Heat-resistant ductile cast iron and preparation method thereof

A heat-resistant technology for ductile iron, applied in the field of heat-resistant ductile iron, can solve the problems of heat-resistant cast iron mechanical properties, material heat resistance reduction, material brittleness, etc., to improve high-temperature performance, increase high-temperature strength, improve resistance Oxidative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

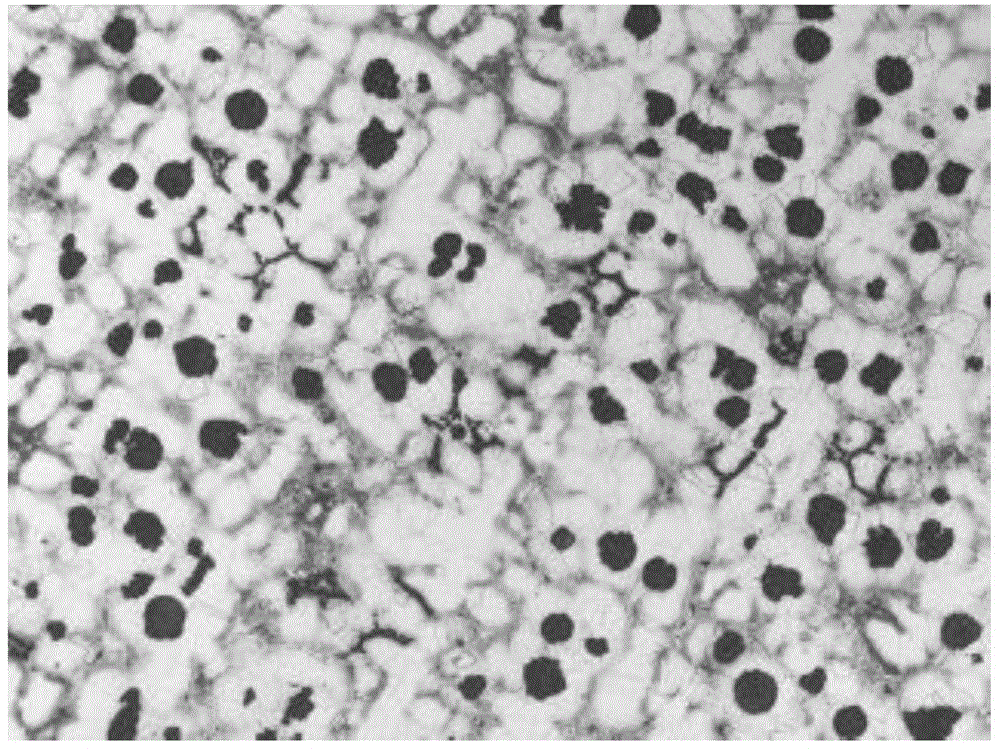

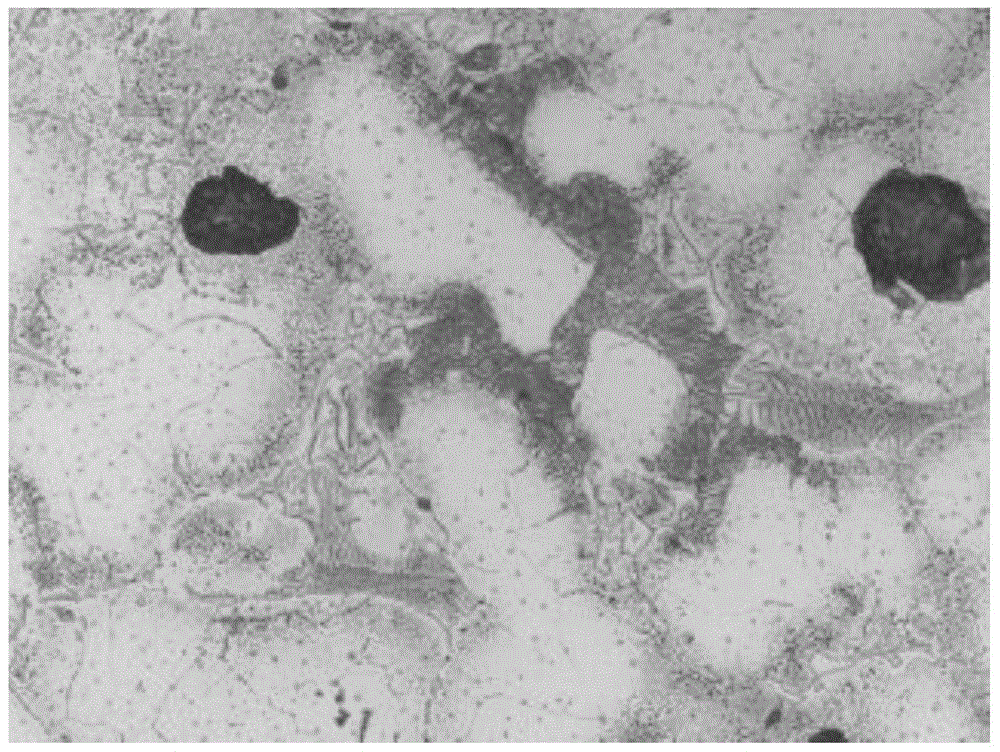

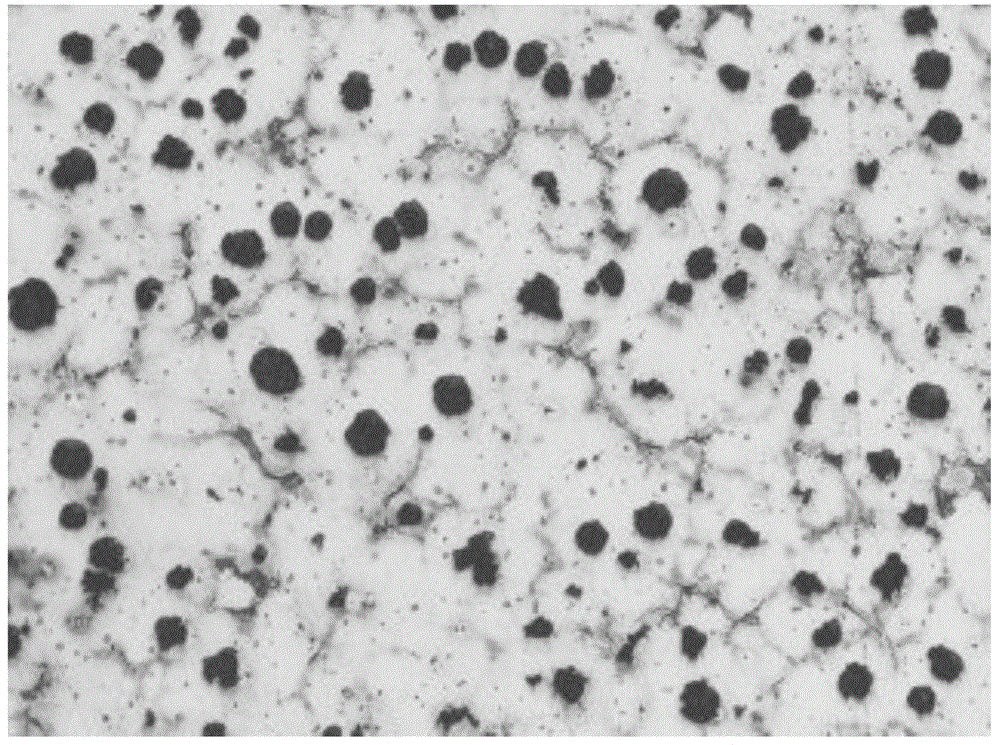

Image

Examples

Embodiment 1)

[0044] The alloy components and mass percentages of the heat-resistant ductile iron in this example are C: 2.98%, Si: 4.36%, W: 2.86%, Mg: 0.037%, V: 0.23%, Re: 0.027%, Mo: 0.36 %, Mn: 0.11%, P: 0.016%, S: 0.008%, and the balance is iron and unavoidable impurities.

[0045] The preparation method of the heat-resistant ductile iron of the present embodiment comprises the following specific steps:

[0046] A. Alloy melting.

[0047] According to the composition and content of the alloy, the carburizer, pig iron, scrap steel, ferro-tungsten and ferromolybdenum are put into the intermediate frequency induction furnace. (High temperature calcined graphitized crystal recarburizer). After the molten iron is completely melted, carry out slag removal, slag removal, heat preservation, and spectral composition analysis. When the temperature of the molten iron rises to 1450°C, ferrosilicon and ferrosilicon are added.

[0048] B. Hot metal tapping, inoculation and spheroidizing treatmen...

Embodiment 2)

[0055] The alloy components and mass percentages of the heat-resistant ductile iron in this example are C: 3.16%, Si: 4.43%, W: 2.17%, Mg: 0.027%, V: 0.19%, Re: 0.010%, Mo: 0.15 %, Mn: 0.19%, P: 0.024%, S: 0.018%, Nb: 0.40%, and the balance is iron and unavoidable impurities.

