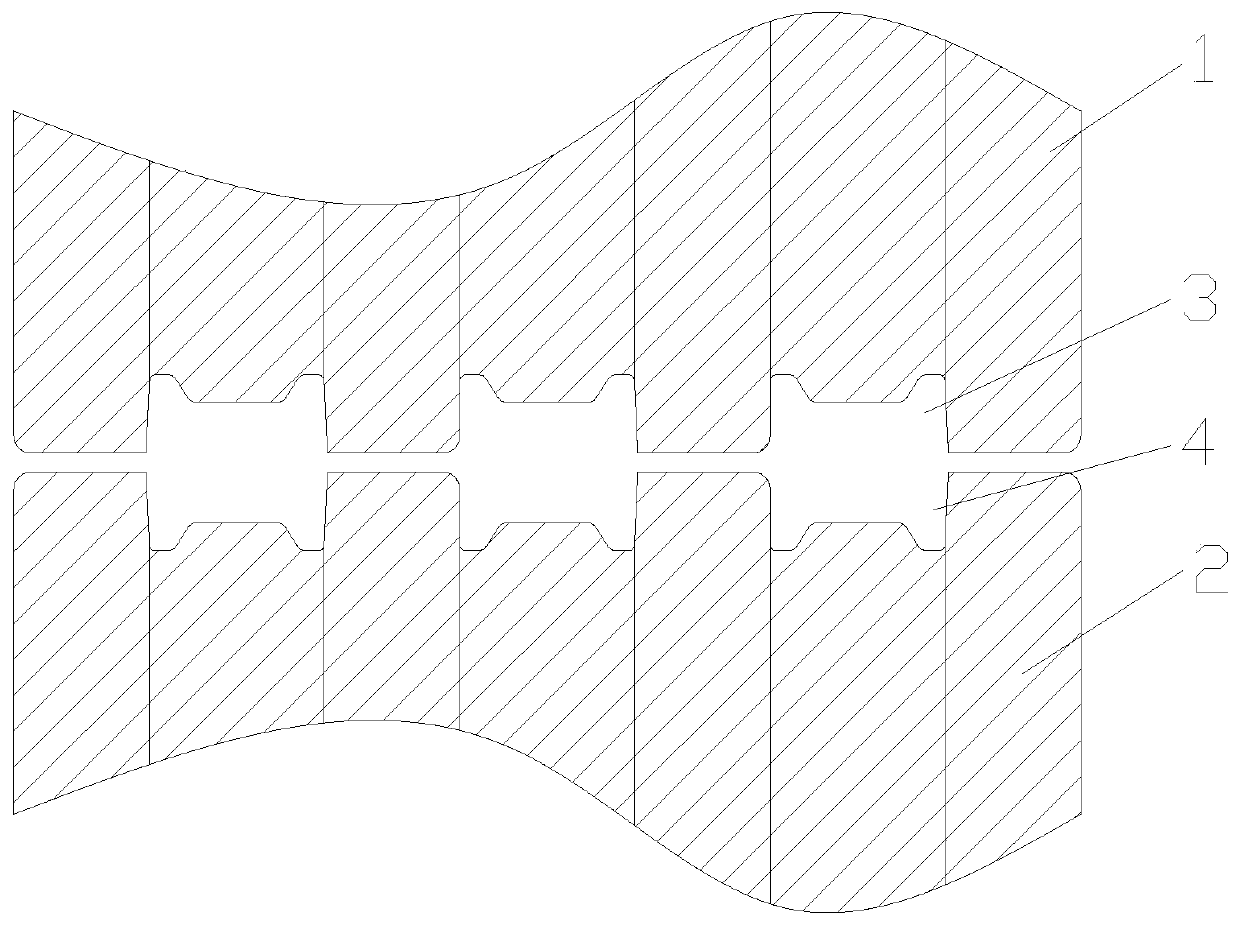

Nickel-molybdenum-vanadium alloy semi-steel roll used for section mill S-shaped rack

A technology of semi-steel rolls and vanadium alloys, which is applied in the field of nickel-molybdenum-vanadium alloy semi-steel rolls for racks, which can solve the problems of wear resistance, hardness drop impact extrusion toughness, heat crack resistance and lack of plasticity, and roll processing efficiency reduction , surface roughness and other problems, to achieve the effect of improving wear resistance, processing efficiency and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A production and processing process of nickel-molybdenum-vanadium alloy semi-steel rolls for the S frame of a section steel rolling mill, including the following steps: S1, selecting the chemical composition of the rolls: C: 1.40%, Si: 0.40%, Mn: 0.80%, P: 0.01 %, S: 0.01%, Cr: 2.0%, Ni: 2.50%, Mo: 0.40%, V: 0.20%, Nb: 0.20%; S2, smelting and burning: smelting in an intermediate frequency induction furnace, during which 50% of quartz sand is used %, lump lime 20%, fluorite powder 5% mixed slagging agent; when the temperature reaches 1530°C, the scum appears white, and the slag is produced; then add 0.03% aluminum for deoxidation, and then tap the steel into the ladle. Argon blowing and oscillating using the refining process outside the furnace; adding 1 kg of yttrium-based heavy rare earth molten steel modifier to remove H and N elements; pouring after sedation for 6 minutes; heat treatment for S3 and roll rough opening: leave 5 mm machining allowance on one side ;The h...

Embodiment 2

[0025] A production and processing process of nickel-molybdenum-vanadium alloy semi-steel rolls for the S frame of a section steel rolling mill, including the following steps: S1, selecting the chemical composition of the rolls: C: 1.60%, Si: 0.60%, Mn: 1.30%, P: 0.02 %, S: 0.02%, Cr: 2.5%, Ni: 2.8%, Mo: 0.60%, V: 0.30%, Nb: 0.30%; S2, smelting and burning: smelting in an intermediate frequency induction furnace, during which quartz sand 65 %, lump lime 27%, fluorite powder 8% mixed slag forming agent; when the temperature reaches 1550°C, the scum will appear white; then add 0.03% aluminum for deoxidation, and then tap the steel into the ladle. Argon blowing and oscillation is carried out by refining process outside the furnace; 2 kg of yttrium-based heavy rare earth molten steel modifier is added to remove H and N elements; pouring after calming down for 7 minutes; heat treatment of S3 and roll rough opening type: leave 5 mm machining allowance on one side ;The heat treatment...

Embodiment 3

[0027]A production and processing process of nickel-molybdenum-vanadium alloy semi-steel rolls for the S frame of a section steel rolling mill, comprising the following steps: S1, selecting the chemical composition of the rolls: C: 1.80%, Si: 0.80%, Mn: 1.60%, P: 0.03 %, S: 0.025%, Cr: 3.0%, Ni: 3.50%, Mo: 0.80%, V: 0.40%, Nb: 0.40%; S2, smelting and burning: smelting in an intermediate frequency induction furnace, during which 80% of quartz sand is used %, lump lime 30%, fluorite powder 10% mixed slag forming agent; when the temperature reaches 1580 ℃, the scum will appear white; then add 0.03% aluminum for deoxidation, and then tap the steel into the ladle. Argon blowing and oscillating using the refining process outside the furnace; adding 3 kg of yttrium-based heavy rare earth molten steel modifier to remove H and N elements; pouring after sedation for 8 minutes; heat treatment of S3 and roll rough opening type: leave 8 mm machining allowance on one side ;The heat treatmen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com