Patents

Literature

61results about How to "Improve matrix strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cold-rolled hot-galvanized dual-phase steel plate with flanging property and manufacturing method thereof

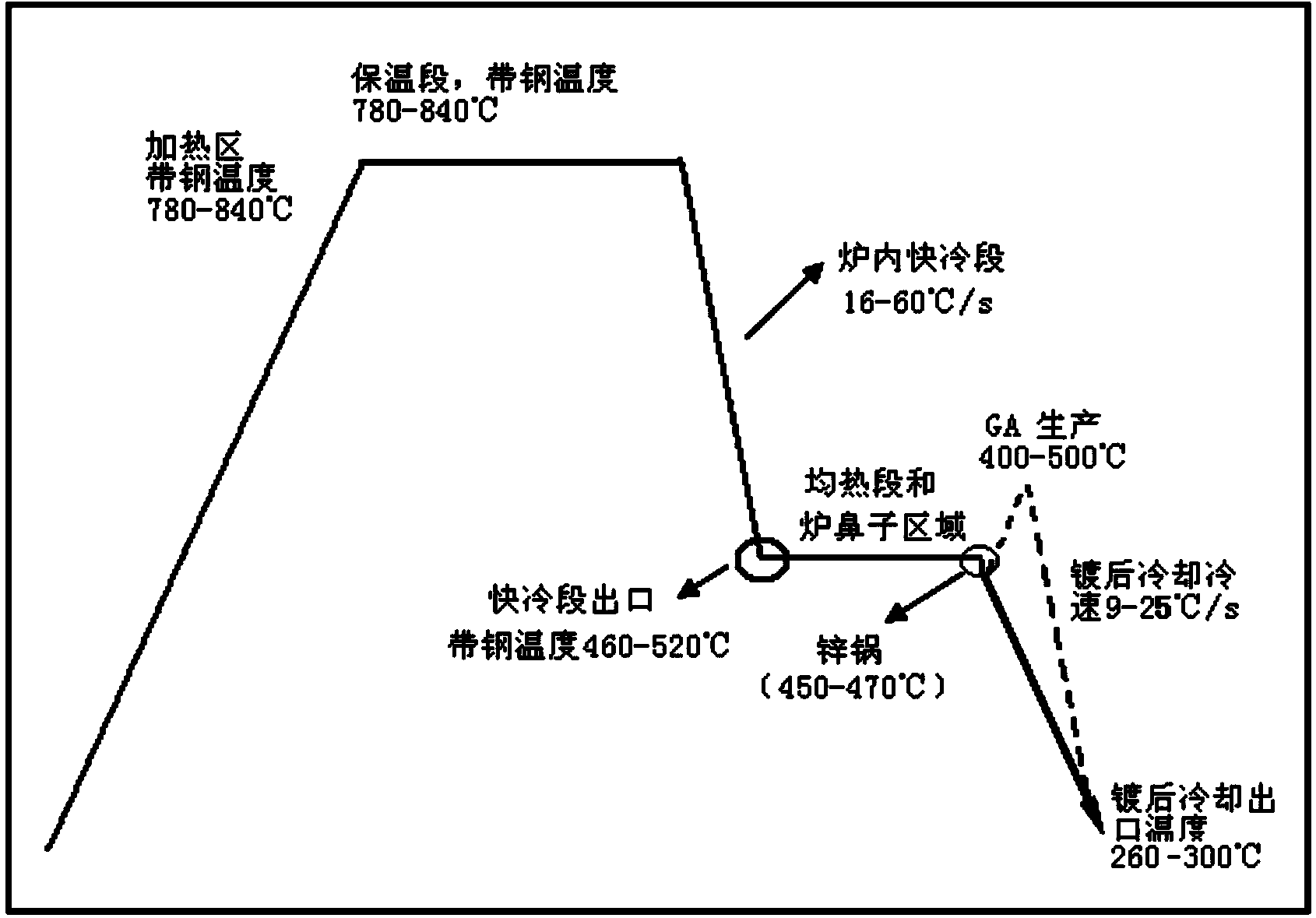

The invention relates to a cold-rolled hot-galvanized dual-phase steel plate with a flanging property and a manufacturing method thereof. The steel plate comprises the following chemical components by weight percent: 0.06% to 0.095% of C, 0.3% to 0.6% of Si, 1.4% to 1.8% of Mn, greater than 0% and less than or equal to 0.02% of P, greater than 0% and less than or equal to 0.01% of S, 0.02% to 0.05% of Al, 0.35% to 0.55% of Cr, 0.02% to 0.04% of Nb, greater than 0% and less than or equal to 0.005% of N and the balance of Fe. According to the steel plate provided by the invention, the austenite is dispersedly distributed in a ferrite matrix via the refining of austenite grains by adding the Nb element and controlling temperatures during hot rolling and finish rolling and a rolling temperature; the amount of the austenite after annealing is increased by limiting the content of C and carrying out high-temperature annealing in a continuous hot-galvanized annealing furnace, so that tissues in low-C martensite are obtained after quenching. Thus, the hardness of the martensite is decreased. As a result, a hardness difference between the martensite phase and the ferrite phase is reduced.

Owner:ANSC TKS GALVANIZING

High elasticity and high strengh steel and its producing method

An impact-resistant and wear-resistant high-elasticity and high-strength steel, wherein the steel contains 0.26-0.48 wt% C, 1.4-2.5 wt% Si, 0.5-1.0 wt% Mn, 1.4-2.4 wt% % Cr, 0.01-0.1% by weight of Ni, 0.01-0.5% by weight of Mo, 0.005-0.04% by weight of Al, 0.05-0.1% by weight of V, 0.0025-0.02% by weight of N, the rest is Fe and unavoidable of impurities. The impact-resistant, wear-resistant high-elasticity and high-strength steel of the present invention has high hardness, high strength, high toughness and high elasticity, and the weldability, low-temperature tempering resistance and high-temperature tempering resistance, hardenability, Mechanical properties such as wear resistance, impact toughness, and tensile strength are excellent, so when used under severe conditions, the mold life and component life are much longer than conventional steels.

Owner:CF +2

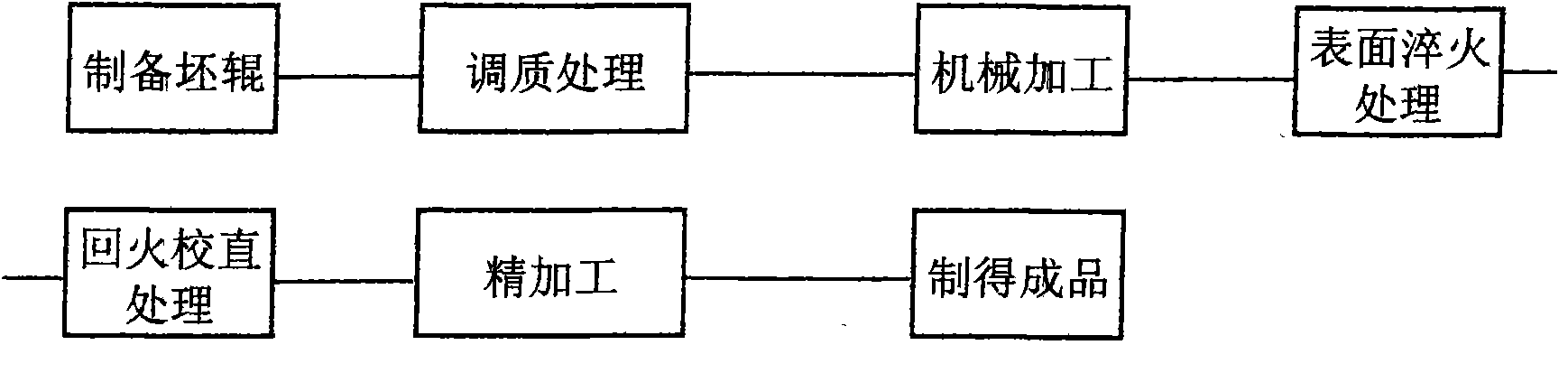

Hot rolling hot straightening roll suitable for thick steel plates with thickness of less than or equal to 60mm and preparation method thereof

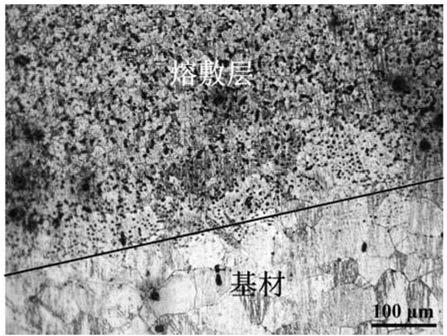

InactiveCN102108469AImprove matrix strengthGood resistance to cold and heat fatigueFurnace typesHeat treatment furnacesSheet steelMatrix strength

