A production process of rolls for high-end rail rolling mills

A production process and roll technology, which is applied in the field of roll production process for high-end rail rolling mills, can solve the problems of high rolling pressure, broken roll operation, and low rolling output, and achieve improved red hardness, hardenability, and thermal crack resistance The effect of improving performance and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

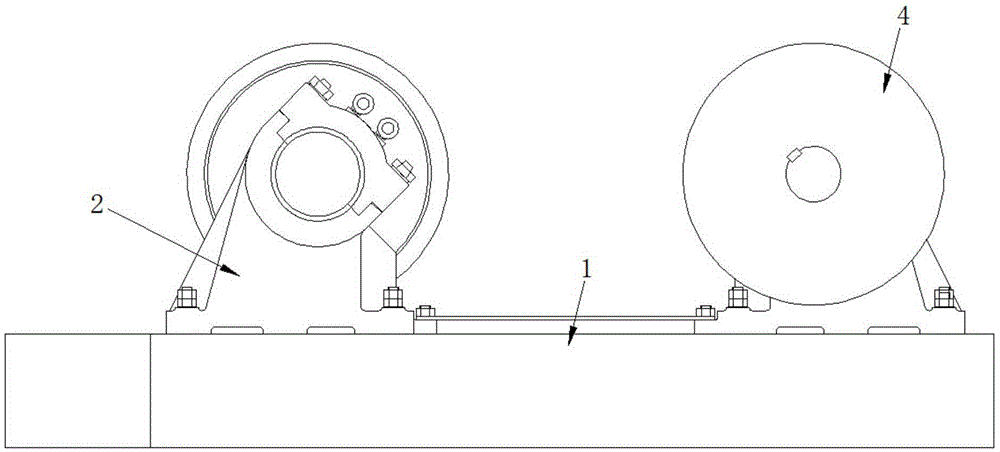

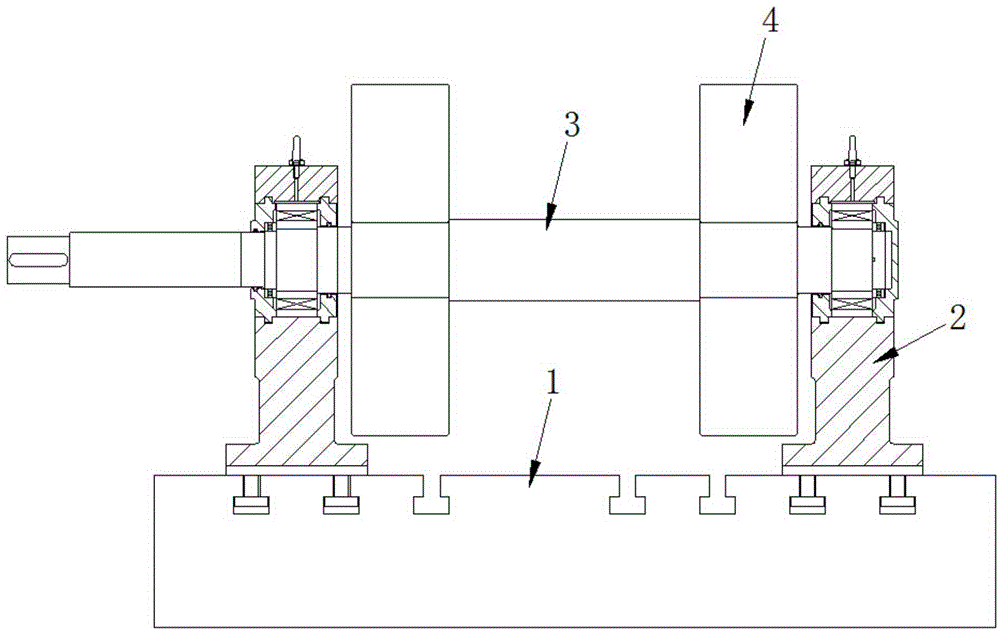

[0025] See figure 1 and figure 2 , the high-end rail rolling mill roll production process of the present embodiment comprises the following steps:

[0026] ①. Add appropriate amount of nickel, molybdenum alloy elements and trace amounts of yttrium-based heavy rare earth, vanadium, niobium, and boron elements to smelt high-purity molten iron.

[0027] Among them, the amount of yttrium-based heavy rare earth added is 2-3 kg per ton of molten iron, and the specific chemical composition of the smelted high-purity molten iron is: C: 3.00-3.50%, Si: 1.50-2.20%, Mn: 0.50-1.00 %, Cr: 0.10-0.50%, Ni: 2.50-3.50%, Mo: 0.40-1.00%, V: 0.05-0.15%, Nb: 0.05-0.15%, B: 0.05-0.20%, P≤0.05%, S ≤0.03%, Mg≥0.04%, Re: 0.02-0.03%, the rest is Fe.

[0028] ②. Using silicon calcium and rare earth magnesium spheroidization treatment, and then continuously inoculating with barium calcium inoculant.

[0029] ③. After the inoculation is completed, calm down for a while and start pouring the rolls. Af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com