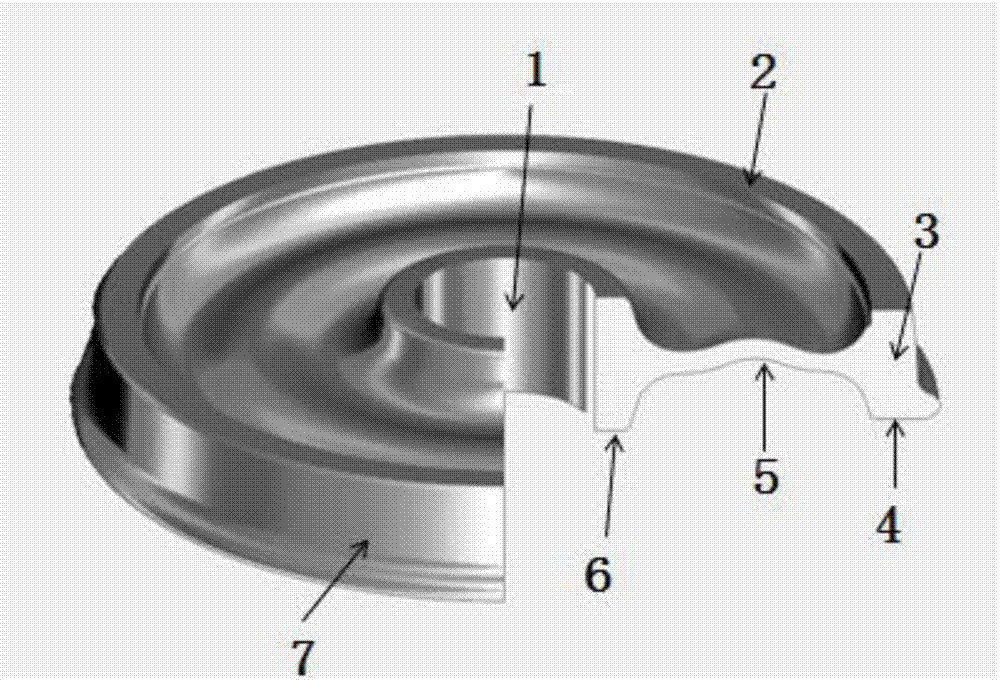

A kind of bainitic steel wheel for rail transit produced by low-cost fine-tuning and its manufacturing method

A technology for rail transit and bainite steel, applied in the field of steel manufacturing, can solve the problems of uneven hardness, micro cracks in the rim, low yield strength of the rim, etc., achieve good comprehensive mechanical properties, improve structural stability, and low notch The effect of sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] A bainitic steel wheel for rail transit produced by a low-cost precision section, containing the following elements by weight percentage as shown in Table 2 below.

[0068] A method for manufacturing a bainitic steel wheel for rail transit produced at low cost, comprising the following steps:

[0069] The molten steel whose chemical composition is shown in Example 1 in Table 2 is formed through electric furnace steelmaking process, LF furnace refining process, RH vacuum treatment process, round billet continuous casting process, ingot cutting and rolling process, heat treatment process, processing, and finished product inspection process. The heat treatment process is as follows: heating to 860-930°C and keeping it warm for 2.0-2.5 hours, spraying water on the rim to strengthen cooling, cooling to below 400°C, using residual heat for self-tempering, cooling to room temperature after tempering, and no additional tempering deal with.

