pouring; 2, quenching at 505-520 DEG C, and carrying out aging treatment at 210-225 DEG C; 3, extruding into an aluminium alloy rod at 485-510 DEG C; 4, drawing into a first aluminium alloy wire at 290-310 DEG C; 5, drawing into a second aluminium alloy wire with the diameter of 1-2.5mm at 330-360 DEG C; and 6, carrying out thermalinsulation on the second aluminium alloy wire for 3-5 hours at 350-380 DEG C, then reducing the temperature to 230-260 DEG C, carrying out thermal insulation for 6-10 hours, and air cooling to the room temperature. The Al-Cu-Sr-RE-Ge aluminium alloy wire has excellent electric conductivity and heat resistance and is high in strength, toughness and fatigue resistance.

Owner:安徽峰创云通数据科技有限公司

Sulfuric acid corrosion-resistant pure austenitic stainless steel electrode with high nickel and copper content and low thermal crack sensitivity and preparation method

ActiveCN109570824BNot prone to redness and crackingEasy to remove slagWelding/cutting media/materialsSoldering mediaNiobiumSS - Stainless steel

The invention discloses a sulfuric acid corrosion-resistant pure austenitic stainless steel electrode with high nickel and copper content and low thermal crack sensitivity, which is composed of a nickel-chromium-molybdenum-copper-iron alloy welding core and a coating covering the surface of the welding core. The content is: 7-13 parts by weight of rutile powder, 4-8 parts by weight of marble powder, 1.0-4.0 parts by weight of fluorite powder, 1.5-4.0 parts by weight of mica powder, 1.5-3.0 parts by weight of potassium feldspar powder, 2-3 parts by weight of electrolytic manganese parts by weight, 0.25-0.6 parts by weight of niobium powder, 1.0-2.0 parts by weight of metallic chromium powder, 0.2-0.6 parts by weight of ferromolybdenum powder, 0.1-0.5 parts by weight of soda ash and 0.1-0.5 parts by weight of sodium alginate. Compared with the existing ones, the electrode deposited metal of the invention has excellent mechanical properties, strong thermal crack resistance and excellent intergranular corrosion resistance.