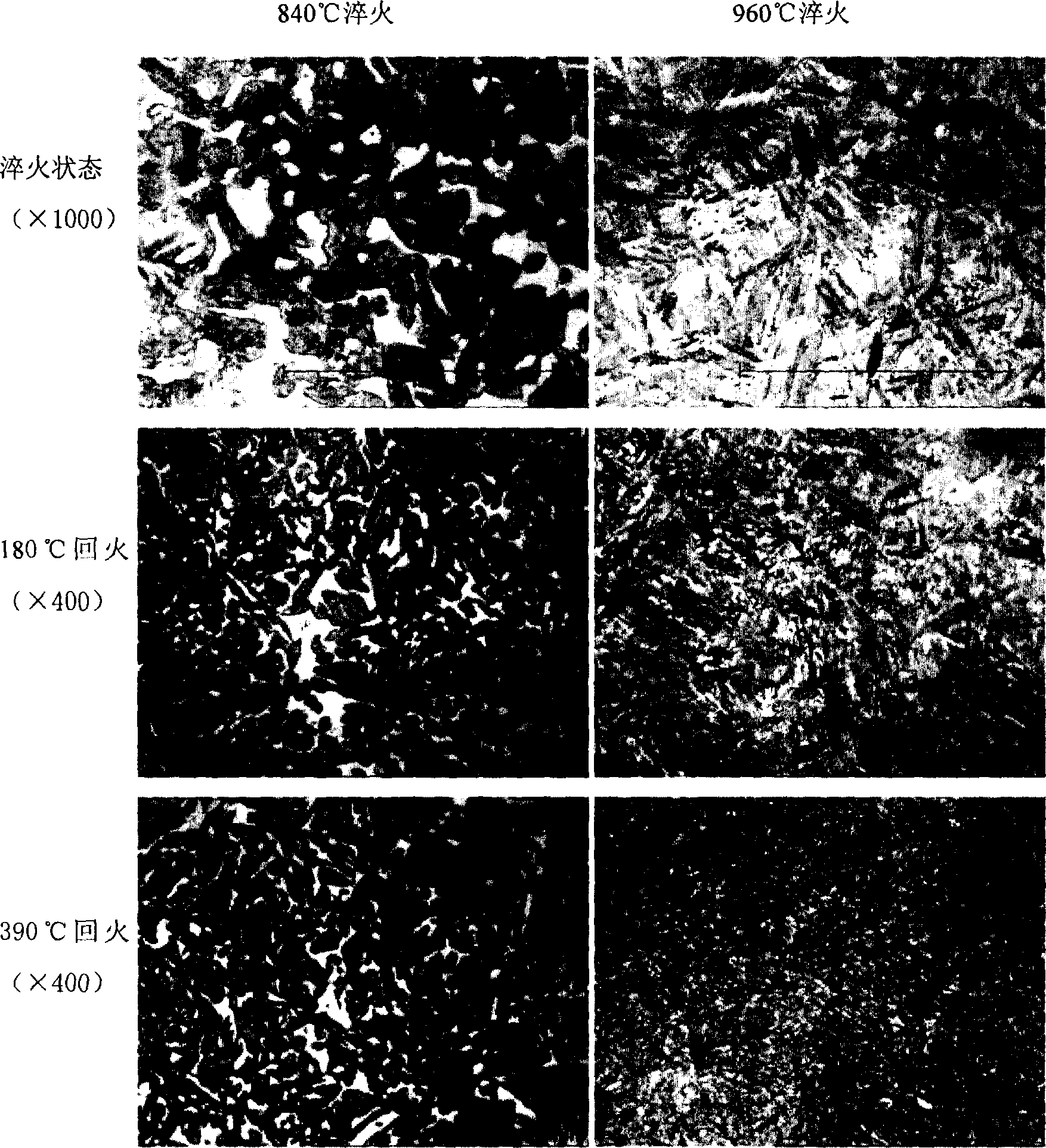

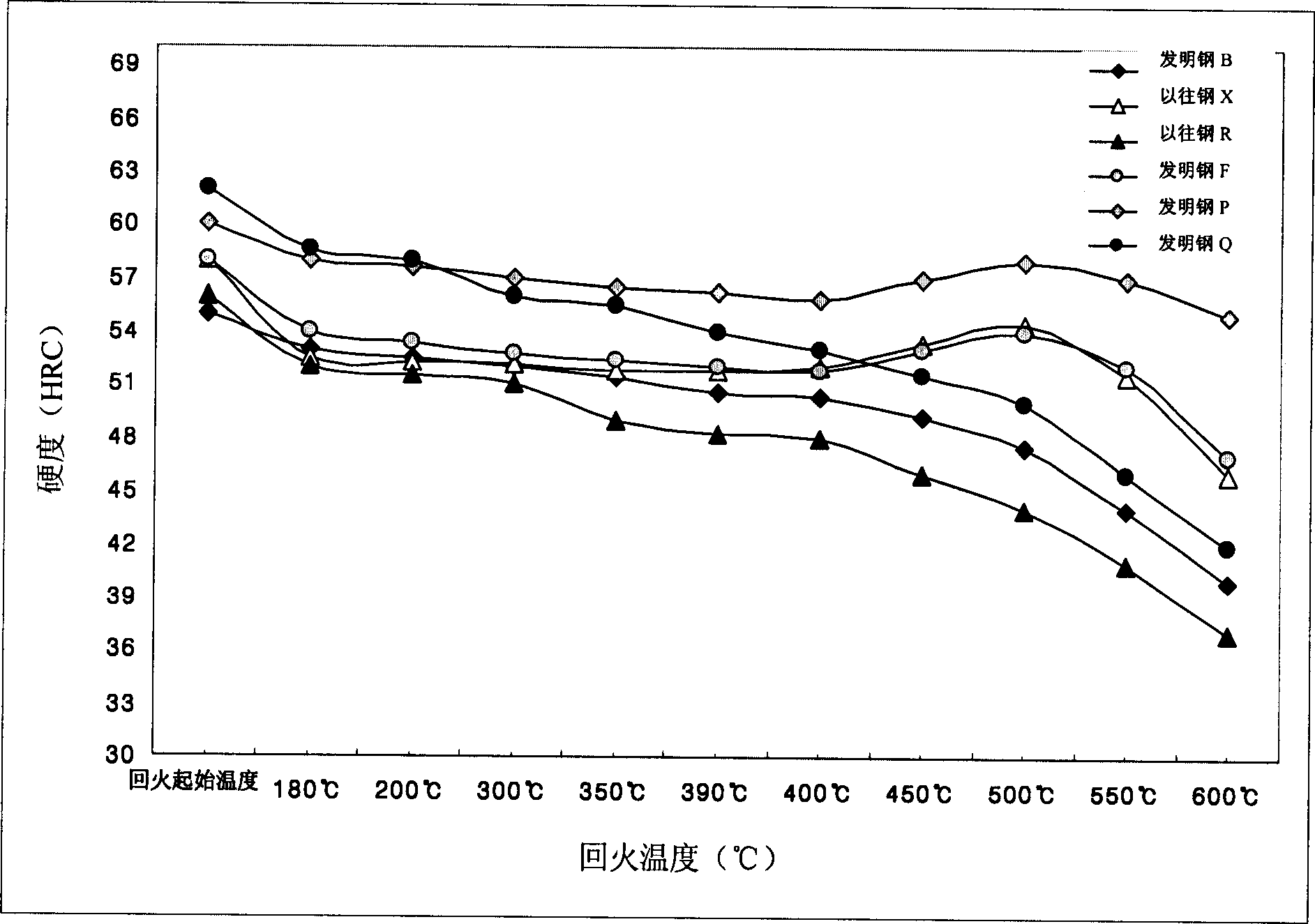

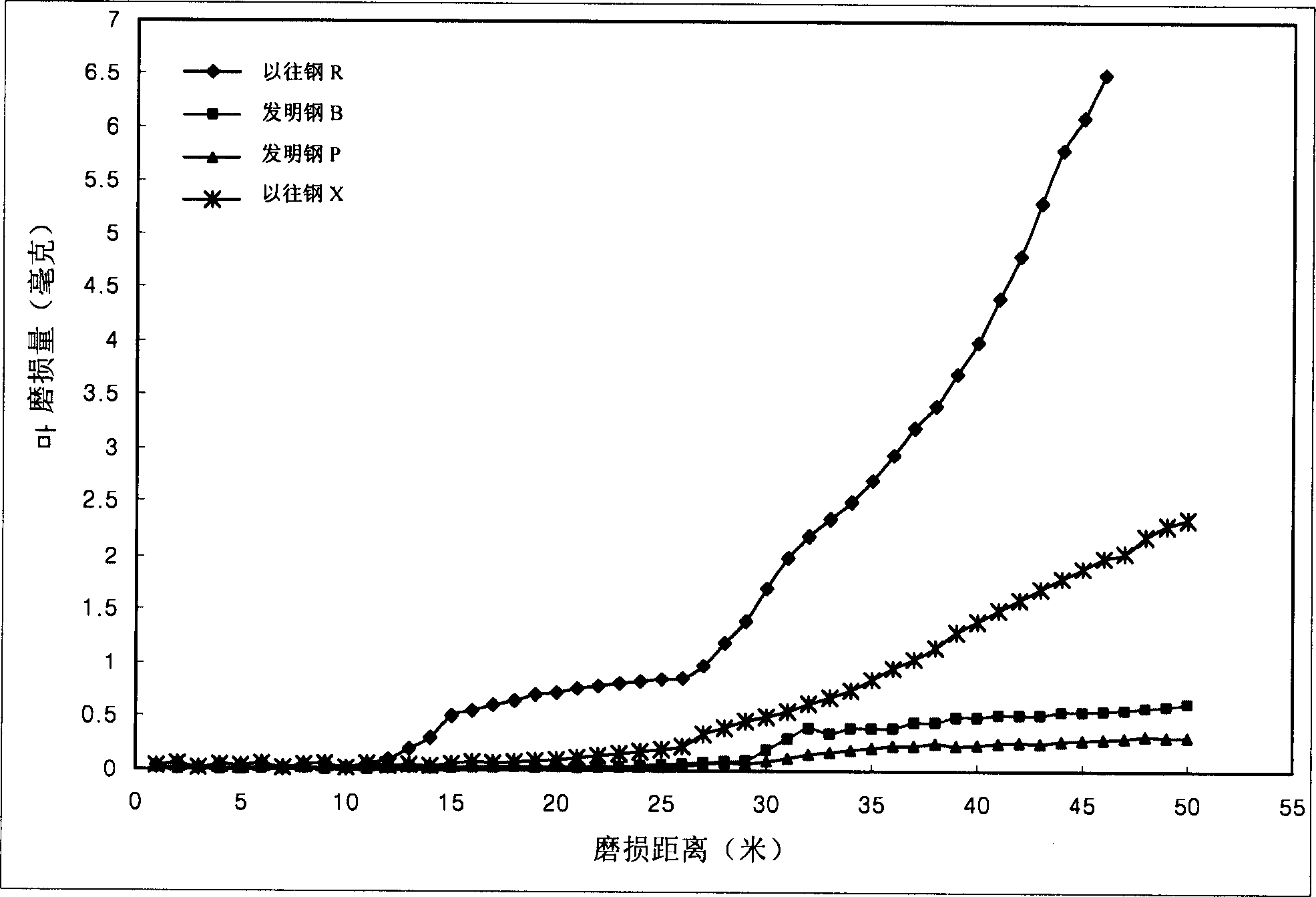

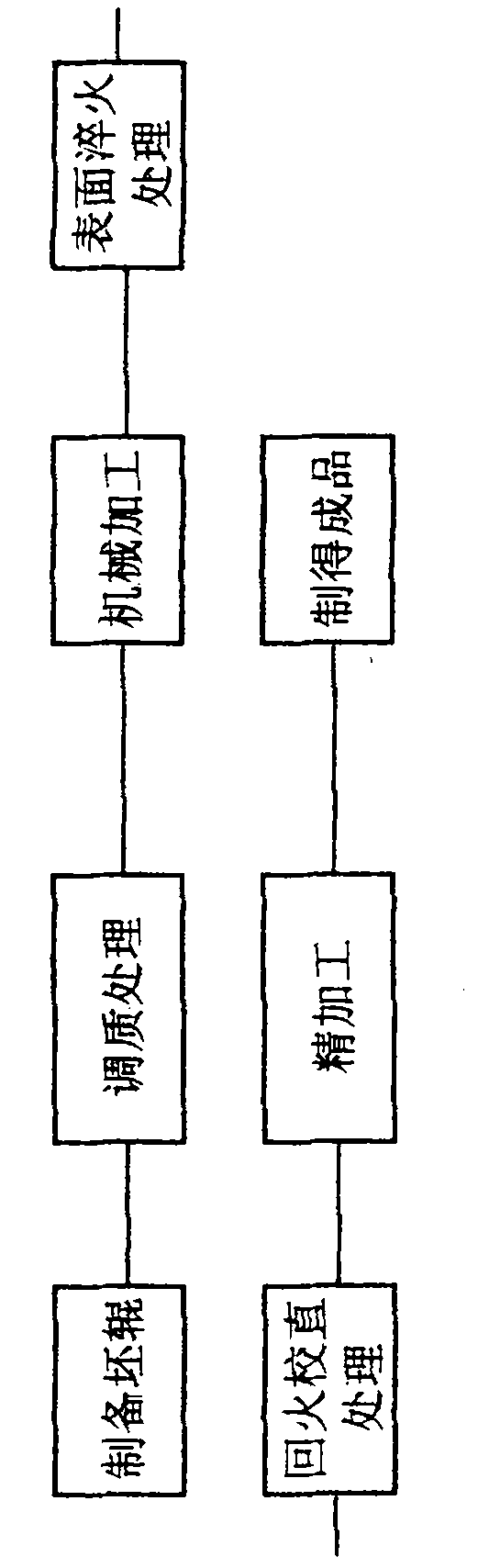

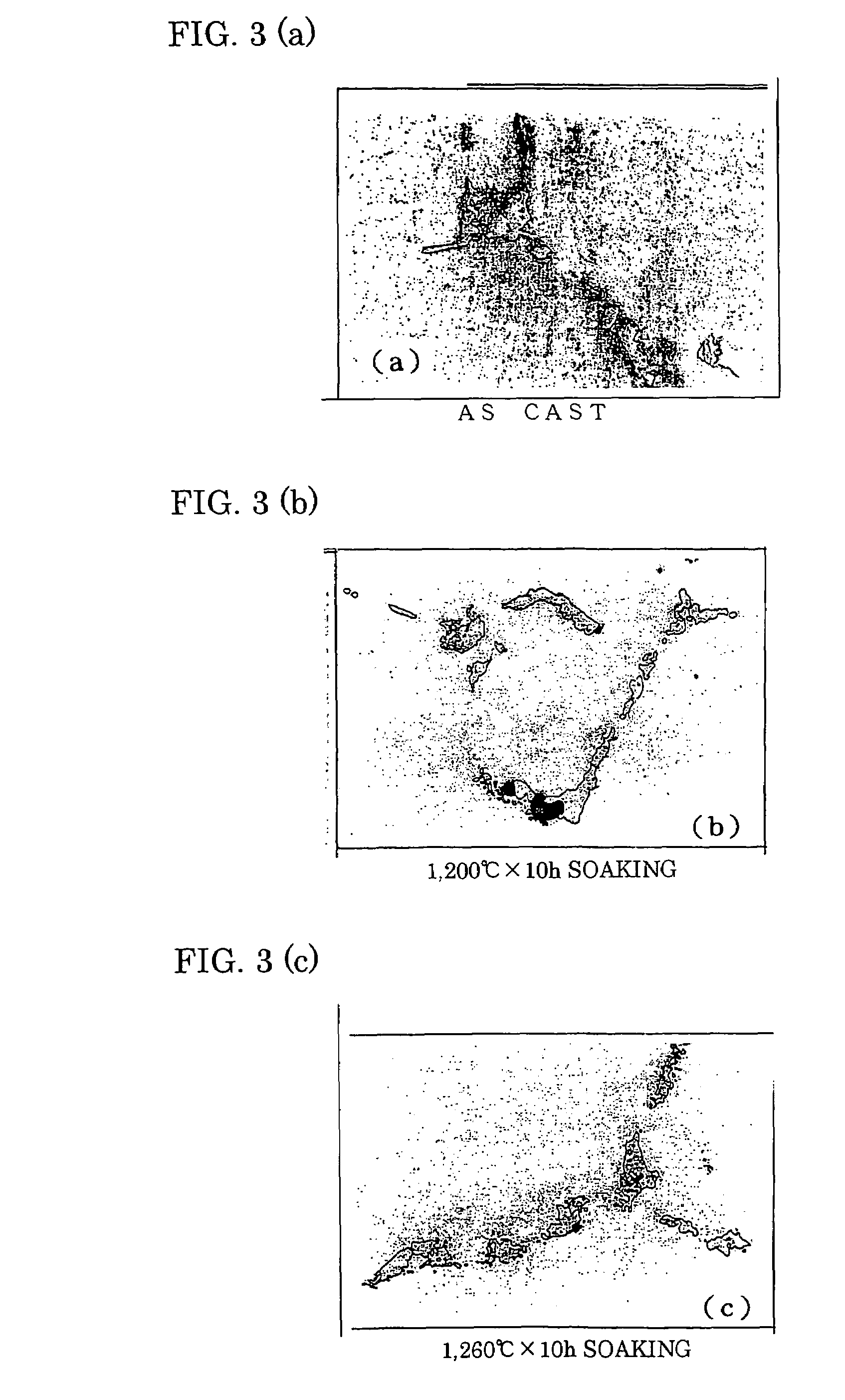

The invention discloses a hot rolling hot straightening roll suitable for thick steel plates with thickness of less than or equal to 60mm and a preparation method thereof. The hot straightening roll comprises the following components in percentage by weight: 4.5 to 6.0 percent of Cr, 1.0 to 2.0 percent of Mo, 0.6 to 1.5 percent of Si, 0.8 to 1.2 percent of Ni, 0.8 to 2.0 percent of V, 0.35 to 0.6 percent of C, less than or equal to 0.02 percent of P, less than or equal to 0.01 percent of S, and the balance of Fe and inevitable impurities. The preparation method sequentially comprises the following steps of: preparing a blank roll; conditioning; machining; performing surface quenching treatment; annealing; and performing finish machining, wherein the surface quenching temperature is 1,130 to 1,170 DEG C; the annealing temperature is 520 to 580 DEG C and the annealing time is more than or equal to 10 hours; and during annealing, roll straightening treatment that pressure straightening is performed on high points through heavy objects is carried out. The hot straightening roll product has the characteristics of high matrix strength, high comprehensive performance, high surface hardness and wear resistance, high cold and hot fatigue resistance, and the like; and the preparation method has the characteristics of simplicity, convenience, reliability, low process cost, high quality of product and the like.

Owner:CHANGZHOU BAOLING HEAVY IND MACHINERY

Nickel based alloys for internal combustion engine valve seat inserts, and the like

InactiveUS6482275B1Improving insert retention characteristicGood high-temperature compressive yield strengthMachines/enginesWelding/cutting media/materialsManganeseAlloy

A nickel based alloy is provided which includes, in weight percentage,carbon from about 2 to about 3;chromium from about 30 to about 40;tungsten from about 12 to about 18;iron from about 3.5 to about 8.5;molybdenum from about 1 to about 8;manganese up to about 0.5;silicon up to about 1.0; andthe balance nickel and incidental impurities. The alloy is useful for internal combustion engine valve seat inserts and the like.

Owner:L E JONES CO

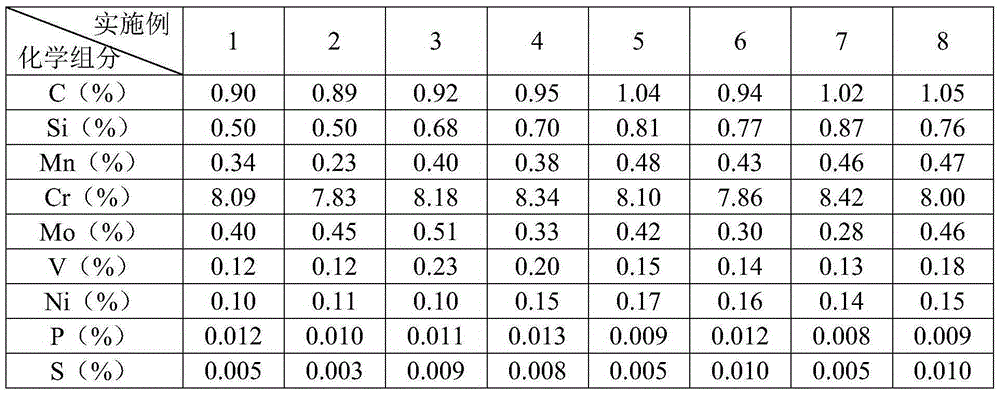

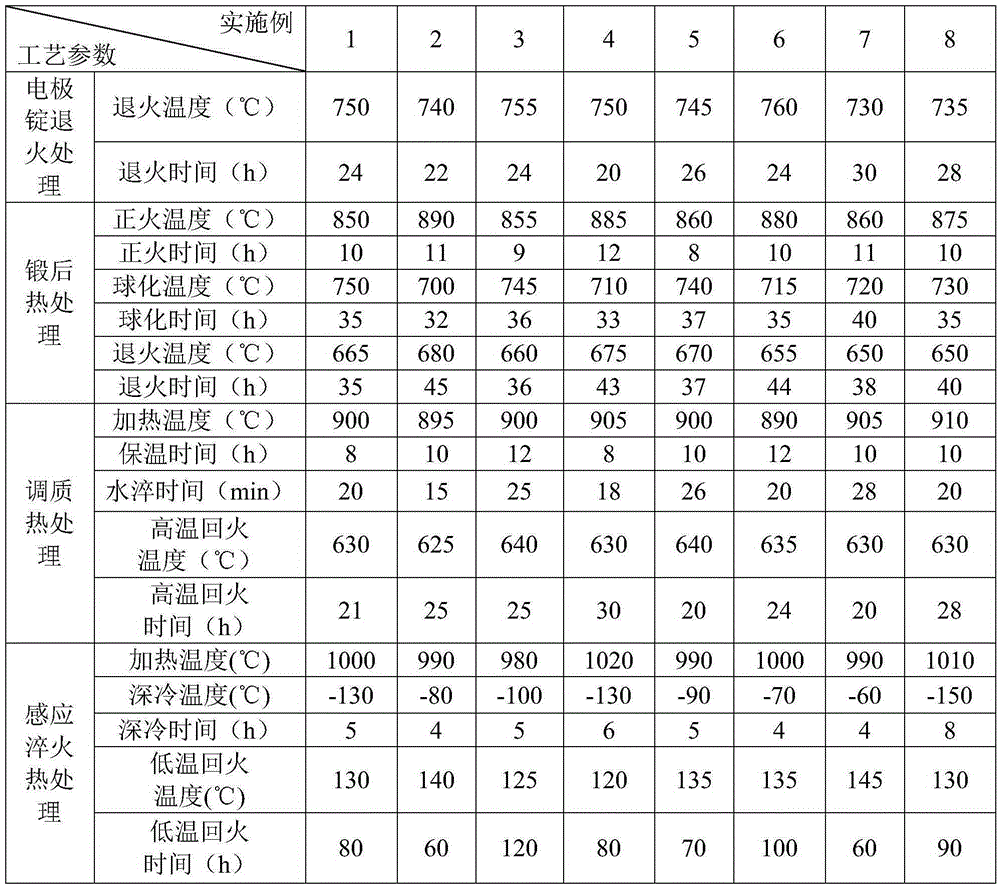

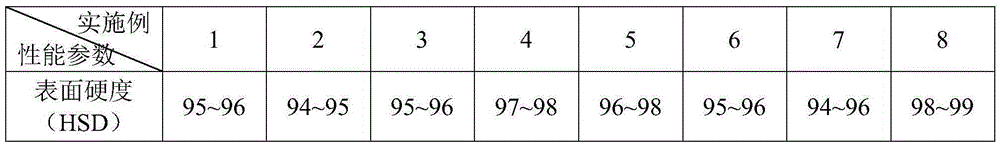

High-wear-resisting cold roll and manufacturing method thereof

ActiveCN105385959AManufacturing Process Step ImprovementsImprove purityMetallurgyHigh wear resistance