[0056] The preparation method of the heat-resistant ductile iron of the present embodiment comprises the following specific steps:

[0057] A. Alloy melting.

[0058] According to the composition and content of the alloy, the carburizer, pig iron, scrap steel, ferro-tungsten and ferromolybdenum are put into the intermediate frequency induction furnace. (High temperature calcined graphitized crystal recarburizer). After the molten iron is completely melted, carry out slag removal, slag removal, heat preservation, and spectral composition analysis. When the temperature of the molten iron rises to 1450°C, ferrosilicon, ferrovanadium and ferroniobium are added.

[0059] B. Hot metal tapping, inoculation ...

Embodiment 3)

[0066] The alloy components and mass percentages of the heat-resistant ductile iron in this example are C: 3.03%, Si: 4.46%, W: 2.10%, Mg: 0.039%, V: 0.21%, Re: 0.013%, Mo: 0.31 %, Mn: 0.15%, P: 0.022%, S: 0.012%, Nb: 0.32%, and the balance is iron and unavoidable impurities.

[0067] The preparation method of the heat-resistant ductile iron of the present embodiment comprises the following specific steps:

[0068] A. Alloy melting.

[0069] According to the composition and content of the alloy, the carburizer, pig iron, scrap steel, ferro-tungsten and ferromolybdenum are put into the intermediate frequency induction furnace. (High temperature calcined graphitized crystal recarburizer). After the molten iron is completely melted, carry out slag removal, slag removal, heat preservation, and spectral composition analysis. When the temperature of the molten iron rises to 1430°C, ferrosilicon, ferrovanadium and ferroniobium are added.

[0070] B. Hot metal tapping, inoculation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| oxidation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com