Owner:ATLANTIC CHINA WELDING CONSUMABLES

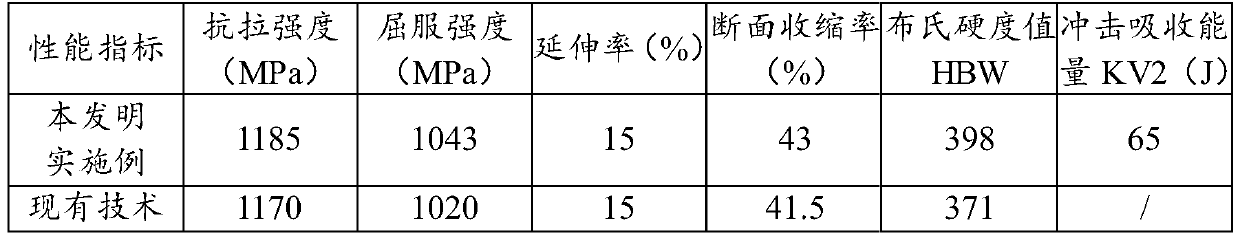

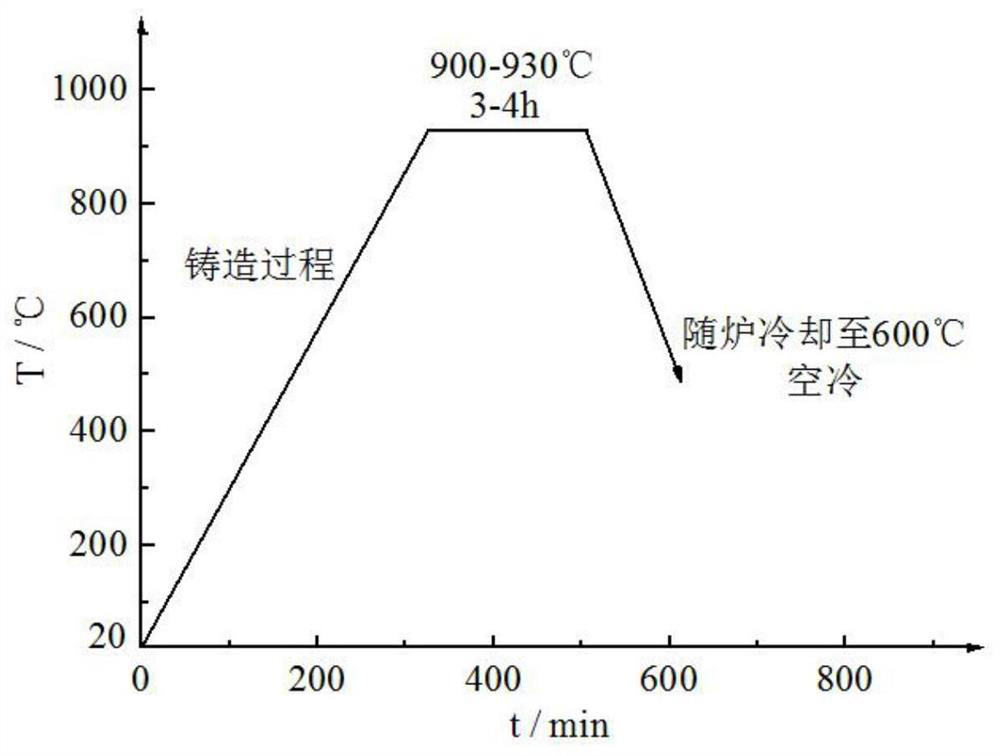

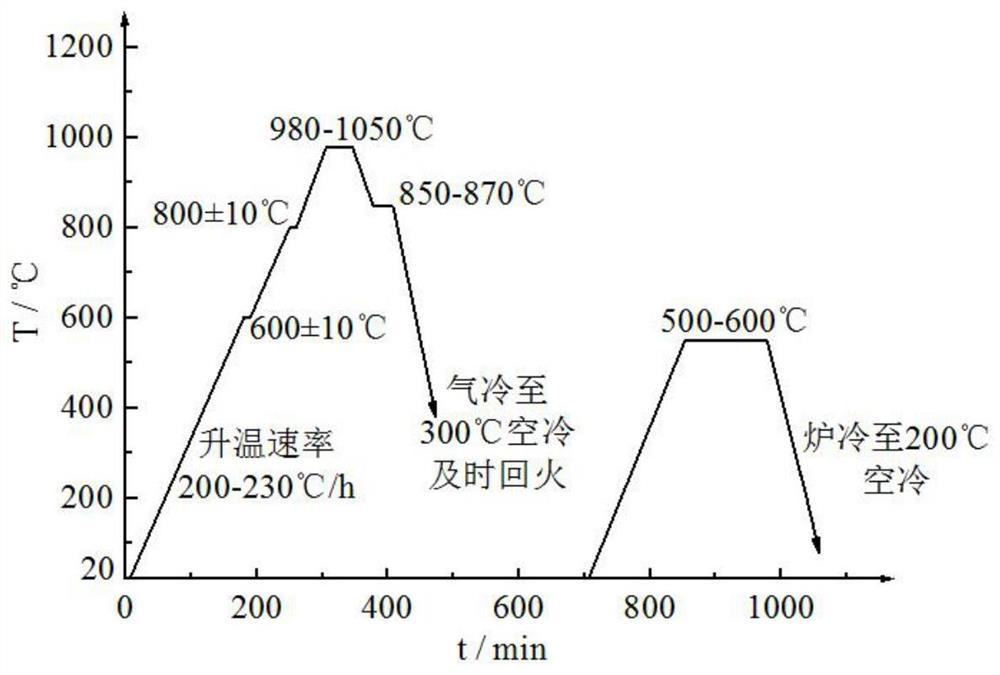

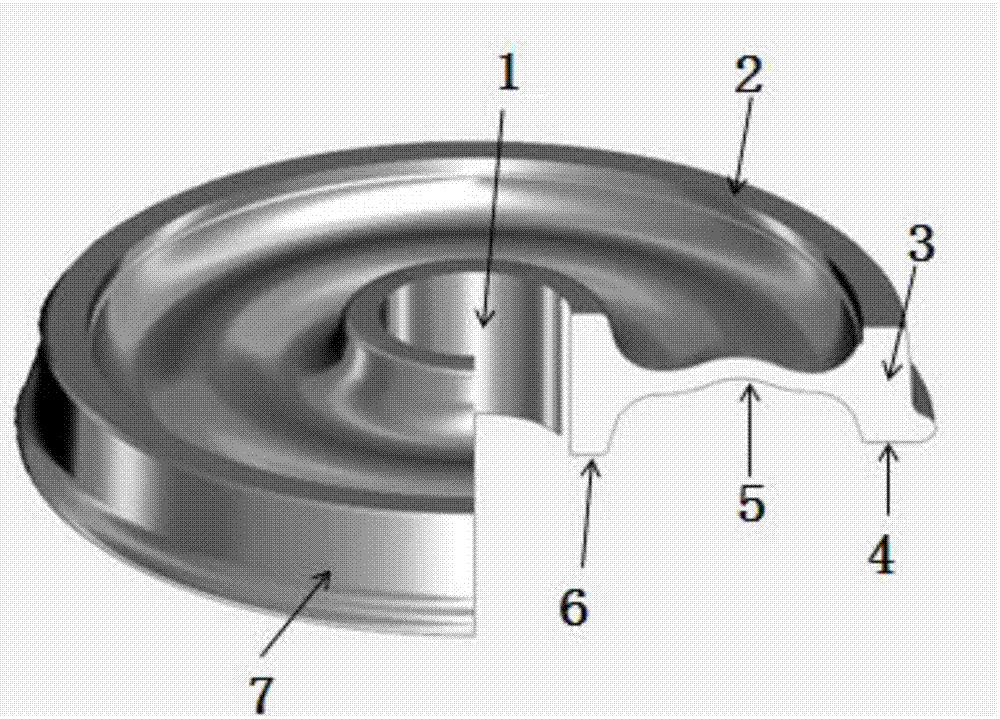

Low-alloy cast steel for high-speed train brake disc, heat treatment method of low-alloy cast steel and brake disc

The invention belongs to the technical field of metal materials for rail traffic, and particularly relates to low-alloy cast steel for a high-speed train brake disc, a heat treatment method of the low-alloy cast steel and the brake disc. The low-alloy cast steel comprises components in percentage by weight as follows: 0.12%-0.20% of carbon, 0.001%-0.003% of boron, 0.01%-0.05% of aluminum, 0.02%-0.07% of titanium, 0.35%-0.55% of silicon, 1.0%-1.8% of manganese, 0.10%-0.30% of chromium, 0.20%-0.40% of molybdenum, 0.15%-0.35% of nickel, smaller than or equal to 0.01% of phosphorus, smaller than or equal to 0.01% of sulfur, smaller than or equal to 0.1% of other components and the balance iron. The low-alloy cast steel has reasonable chemical composition and proportion, excellent comprehensivemechanical properties and high cost performance, and the prepared brake disc has better performance when compared with a brake disc in the prior art and can meet the use requirement of the high-speedtrain brake disc.

Owner:南京中盛铁路车辆配件有限公司

A kind of bainitic steel wheel for rail transit produced by low-cost fine-tuning and its manufacturing method

ActiveCN106191666BImprove organizational stabilityImprove mechanical propertiesFurnace typesHeat treatment furnacesSulfurRare earth

The invention discloses a bainitic steel wheel for rail transit produced at low cost and fine-tuned, and a manufacturing method thereof. , rare earth RE: 0.001~0.040%, phosphorus P≤0.020%, sulfur S≤0.020%, the rest is iron and unavoidable residual elements; and 3.00%≤Si+Mn≤5.00%. Compared with the existing technology, through the alloy design and manufacturing process, especially the heat treatment process and technology, the wheel rim obtains a carbide-free bainite structure; the spoke plate and the hub obtain a granular bainite and supersaturated ferrite structure And a small amount of pearlite, the wheel has high comprehensive mechanical properties; no special alloying elements such as Mo, Ni, V, Cr and B are added, and the heat treatment process and technology are fully utilized to greatly reduce the cost of steel and realize precise production.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

A kind of submerged arc welding flux-cored welding wire and its preparation method

ActiveCN109434321BImprove crack resistanceImprove thermal crack resistanceWelding/cutting media/materialsSoldering mediaCrack resistanceFerrosilicon