The invention relates to a high-wear-resisting cold roll. Chemical components in the cold roll comprise, by weight percentage, 0.80%-1.20% of C, 0.4%-1.20% of Si, 0.20%-0.50% of Mn, 7.50%-9.00% of Cr, 0.20%-1.00% of Mo, 0.05%-0.50% of V, less than or equal to 0.40% of Ni, less than or equal to 0.015% of S, less than or equal to 0.015% of P and the balance Fe and inevitable impurities. The high-wear-resisting cold roll has the high wear resistance; and under the same using condition, the service life of the roll is prolonged by more than one time than a roll made of original common chrome steel system materials.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

Contact fatigue-highly resistant cold-rolling intermediate roller and manufacture method thereof

ActiveCN104294168AReduce contentIncrease contentFurnace typesHeat treatment furnacesMo elementMatrix strength

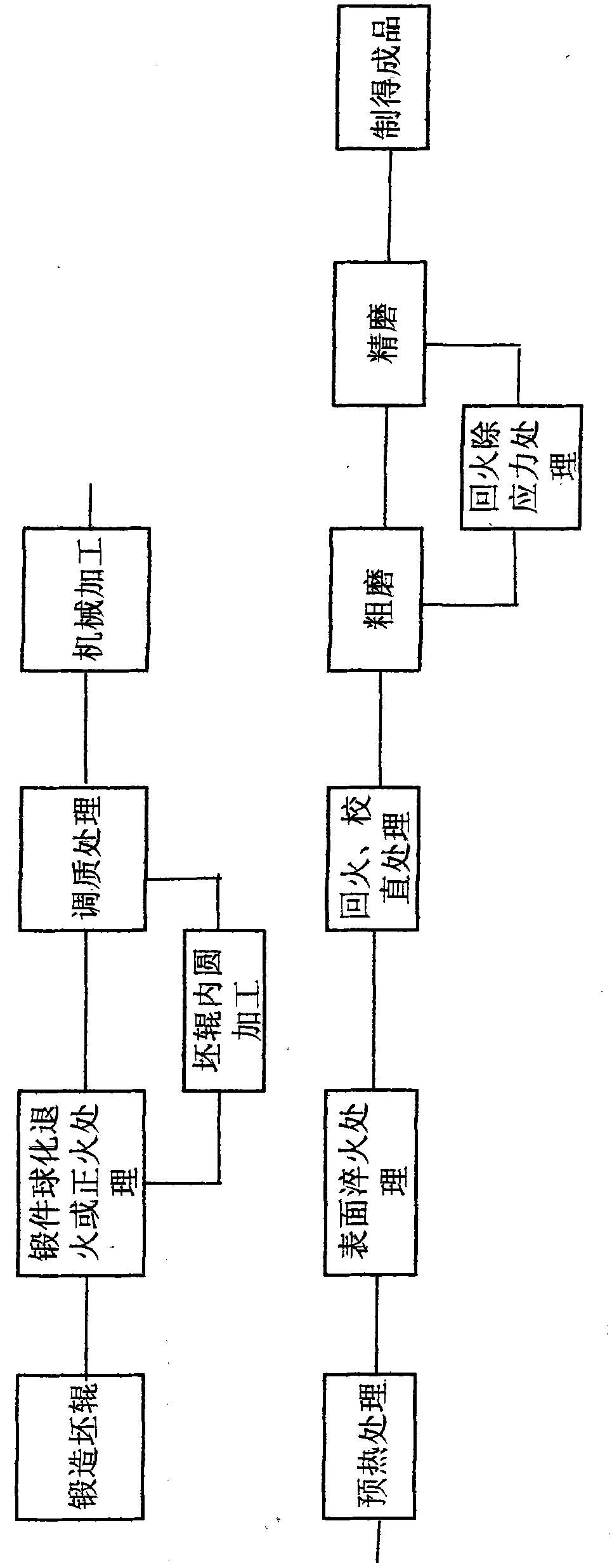

The invention discloses a contact fatigue-highly resistant cold-rolling intermediate roller and a manufacture method thereof, the roller comprises the following components by weight percentage: 0.70-0.85% of C, 0.40-1.00 of Si, 0.20-0.60% of Mn, 2.80-3.50% of Cr, 0.25-0.60% of Ni, 0.30-0.50% of Mo, 0.10-0.30% of V, less than or equal to 0.02 of P; less than or equal to 0.015 of S, and the balance of Fe and inevitable impurities. The manufacture method comprises the following steps: smelting in an electric furnace, refining outside the electric furnace, degassing under vacuum, casting an electrode bar, remelting electroslag, forging, annealing and performing heat treatment, roughly machining, tempering and performing heat treatment, semifinishing, performing heat treatment on the roller body, finely tempering, and acquiring the finished product roller. By reducing the content of an element C and increasing the content of Si, Ni and Mo elements, strength and toughness performance as well as the matrix strength of the intermediate roller can be increased, and tissue can be refined, and the cold-rolling intermediate roller has high contact fatigue resistance through heat treatment.

Owner:YIXING YONGCHANG ROLL

Alloy for producing cold rolled working roll and method for producing same

The invention relates to an alloy for cold-rolling worker rollers and its preparing process, wherein the alloy comprises the main chemical constituents of: C 0.9-1.2%, Si 0.85-1.25%, Mn 0.40-0.60%, Cr 2.50-5.50%, Ni 0.25-0.45%, Mo 0.25-0.45%, V 0.05-0.155 and balancing Fe.

Owner:BAOSTEEL ROLL SCI & TECH

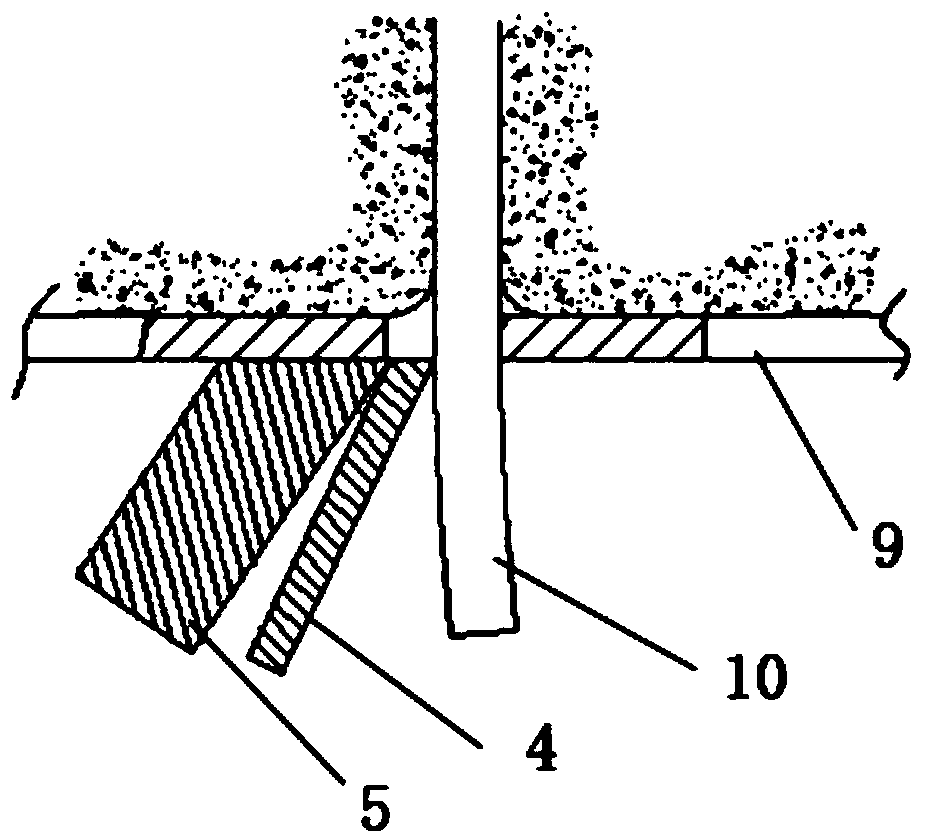

Nitrided high-speed steel roller used for bar cutting rack and manufacturing method of nitrided high-speed steel roller

ActiveCN106216405AImprove matrix strengthHigh strengthRollsMetal rolling arrangementsTungstenNiobium

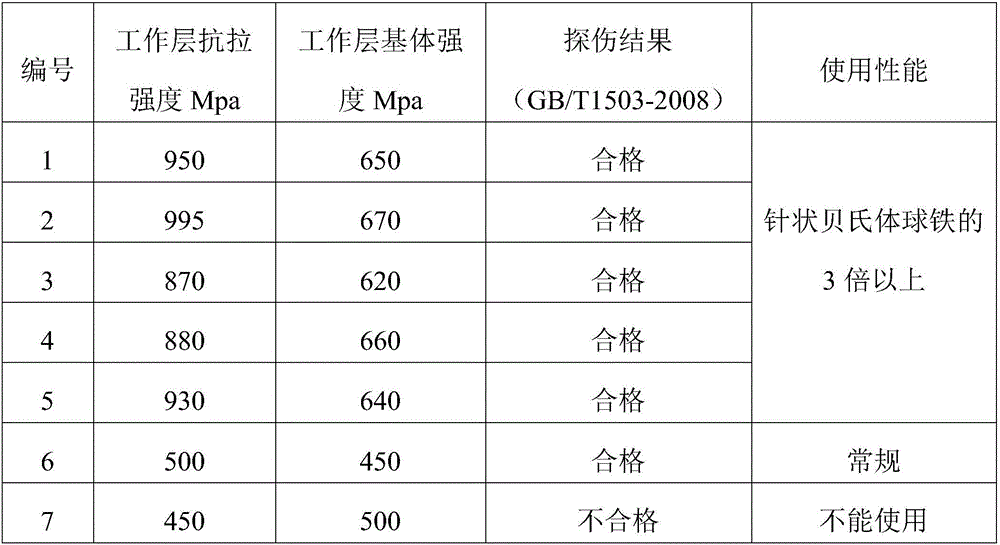

The invention relates to a nitrided high-speed steel roller used for a bar cutting rack and a manufacturing method of the nitrided high-speed steel roller, and belongs to the technical field of roller manufacturing. The nitrided high-speed steel roller comprises a roller neck and a roller body composed of a working layer, a transition layer and a core part. The working layer is composed of, by weight, 1.2-2.2% of carbon, 7.0-13.5% of chromium, 0.2-1.2% of nickel, 0.5-1.5% of molybdenum, 1.0-2.5% of vanadium, 1.0-2.5% of tungsten, 1.0-3.0% of niobium, 0.05-0.1% of rare earth, less than or equal to 0.04% of phosphorus, less than or equal to 0.04% of sulfur, less than or equal to 0.5% of manganese, 0.6-1.5% of silicon and the balance iron. The substrate strength of the working layer is greater than or equal to 600 MPa, and the tensile strength of the working layer is greater than or equal to 800 MPa. The substrate strength of the high-speed steel roller is improved, the grain is refined, the rolling environment requirement of the bar rolling mill cutting rack is met, and the rolling requirement of the cutting rack is met.

Owner:邢台轧辊线棒辊有限责任公司

Corundum micro-pore heat-insulating and fireproof material and preparation method thereof

InactiveCN102731118AReduce thermal stressImprove matrix strengthCeramicwareNano al2o3Temperature resistance

The invention relates to a corundum micro-pore heat-insulating and fireproof material and a preparation method thereof. The contents of raw materials of the corundum micro-pore heat-insulating and fireproof material are as follows: 40-50 wt% of corundum grain, 40-45 wt% of corundum fine powder, 5-10 wt% of active a-aluminum oxide micro-powder and 5-10 wt% r-aluminum oxide micro-powder, an additive, a dispersant account for 0.1-0.5 wt% of the above raw materials, nano aluminum oxide powder accounting for 0.1-1.5 wt% of the above materials and water accounting for 5-10 wt% of the above materials. The preparation method comprises the following steps of: dispersing the nano aluminum oxide powder into the water and dispersing under an ultrasonic vibration condition for 1-5 minutes to prepare a uniform suspension solution; then, gradually dropwise adding the suspension solution into a mixed material, and vibrating and molding; maintaining at a room temperature for 24-48 hours; de-molding and carrying out heat treatment at 1400-1600 DEG C; and keeping the heat for 1-5 hours. The corundum micro-pore heat-insulating and fireproof material and the preparation method thereof have the advantages of simple preparation process and lower energy consumption; a product has the advantages of small average hole diameter, high fireproof degree, great high-temperature resistance, low thermal conductivity and strong anti-corrosion resistance; and the product can be directly applied to a working layer of thermal equipment.

Owner:WUHAN UNIV OF SCI & TECH

Cold roller for rolling stainless steel plates, and preparation method of cold roller

InactiveCN105063500AImprove matrix strengthReduce C contentIncreasing energy efficiencyFurnace typesSteel platesCryogenic treatment

The invention discloses a cold roller for rolling stainless steel plates, and a preparation method of the cold roller. The cold roller is prepared from the following components in percentage by weight: 0.50-0.90% of C, 0.20-0.80% of Si, 0.40-1.0% of Mn, 2.8-4.0% of Cr, 0.20-0.60% of Ni, 0.20-0.60% of Mo, S which is smaller than or equal to 0.015%, P which is smaller than or equal to 0.015%, and the balance of Fe and inevitable impurities. The preparation method comprises the following steps: manufacturing roller blank; performing rough processing and quenched-tempered heat treatment on the manufactured roller blank; performing semi fine processing on the heated roller blank; finely grinding a roller body and performing ultrasonic flaw examination; performing high-temperature induction quenching on the ground roller body under 920-950 DEG C; immediately performing cryogenic treatment on the quenched roller under minus 80-minus 100 DEG C; and performing tempering heat preservation on the cooled roller under 160-180 DEG C. According to the cold roller disclosed by the invention, the surface hardness is 85-90 HSD, and the cold roller has a good crack-expansion resisting performance and high basal-body strength.

