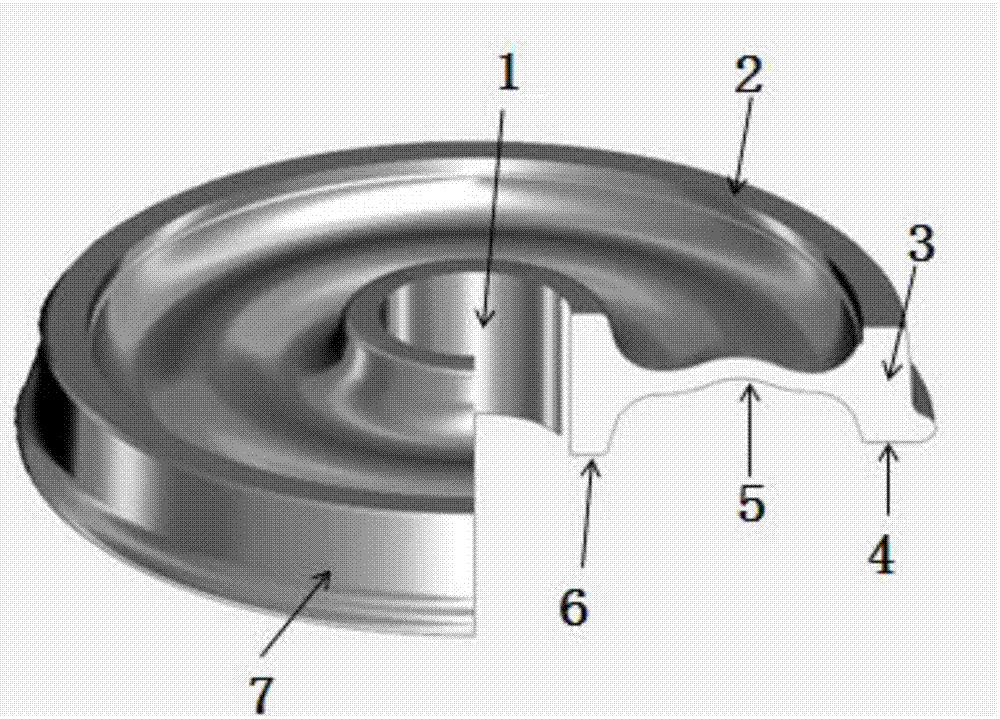

A high-strength, high-toughness, thermal-crack-resistant bainitic steel wheel for rail transit and its manufacturing method

A technology of rail transit and bainitic steel, applied to bainitic steel wheels for thermal cracking-resistant rail transit and its manufacture, design and manufacture of steel grades for other parts and similar parts of rail transit, high toughness, high strength In this field, it can solve the problems of micro-crack initiation, low impact toughness, and peeling of the rim, and achieve good comprehensive mechanical properties, high impact toughness, and easy production control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070]A high-strength, high-toughness, thermal-crack-resistant bainitic steel wheel for rail transit, containing the following elements in the following table 2 in weight percentage.

[0071] A method for manufacturing a high-strength, high-toughness, thermal-crack-resistant bainitic steel wheel for rail transit, comprising the following steps:

[0072] The molten steel whose chemical composition is shown in Example 1 in Table 2 is formed through electric furnace steelmaking process, LF furnace refining process, RH vacuum treatment process, round billet continuous casting process, ingot cutting and rolling process, heat treatment process, processing, and finished product inspection process. The heat treatment process is as follows: heating to 860-930° C. for 2.0-2.5 hours, cooling the rim tread with controlled water spray, then tempering at 220° C. for 4.5-5.0 hours, and then cooling to room temperature.