A flux-cored welding wire for submerged arc welding, including a steel strip and a flux core, wherein the chemical composition of the steel strip, by weight percentage: C≤0.02%, Mn0.2‑1.2%, Si0.3‑1.8%, Cr22‑28 %, W2‑8%, Cu 0.2‑0.4%, V0.1‑0.3%, S≤0.005%, P≤0.006%, the balance is Fe; the composition of the drug core is calculated by its weight percentage: marble 20‑35%, Fluorite 15‑28%, Mica 7‑12%, Titanium Dioxide 6‑14%, Ferro Vanadium 2‑8%, Ferrosilicon 2‑6%, FerroTitanium 2‑12%, Ferroboron 13‑17%, Ferromolybdenum 2-8%, graphite 3-12%, and the balance is ferrochromium; the welding wire of the present invention can improve its toughness and crack resistance while improving the hardness of the deposited metal, and improve it from both metallurgy and technology. It ensures the strength, toughness and crack resistance of high-hardness deposited metal, and at the same time ensures good welding processability, easy slag removal, no spatter, high hardness and excellent wear resistance.

Owner:江苏佳腾新材料有限公司

Low-zinc hot dipping aluminum alloy coating material containing Mg multiple combination metamorphism

InactiveCN103131983ALow costImprove wettabilityHot-dipping/immersion processesExtensibilityRare earth

The invention discloses a low-zinc hot dipping aluminum alloy coating material containing Mg multiple combination metamorphism. The material comprises, by weight, 20% to 22% of alloying component Zn, 4.0% of alloying enhancer Cu, 0.2% of polarization metamorphism agent Mg, 1% of solvent passivant Mn, 0.1% of precipitation hardening agent Sb, 0.01% of grain refiner Zr, 2.0% of substrate interface reaction buffer agent Fe, 0.5% of rare earth addition, the balance A1 and inevitable trace impurities. The problem that hot-dip galvanizing occupies a high proportion of zinc is solved, zinc resources are saved, the aluminum alloy coating materials which are good in wettability to base steel, high in bonding force, high in intensity, good in extensibility, high temperature resistance, good in corrosion resistance, good in machinability and weldability are obtained by utilizing Mg and the above alterant and low-zinc aluminum alloys, and the aluminum alloy coating materials are used for hot dipping of high quality steel.

Owner:GUIZHOU ACAD OF SCI

A kind of metal centrifugal roll ring and its manufacturing process

ActiveCN105463308BImprove surface qualityEnhanced and improved surface qualityFurnace typesHeat treatment furnacesCrack resistanceChemical composition

The invention discloses a centrifugal metal roll ring and a manufacturing process thereof. The centrifugal metal roll ring comprises an inner layer and an outer layer which are made of different materials. The inner layer comprises 0.80%-1.2% of C, 1.00%-2.00% of Si, 0.50%-1.50% of Mn, not larger than 0.03 of P, 0.20%-1.00% of Ni, not larger than 0.20% of Mo, not smaller than 0.04% of Mg and the balance Fe. The outer layer comprises 2.00%-3.00% of C, 0.50%-1.50% of Si, 0.80%-1.50% of Mn, not larger than 0.10% of P, not larger than 0.03% of S, 12.00%-18.00% of Cr, not smaller than 0.50% of Ni, 0.20%-1.50% of Mo and the balance Fe. Compared with high-chromium cast iron and a high-carbon semi-steel roll ring which are obtained through inblock casting and centrifugal casting, by the adoption of the centrifugal metal roll ring, precious metal is saved, production cost is lowered by 18% to 22%, the roll ring is easy to cut, and the matrix organization, impact toughness, wear resistance and heat crack resistance can be improved greatly.

Owner:江苏凯达重工股份有限公司

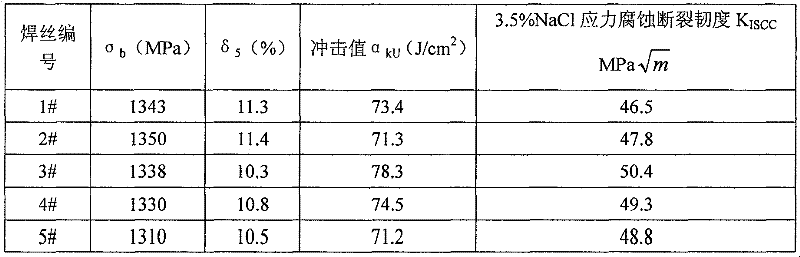

Welding wire for gas shielded welding of aging martensitic stainless steel

ActiveCN101704169BGood welding performanceImprove corrosion resistanceWelding/cutting media/materialsSoldering mediaMartensitic stainless steelSS - Stainless steel