Owner:YIXING YONGCHANG ROLL

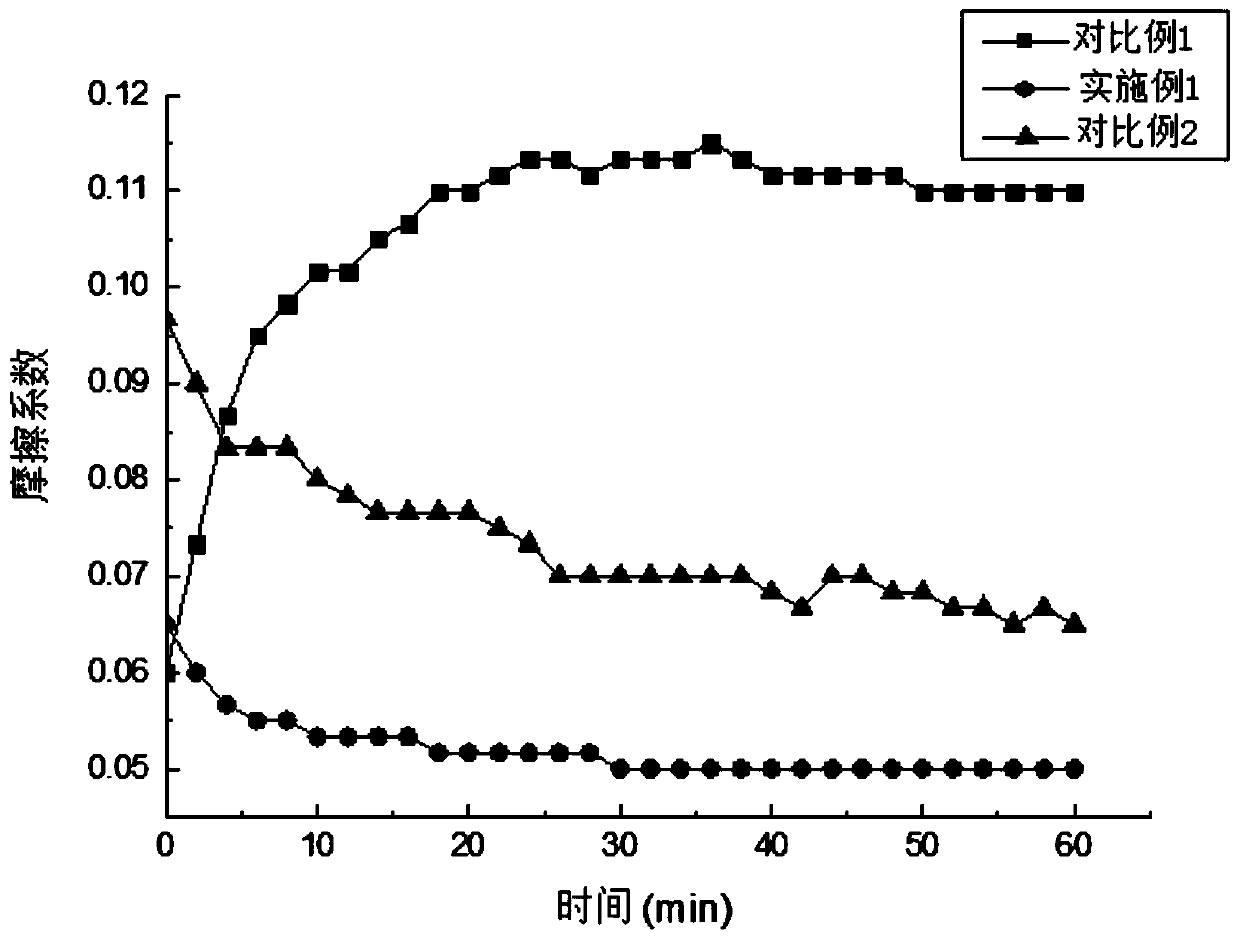

Tungsten carbide enhanced copper-based powder metallurgy friction material and preparing method thereof

ActiveCN109468487AImprove adverse effectsIncrease coefficient of frictionTransportation and packagingMetal-working apparatusMatrix strengthMaterials science

The invention discloses a tungsten carbide enhanced copper-based powder metallurgy friction material. The friction material comprises following raw materials including, by weight percent, 50%-70% of copper powder, 10%-20% of iron powder, 1%-5% of tin powder, 6%-11% of graphite and 0.01%-15% of tungsten carbide. Compared with similar materials, the novel tungsten carbide enhanced copper-based powder metallurgy friction material has the advantages that the matrix strength is high, hardness is high, the friction coefficient is high, the friction performance is stable, the abrasion amount is low,the preparing technology is simple, and the production cost is low; the comprehensive performance of the material is improved, and it is guaranteed that the material has stable friction performance, the high friction coefficient and good abrasion resistance; few microelement kinds exist, lead, asbestos and other components doing harm to health are not contained, the requirements for health safetyand environment protection are met; and in the preparing technology, the technology is simple, large-batch production is conveniently achieved, and the manufacturing cost is low.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

High-reaming hot-rolled acid-pickling steel plate above 500-MPa level and manufacturing method thereof

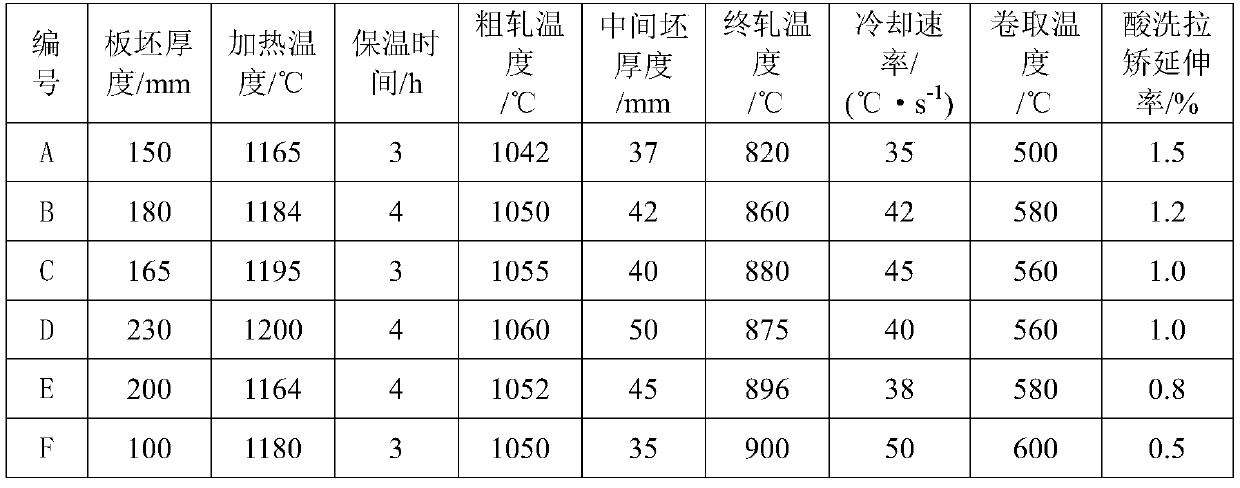

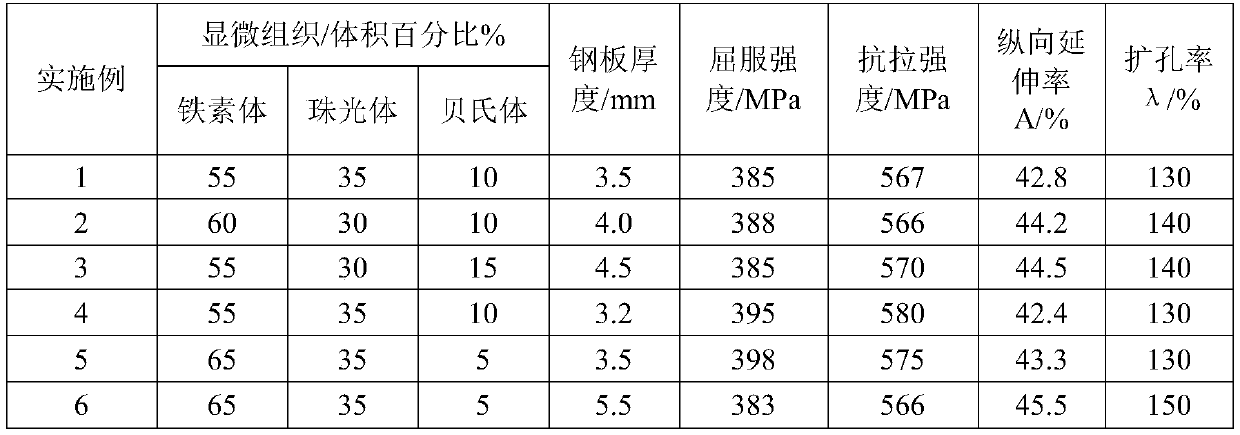

The invention discloses a high-reaming hot-rolled acid-pickling steel plate above a 500-MPa level and a manufacturing method thereof. The chemical components of steel comprises, by weight, 0.02%-0.07%of carbon, 0.01%-0.06% of silicon, 1.20%-1.40% of manganese, 0.030%-0.050% of aluminum, 0.010%-0.017% of niobium, 0.20%-0.40% of molybdenum, 0.010% of phosphorus, 0.005% of sulphur and the balance iron and inevitable impurities. The manufacturing method comprises the steps that continuously-cast billets with the thickness being 100-230 mm are heated to the temperature between 1160 DEG C and 1200DEG C, and heat preservation is conducted for 3 to 4 hours; the temperature of rough rolling is equal to or lower than 1060 DEG C, the thickness of intermediate billets is between 35mm and 50mm, and the precision rolling finishing rolling temperature is between 820 DEG C and 900 DEG C; forepart rapid continuous laminar cooling is adopted after finishing rolling, the cooling rate is 30-50 DEG C persecond; the coiling temperature is between 500 DEG C and 600 DEG C; and hydrochloric acid is adopted so that through-coiling continuous cleaning can be conducted on steel plate oxide scale, and the range of the pulling-rectifying elongation rate is between 0.5% and 1.5%. The high-reaming hot-rolled acid-pickling steel plate above the 500-MPa level has high-strength and high-reaming properties.

Owner:ANGANG STEEL CO LTD

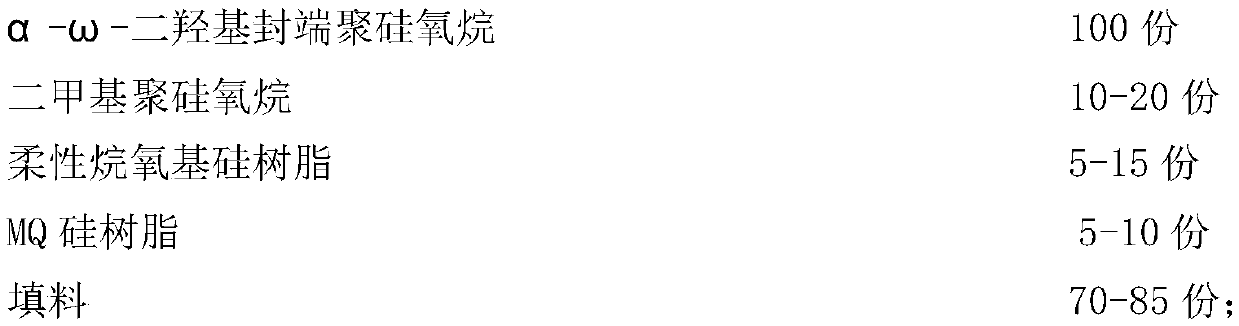

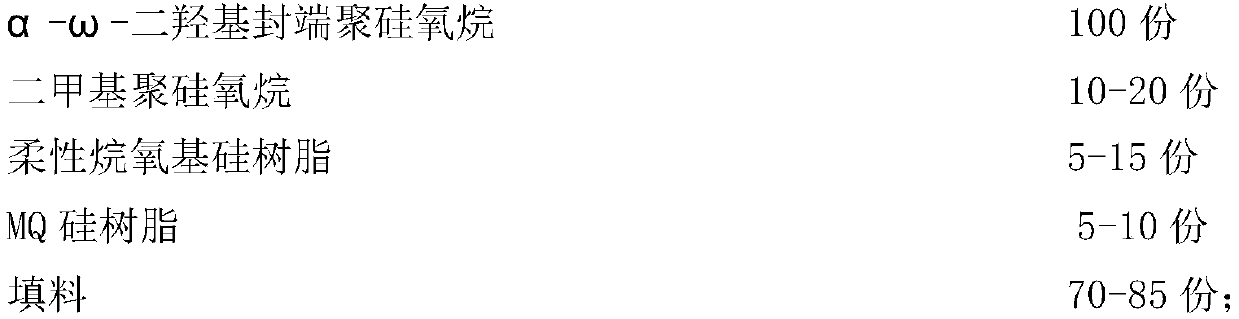

Silicon resin type bi-component elastic silicone sealant for hollow glass and preparing method thereof

ActiveCN106190013AHigh hardnessWear-resistantNon-macromolecular adhesive additivesMacromolecular adhesive additivesAdhesiveSilanes

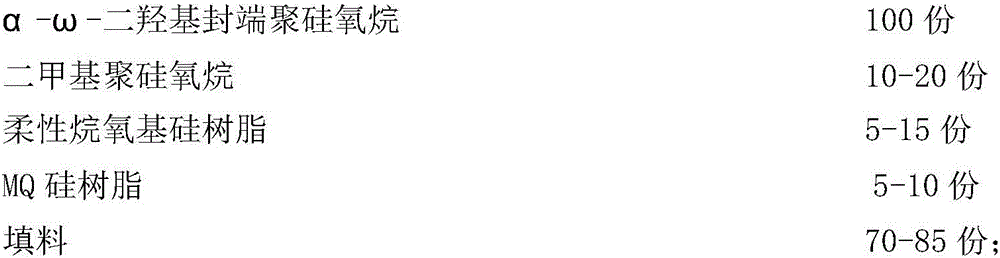

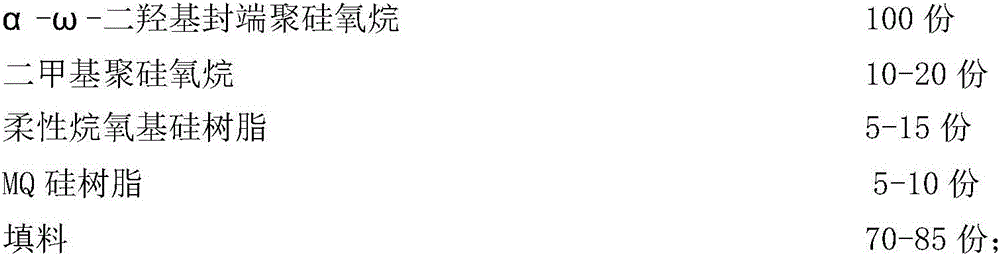

The invention relates to silicon resin type bi-component elastic silicone sealant for hollow glass and a preparing method thereof. The sealant comprises a component A and a component B; the component A is prepared from, by weight, 100 parts of alpha-omega-dyhydroxy-terminated polysiloxane, 10-20 parts of dimethyl polysiloxane, 5-15 parts of flexible alkoxy silicon resin, 5-10 parts of MQ silicon resin and 70-85 parts of filler; the component B is prepared from, by weight, 40-60 parts of dimethyl polysiloxane, 5-10 parts of carbon black, 10-25 parts of alkoxy silane crosslinking agent, 5-20 parts of coupling agent, 1-2 parts of catalyst and 0.01-0.1 part of ultraviolet absorbent. By means of the synergistic effect of flexible alkoxy silicon resin and MQ silicon resin, the prepared silicone sealant has excellent elasticity and impact resistance and lasting high-strength adhesive properties, is high in peel strength, high in mechanical strength, high in high and low temperature resistance, high in weather fastness and small in compression set.

