High-strength wear-resisting heat-resisting aluminium alloy material and preparation process thereof

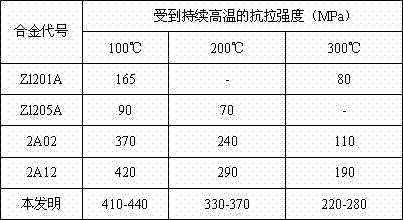

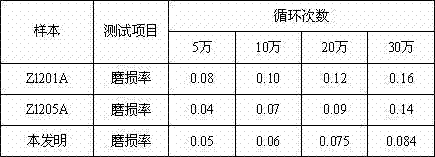

An aluminum alloy material, high-strength technology, applied in the field of aluminum alloy materials and its preparation, can solve the problems of unsustainable application, high alloy cost, poor castability, etc., achieve high temperature deformation resistance and wear resistance enhancement, and high product quality , the effect of strong castability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1. The high-strength wear-resistant and heat-resistant aluminum alloy material has the following chemical components by weight percentage: copper (Cu): 4.0-6.5%, titanium (Ti): 0.06-0.4%, manganese (Mn): 0.08-0.6%, Antimony (Sb): 0.03-0.4%, Nickel (Ni): 0.4-0.6%, Cobalt (Co): 1.2-1.8%, Zirconium (Zr): 0.2-0.3%, Rare Earth Elements (RE): 0.2-1.8% , and the balance is aluminum (Al). In this example, the total amount of aluminum alloy prepared according to the above ratio is 1300 kg, and the weight of the required elements is calculated: copper (Cu): 52 kg, titanium (Ti): 1.3 kg, manganese (Mn): 1.04 kg, antimony (Sb): 0.39 kg, nickel (Ni): 5.2 kg, cobalt (Co): 15.6 kg, zirconium (Zr): 2.6 kg, rare earth element (RE): 6.5 kg for material preparation; put into graphite crucible for smelting, and the melting temperature is controlled at 800°C. While smelting, first add red copper, 75 manganese agent, 75 titanium agent, ALNi10 intermediate alloy, ALCo10, ALV10 inter...

Embodiment 2

[0038] Example 2. According to the total amount of aluminum alloy to be prepared is 1300kg, calculate the weight of the required elements: copper (Cu): 84.5 kg, titanium (Ti): 5.2kg, manganese (Mn): 7.8 kg, antimony (Sb): 5.2kg, Nickel (Ni): 7.8kg, cobalt (Co): 12.4kg, zirconium (Zr): 3.9kg, rare earth element (RE): 15.6 kg for material preparation; first put the double zero aluminum ingot into the graphite crucible for melting, melting The temperature is controlled at 800°C. While melting, add red copper, 75 manganese agent, 75 titanium agent, ALNi10 intermediate alloy, ALCo10, ALV10 intermediate alloy to the crucible in order, and raise the temperature of the crucible to 950°C. After all the metals are melted Then add pure antimony block metal, and finally add rare earth intermediate alloy; refine the melt in the crucible, add refiner at the same time, and stir to promote the fusion of the alloy; after refining, slag, stand still, adjust the temperature of the melt to 750 ℃ ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com