High-modulus asphalt mixture and preparation method thereof

An asphalt mixture, high modulus technology, applied in the field of asphalt pavement materials, high modulus asphalt mixture and its preparation, can solve the problems of insufficient high temperature deformation resistance, etc., to solve rutting disease, improve flexibility and low temperature resistance performance , Improve the effect of project quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] This embodiment provides a high modulus asphalt mixture, which is made of the following raw materials in terms of mass fraction: 5.6% of the base asphalt, 6.0% of the high modulus additive as the base asphalt, and 50% of the mineral powder as the base asphalt , the balance is aggregate, and the sum of the mass fractions of raw materials is 100%.

[0048] The high modulus additive is ultra high molecular weight polyethylene.

[0049] Aggregate with a particle size in the range of 0-3mm, aggregates with a particle size in the range of 3-5mm, aggregates with a particle size in the range of 5-10mm and aggregates with a particle size in the range of 10-15mm The mass ratio of materials is 30:20:20:14.

[0050] The preparation method of the high modulus asphalt mixture of the present embodiment comprises the following steps:

[0051] Step 1, high modulus asphalt mixture raw material preparation:

[0052] Mix the graded aggregates evenly, store the mineral powder separately,...

Embodiment 2

[0059] The present embodiment provides a kind of high-modulus asphalt mixture, in terms of mass fraction, made of the following raw materials: base asphalt is 5.6%, high modulus additive is 6.0% of base asphalt, biomass heavy oil is as base asphalt 20%, the mineral powder is 50% of the matrix asphalt, the balance is aggregate, and the sum of the mass fractions of raw materials is 100%.

[0060] The high modulus additive is ultra high molecular weight polyethylene.

[0061] Aggregate with a particle size in the range of 0-3mm, aggregates with a particle size in the range of 3-5mm, aggregates with a particle size in the range of 5-10mm and aggregates with a particle size in the range of 10-15mm The mass ratio of materials is 30:20:20:14.

[0062] The preparation method of the high modulus asphalt mixture of the present embodiment comprises the following steps:

[0063] Step 1, prepare blended asphalt:

[0064] Add biomass heavy oil to base asphalt, and shear at a high speed o...

Embodiment 3

[0073] This embodiment provides a high modulus asphalt mixture, which is made of the following raw materials in terms of mass fraction: base asphalt is 5.6%, high modulus additive is 4.0% of base asphalt, and mineral powder is 50% of base asphalt , the balance is aggregate, and the sum of the mass fractions of raw materials is 100%.

[0074] The raw material specifications of high modulus additive, mineral powder and aggregate are all the same as in Example 1.

[0075] The preparation method of the high modulus asphalt mixture in this embodiment is basically the same as the preparation method of the high modulus asphalt mixture in Example 1.

[0076] The high and low temperature performance of the high modulus asphalt mixture in this example is: G* / sinδ at 70°C is 1004Pa; creep stiffness modulus at -12°C is 232MPa at 60s, and at -12°C at 60s The creep rate is 0.289.

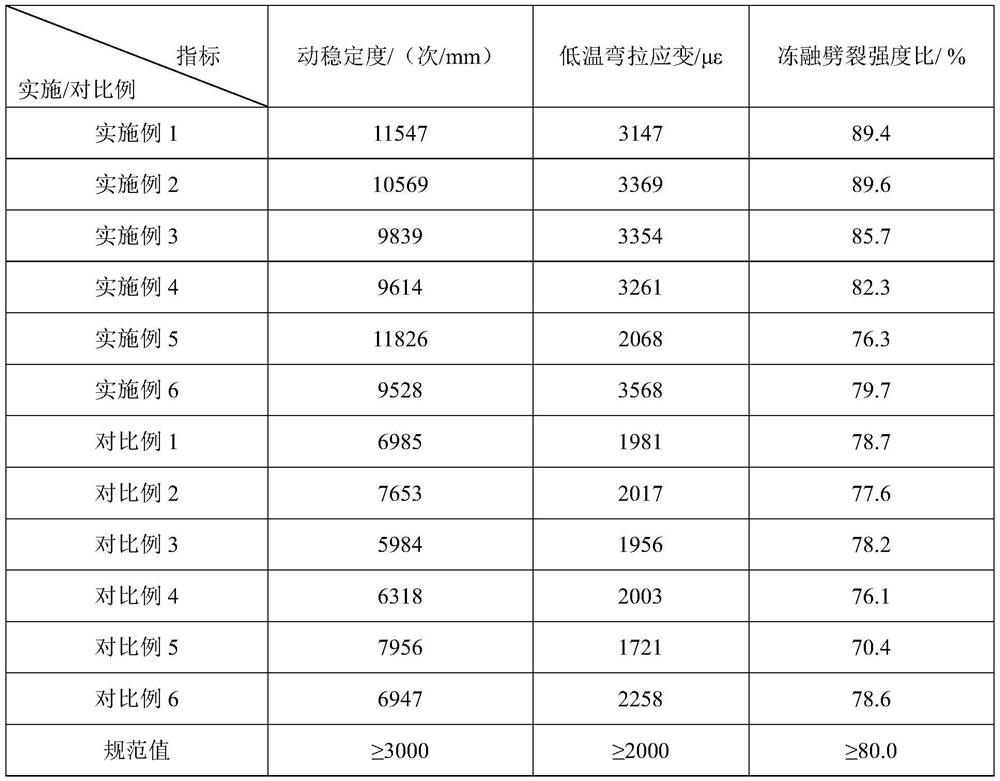

[0077] Table 3 and Table 4 show the conventional road performance of this embodiment and the dynamic modulus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com