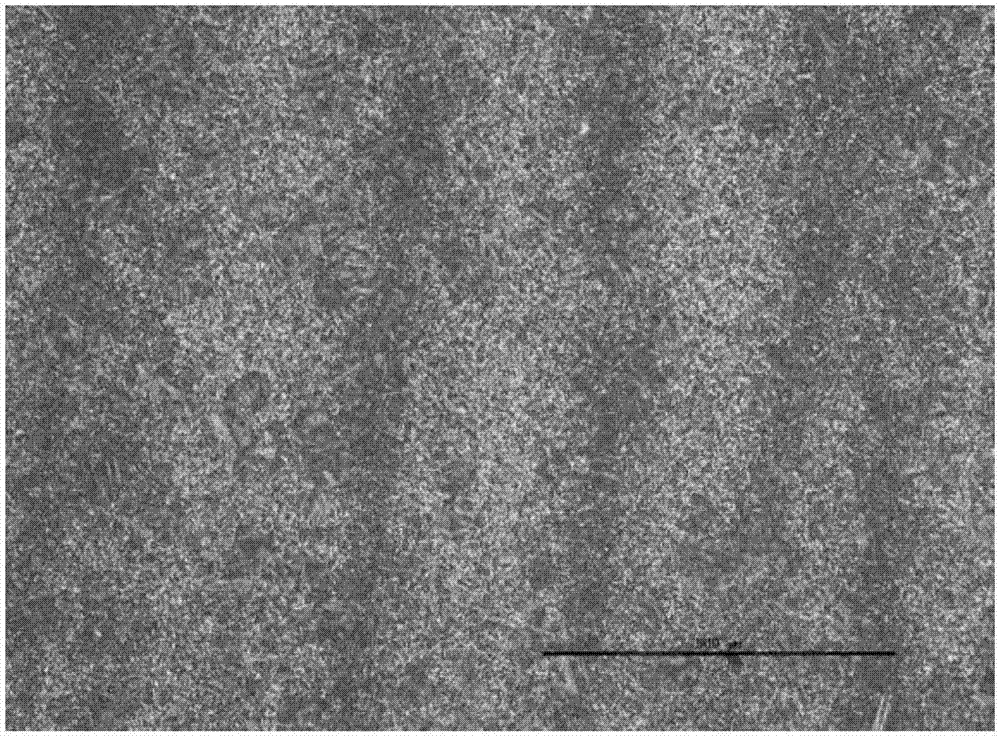

[0070] Such as Figure 2a , Figu...

Embodiment 2

[0072] A bainitic steel wheel for rail transit produced by a low-cost precision section, containing the following elements by weight percentage as shown in Table 2 below.

[0073] A method for manufacturing a bainitic steel wheel for rail transit produced at low cost, comprising the following steps:

[0074]The molten steel whose chemical composition is shown in Example 2 in Table 2 is formed through electric furnace steelmaking process, LF furnace refining process, RH vacuum treatment process, round billet continuous casting process, ingot cutting and rolling process, heat treatment process, processing, and finished product inspection process. The heat treatment process is as follows: heating to 860-930°C for 2.0-2.5 hours, cooling the rim with water spray, cooling to below 400°C, self-tempering with residual heat, cooling to room temperature after tempering, no additional tempering treatment .

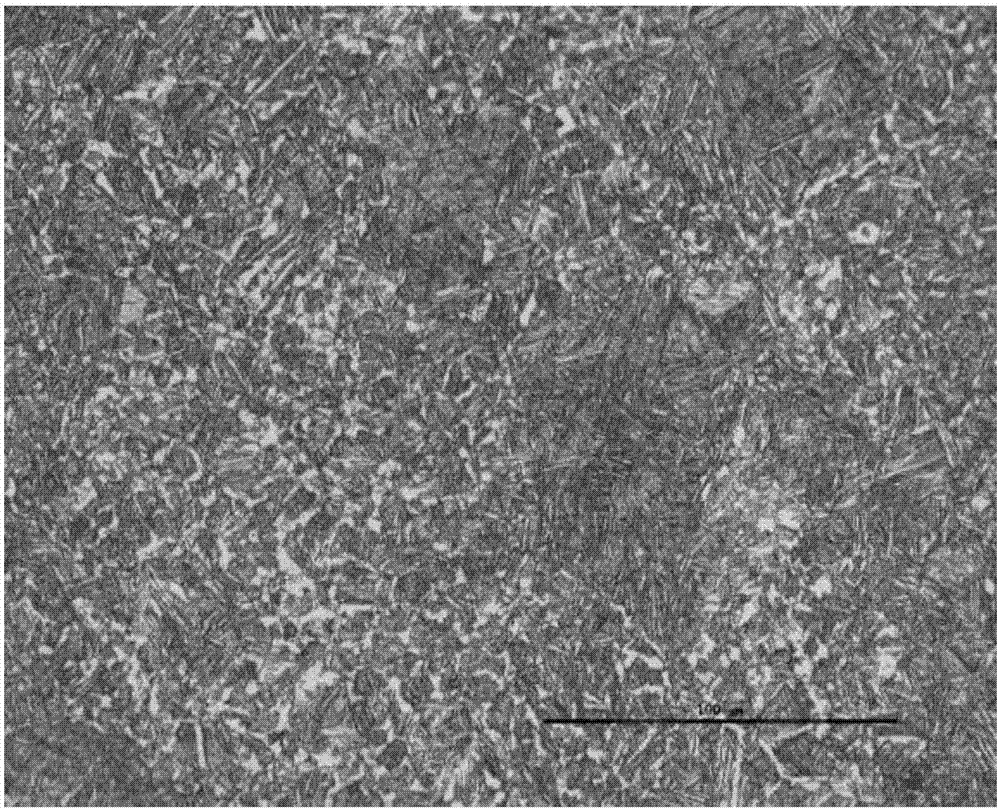

[0075] As shown in FIG. 3 , the metallographic structure of the wheel rim prepa...

Embodiment 3

[0077] A bainitic steel wheel for rail transit produced by a low-cost precision section, containing the following elements by weight percentage as shown in Table 2 below.

[0078] A method for manufacturing a bainitic steel wheel for rail transit produced at low cost, comprising the following steps:

[0079] The molten steel whose chemical composition is shown in Example 2 in Table 2 is formed through electric furnace steelmaking process, LF furnace refining process, RH vacuum treatment process, round billet continuous casting process, ingot cutting and rolling process, heat treatment process, processing, and finished product inspection process. The heat treatment process is as follows: heating to 870-890°C and keeping it warm for 2.0-2.5 hours, spraying water on the tread surface of the rim to cool down to below 400°C, using residual heat for self-tempering, cooling to room temperature after tempering, and no additional tempering deal with.

[0080] Such as Figure 4a , 4b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com