Patents

Literature

30results about How to "Impact resistance has" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

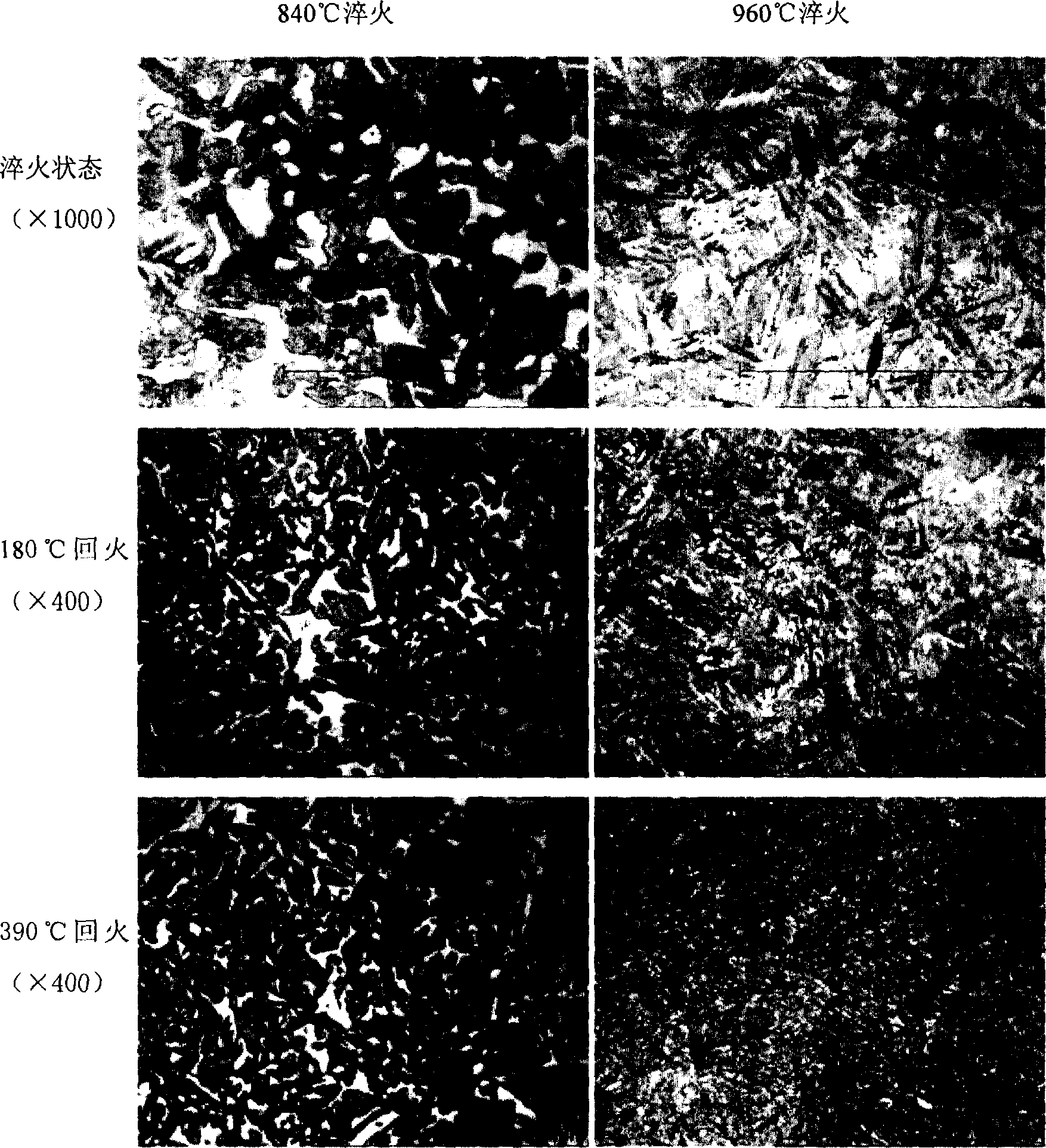

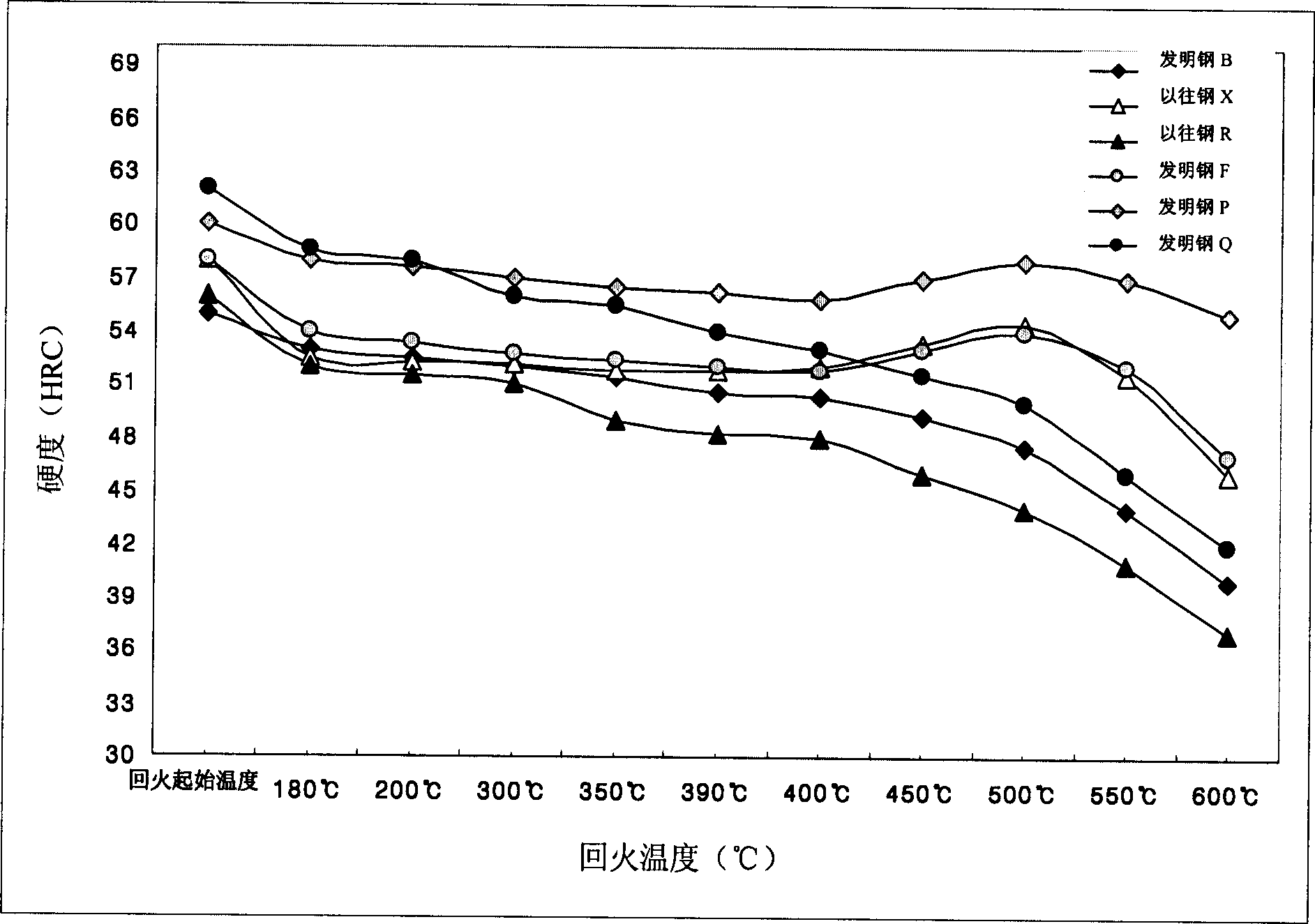

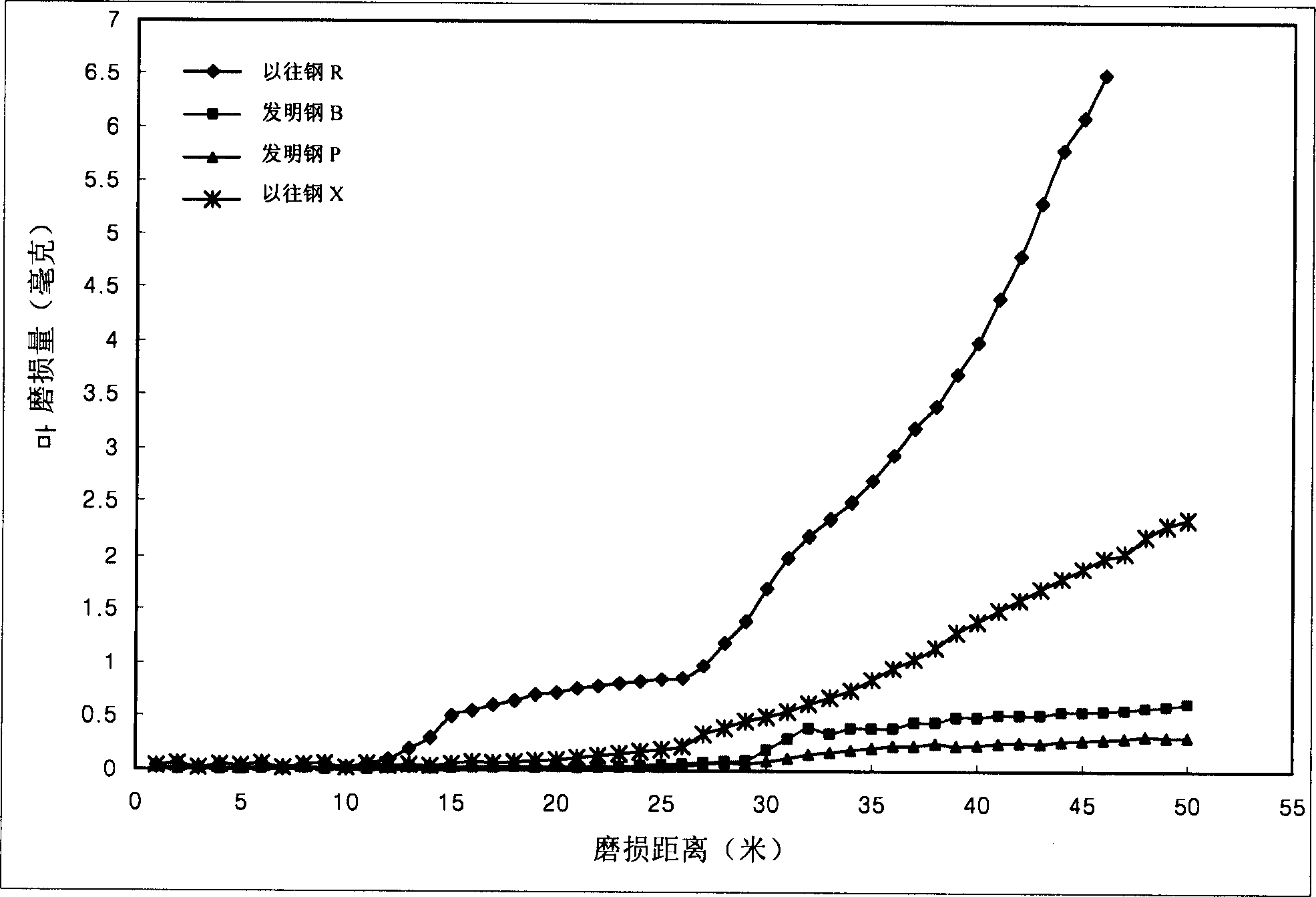

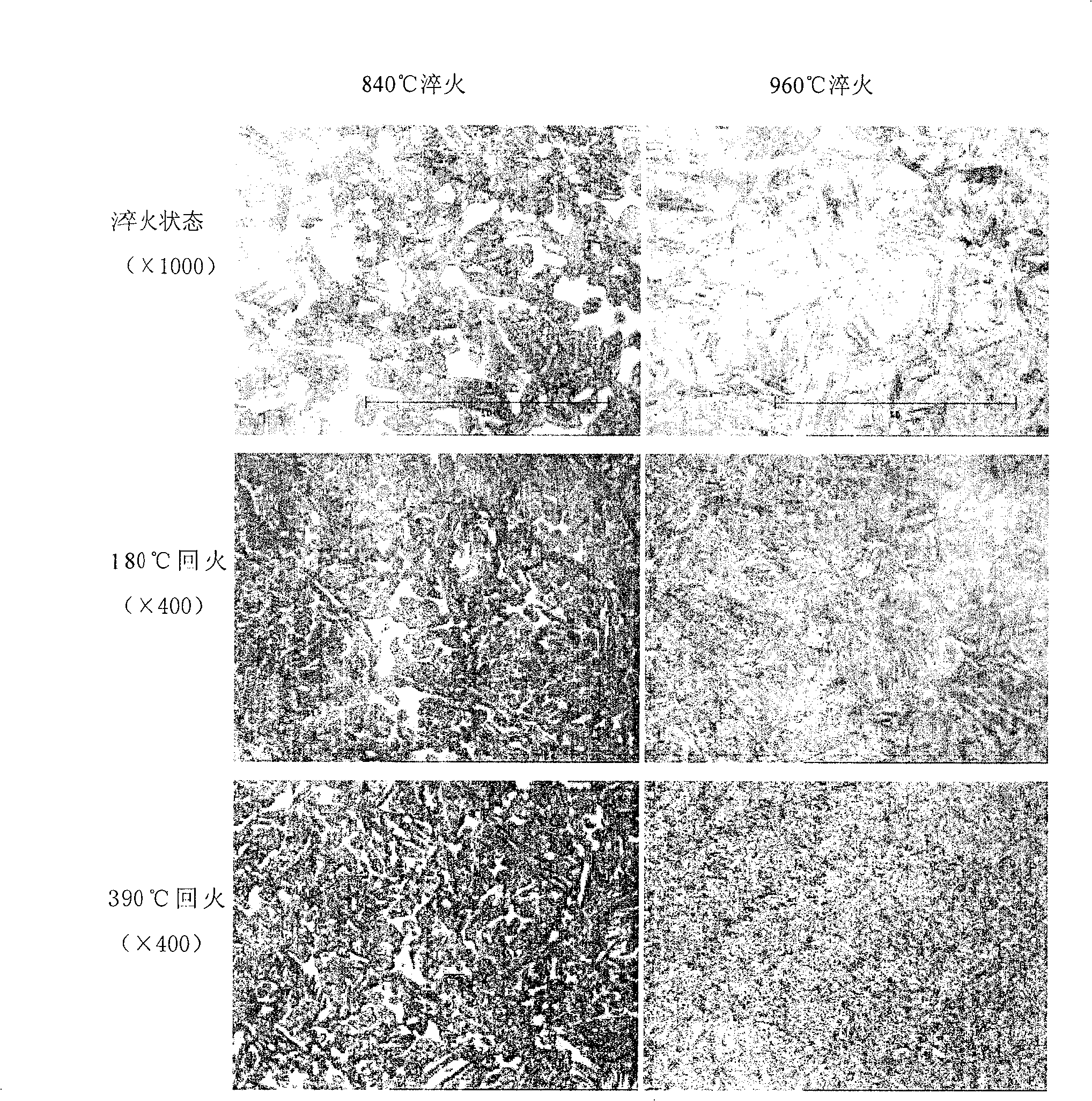

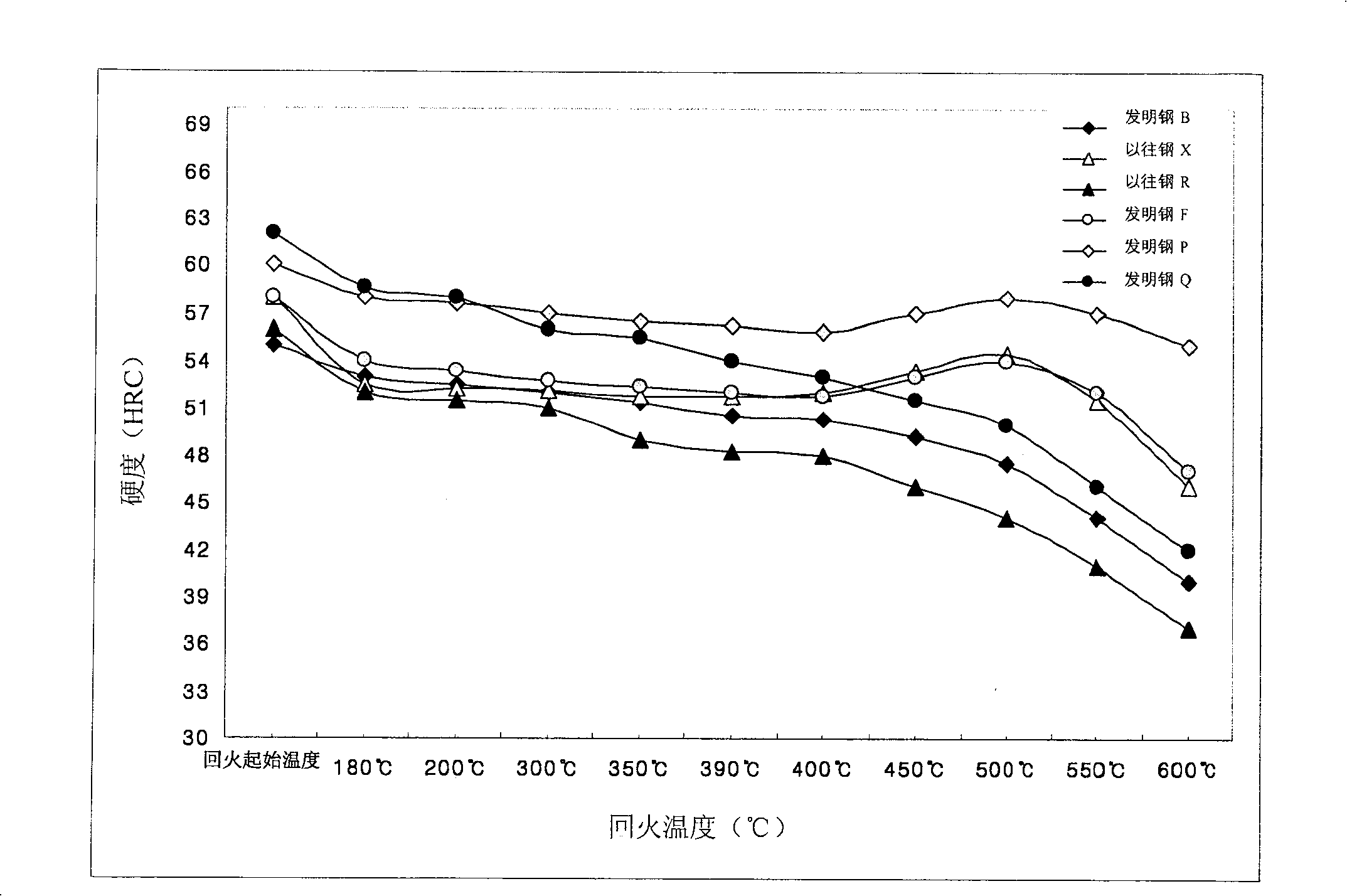

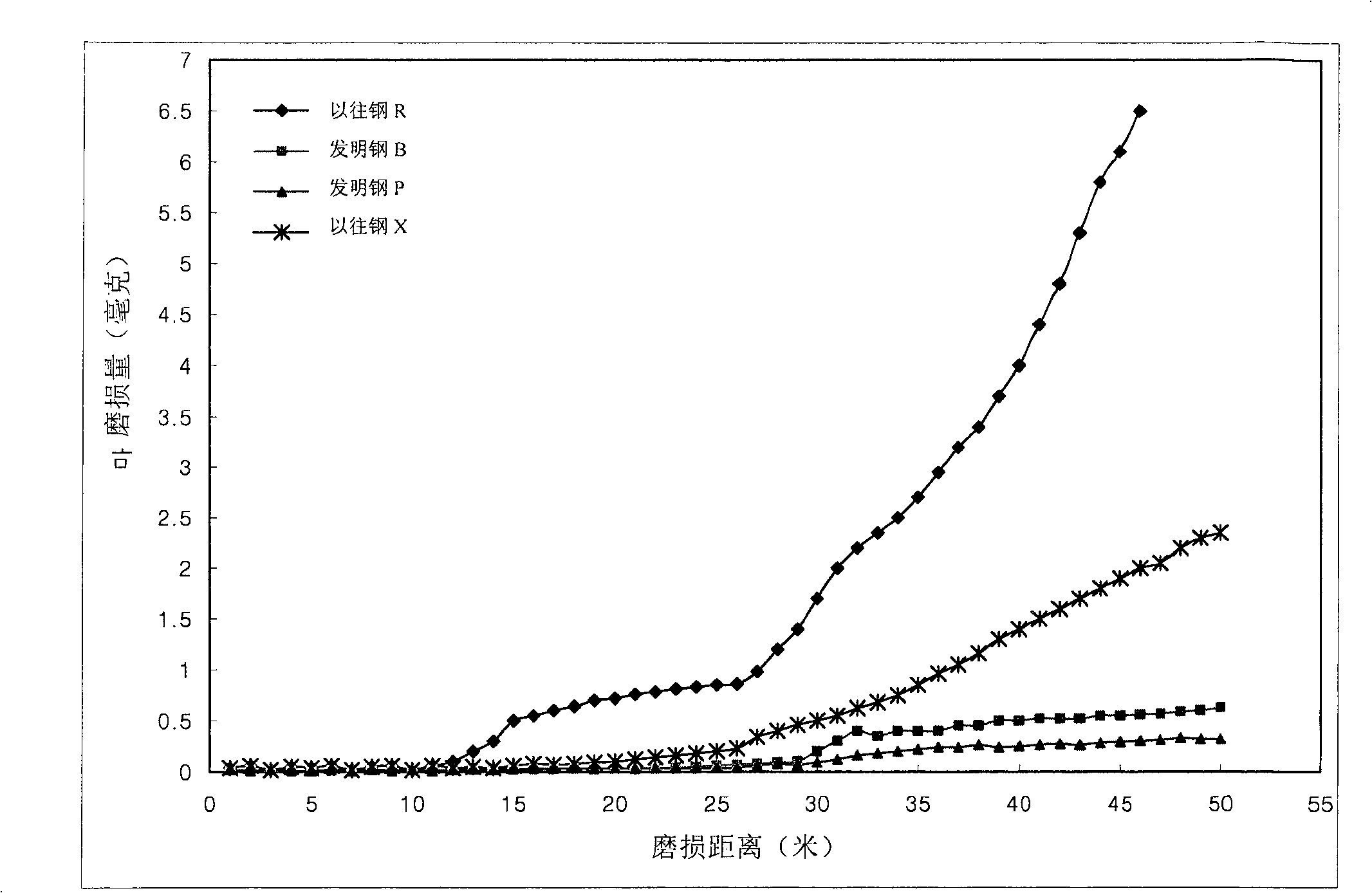

High elasticity and high strengh steel and its producing method

An impact-resistant and wear-resistant high-elasticity and high-strength steel, wherein the steel contains 0.26-0.48 wt% C, 1.4-2.5 wt% Si, 0.5-1.0 wt% Mn, 1.4-2.4 wt% % Cr, 0.01-0.1% by weight of Ni, 0.01-0.5% by weight of Mo, 0.005-0.04% by weight of Al, 0.05-0.1% by weight of V, 0.0025-0.02% by weight of N, the rest is Fe and unavoidable of impurities. The impact-resistant, wear-resistant high-elasticity and high-strength steel of the present invention has high hardness, high strength, high toughness and high elasticity, and the weldability, low-temperature tempering resistance and high-temperature tempering resistance, hardenability, Mechanical properties such as wear resistance, impact toughness, and tensile strength are excellent, so when used under severe conditions, the mold life and component life are much longer than conventional steels.

