Seamless steel pipe thickening mould material with long service life and heat treatment technology thereof

A seamless steel pipe and mold technology, applied in the field of long-life seamless steel pipe thickening mold material and heat treatment process, can solve the problem of not being suitable for high-alloy, high-strength seamless steel thickening molds, increasing time and cost, and heat treatment Process complexity and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 7

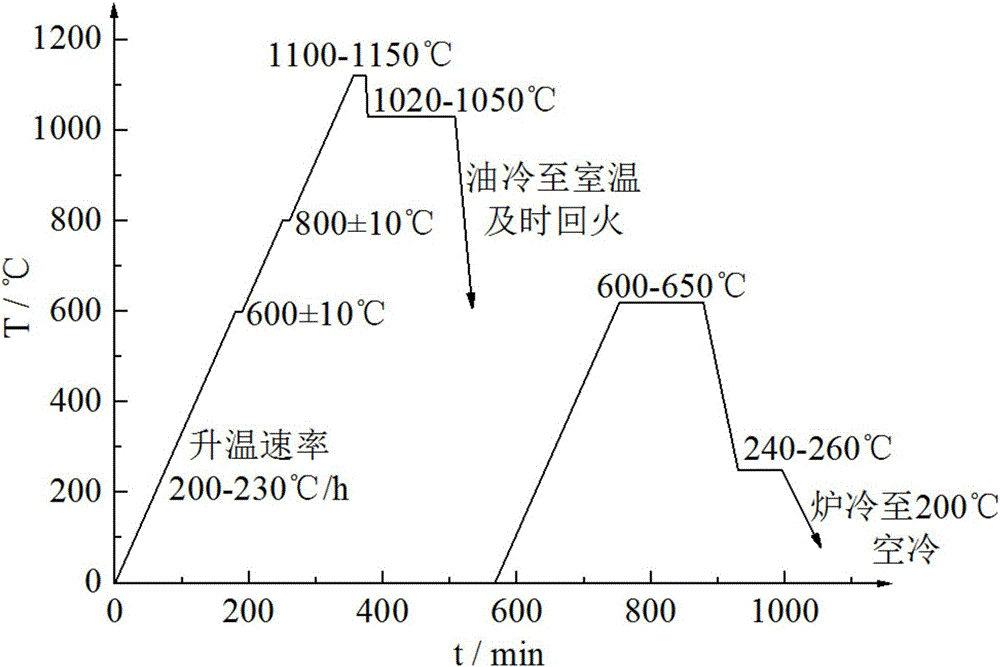

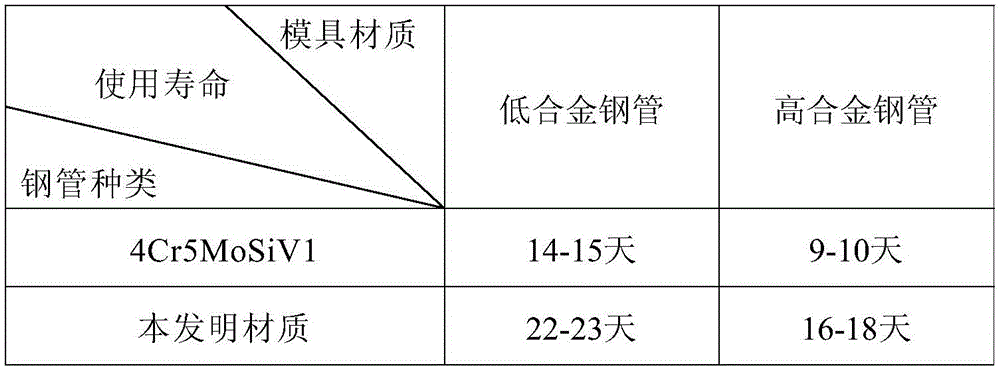

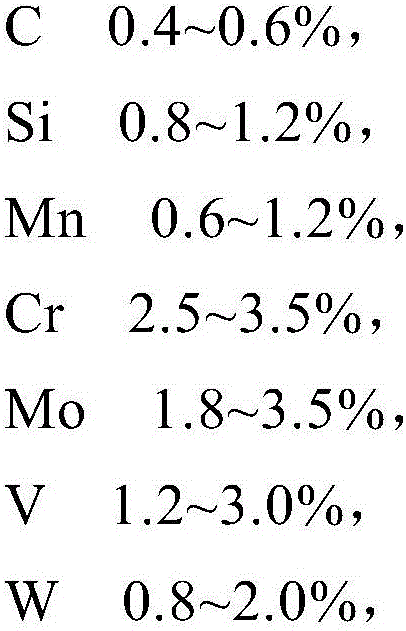

[0086] According to the range of chemical composition designed by the present invention, the intermediate frequency furnace is used to refine the electroslag rod, and the composition is strictly controlled to reduce the harmful alloy elements of the steel ingot; the smelting adopts two electroslag remelting, and the spheroidization is carried out after each remelting Annealing, that is, annealing after intermediate frequency smelting, primary electroslag remelting, spheroidizing annealing, secondary electroslag remelting, and spheroidizing annealing, greatly improves the quality of steel, reduces and eliminates defects such as micro-bubbles, inclusions, and micro-cracks; Carry out forging afterwards, forging ratio>5, quenching and tempering heat treatment and final heat treatment process designed by the present invention. Afterwards, the material was made into a seamless steel pipe thickening die, and different steel types were tested and rolled, and the service life is shown i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com