Lithium-ion battery with high rate discharge performance

A lithium-ion battery, high-rate discharge technology, applied in the field of lithium-ion batteries, can solve the problems that the internal resistance of the battery cannot meet the needs of the product, the tabs are torn or broken, the mold wear rate increases, and the discharge rate is increased. High performance, easy operation and high welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

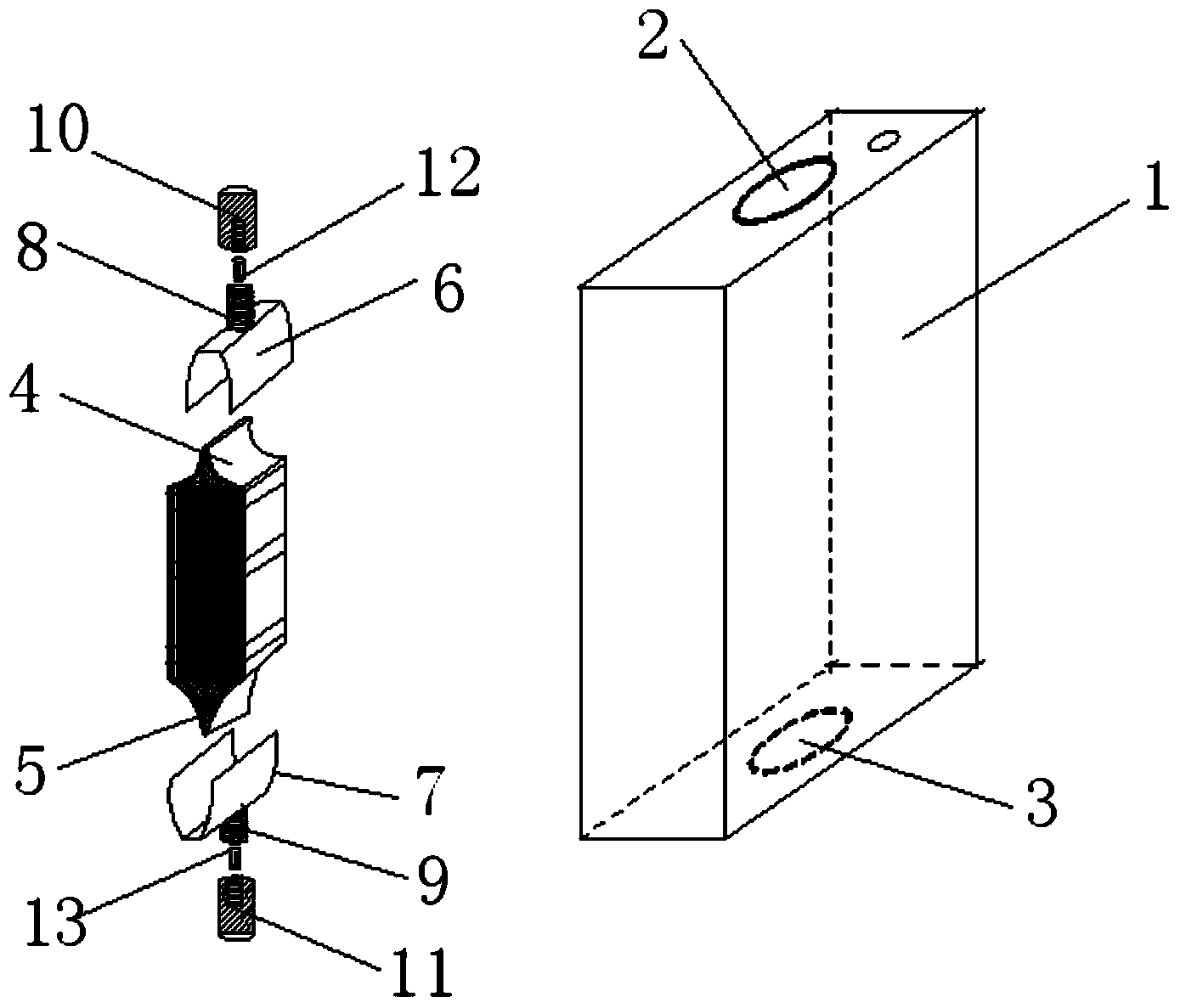

[0035] The present invention will be further described below in conjunction with the accompanying drawings.