Owner:CF +2

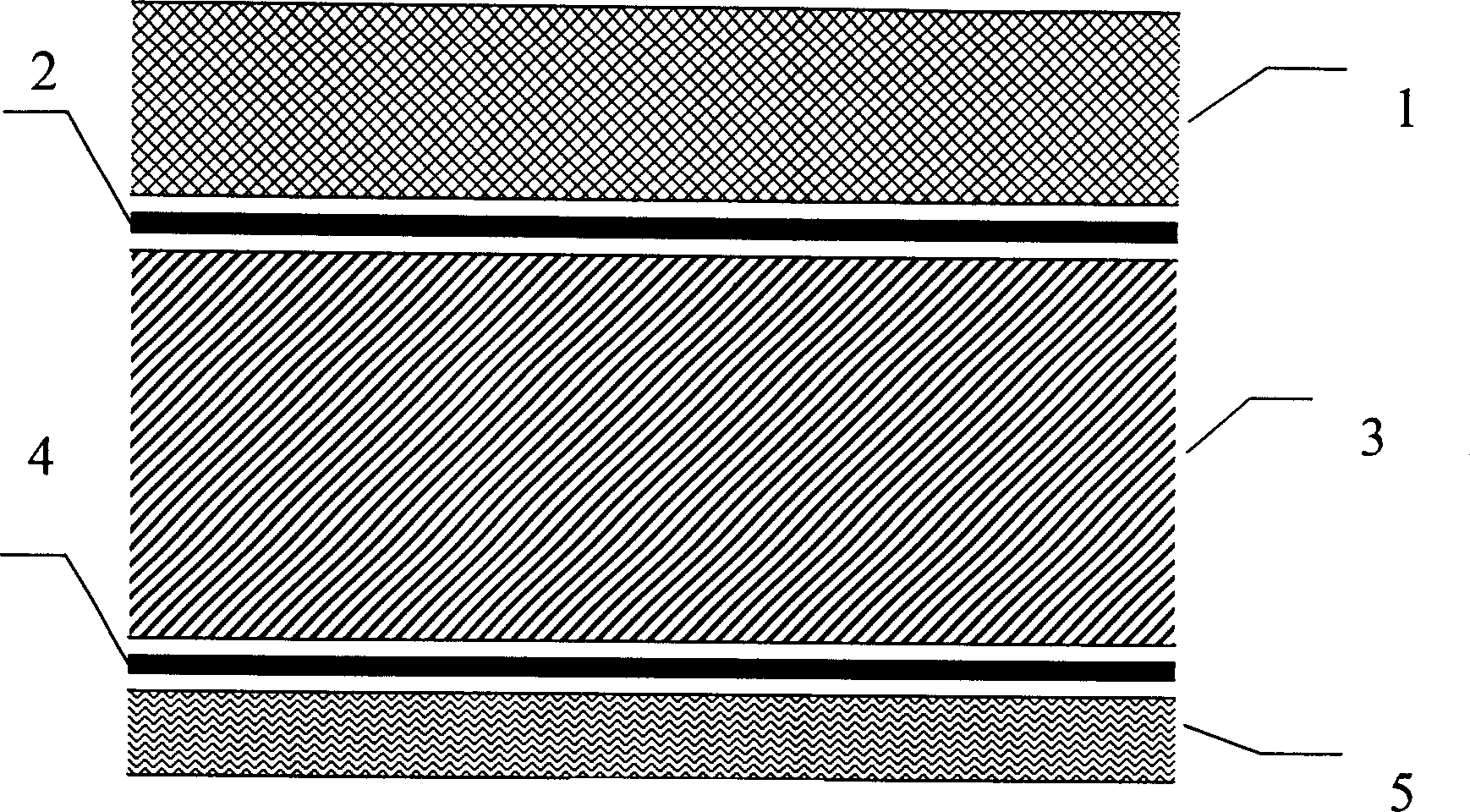

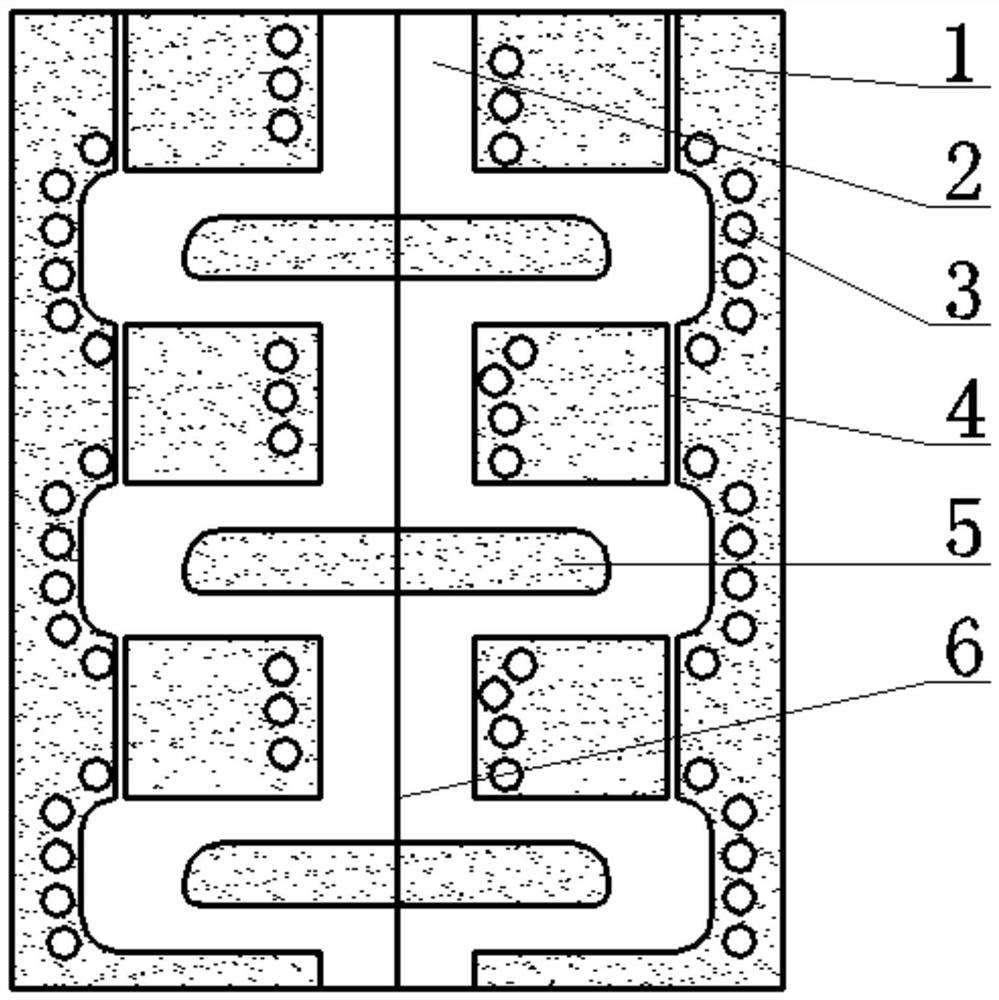

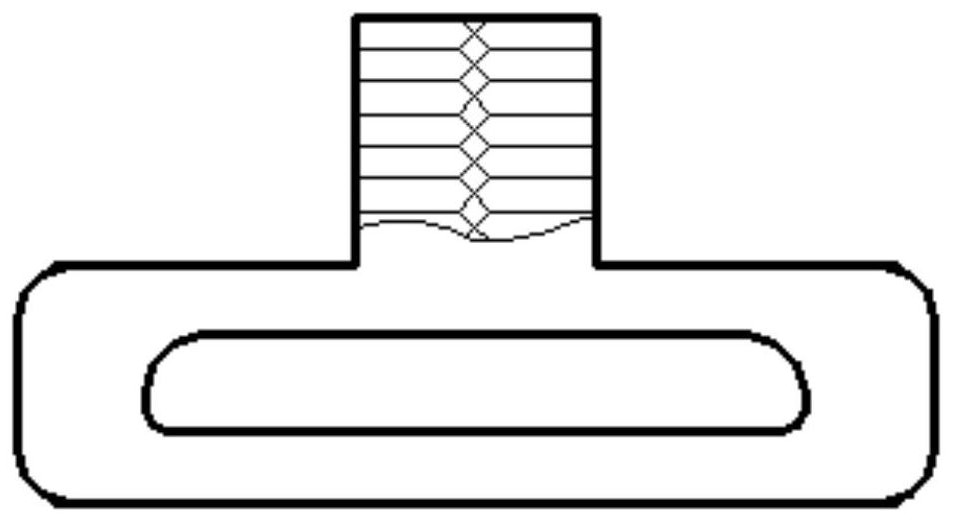

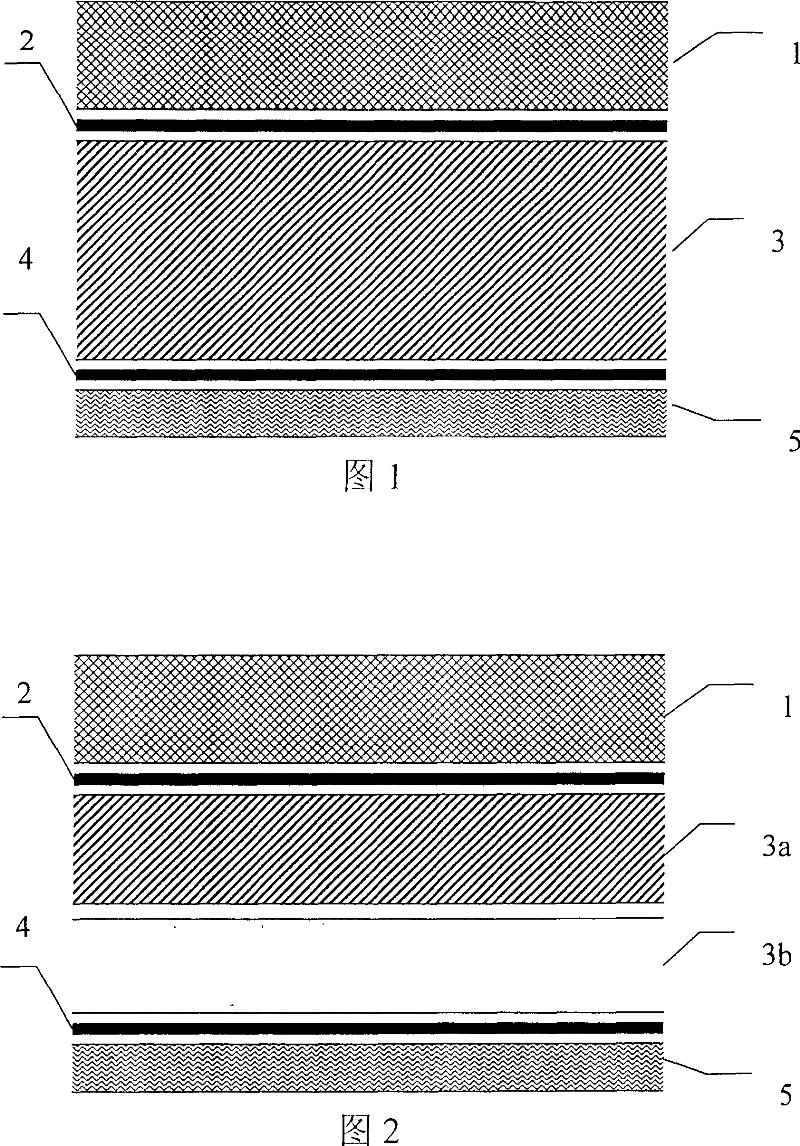

Composite material for interior decoration of automobiles and manufacturing method thereof

ActiveCN1799827ALow investment costLow costLamination ancillary operationsLaminationSurface layerIn vehicle

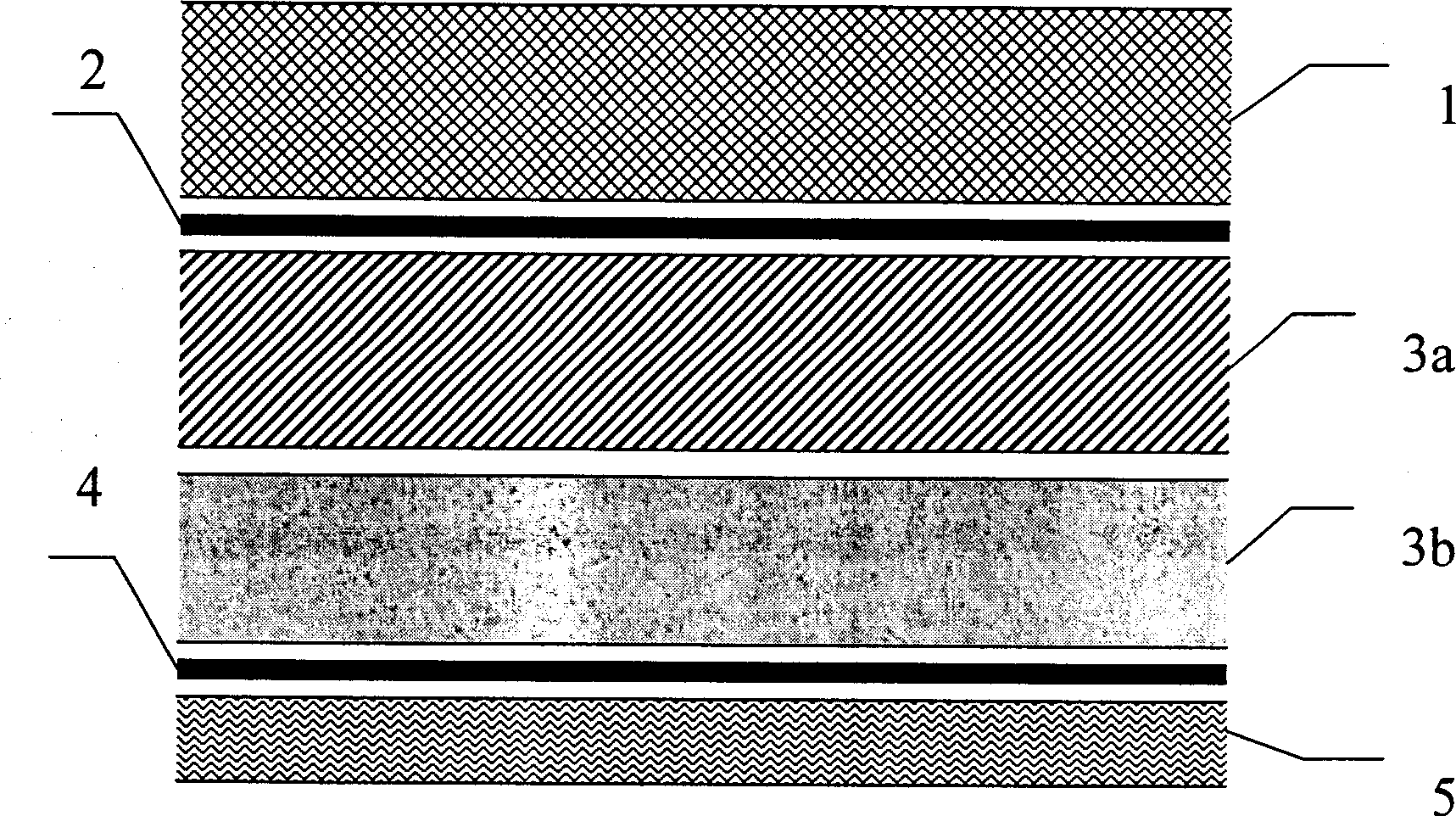

The invention relates to a composite material used in vehicle inner decoration and relative producing method. Said composite material is formed by five or six non-woven sheets as surface layer, de-molding layer, filled layer, de-molding layer and base material layer. Wherein, the filled layer can be formed by hot-melt felt (3a) and polypropylene felt (3b). The producing method comprises that using the de-molding layer (4) as lower layer, the filled layer (3) as intermediate layer and the de-molding layer (2) as upper layer to be piled and arranged between the upper and lower heating plates of heat device; adhering said three layers after low-pressure high-temperature heating into the frame of soft-sandwich type; moving said frame into the lower mould of molding mould and above the base material layer (5); coating the surface layer (1) on the frame; closing the mould to be pressurized and shaped; cutting the hole and edge; and lifting upper mould to attain the final product. The invention has the advantages of lower cost, un-deformed product, high strength, impact resistance, welding availability, short producing process and high efficiency.