Owner:山东宝龙达实业集团有限公司

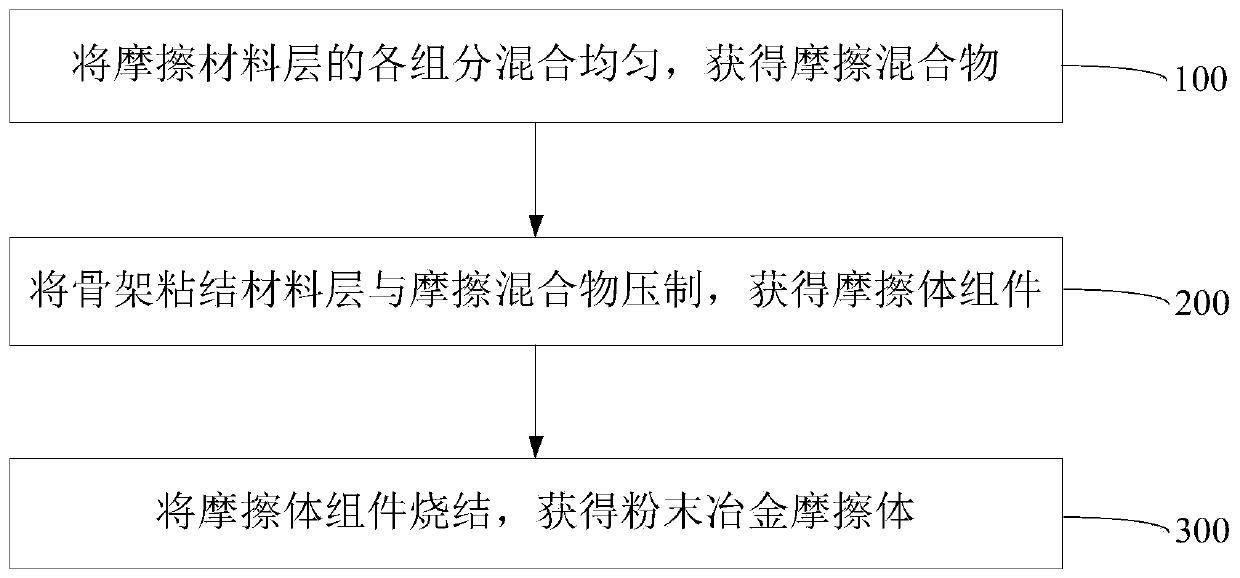

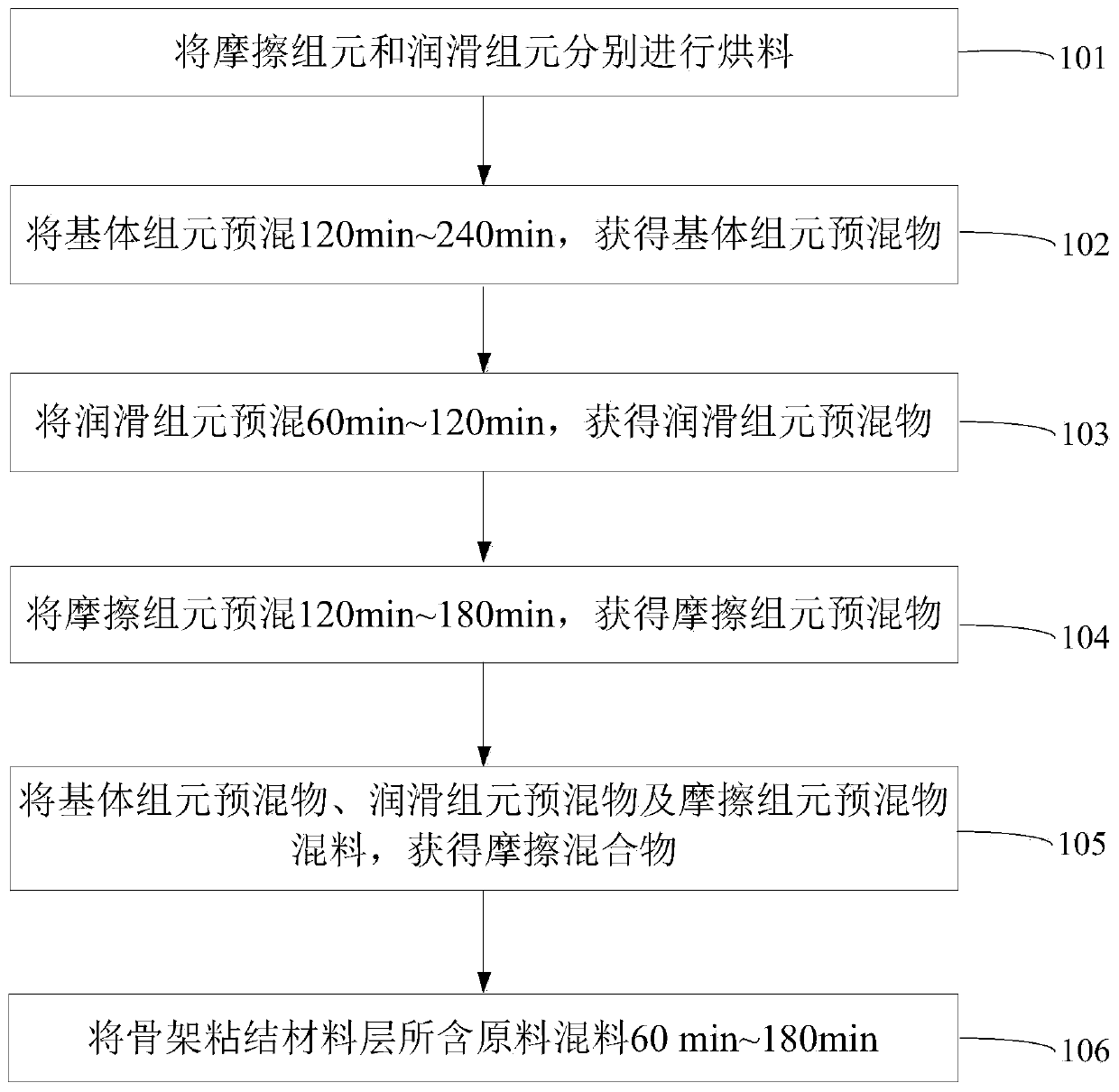

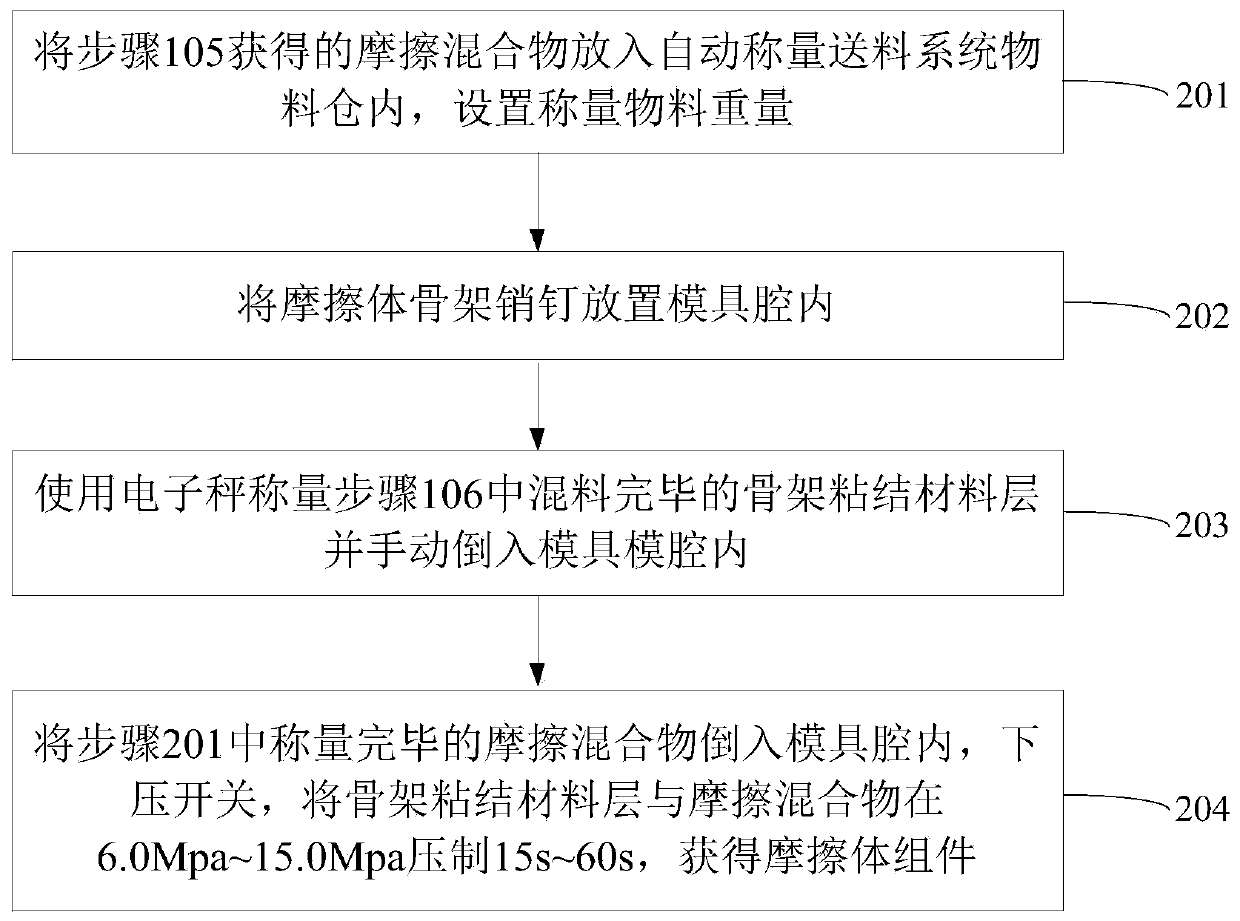

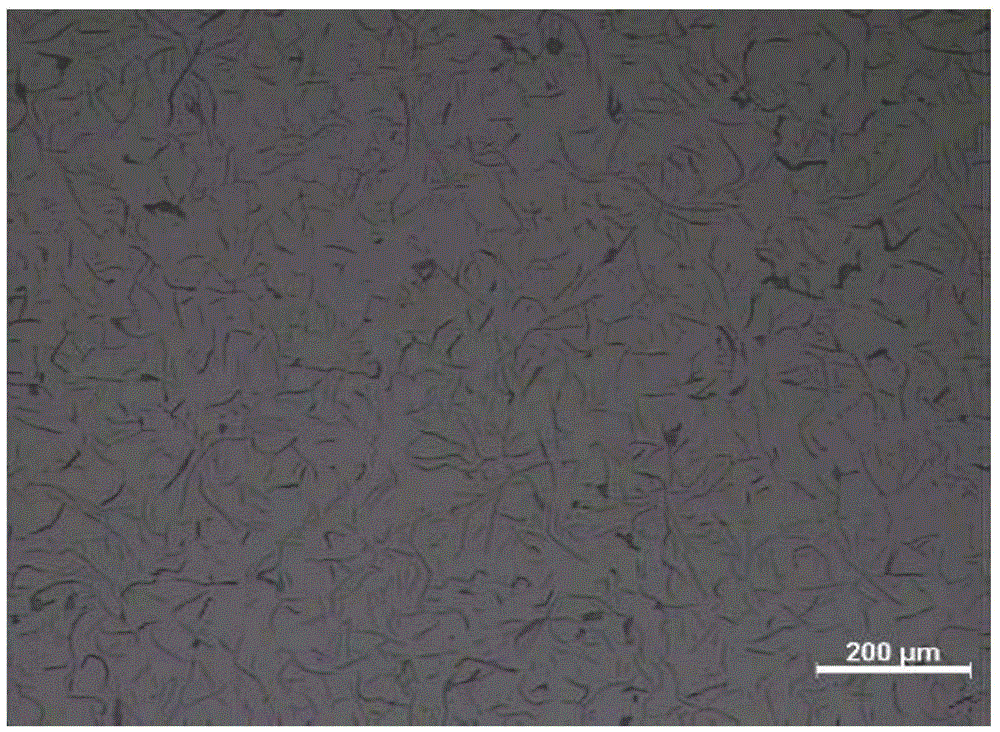

Powder metallurgy friction body and manufacturing method thereof, powder metallurgy brake pad

ActiveCN111570801AImprove matrix strengthExtend your lifeFriction liningActuatorsMolybdenum trioxideFlake graphite

The invention discloses a powder metallurgy friction body and a manufacturing method thereof, and a powder metallurgy brake pad. The powder metallurgy brake pad has relatively strong wear-resisting performance, can solve the phenomena of dreg falling, chip falling and entire friction material fall-off of an existing friction body in the process of vehicle braking, and thereby improves the servicelife of the friction body. The powder metallurgy friction body comprises a friction material layer which is composed of a substrate element, a lubricating element and a friction element, and a skeleton bonding material layer which is used for bonding the friction material layer and a friction body skeleton; the substrate element comprises bronze powder, reduced iron powder, manganese-iron alloy powder and nano molybdenum trioxide; the lubricating element comprises zinc sulfide and crystalline flake graphite; the friction element comprises titanium dioxide, zirconium oxide, feldspar and zirconsand; and the skeleton bonding material layer comprises bronze powder, reduced iron powder, manganese powder, molybdenum powder and tin powder. The powder metallurgy friction body can manufacture thepowder metallurgy brake pad and the powder metallurgy brake pad is applied to the aspect of urban railway transportation.

Owner:北京浦然轨道交通科技股份有限公司 +1

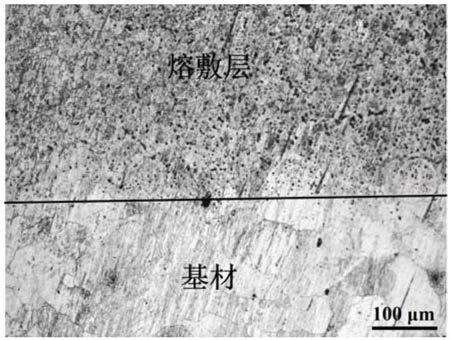

Method for improving magnesium alloy welded joint through surface microalloying

ActiveCN108977805AHigh yield strengthHigh tensile strengthMetallic material coating processesRare-earth elementWeld seam

The invention discloses a method for improving a magnesium alloy welded joint through surface microalloying, and belongs to the technical field of welding technologies in material processing. Mixed powder composed of metal powder including Al, Ti, Cr, Mn and Ni and rare earth element powder including Sc and Nd is developed, and a laser microalloying technology is used for conducting surface modification on a magnesium alloy welding seam area to improve the comprehensive performance of the magnesium alloy welded joint, wherein the power comprises the components in percentage by mass: 9.1%-9.4%of Al, 5.4-5.8% of Ti, 4.1-4.3% of Cr, 0.05-0.2% of Mn, 0.03-0.2% of Sc, 0.8%-2.2% of Nd and the balance Ni, and the grain size of laser microalloyed powder is 100-300 meshes. The laser microalloyingtechnology is adopted to obtain a nanophase-containing cladding layer good in performance on the surface of the magnesium alloy welded joint, and rare earth elements, the other alloy elements and a Mgalloy substrate molten layer can generate a large number of alloy compound wild phases and can effectively refine a microstructure of the cladding layer, improve the mechanical performance of the magnesium alloy welded joint and greatly improve the corrosion resistance performance of the magnesium alloy welded joint.

