A low-cost and high-wear-resistant stretching and reducing roll and its heat treatment process

A process and annealing treatment technology, which is applied in the field of low-cost and high-wear-resistant seamless steel pipe tensioning and reducing roll material and its heat treatment process, which can solve the problems of easy roll breakage, high roll consumption, and prone to ring rolling marks on the roll surface. , to achieve the effect of prolonging service life, improving production efficiency, and improving oxidation resistance and thermal crack resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

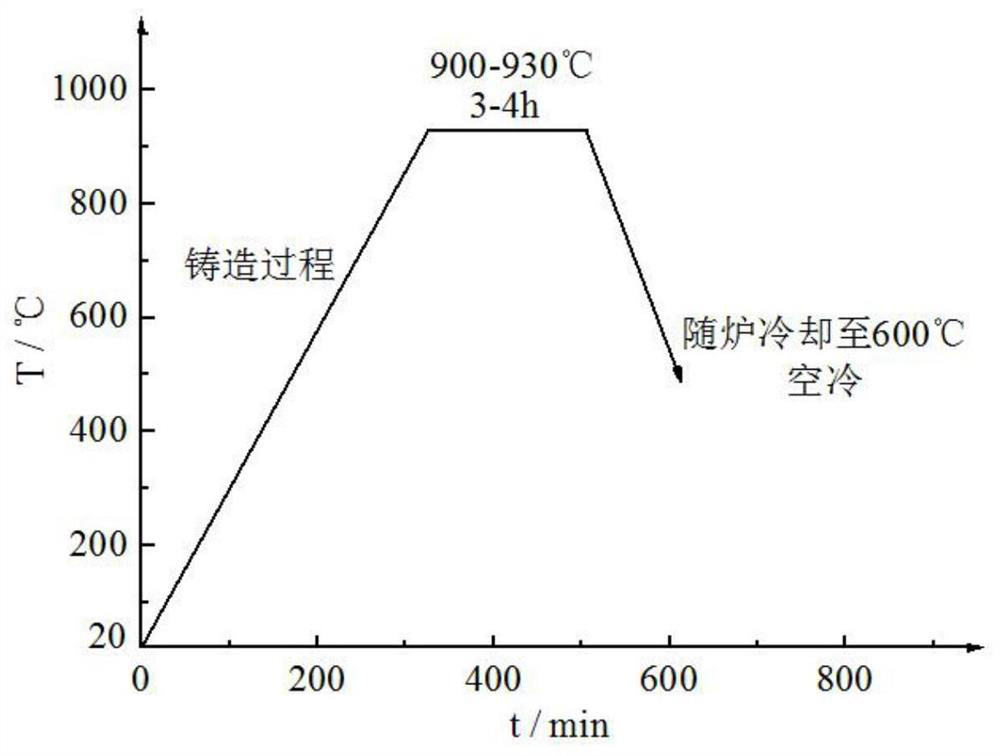

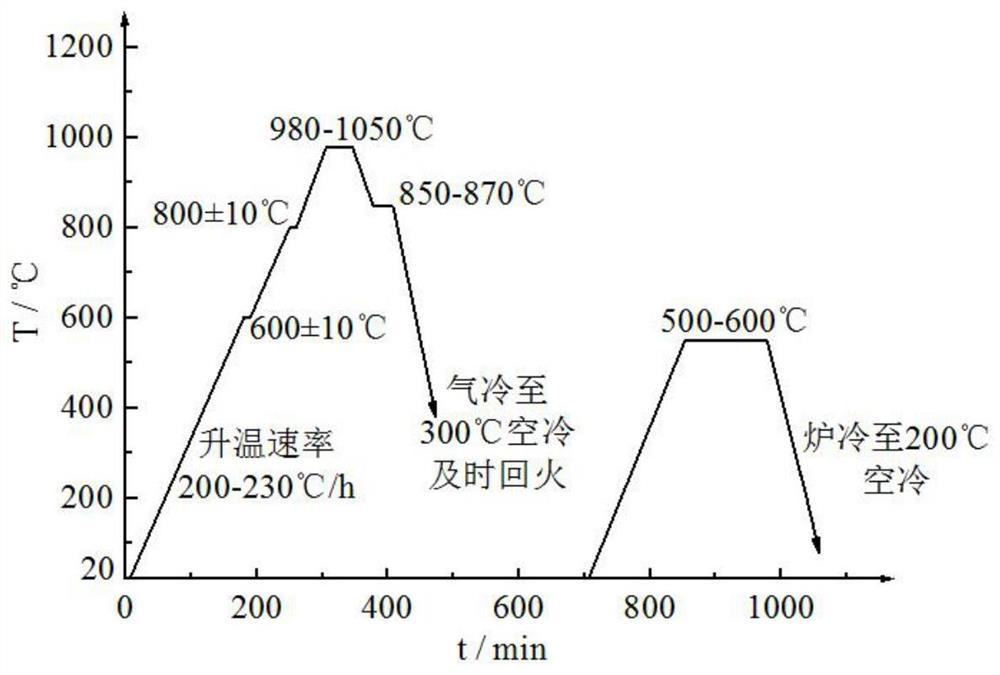

[0074] According to the scope of the chemical composition designed by the present invention, the induction furnace is used for smelting, and inoculation and modification are carried out during the smelting process; during the cooling process after casting, the annealing process is carried out with the furnace keeping warm for 3 hours at 920°C; with a heating rate of 200°C / h Heating, at 600°C, carry out 8min uniform temperature preservation; continue to heat up at a heating rate of 200°C / h, at 800°C, carry out 8min uniform temperature preservation; quench at 1010°C, hold for 30min, and cool to 850 ℃, keep warm for 25 minutes, then blow nitrogen to cool, control the cooling rate to 5 ℃ / s, cool down to below 300 ℃, take out the furnace and air cool to room temperature, and temper in time (within 2-3h). Tempering: Heating at a heating rate of 200°C / h, tempering at 550°C for 120 minutes; cooling to 200°C with the furnace, and air cooling to room temperature. The tempering process o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com