Owner:上海汽车地毯总厂有限公司

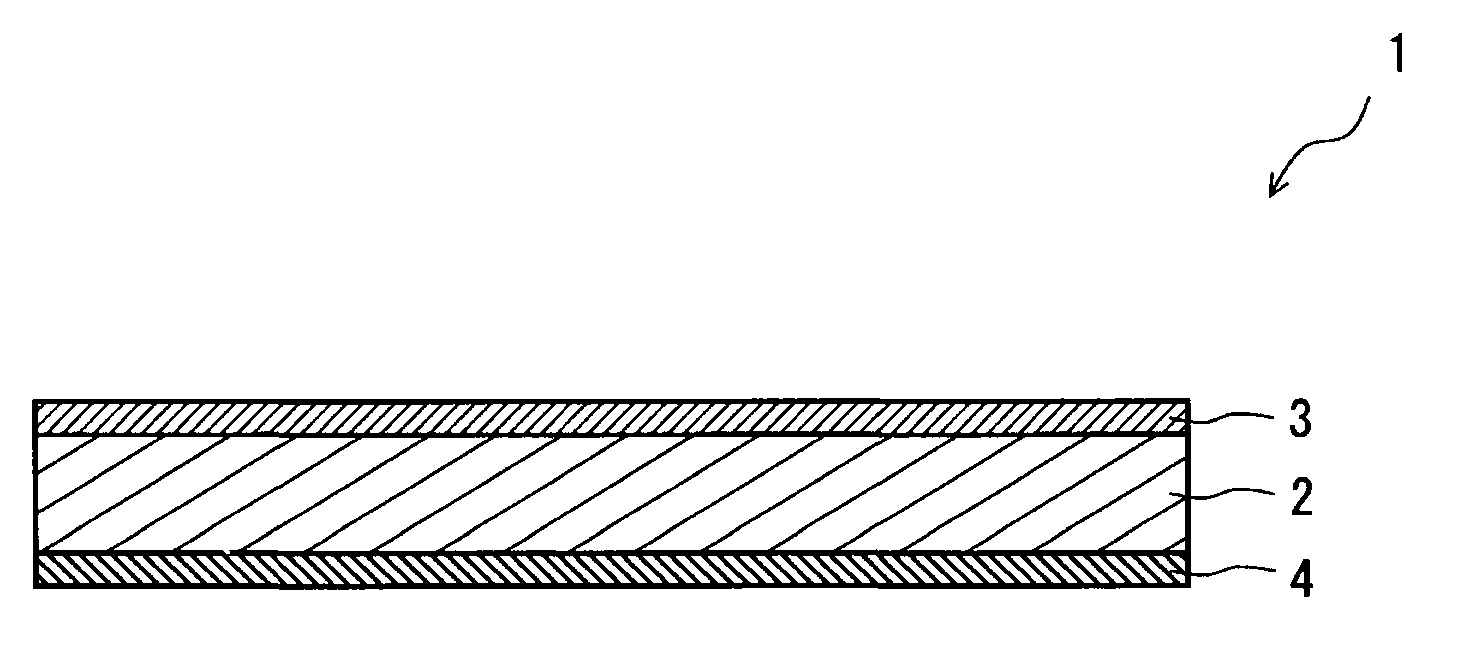

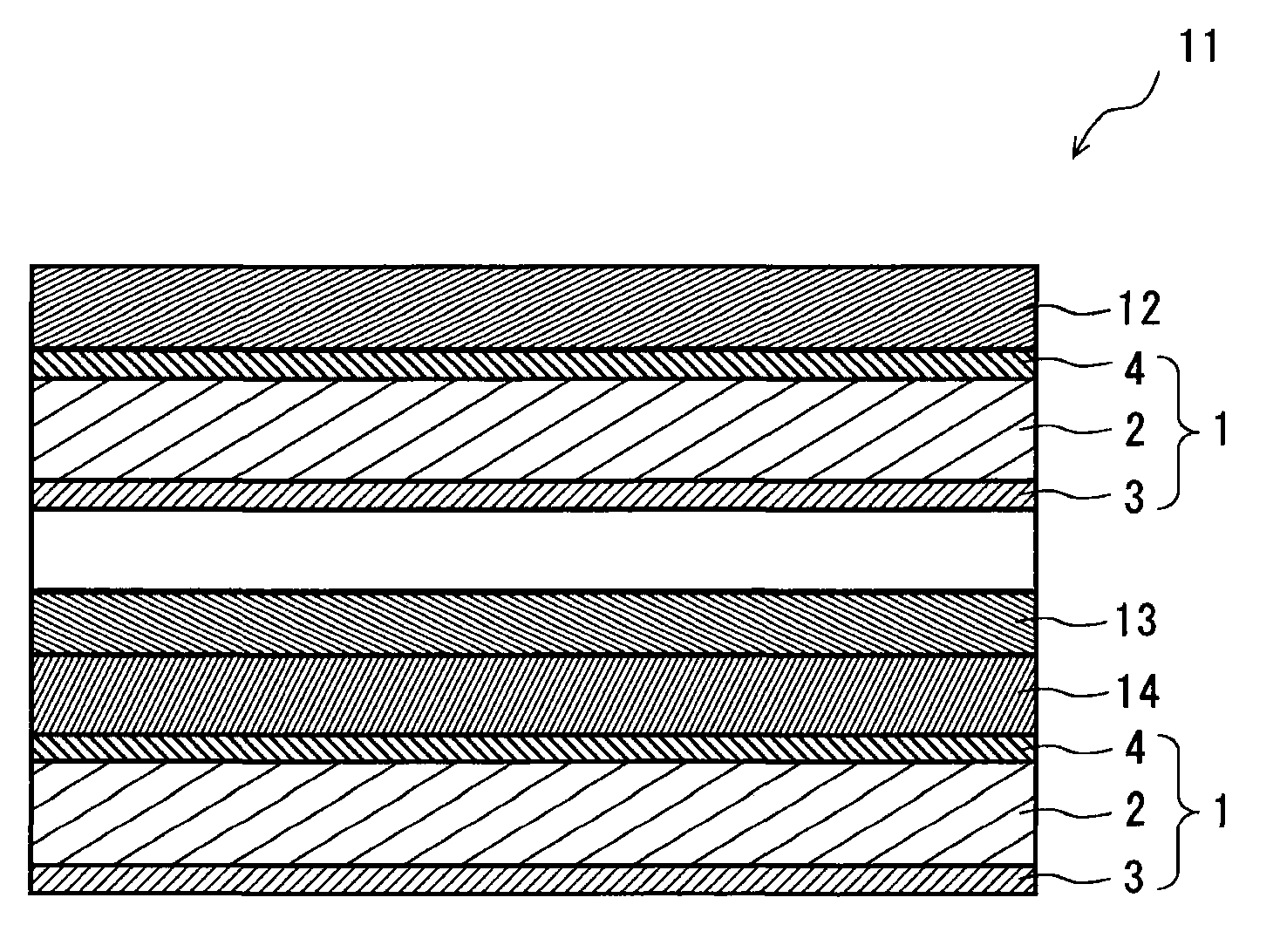

Hard coating film and touch panel using the same

InactiveCN102922806AImprove impact resistanceImpact resistance hasSynthetic resin layered productsNon-linear opticsAcrylic resinMetallurgy

The purpose of the invention is to provide a hard coating film and a touch panel using the same. The hard coating film of the invention comprises a transparent basis material layer which uses polycarbonate resin as main ingredient and a hard coating layer which is bonded on one side of one surface of the transparent basis material layer. The average thickness of the transparent basis material layer is more than 5 [mu] m but less than 50 [mu] m. Preferably, the photoelastic coefficient of the basis material layer is under 40*10-12 / Pa. In addition, preferably, hard coating layer also comprises a bonding layer which is bonded on the other surface of the basis material layer. Preferably, the main ingredient of the adhesives constituting the bonding layer is acrylic resin adhesives. Preferably, the haze degree of the hard coating film is less than 2% and the light transmissivity of the hard coating film is over 87%.

Owner:KEIWA INCORPORATED

Impact-resistant and high-strength domestic ceramic glaze

The invention relates to an impact-resistant and high-strength domestic ceramic glaze, and belongs to the technical field of domestic ceramics. The impact-resistant and high-strength domestic ceramic glaze comprises the following components in parts by weight: 45 to 55 parts of Yunnan kaolin, 25 to 35 parts of Guangxi kaolin, 18 to 25 parts of potassium feldspar, 5 to 10 parts of spodumene, 10 to 15 parts of wollastonite powder, 0.1 to 0.5 part of cobalt oxide, 0.3 to 0.5 part of magnesium oxide, and 0.1 to 0.5 part of titanium dioxide. The preparation method comprises the following steps: allowing raw materials from which impurities are removed to be subjected to crushing, mixing and coarse grinding, sieving through a 6 to 12-mesh sieve, slurrying, performing wet ball-milling for 50 to 75 minutes, sieving through a 200 to 300-mesh sieve, filter pressing, ageing for 8 to 20 days at room temperature to obtain finished product mud; rolling the finished product mud to be molded to obtain a green body; and firing the green body for 3 to 5 hours at a temperature of 300 to 350 DEG C, cooling and then firing for 8 to 8.5 hours at a temperature of 1000 to 1100 DEG C, polishing after cooling to room temperature to obtain the product. The domestic ceramic has good thermal stability and stable chemical properties, is light and delicate, and has the characteristics of impact resistance and high strength.