The present invention relates to a welding wire suitable for welding aging martensitic stainless steel. The welding wire comprises the following chemical components, by weight percent: 0.01-0.09% of C, 0.2-0.6% of Si, 0.2-1.0% of Mn, less than or equal to 0.025% of P, less than or equal to 0.025% of S, 14-17% of Cr, 4.2-5.8% of Ni, 3.0-4.0% of Cu, 0.1-0.5% of Nb, less than or equal to 0.75% of Mo and the balance of Fe. The welding wire used for welding 15-5PH aging martensitic stainless steel can avoid forming a ferrite net in the martensitic tissue of a welding seam, so that the plasticity and the toughness of a joint are ensured, and the welding wire also has superior welding properties and can effectively avoid welding thermal cracks. After being used for welding the 15-5PH stainless steel, the welding wire has favorable all-round properties by complete heat treatment and is suitable for the gas shielded welding of the aging martensitic stainless steel in the fields of the aviation industry and other industries.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

A low-cost and high-wear-resistant stretching and reducing roll and its heat treatment process

ActiveCN111101077BRaise room temperatureImprove mechanical propertiesFurnace typesHeat treatment furnacesMechanical engineeringHeat treating

Owner:BAOSHAN IRON & STEEL CO LTD

Low-zinc hot dipping aluminum alloy coating material containing Mg multiple combination metamorphism

InactiveCN103131983BHigh strengthImprove heat resistanceHot-dipping/immersion processesExtensibilityRare earth

The invention discloses a low-zinc hot dipping aluminum alloy coating material containing Mg multiple combination metamorphism. The material comprises, by weight, 20% to 22% of alloying component Zn, 4.0% of alloying enhancer Cu, 0.2% of polarization metamorphism agent Mg, 1% of solvent passivant Mn, 0.1% of precipitation hardening agent Sb, 0.01% of grain refiner Zr, 2.0% of substrate interface reaction buffer agent Fe, 0.5% of rare earth addition, the balance A1 and inevitable trace impurities. The problem that hot-dip galvanizing occupies a high proportion of zinc is solved, zinc resources are saved, the aluminum alloy coating materials which are good in wettability to base steel, high in bonding force, high in intensity, good in extensibility, high temperature resistance, good in corrosion resistance, good in machinability and weldability are obtained by utilizing Mg and the above alterant and low-zinc aluminum alloys, and the aluminum alloy coating materials are used for hot dipping of high quality steel.

Owner:GUIZHOU ACAD OF SCI

Improved composite high-chromium iron-cast roller

It is a type of complex high-chromium green roll with strong oxidation resistance and wearable property. Components of its working lining are as follows: 2.5-3.0% C,0.5-1.2% Si,0.6-1.2% Mn,1.0-1.5% Ni,12-20% Cr,0.5-3.5 % Mo,0.05-0.5% V,0.2-1.5% W,0.03-0.3% Al, 0.03-0.1% N ,P <=0.04%,S <=0.04%,iron and impurity the rest. Advantages of this kind of green roll are as follows: wear-resisting property was improved by 50% ,mm rolling quantity increased by 30%,its life-span and rolling output were doubled, draw resistent intensity was reinforced and rigidity asymmetry was lowered effectively.

