Welding wire for gas shielded welding of aging martensitic stainless steel

A martensitic stainless steel, gas shielded welding technology, used in welding media, welding equipment, welding/cutting media/materials, etc., can solve problems such as reduced stress corrosion resistance, reduced corrosion resistance, and reduced weld toughness and plasticity. , to achieve good corrosion resistance and stress corrosion resistance, prevent welding hot cracks, and good weldability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The preparation method of welding wire is:

[0019] (1) Ratio of charge

[0020] According to the target content of each element and the smelting loss coefficient, determine the ratio of each raw material.

[0021] (2) Vacuum induction furnace is used to smelt welding wire steel. The process conditions are: vacuum degree 0.1-10Pa, refining temperature 1530-1590°C, refining time 5-15 minutes, pouring temperature 1460-1550°C.

[0022] (3) Using vacuum consumable electric arc furnace to remelt welding wire steel, the process conditions: vacuum degree 0.1-1.0Pa, voltage 20-35V, current density 150-200A / cm 2 , Melting speed 5.0 ~ 10.0cm / min.

[0023] (3) Blank forging

[0024] After removing the shrinkage cavity and skin of the ingot, carry out billet forging. The forging specification is: heating temperature 1150°C±10°C, holding temperature for 60 minutes, gradually increasing the amount of deformation, and forging into a square bar.

[0025] (4) Free forging

[0026] ...

Embodiment

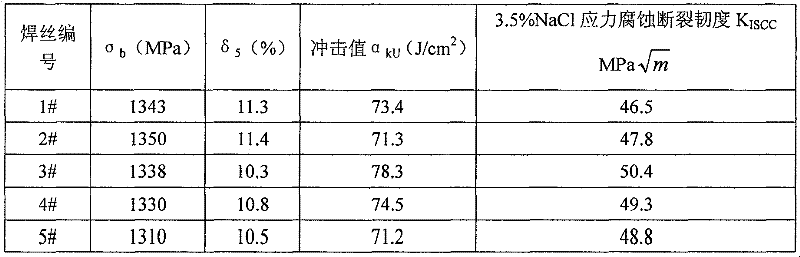

[0034] Prepare 5 welding wires respectively, and the components of the welding wires adopt the components in Table 1 respectively.

[0035] Table 1 Welding wire composition (wt.%)

[0036]

C

Si

mn

P

S

Cr

Ni

Cu

Nb

Mo

Fe

1#

0.03

0.40

0.60

0.015

0.015

15.0

5.2

3.2

0.40

—

Bal.

2#

0.09

0.40

0.60

0.01

0.005

15.8

5.8

3.5

0.50

—

Bal.

3#

0.01

0.30

0.70

0.02

0.015

15.9

4.5

3.5

0.35

—

Bal.

4#

0.04

0.60

0.65

0.02

0.015

16.8

5.5

3.7

0.30

0.30

Bal.

5#

0.06

0.30

0.50

0.015

0.015

14.2

4.2

3.5

0.40

0.20

Bal.

[0037] (1) Ratio of charge

[0038] According to the target content of each element and the smelting loss coeffi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com