Modified polypropylene material for high-performance thin-wall automobile door panel and preparation method thereof

A polypropylene material and high-performance technology, applied in the field of modified polypropylene materials for high-performance thin-walled automobile door panels and their preparation, can solve the defects of tiger skin pattern on the surface of thin-walled door panels, low fluidity, and low material fluidity, etc. problems, to achieve the effect of eliminating tiger skin defects, improving fluidity, and eliminating tiger skin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in combination with embodiments.

[0030] The technical scheme of this embodiment is:

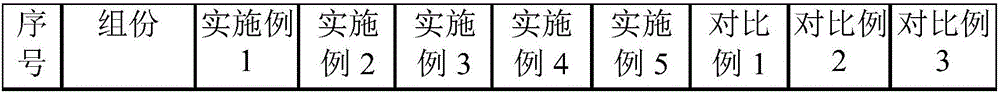

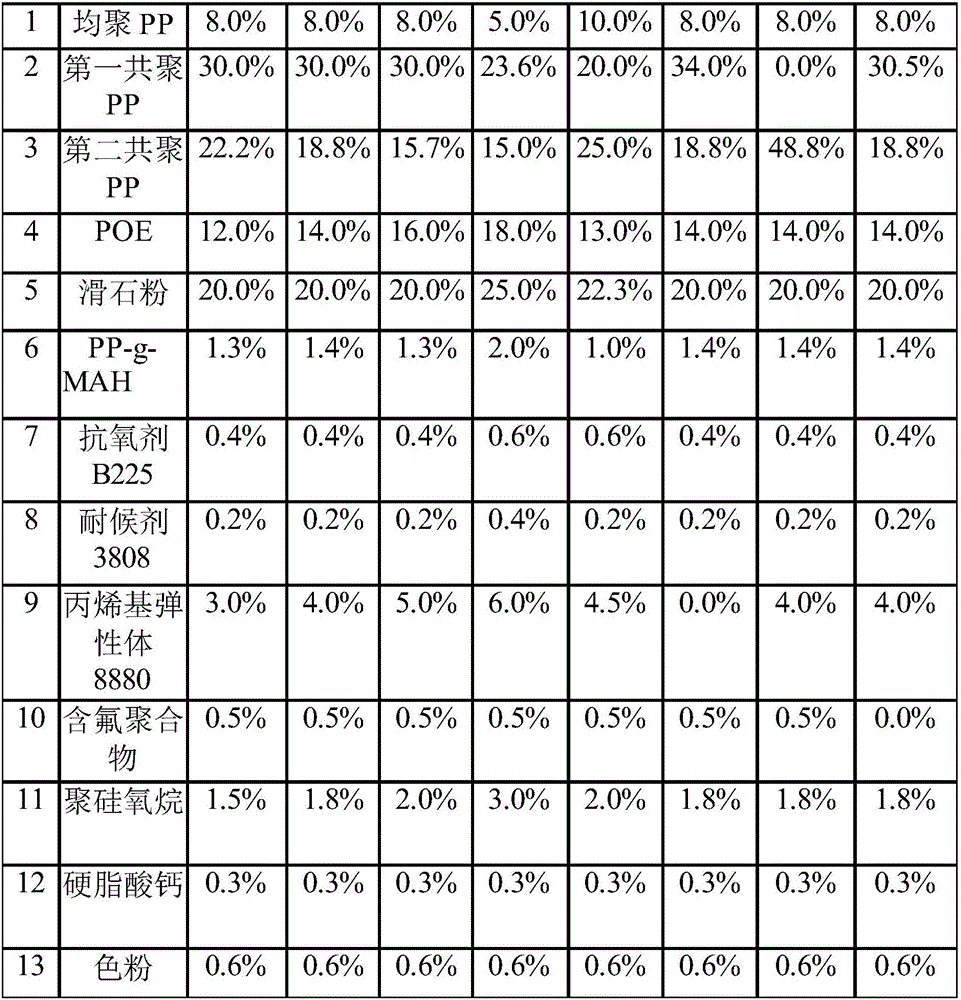

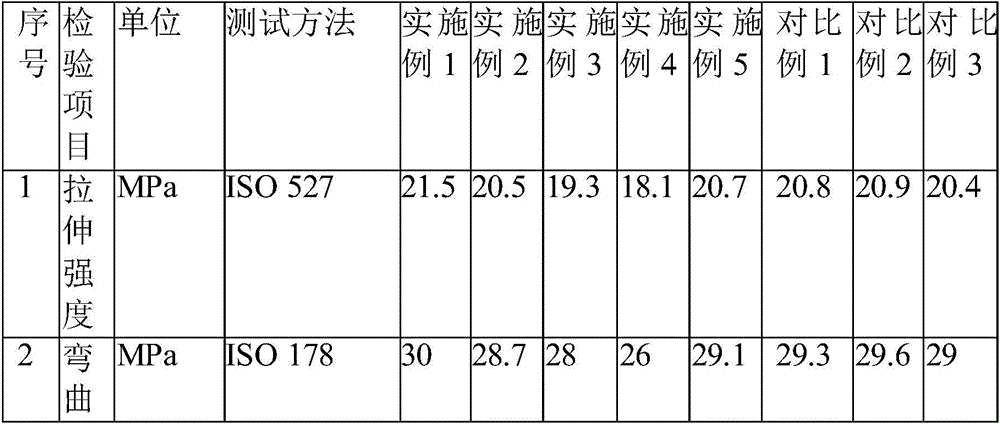

[0031] A modified polypropylene material for high-performance thin-walled automobile door panels, which is composed of the following components in mass percentage: homopolymer PP5%-10%, first copolymer PP20%-30%, second copolymer PP 15%-25%, Toughening agent 12%-18%, compatibilizer 1%-2%, antioxidant 0.4%-0.6%, weather resistance agent 0.2-0.4%, melt index regulator 3%-6%; mineral strengthening agent 20%- 25%, anti-scratch agent 1.5-3%, other additives 1-2%.

[0032] The above-mentioned MFI is selected from the olefin elastomer 8880 produced by ExxonMobil Chemical’s proprietary metallocene technology.

[0033] The preparation method of the modified polypropylene material for high-performance thin-walled automobile door panels comprises homopolymerized PP, first copolymerized PP, second copolymerized PP, toughening agent, compa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com