Owner:GUANGDONG YANHONG CERAMICS CO LTD

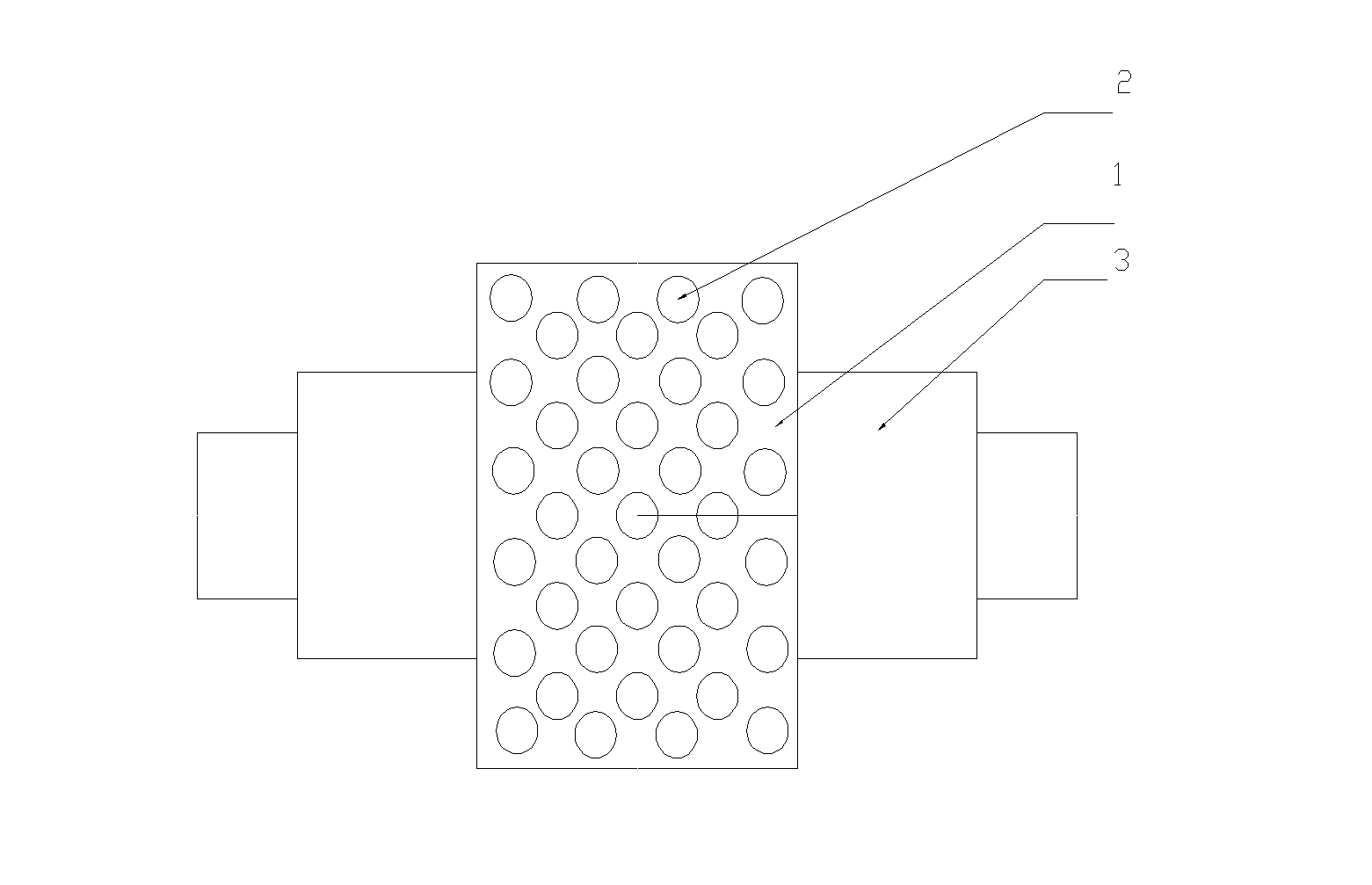

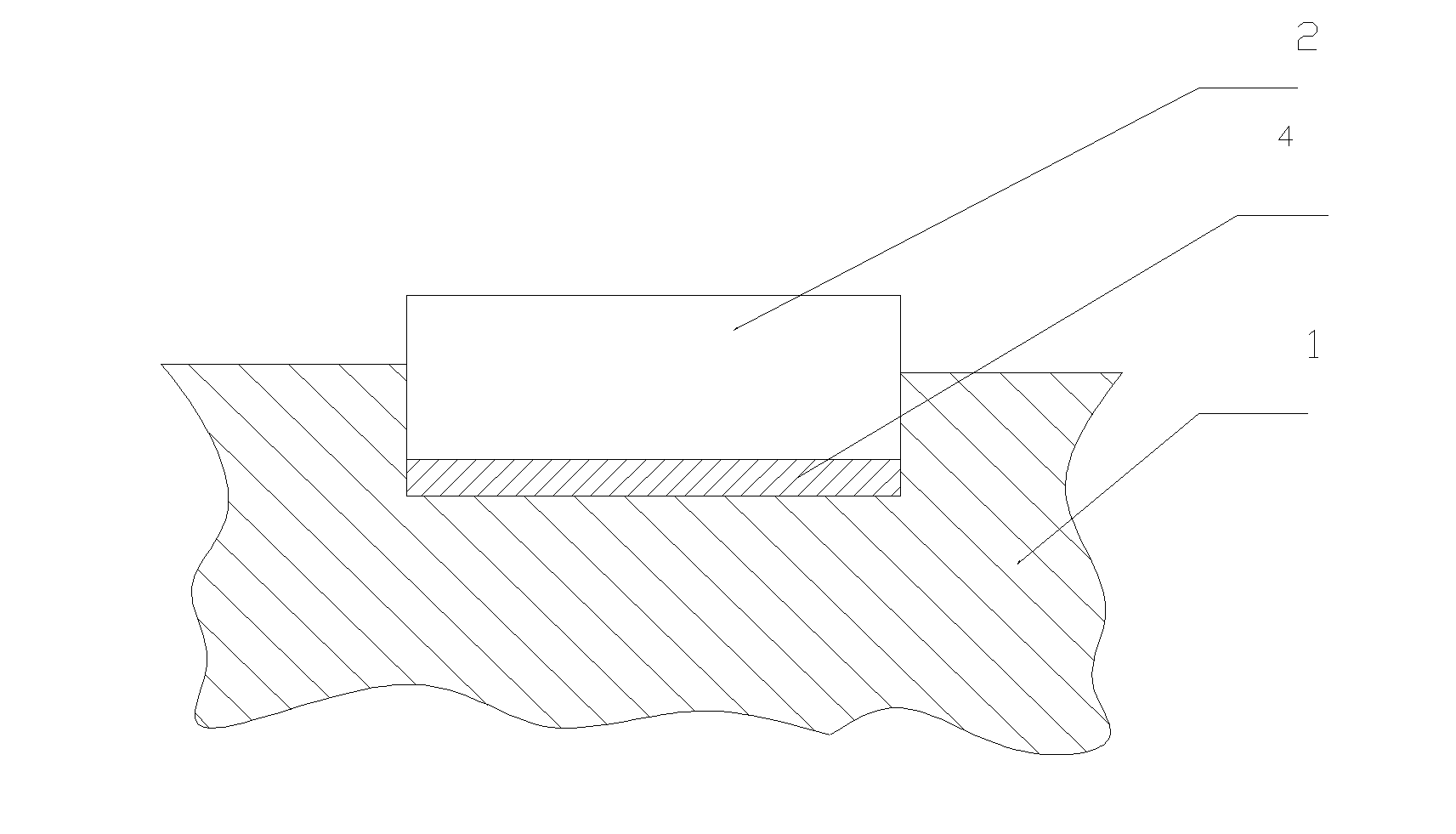

High-wearable extrusion roller of roller press and manufacture process thereof

InactiveCN102441462AHigh strengthFatigue resistance hasGrain treatmentsManufacturing technologyAlloy

The invention relates to a high-wearable extrusion roller of a roller press and a manufacture process thereof, belonging to the technical field of extrusion rollers; circular grooves are machined on the surface of the extrusion roller every 3-6 mm; a hard alloy cylinder is embedded in the groove; the hard alloy cylinder is 2 mm higher than the surface of the extrusion roller; then, hard alloy is connected with the extrusion roller through a brazing method; the hard alloy contains the following components in percentage by weight: 66-92% of WC, 0-30% of TiC, 3.9-8% of Co and 0.1-0.3% of Cr; compared with the overlaying welding method, after the extrusion roller is brazed with the hard alloy, the wearable property is greatly increased; the service life is long; the replacement time of the extrusion roller is reduced; and the equipment utilization rate is increased.