Owner:JIANGSU GONGCHANG ROLL

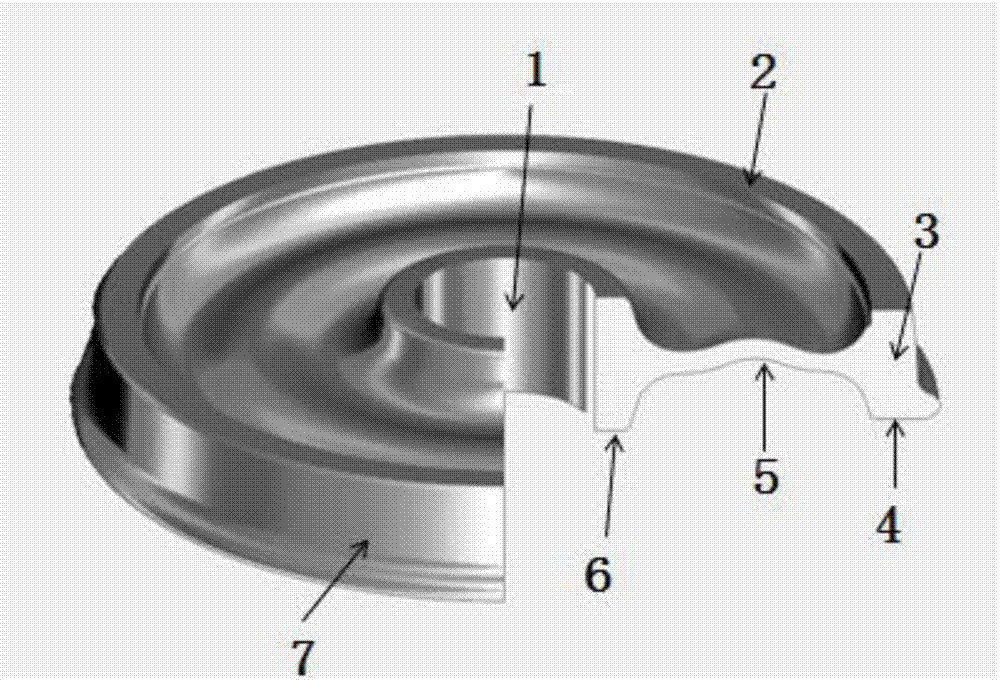

A high-strength, high-toughness, thermal-crack-resistant bainitic steel wheel for rail transit and its manufacturing method

ActiveCN106191665BImprove toughnessLow notch sensitivityFurnace typesHeat treatment furnacesCrack resistanceManganese

The invention provides a high-strength, high-toughness, thermal-crack-resistant bainite steel wheel for rail transit and a manufacturing method thereof. 0.20~1.00%, boron 0.0001~0.035%, nickel 0.10~1.00%, phosphorus≤0.020%, sulfur≤0.020%, the rest is iron and unavoidable residual elements; and 1.50%≤Si+Ni≤3.00%, 1.50% ≤Mn+Ni+Cu≤3.00%. Compared with the prior art, the present invention enables the wheel rim to obtain a carbide-free bainite structure through the chemical composition design of the steel and the wheel manufacturing process, especially the heat treatment process and technology; Supersaturated ferrite-based metallographic structure, the wheel has high strength, high toughness, and thermal crack resistance.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

Low zinc hot dipping aluminium alloy plating material containing Ca multi-combination metamorphism

InactiveCN103131986BLower eutectic temperatureIncrease wetting and fusion abilityHot-dipping/immersion processesExtensibilityLiquid viscosity

The invention discloses low zinc hot dipping aluminium alloy plating material containing Ca multi-combination metamorphism. The composition of alloy comprises, by element weight, 10%-13% of Zn, 5.0% of alloy enhancer Cu, 0.03 % of polarization metamorphic agent Ca, 0.2 % of solvent passivator Mo and 0.5% of rare earth addition, and the rest of the composition of the alloy are A1 and micro impurities which are unavoidable. The low zinc hot dipping aluminium alloy plating material containing the Ca multi-combination metamorphism solves the problems that due to dissolution of iron in a hot dipping plating process, zinc liquid viscosity is enabled to be increased and the capability of the surface of an infiltrating steel matrix is reduced, the thickness of a zinc layer is obviously increased due to the fact that iron content in zinc liquid is increased, and therefore ductility and the appearance of the a plating layer are enabled to be poor, and other problems are solved too. The aluminium alloy plating material for hot dipping is obtained, wherein the aluminium alloy plating material for hot dipping is good in matrix wettability, strong in binding force, high in strength, good in extensibility, high temperature-resistance, thin in plating layer, and strong in corrosion resistance.