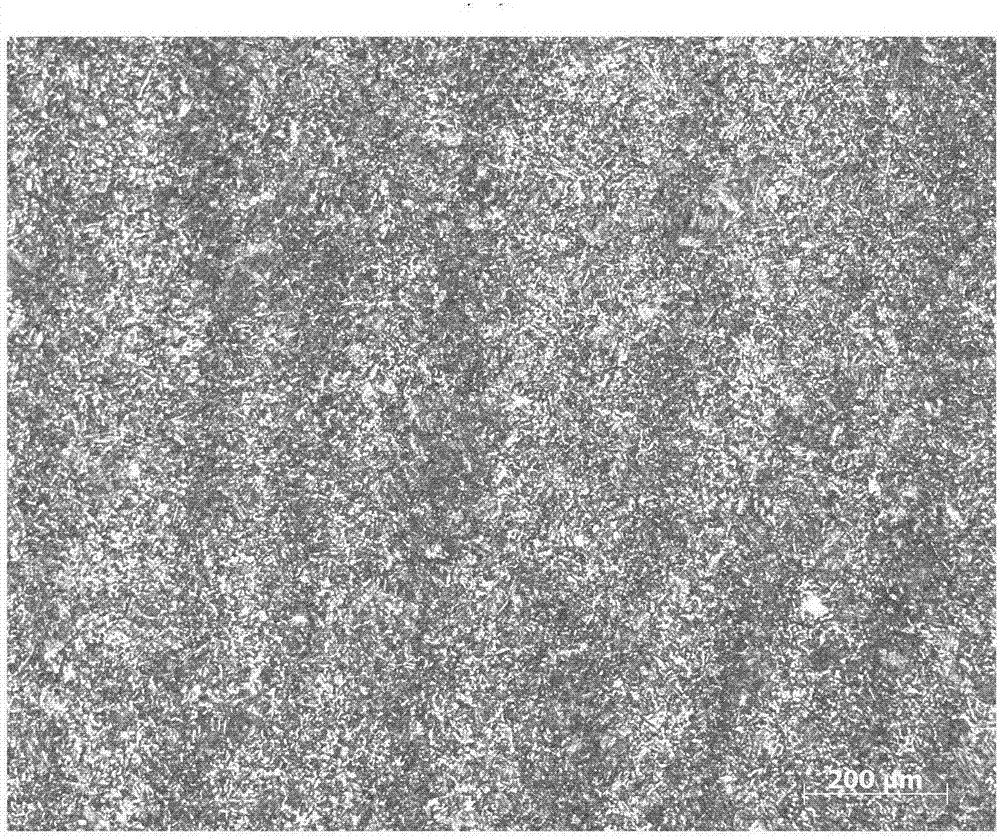

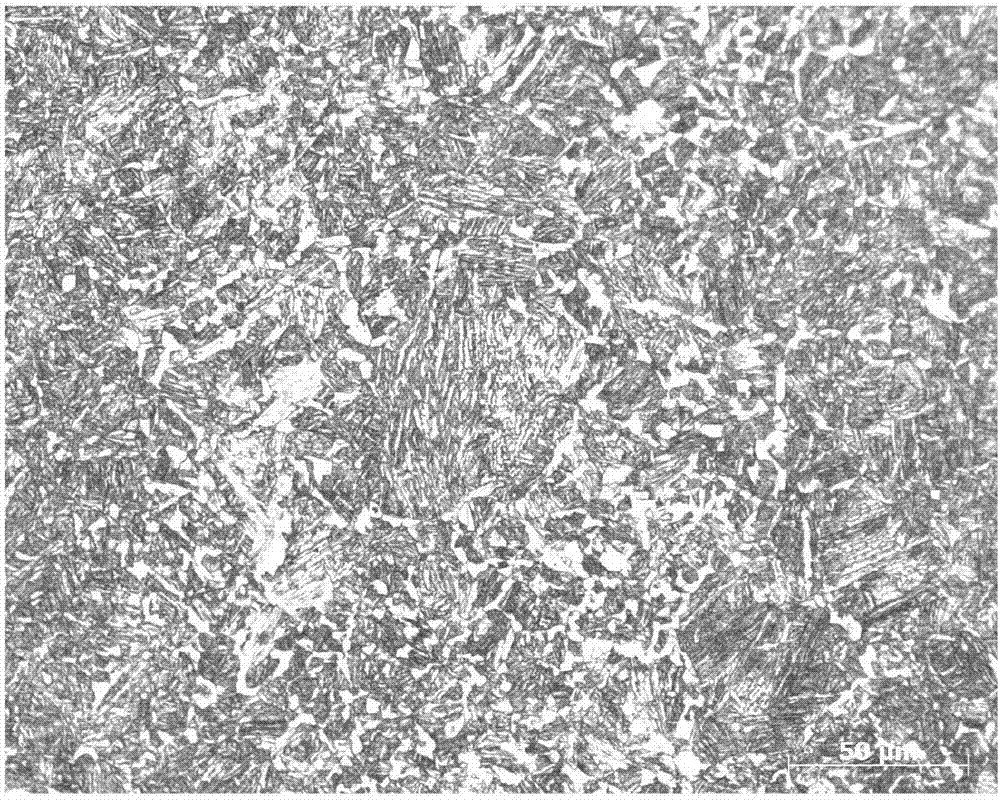

[0073] Such as Figure 2a , Figure 2b As shown, the metallographic s...

Embodiment 2

[0075] A high-strength, high-toughness, thermal-crack-resistant bainitic steel wheel for rail transit, containing the following elements in the following table 2 in weight percentage.

[0076] A method for manufacturing a high-strength, high-toughness, thermal-crack-resistant bainitic steel wheel for rail transit, comprising the following steps:

[0077] The molten steel whose chemical composition is shown in Example 2 in Table 2 is formed through steelmaking process, refining process, vacuum degassing process, round billet continuous casting process, ingot cutting process, forging and rolling process, heat treatment process, processing, and finished product inspection process. The heat treatment process is as follows: heating to 860-930° C. for 2.0-2.5 hours, cooling the rim tread with controlled water spraying, then tempering at 280° C. for 4.5-5.0 hours, and cooling to room temperature.

[0078] Such as Figure 3a , 3b , 3c, and 3d, the metallographic structure of the whe...

Embodiment 3

[0080] The molten steel whose chemical composition is shown in Example 3 in Table 2 is formed through steelmaking process, refining process, vacuum degassing process, round billet continuous casting process, ingot cutting process, forging and rolling process, heat treatment process, processing, and finished product inspection process. The heat treatment process is as follows: heating to 860-930° C. for 2.0-2.5 hours, cooling the rim tread with controlled water spray, and then tempering at 320° C. for 4.5-5.0 hours.

[0081] Such as Figure 5a , 5b As shown, the metallographic structure of the wheel rim prepared in this embodiment is mainly carbide-free bainite. The mechanical properties of the wheel in this embodiment are shown in Table 3, and the strength and toughness matching of the wheel is better than that of the CL60 wheel.

[0082] The chemical composition (wt %) of table 2 embodiment 1,2,3 and comparative example wheel

[0083]

[0084] Table 3 Embodiment 1, 2, 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com