Owner:NEW MATERIAL INST OF SHANDONG ACADEMY OF SCI +1

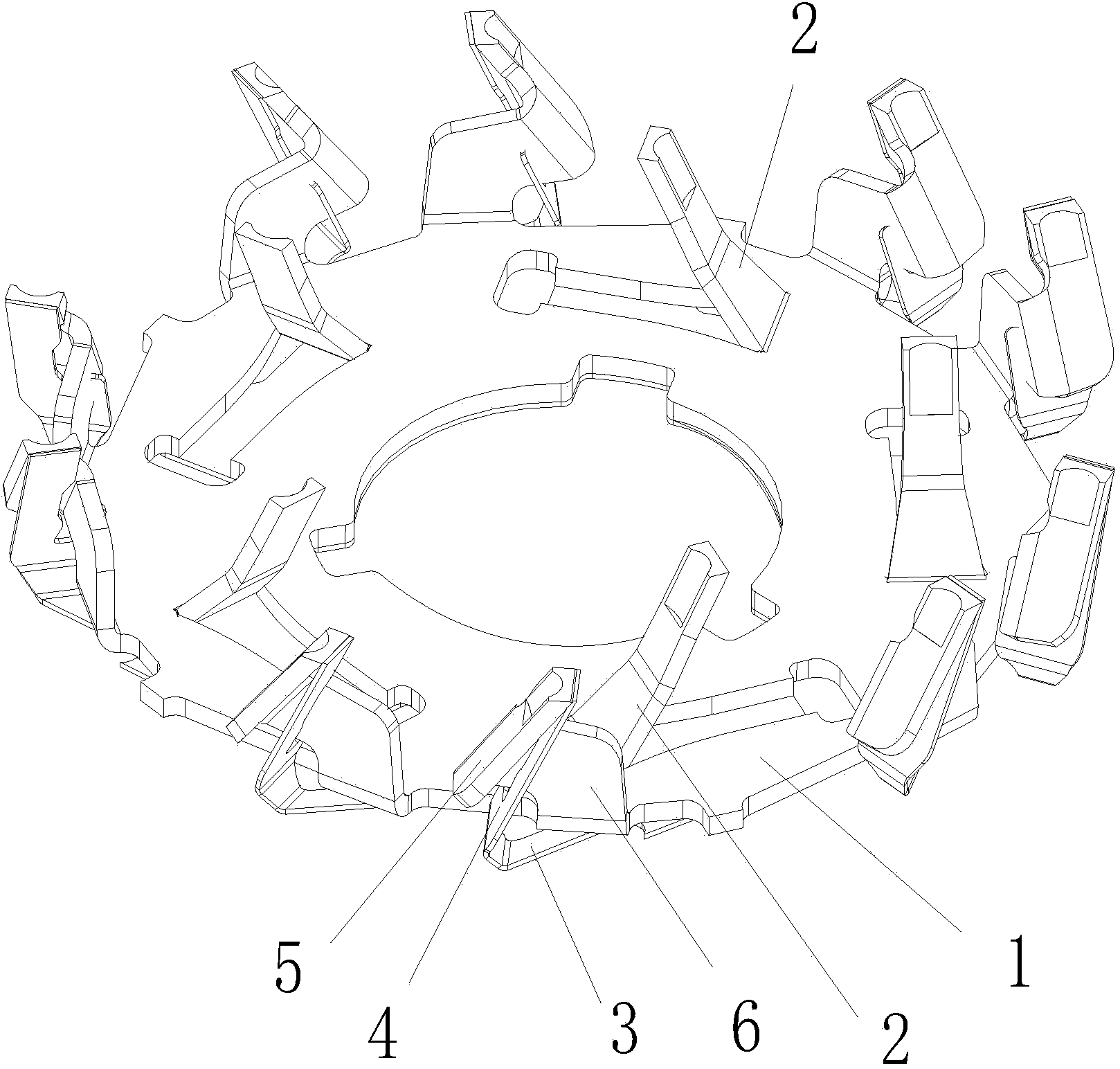

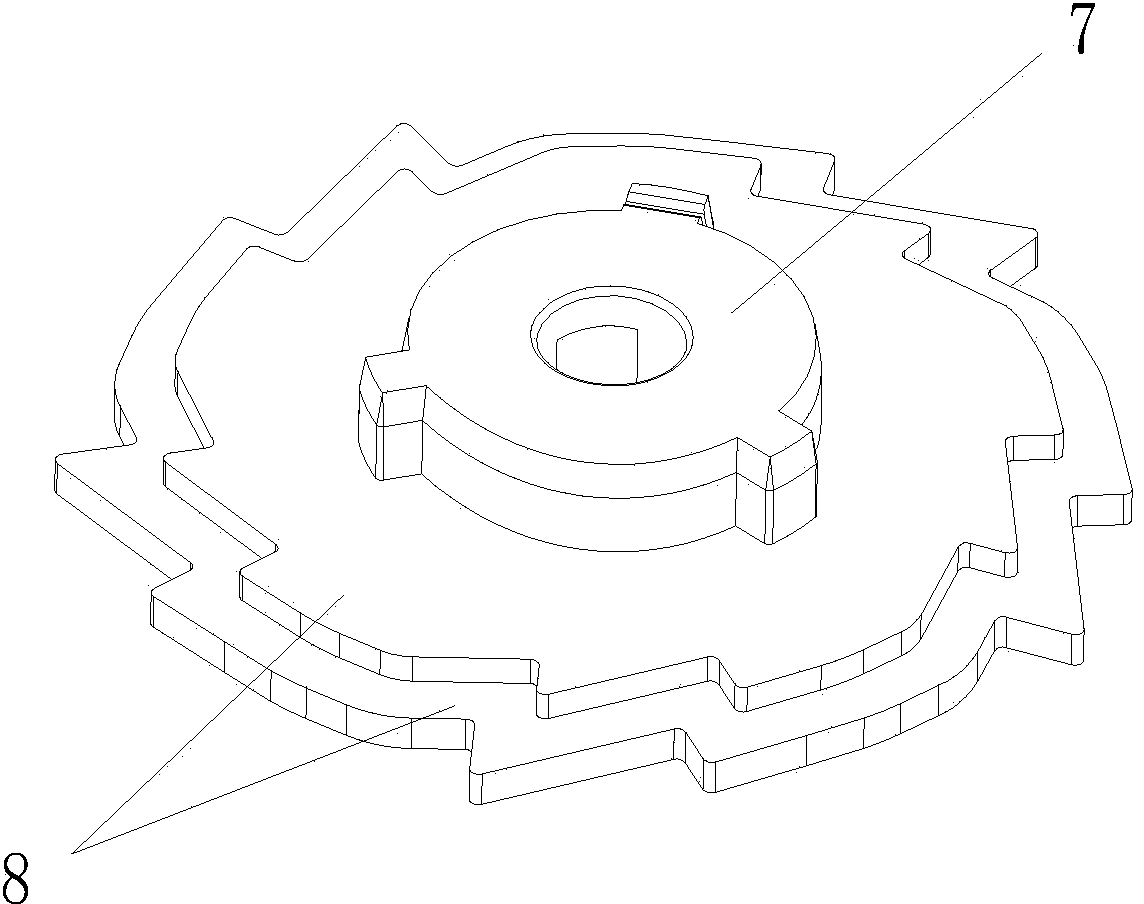

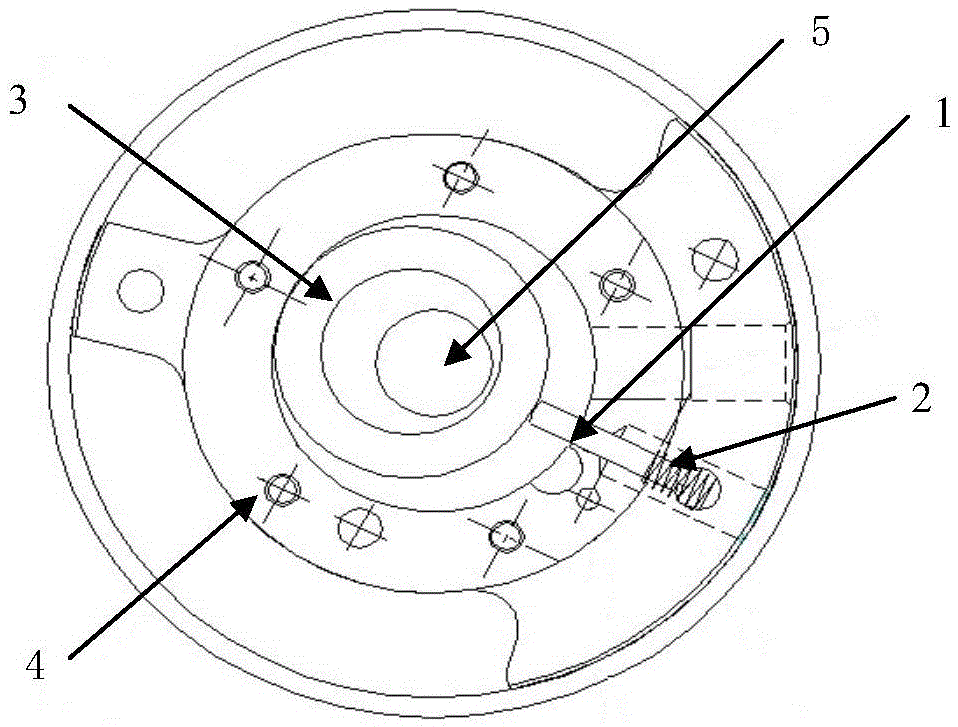

Shaving head device of rotary type electric shaver

ActiveCN103707332AImprove shaving effectImprove matrix strengthMetal working apparatusElectric razorsUltimate tensile strength

The invention relates to a shaving head device of a rotary type electric shaver. The shaving head device comprises a shaving head blade and a blade net, and is characterized in that the shaving head blade comprises inner circle knives and outer circle knives, the inner circle knives and the outer circle knives are concentrically arranged on a main blade base, auxiliary blades are arranged at the bottom of the main blade base, and elastic auxiliary knives are arranged on the peripheries of the auxiliary blades; the auxiliary knives are arranged at the front ends of the working portions of the outer circle knives of a main blade when the outer circle knives rotate, included angles are formed between the auxiliary knives and the outer circle knives of the main blade, and the auxiliary knives rebound after being in contact with beards to be then in contact with the outer circle knives to be lifted upwards. According to the structure of the shaving head device, the strength of a base body can be effectively improved through the inner circle knives, it is guaranteed that the coincidence of running tracks of the knives in working is high, the service life of the knives is prolonged, the matching degree of the blade and the blade net is improved, the sharpness is high, and the sound coincidence is high. The beards can conveniently enter the blade net at multiple angles through the design of the M-shaped blade net, and the shaving efficiency is improved.

Owner:HAINING XINYI MACHINERY & ELECTRICAL

Foamed wall material and preparation method thereof

The invention discloses a foamed wall material and a preparation method thereof. In the prior art, the method for recycling light construction waste does not exist. A purpose of the invention is to solve the disadvantage in the prior art. The invention provides a foamed wall material, which comprises the following raw materials by weight: 40-60 parts of light construction waste, 15-30 parts of cement, 5-20 parts of an admixture, 0.5-5 parts of a composite foaming agent, 0.2-0.4 part of fiber, 0.2-0.7 part of a water reducing agent, 0.08-0.15 part of a foam stabilizer and 45-65 parts of water.According to the invention, the foamed wall material is prepared by using the light construction waste as the raw material, the characteristics of the light construction waste are fully considered, and the light construction waste does not need to be further grinded after being grinded, so that the procedures and the energy are saved, the high-temperature and high-pressure maintenance with the boiler is not required, the energy consumption is reduced, and the utilization rate of the construction waste is increased.

Owner:深圳市鹏城建筑集团有限公司

Gear machining and heat treatment process

InactiveCN105714040AAdd depthImprove heating uniformitySolid state diffusion coatingMetal working apparatusGear grindingProduct inspection

The present invention discloses a gear machining and heat treatment process, and the gear machining process successively comprises forging, normalizing, quenching and tempering, vertical machining, gear shaping, annealing, vertical machining, gear shaping, vertical milling, stabilizing aging, gear grinding, nitriding and finished product inspection, wherein the step of normalizing is normalizing at (880 + / -10) DEG C for (3-4) h, and then cooling in air; the step of quenching and tempering is quenching and tempering at (850 + / -10) DEG C for (3-4) h, quenching with water, and cooling with oil; the step of the annealing is annealing at (530 + / -10) DEG C for (3-4) h, cooling in a furnace in the heating and cooling rate of less than or equal to 50 DEG C / h; the step of stabilizing aging is stabilizing aging at (510 + / -10) DEG C for (3-4) h, and cooling in the furnace in the heating and cooling rate of less than or equal to 2 5 DEG C / h; and the step of nitriding is nitriding at (510 + / -10) DEG C for (10-12) h, and cooling in the furnace in the heating and cooling rate of less than or equal to 2 5 DEG C / h. The gear machining and heat treatment process is more reasonable, and can reduce distortion after nitriding to improve the overall performance of a gear.

Owner:CHONGQING YUANHUANG MACHINERY MFG CO LTD

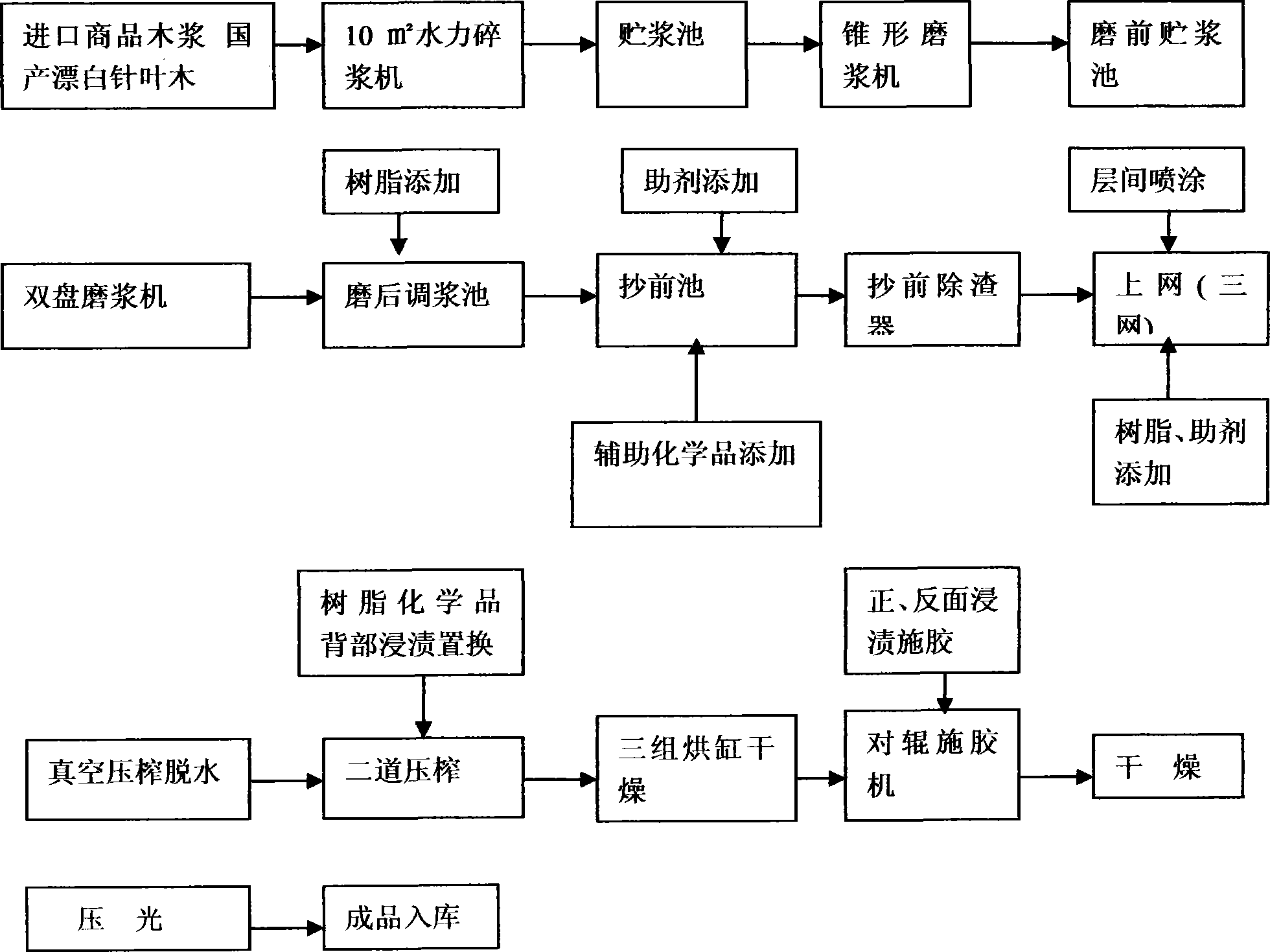

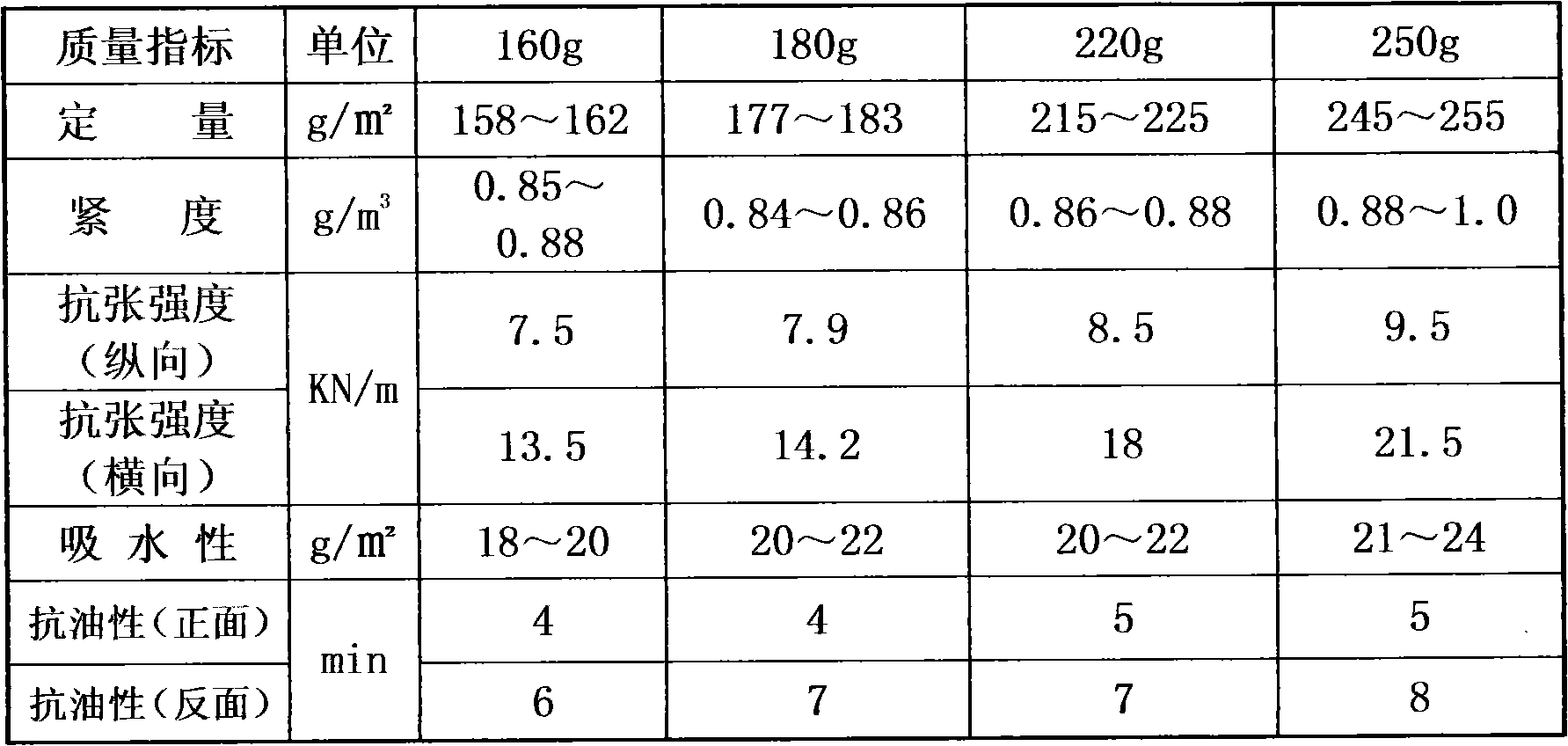

Strong abrasive belt base paper and preparation method

InactiveCN102441851BHigh peel strengthImprove matrix strengthNon-fibrous pulp additionSpecial paperProcess engineeringWet strength

The invention provides strong abrasive belt base paper and a preparation method. The strong abrasive belt base paper is high in strength and fine in flexibility and impermeability and is not layered. The preparation method for the base paper includes steps that 1, wood pulp is disintegrated, 2, the pulp is proportioned, materials are blended, and a pH (potential of hydrogen) value in blended materials is controlled to range from 6.5 to 7.0, 3, interlayer spraying of the paper on a screen is carried out, 4, a back is prestressed, replaced and dried, and 5, front and back impregnation, glue application and drying are carried out. Multiple times of glue application are realized in a paper making process, glue content in the paper is increased, the strength of a product is improved, and the product is not layered and is fine in flexibility and impermeability. The heavy base paper is high in interlayer peeling strength, dry and wet strengths of the heavy base paper meet indexes of like imported products, oil impermeability of the heavy base paper can completely meet the strong abrasive belt production requirement of the industry of coated abrasive tools, and performances, such as the strength, the flexibility and the like, of a base of a produced abrasive belt product are improved obviously.