Owner:贵州铝厂有限责任公司

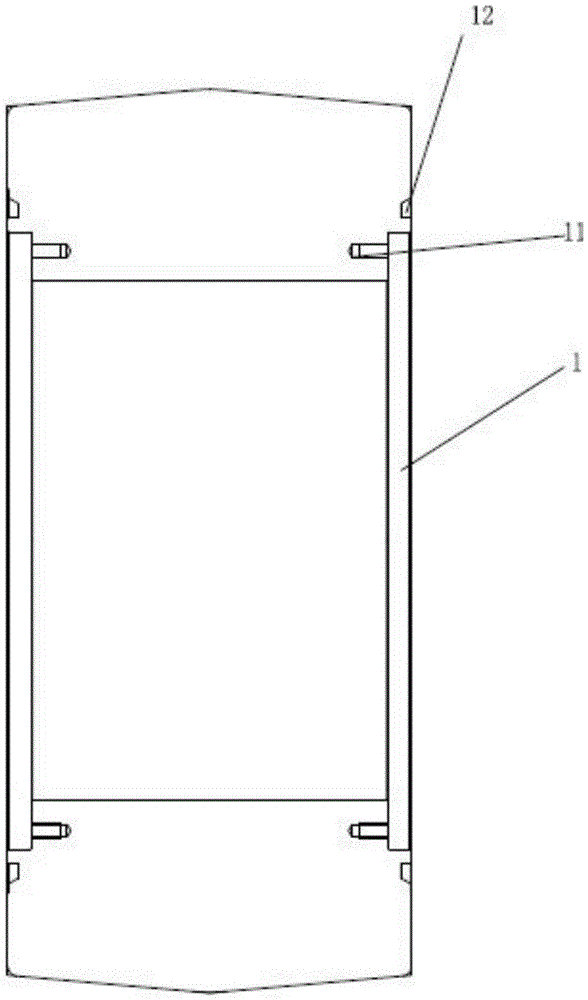

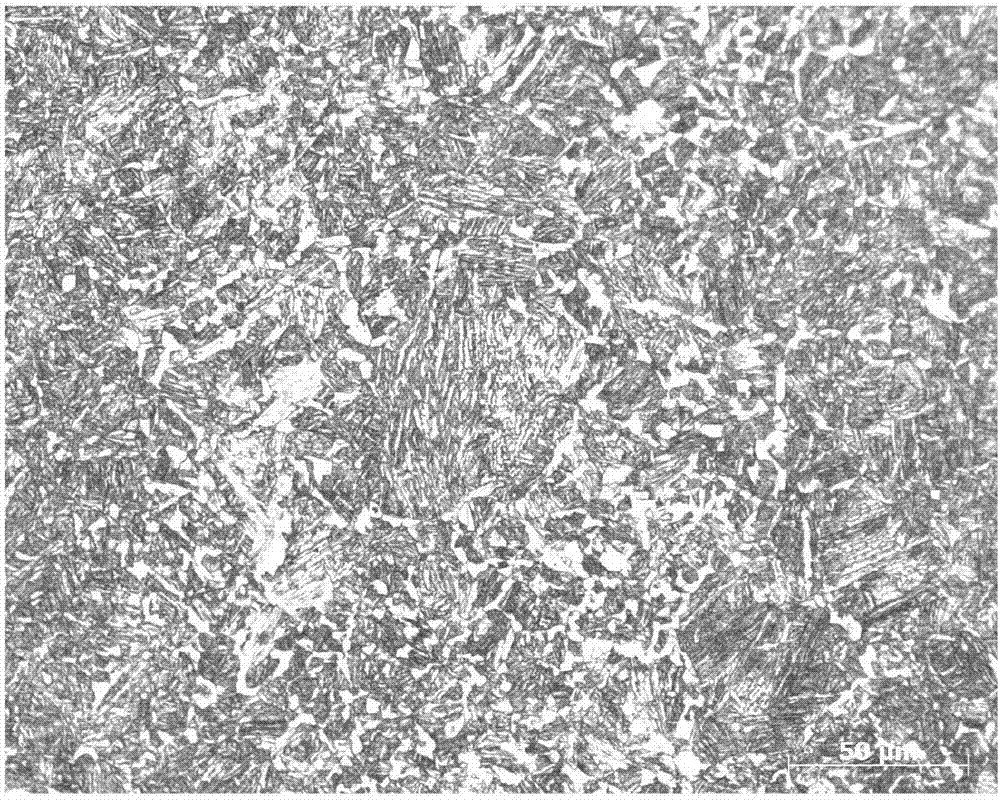

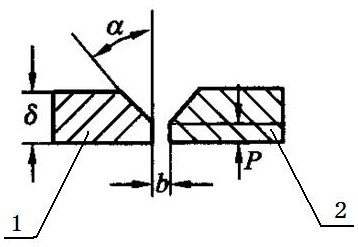

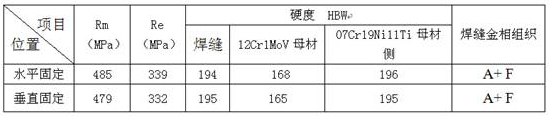

Welding method for 12Cr1MoV and 07Cr19Ni 11Ti dissimilar steel

PendingCN113878207ASolve the problem of welding processGuaranteed safe service lifeArc welding apparatusWelding/soldering/cutting articlesWeld seamSS - Stainless steel

