Low-alloy cast steel for high-speed train brake disc, heat treatment method of low-alloy cast steel and brake disc

A technology of low-alloy cast steel and heat treatment method, which is applied in the field of metal materials in rail transit, can solve problems such as difficult competition, high price of brake disc products, and difficulty in meeting high-speed trains to reduce operating costs, so as to achieve cost reduction and high strength. , long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0040] The low-alloy cast steel of the present invention, its components and the weight percent of each component are: carbon 0.12-0.20%; boron 0.001-0.003%; aluminum 0.01-0.05%; titanium 0.02-0.07%; 0.55%; manganese 1.0-1.8%; chromium 0.10-0.30%; molybdenum 0.20-0.40%; nickel 0.15-0.35%; oxygen≤50ppm; nitrogen≤150ppm; phosphorus≤0.01; 0.1; the rest is iron.

[0041] The order of adding titanium, aluminum and boron in the low-alloy cast steel of the present invention is: first add aluminum, then add titanium, and finally add boron.

[0042] The low-alloy cast steel of the present invention can be smelted by a conventional induction electric furnace or an electric arc furnace.

[0043] The heat treatment method of low alloy cast steel of the present invention adopts normalizing treatment+quenching and tempering treatment, comprises the following steps:

[0044] (1) Normalizing treatment: heat the casting to 900°C-950°C, keep it warm for 3-5 hours, and then air-cool it to room...

PUM

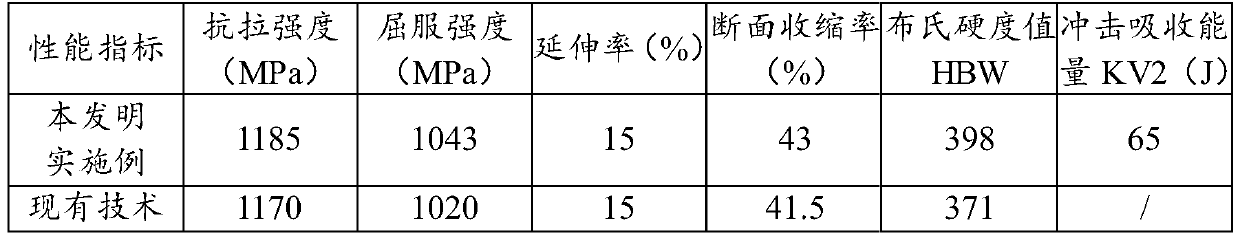

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| impact absorption energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com