Owner:湖北圣立纸业科技有限公司

Engine belt wheel hub production process

InactiveCN107267853AReduce unevennessImprove machining accuracyFurnace typesHeat treatment furnacesRheniumX-ray

The invention discloses an engine belt wheel hub production process. The engine belt wheel hub production process comprises the steps of a, ingredient preparing, b, blank manufacturing, c, heat treatment, d, machining, e, spraying, and f, inspecting and packing; in the step b, blank manufacturing comprises the steps that the processing materials prepared in the step a are melted through an oil furnace or an electric furnace at first, then molten metal is subjected to casting cooling molding, and X-ray flaw detection is conducted on a molded blank finally; wherein, before molten metal casting operation, an inoculant is added into the molten metal to conduct furnace front deoxidation inoculation treatment, and the inoculant is obtained in the mode that montmorillonite, rhenium, graphite powder, silicon barium and a silane coupling agent are mixed, heated, melted and crushed into particles with the average grain diameter being 10-15 mm after water cooling and drying finally. The engine belt wheel hub production process is simple in step and easy to operate and master; meanwhile, the structure nonuniformity can be reduced; and the machining precision, the matrix strength and the durability are improved.

Owner:WUHU CHENGTUO AUTO PARTS

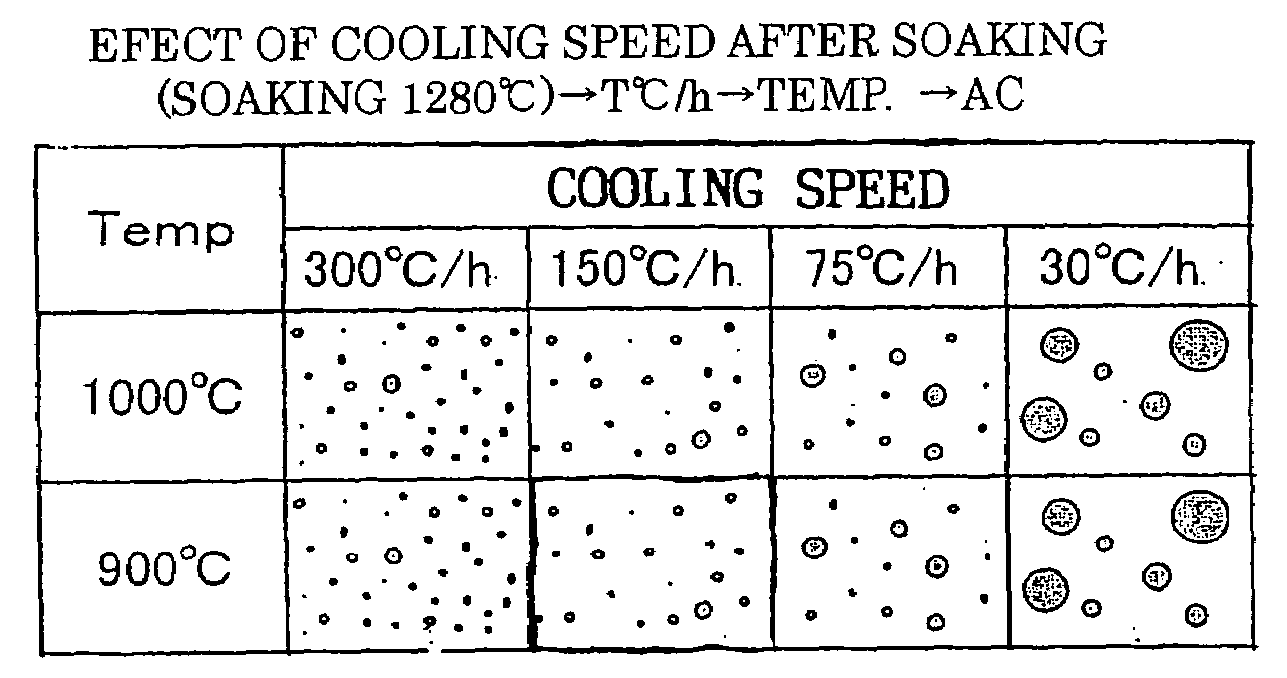

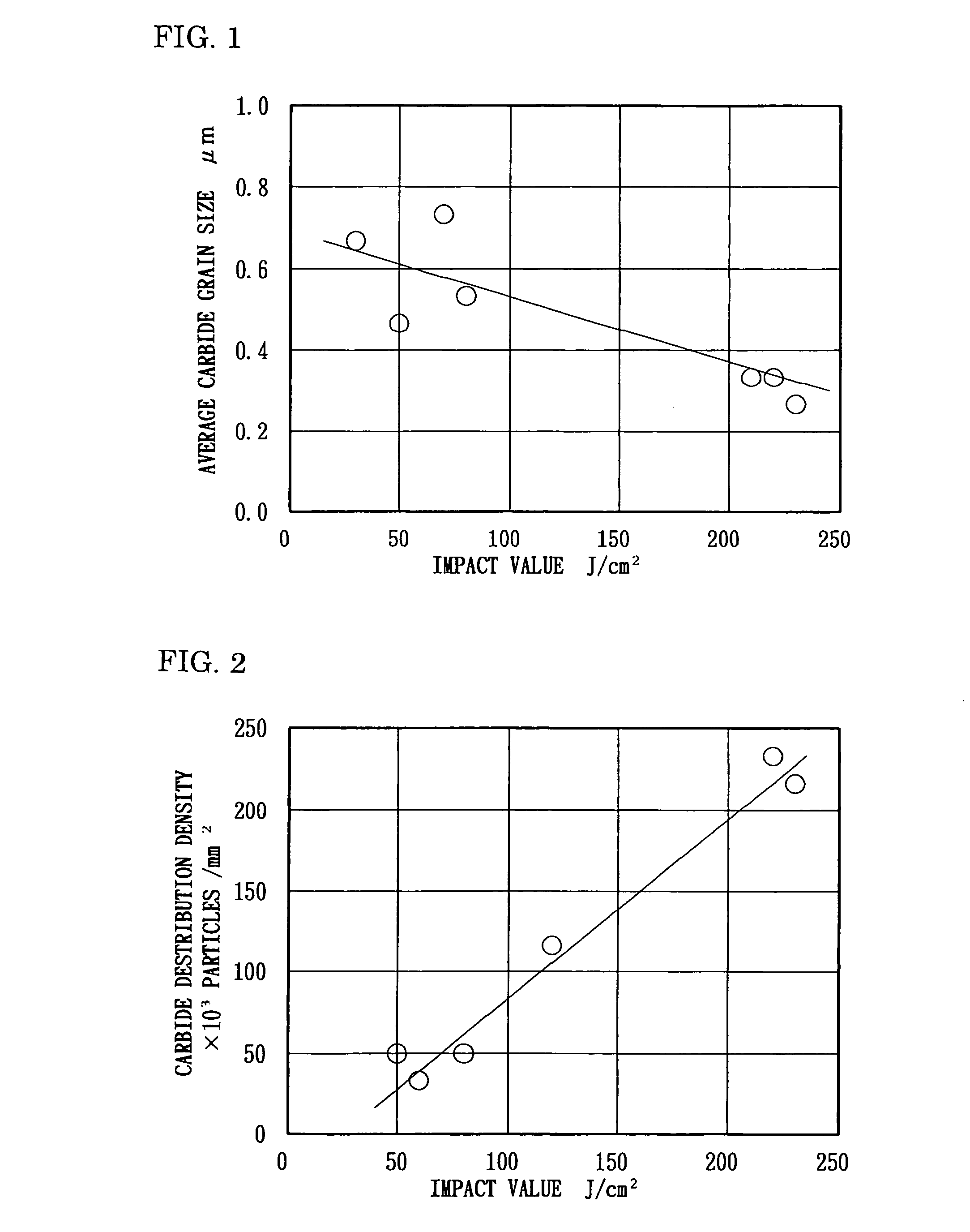

High speed tool steel

A high speed tool steel, which is high in impact value and free from variations in tool performance, comprising, by mass %, of: 0.4≦C≧0.9; Si≦1.0; Mn≦1.0; 4≦Cr≧6; 1.5–6 in total of either or both of W and Mo in the form of (½W+Mo) wherein W≦3; 0.5–3 in total of either or both of V and Nb in the form of (V+Nb); wherein carbides dispersed in the matrix of the tool steel have an average grain size of ≦0.5 μm and a dispersion density of particles of the carbides is of ≧80×103 particles / mm2.

Owner:HITACHI METALS LTD

Hydraulic motor cushion block and preparation method thereof

InactiveCN111515388AChange machinabilityImprove toughnessSolid state diffusion coatingReciprocating piston enginesAdhesiveSpindle oil

The invention discloses a hydraulic motor cushion block and a preparation method thereof. The preparation method comprises the following steps that nickel, vanadium, manganese sulfide, graphite, zincstearate, spindle oil and iron powder are weighed according to a weight ratio and uniformly mixed to obtain matrix mixed powder; copper powder, iron and an adhesive are weighed and uniformly mixed toobtain copper-infiltrated sheet mixed powder; the matrix mixed powder and the copper-infiltrated sheet mixed powder are added into corresponding molds and pressed and formed to obtain a matrix pressedblank and a copper-infiltrated sheet; the copper-infiltrated sheet is placed on the top end face of the matrix pressed blank, and copper infiltration sintering is carried out in a protective atmosphere to form a sintered blank; two-end-face machining and counter bore machining are carried out on the sintered blank to obtain a matrix blank; and surface sand blasting treatment and surface coating are carried out on the matrix blank to obtain the hydraulic motor cushion block. The cushion block prepared through the method is excellent in performance and has good strength, toughness and frictional wear performance; and the preparation method is simple in process, high in production efficiency and low in machining cost.

Owner:合肥波林新材料股份有限公司

Self-lubricating copper-based abrasion-resistant alloy and preparation method thereof

InactiveCN103290258AImprove matrix strengthImprove self-lubricationBearing componentsRare-earth elementLubrication

The invention relates to a self-lubricating copper-based abrasion-resistant alloy which consists of the following elements in percentage by weight: 75-85wt% of Cu, 5-8wt% of Sn, 0.5-2wt% of lanthanum-cerium misch metal and the balance of lead; and an alloy material is prepared by weighing the raw materials according to the proportion, subsequently pre-smelting the alloy in a medium-frequency induction furnace, and carrying out atomization and deposition by using spraying forming equipment. According to the alloy material, on the basis of the conventional ZCuPb15Sn8 cast alloy, by adopting the novel preparation process with the addition of rare earth elements and spraying deposition, the strength and the self-lubrication of a matrix are improved, and the abrasion resistance is remarkably improved.

Owner:TONGJI UNIV

Copper base alloy sliding bearing

ActiveCN103290255AImprove corrosion resistanceIncreased shear strengthMetallic material coating processesPowdery paintsMisch metalCerium

The invention relates to a copper base alloy sliding bearing. The copper base alloy sliding bearing is obtained by adding lanthanum cerium misch metal in a copper base alloy raw material, preparing a bearing alloy body through spray deposition, preparing a coating material, and completing coating through a plasma spurt method. Compared with a traditional casting copper base alloy, the sliding bearing provided by the invention has the advantages that the wear-resisting property is obviously improved, the attrition rate is greatly reduced, and the corresponding coating has the good tribological property.

Owner:启东市万润机床附件有限公司

Corundum micro-pore heat-insulating and fireproof material and preparation method thereof

InactiveCN102731118BReduce thermal stressImprove matrix strengthCeramicwareNano al2o3Mixed materials

The invention relates to a corundum micro-pore heat-insulating and fireproof material and a preparation method thereof. The contents of raw materials of the corundum micro-pore heat-insulating and fireproof material are as follows: 40-50 wt% of corundum grain, 40-45 wt% of corundum fine powder, 5-10 wt% of active a-aluminum oxide micro-powder and 5-10 wt% r-aluminum oxide micro-powder, an additive, a dispersant account for 0.1-0.5 wt% of the above raw materials, nano aluminum oxide powder accounting for 0.1-1.5 wt% of the above materials and water accounting for 5-10 wt% of the above materials. The preparation method comprises the following steps of: dispersing the nano aluminum oxide powder into the water and dispersing under an ultrasonic vibration condition for 1-5 minutes to prepare a uniform suspension solution; then, gradually dropwise adding the suspension solution into a mixed material, and vibrating and molding; maintaining at a room temperature for 24-48 hours; de-molding and carrying out heat treatment at 1400-1600 DEG C; and keeping the heat for 1-5 hours. The corundum micro-pore heat-insulating and fireproof material and the preparation method thereof have the advantages of simple preparation process and lower energy consumption; a product has the advantages of small average hole diameter, high fireproof degree, great high-temperature resistance, low thermal conductivity and strong anti-corrosion resistance; and the product can be directly applied to a working layer of thermal equipment.

Owner:WUHAN UNIV OF SCI & TECH

Silicone resin type two-component elastic silicone sealant for insulating glass and preparation method thereof

ActiveCN106190013BHigh hardnessWear-resistantNon-macromolecular adhesive additivesMacromolecular adhesive additivesAdhesiveCompression set

The invention relates to silicon resin type bi-component elastic silicone sealant for hollow glass and a preparing method thereof. The sealant comprises a component A and a component B; the component A is prepared from, by weight, 100 parts of alpha-omega-dyhydroxy-terminated polysiloxane, 10-20 parts of dimethyl polysiloxane, 5-15 parts of flexible alkoxy silicon resin, 5-10 parts of MQ silicon resin and 70-85 parts of filler; the component B is prepared from, by weight, 40-60 parts of dimethyl polysiloxane, 5-10 parts of carbon black, 10-25 parts of alkoxy silane crosslinking agent, 5-20 parts of coupling agent, 1-2 parts of catalyst and 0.01-0.1 part of ultraviolet absorbent. By means of the synergistic effect of flexible alkoxy silicon resin and MQ silicon resin, the prepared silicone sealant has excellent elasticity and impact resistance and lasting high-strength adhesive properties, is high in peel strength, high in mechanical strength, high in high and low temperature resistance, high in weather fastness and small in compression set.