The invention relates to a welding method for 12Cr1MoV and 07Cr19Ni 11Ti dissimilar steel. In the prior art, austenite and pearlitic steel are mostly welded by adopting constantan welding wires, so that the cost is higher, weld joints are deformed and cracked, and welding in the prior art is not suitable for batch production. The dissimilar steel comprises dissimilar steel A (1) and dissimilar steel B (2), the butt gap b of the dissimilar steel A and the dissimilar steel B is 2.0 mm-3.0 mm, the groove angle a is 30 degrees-35 degrees, the truncated edge p is 1.5 mm-2.0 mm, the thickness delta of a pipe is 5 mm, a TGS-347 welding wire is adopted, the diameter of the welding wire is 2.4 mm, assembling is conducted in a free state during welding, manual tungsten electrode argon arc welding is adopted, an internal wire adding welding method is adopted during bottoming, after the pipeline is filled with argon and is stable, root layer welding is conducted, and the temperature between layers is controlled to be smaller than or equal to 350 DEG C; and the method comprises the steps that firstly, grooves in the base metal sides of the dissimilar steel A and the dissimilar steel B are machined, the surfaces of the grooves and the outer walls, within 10 mm, of the two sides of the base metal are cleaned, and then horizontal fixed welding and vertical fixed welding are conducted. The welding method is used for the dissimilar steel of pearlite steel and austenitic stainless steel.

Owner:HUANENG GANSU XIGU THERMAL POWER CO LTD

Heat-resistant ductile cast iron and preparation method thereof

ActiveCN103820700BImprove heat resistanceImprove high temperature oxidation resistanceThermal fatigueAlloy

The invention relates to heat-resisting spheroidal graphite cast iron and a preparation method thereof. The preparation method comprises the following steps: smelting alloy, wherein the alloy comprises the following ingredients by mass: 2.7-3.5% of C, 4.0-5.0% of Si, 1.5-3.5% of W, 0.02-0.05% of Mg, 0.1-0.5% of V, Re being less than 0.03%, 0.15-0.6% of Mo, 0.05-1.0% of Mn, 0 to 0.03% of P, 0 to 0.02% of S, and the balance of iron and unavoidable impurities, discharging molten iron, inoculating the molten iron, spheroidizing, and casting. The heat-resisting spheroidal graphite cast iron prepared by the preparation method is of excellent high-temperature oxidation resistance, high-temperature anti-cracking property and thermal fatigue performance, and is good in mechanical property, low in production cost, and suitable for producing parts of an engine emission system.

Owner:CRRC QISHUYAN INSTITUTE CO LTD +1

A production process of rolls for high-end rail rolling mills

The invention discloses a roller producing technology for a high-end rail rolling mill. The roller producing technology comprises the following steps that firstly, an appropriate number of nickel elements and molybdenum alloy elements and a trace of yttrium basis weight heavy rare earth elements, vanadium elements, niobium elements and boron elements are added, and high-purity molten iron is smelted; secondly, calcium silicon and rare earth magnesium balling is carried out, and continuous generating is carried out through a barium calcium nucleating agent; thirdly, still standing is carried out for a moment after generating, roller pouring is carried out, heat preservation is carried out after pouring till the temperature is equal to the normal temperature, a box is opened, and a roller workblank is obtained; fourthly, a hole is formed in the roller workblank in a coarse mode, a 30-50 mm machining margin is reserved on the single edge in the diameter direction, the roller wokblank is placed in a boiler to be processed at the high temperature, the temperature rises to A cm+30 DEG C, and heat preservation is carried out for a period of time; fifthly, the roller workblank is taken out of the boiler to be hung to a large spray quenching machine to rotate, thermal refining is carried out through water mist spray quenching, and after the temperature of the roller workblank is lowered to the range from 380 DEG C to 450 DEG C, the roller workblank is placed back to the boiler, and heat preservation is achieved. A roller produced through the technology is high in strength and good in abrasion-resisting performance, and almost no hardness difference exits between the roller surface and the bottom of a hole groove or between the roller surface and the side walls or between the roller surface and other areas.

Owner:江苏凯达重工股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com