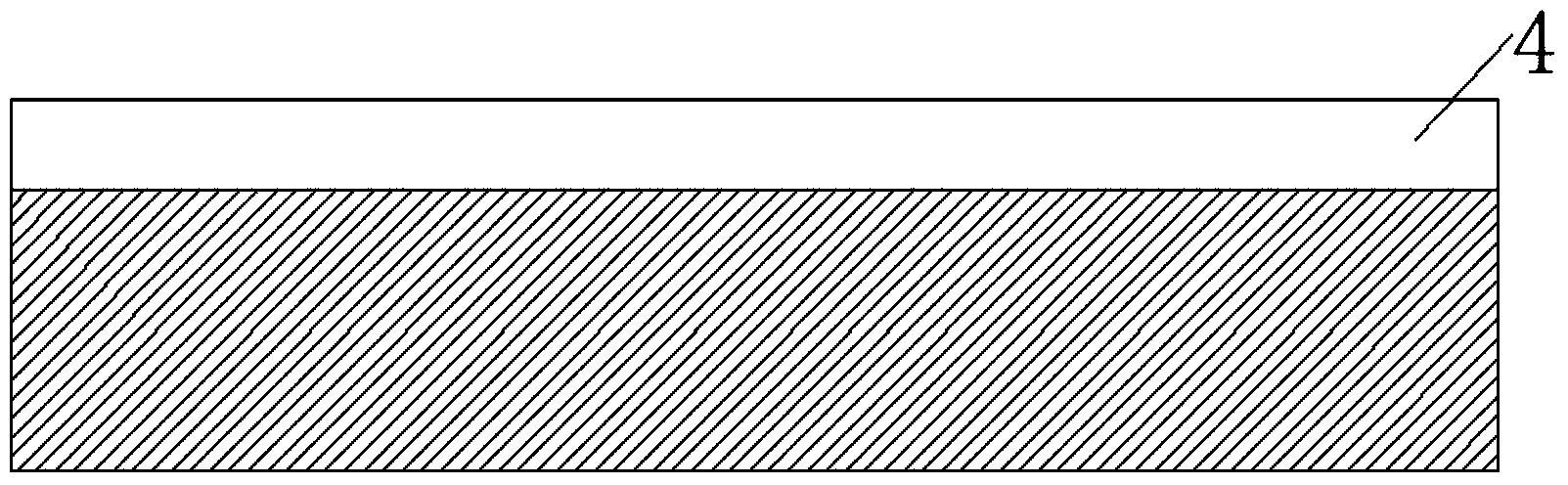

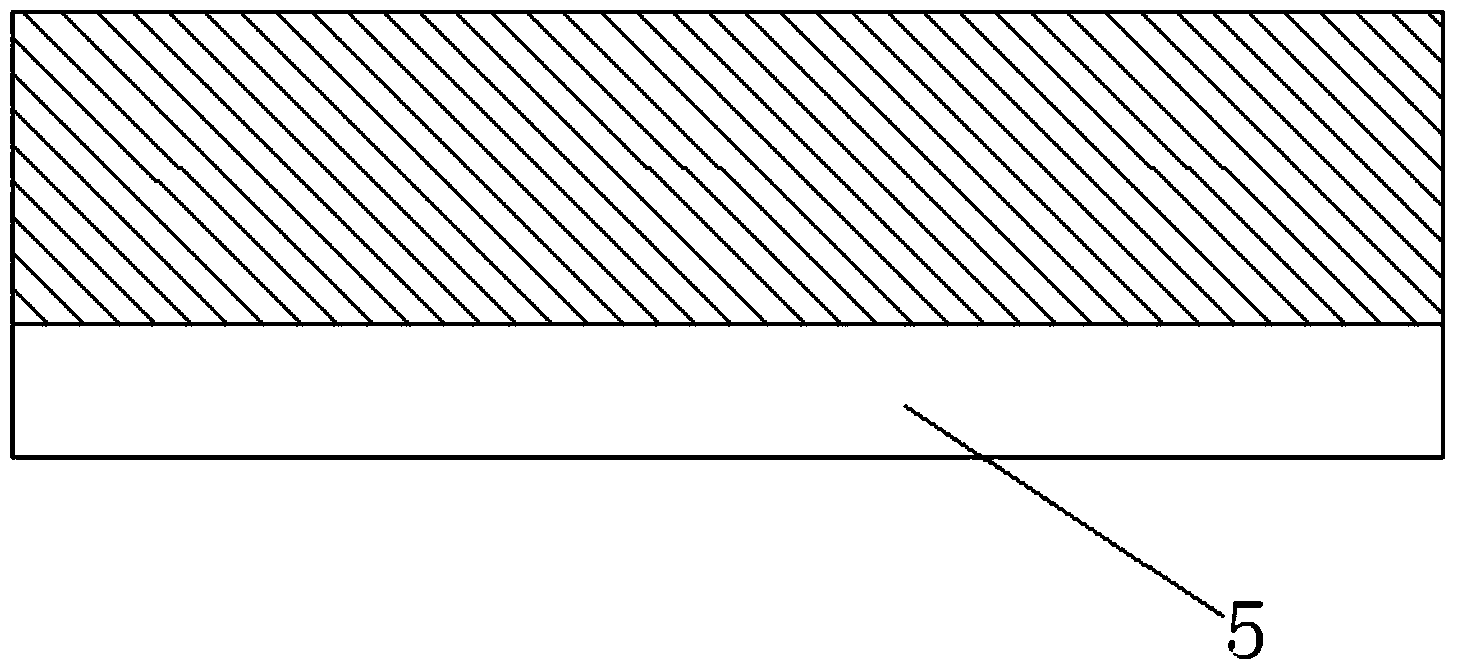

[0036] Such as figure 1As shown, the present invention is a lithium-ion battery with high-rate discharge performance, including a casing 1, an electric cell located in the casing, an upper cover plate 2 and a lower cover plate 3, and the electric cell is composed of a positive electrode tab 4 The positive pole piece, the negative pole piece with the negative pole tab 5 and the diaphragm are made by one of the winding method and the stacking method, and the positive pole tab clamping mechanism 6 and the negative pole tab clamping mechanism 7 are also provided. , the positive pole lug is accommodated and fixed inside the positive pole lug clamping mechanism, and a positive pole stud 8 is arranged on the outside of the positive pole lug clamping mechanism, and the positive pole stud is detachably connected to the upper cover plate , the negative pole lug is accommodated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com