Owner:山东宝龙达实业集团有限公司

A kind of high wear-resistant material and its manufacturing method and application

ActiveCN103898399BReasonable collocationReduce dosageRotary/oscillating piston pump componentsLiquid fuel engine componentsChemical compositionWear resistant

The invention discloses a highly wearable material and a preparation method and an application thereof. The highly wearable material comprises the following chemical components in percentage by weight: 2.90-3.60% of C, 1.80-3.0% of Si, 0.40-1.00% of Mn, less than or equal to 0.15% of S, 0.05-0.45% of P, 0.01-0.20% of B, less than or equal to 1.0% of Cu, less than or equal to 0.06% of Sn, less than or equal to 0.03% of Sb and the balance of Fe and inevitable impurities. The preparation method comprises the following steps: melting; inoculating; re-inoculating; casting to form a piston blank; coarsely machining; thermally treating; finely machining and the like. The material can be applied to manufacturing a piston, a slide block or a crankshaft and the like of a rotary compressor. The piston, the slide block and the crankshaft manufactured by the material are low in cost, and the manufacturing cost is low and the material is highly wearable. For example, after long-term operation of the piston of the compressor, the working faces of the piston are free from remarkable wear and radial leakage of a refrigerant along a first end contact face of the piston-slide block is reduced, so that the performance safety and the reliability of the compressor are improved, and meanwhile, the manufacturing cost is lowered and the material selecting range of the piston for the rotary compressor is expanded.

Owner:PANASONIC WANBAO GUANGZHOU COMPRESSOR

GVTi wear-resistant type semisteel roller and preparation method thereof

InactiveCN110343956AImprove thermal crack resistanceIncreased roll strengthFurnace typesHeat treatment furnacesHardnessTitanium alloy

Owner:宜兴市国昌轧辊有限公司

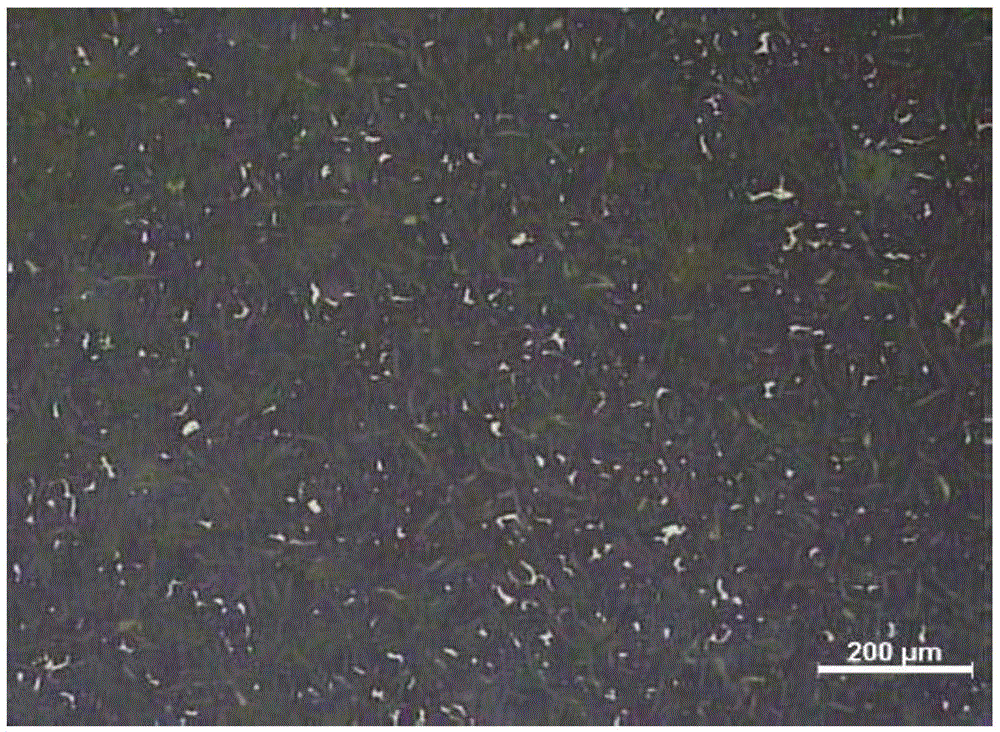

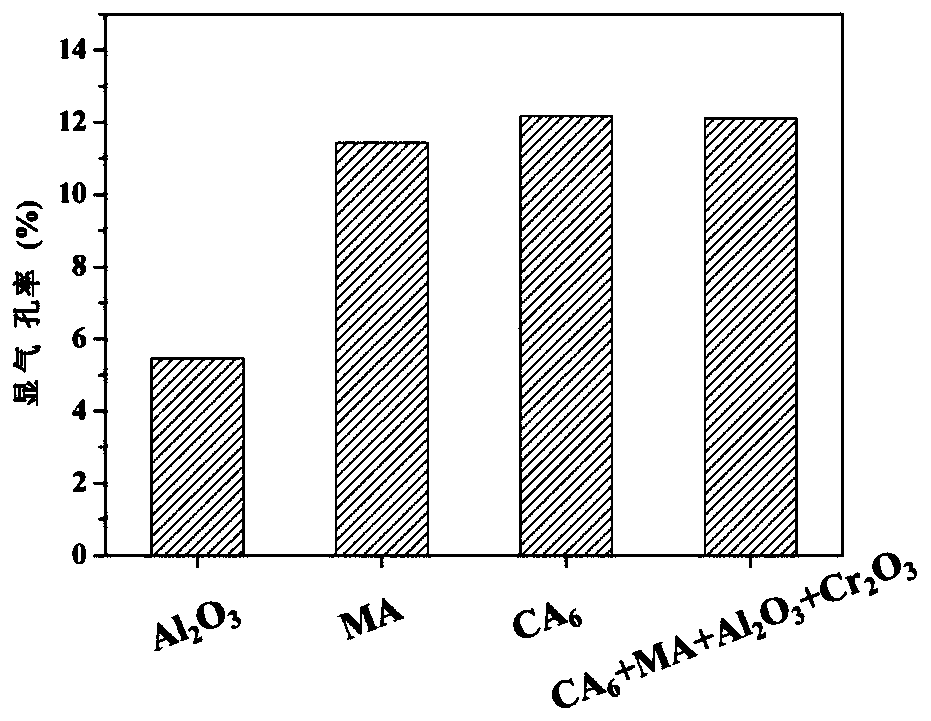

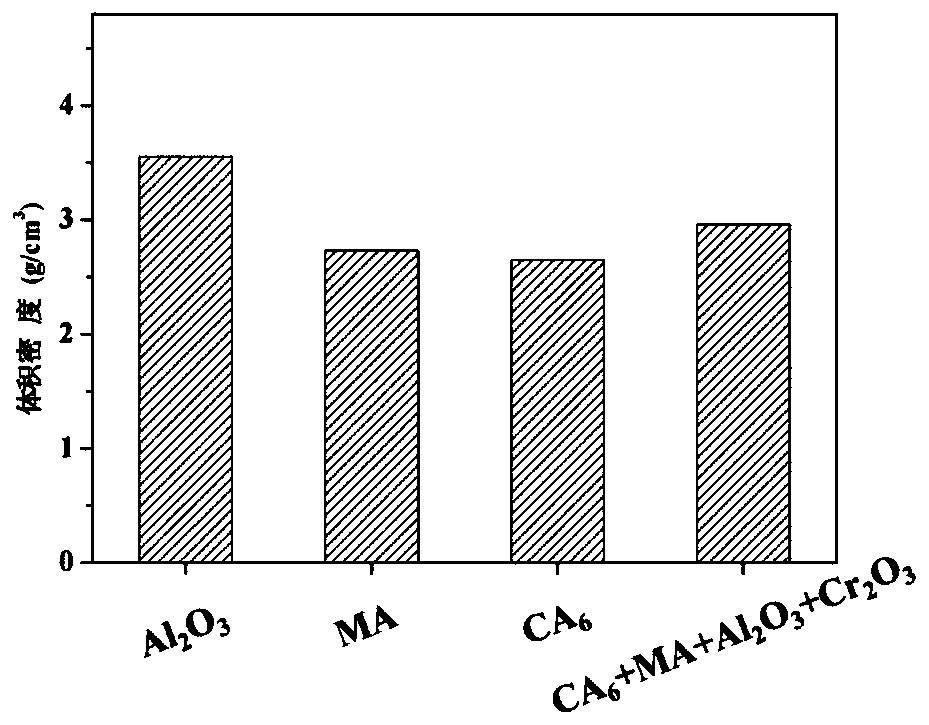

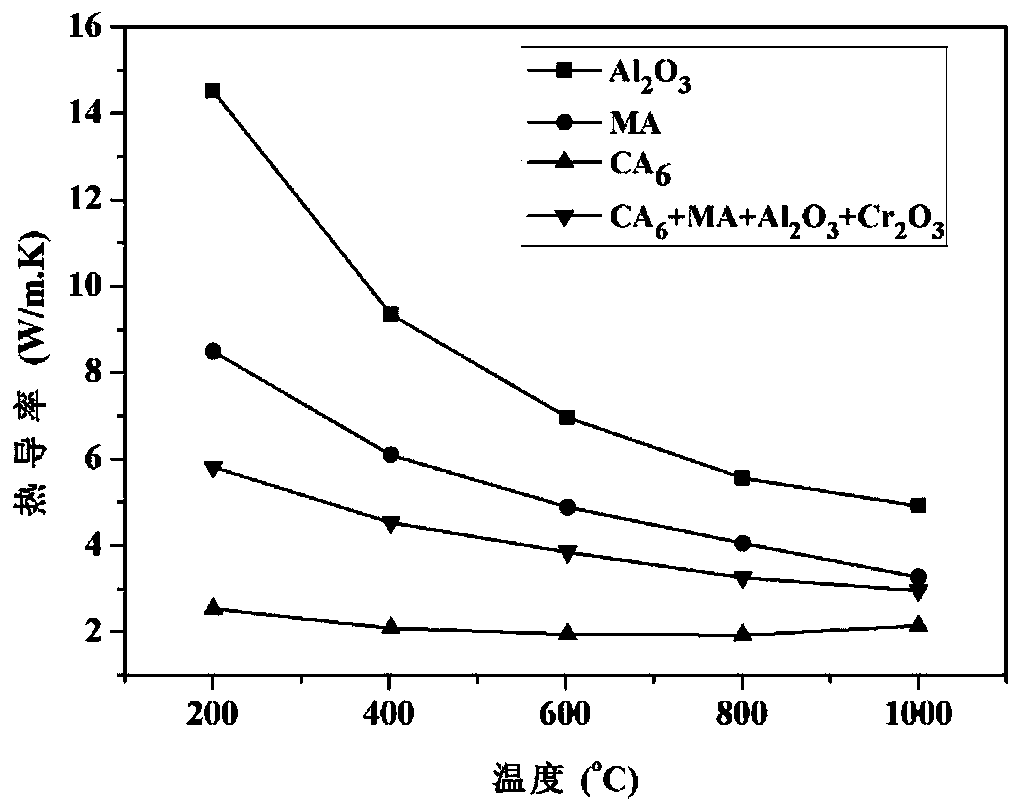

CA6-MA-Cr2O3-Al2O3 ladle lining castable and preparation method thereof

The invention relates to a CA6-MA-Cr2O3-Al2O3 ladle lining castable and a preparation method thereof. According to the technical scheme, 65-75wt% of CA6-MA-Cr2O3-Al2O3 particles, 5-8wt% of alpha-Al2O3micro powder, 3-6wt% of calcium aluminate cement, 7-10wt% of magnesium aluminate spinel fine powder and 8-12wt% of platy corundum fine powder are taken as raw materials, a polycarboxylate water reducing agent and water are added, and stirring, forming, demoulding and baking are carried out to prepare the CA6-MA-Cr2O3-Al2O3 ladle lining castable. The preparation method of the CA6-MA-Cr2O3-Al2O3 particles comprises the following steps of: mixing 60-70wt% of CA6, 4-8wt% of chromium oxide, 10-20wt% of MA and 10-15wt% of aluminum oxide, and ball milling, adding water, granulating, drying, calcining at 1650-1750 DEG C, crushing and screening to obtain the CA6-MA-Cr2O3-Al2O3 particles with three particle size levels respectively. The product prepared by the method has the advantages of high strength, low thermal conductivity, good thermal shock stability, excellent erosion resistance, energy conservation and environmental protection.

Owner:WUHAN UNIV OF SCI & TECH

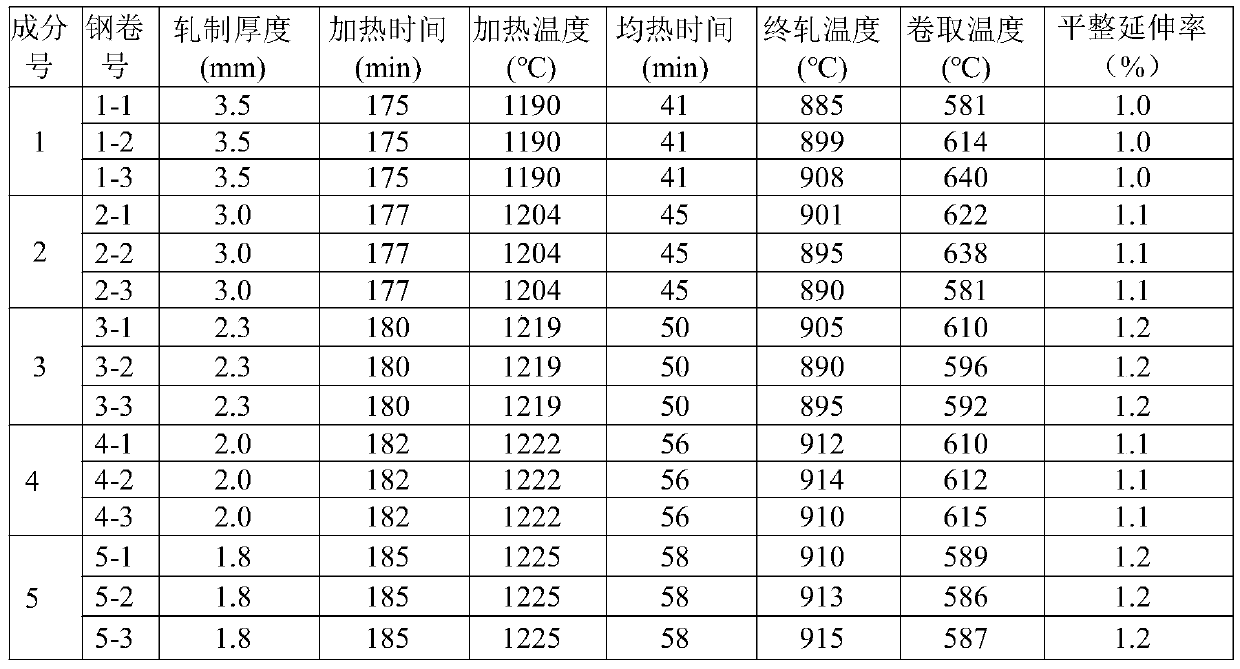

Low-carbon steel coil plate for oil filter thread cover plate and manufacturing method thereof

The invention discloses a low-carbon steel coil plate for an oil filter thread cover plate and a manufacturing method thereof. The low-carbon steel coil plate comprises chemical components including,by weight percent, 0.03 to 0.05% of C, not larger than 0.040% of Si, 0.30 to 0.50% of Mn, not larger than 0.018% of P, not larger than 0.018% of S, 0.028 to 0.058% of Al, 0.030 to 0.060% of Ti, and not larger than 0.0045% of N. A plate blank is heated to be larger than or equal to 1190 DEG C, the heating time is larger than or equal to 175 min, the soaking time is larger than or equal to 40 min, through rough rolling and finish rolling, a hot rolling plate is obtained, the finish rolling final rolling temperature ranges from 885 to 915 DEG C, the coiling temperature is 580 to 640 DEG C, finally, flattening and acid pickling are carried out, according to the properties, Rel is 280 to 330 MPa, Rm is 380 to 430 MPa, A50 is larger than or equal to 40%, the grain size is larger than or equal to9 levels, and the difference between the surface and the 1 / 2 position of the thickness is smaller than or equal to 1 level. The low-carbon steel coil plate has the higher strength, better ductility,uniform in structure property, and free of cracking in stamping broaching and flanging, turning threads on the inner wall of a cap mouth do not generate burrs, and the requirement of the oil filter thread cover plate anti-deforming after the pumping pressure property of an oil filter is improved can be met.

Owner:新余钢铁股份有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com