Owner:BEIJING UNIV OF TECH

Impact-resistant steel ball for ball mill

InactiveCN104120365AImpact resistance hasImprove performanceFurnace typesHeat treatment furnacesRoom temperatureLate stage

The invention discloses an impact-resistant steel ball for a ball mill. The impact-resistant steel ball comprises the following components in percentage by weight: 0.6%-0.8% of C, 0.2%-0.3% of Si, 1.5%-2.3% of Cr, 0.6%-0.8% of Mn, 0.2%-0.3% of Ni, 0.04%-0.06% of Ti, 0.6%-1.2% of Al, 0.05%-0.1% of W, 0.15%-0.25% of Mo, 0%-0.02% of S, 0%-0.06% of P and the balance of Fe. The impact-resistant steel ball for the ball mill is prepared by virtue of the following process steps in the preparation process: S1, weighing raw materials according to the weight percentage of the components, smelting, refining in a refining device, carrying out final deoxidization at the late stage of the refining, pouring, shaping through casting, and then cleaning to obtain a cast; S2, carrying out heat preservation on the cast obtained from the S1 at 850-870 DEG C for 2.5-3.5 DEG C, then carrying out water quenching, increasing the temperature of the quenched cast to 240-260 DEG C, carrying out tempering treatment, carrying out heat preservation for 1-2 hours, transferring into a delayed cooling pit, and slowly cooling to room temperature to obtain an abrasion-resistant steel ball finished product.

Owner:NINGGUO SOUTHERN WEAR RESISTANT MATERIALS

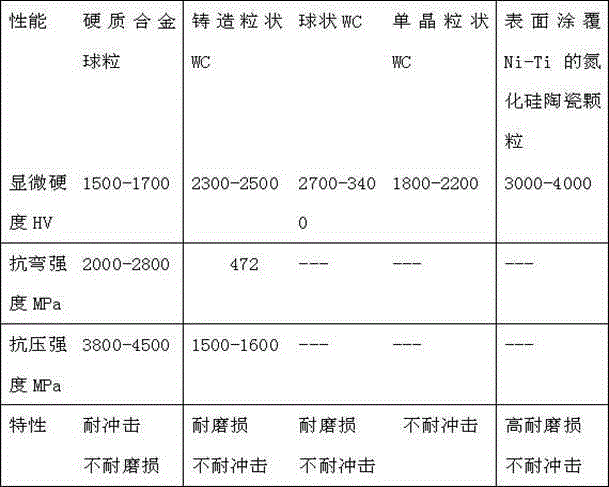

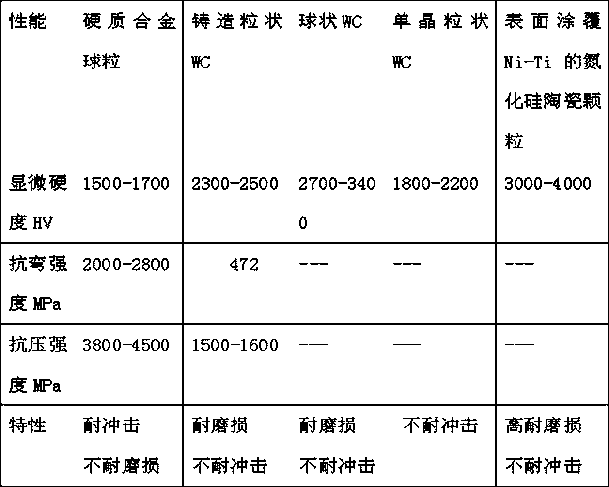

Preparation method of compound tungsten-base tubular welding rod hard-face material

ActiveCN105033509AImprove wear resistanceImpact resistance hasWelding/cutting media/materialsSoldering mediaManganeseSingle crystal

The invention discloses a preparation method of a compound tungsten-base tubular welding rod hard-face material. The preparation method of the compound tungsten-base tubular welding rod hard-face material is characterized in that the raw materials comprise, by weight, 50-65 parts of cemented carbide pellets, 10-12 parts of spheroidal tungsten carbide, 10-30 parts of casting granular tungsten carbide, 6-8 parts of single crystal granular tungsten carbide, 1-2 parts of silicon nitride ceramic particles, 2.5-4.5 parts of silicon-manganese powder and 0.5 part of phenolic resin; the method comprises the steps that the raw materials of the cemented carbide pellets, the spheroidal tungsten carbide, the casting granular tungsten carbide, the single crystal granular tungsten carbide, the silicon nitride ceramic particles and the silicon-manganese powder are mixed for 1-4 h in a mixing machine according to the proportions, and a mixture is obtained; after the mixture obtained in the first step is discharged, the phenolic resin is added in the mixture according to the proportion for even stirring and drying in a drying box, the mixture is maintained for 3 h at 100 DEG C, the mixture is maintained for 3 h at 150 DEG C, and the finished product tubular welding rod hard-face material is obtained after the processed product is taken out of the drying box. The preparation method of the compound tungsten-base tubular welding rod hard-face material is mainly used for preparing the compound tungsten-base tubular welding rod hard-face material.

Owner:株洲金韦硬质合金有限公司

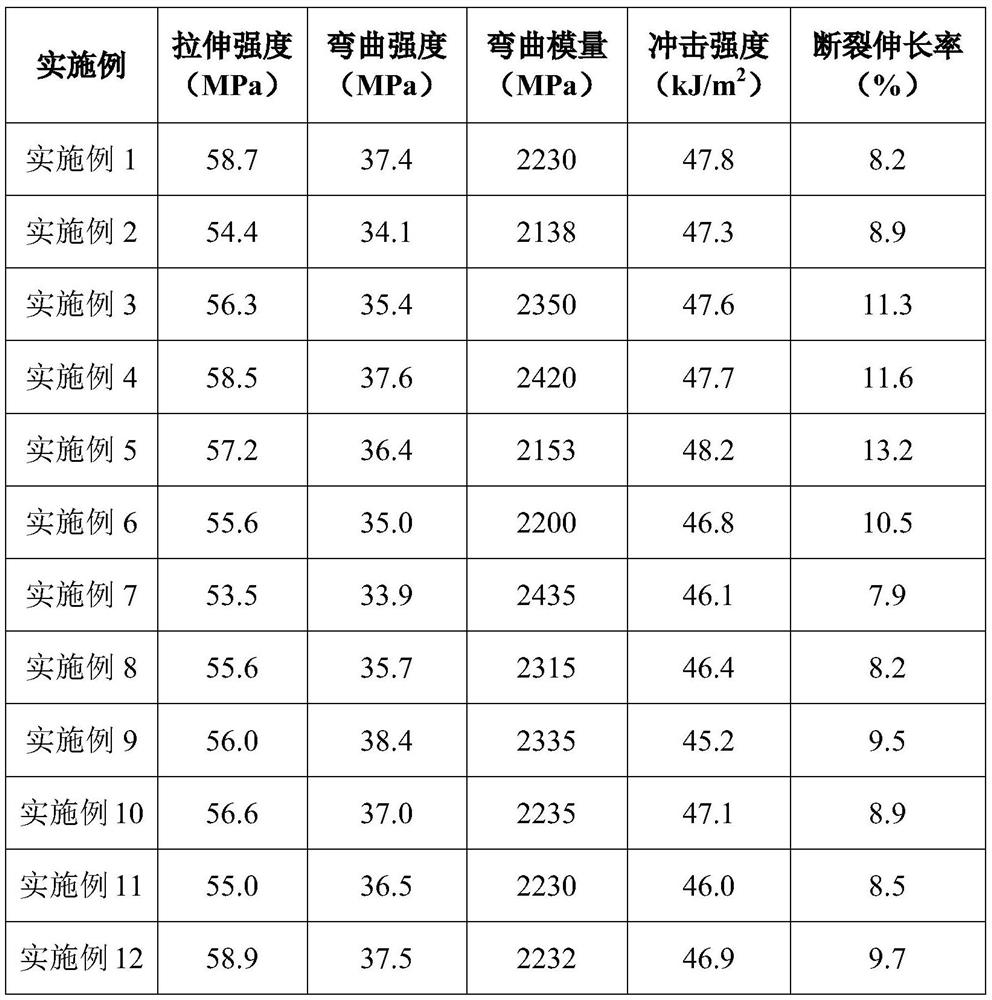

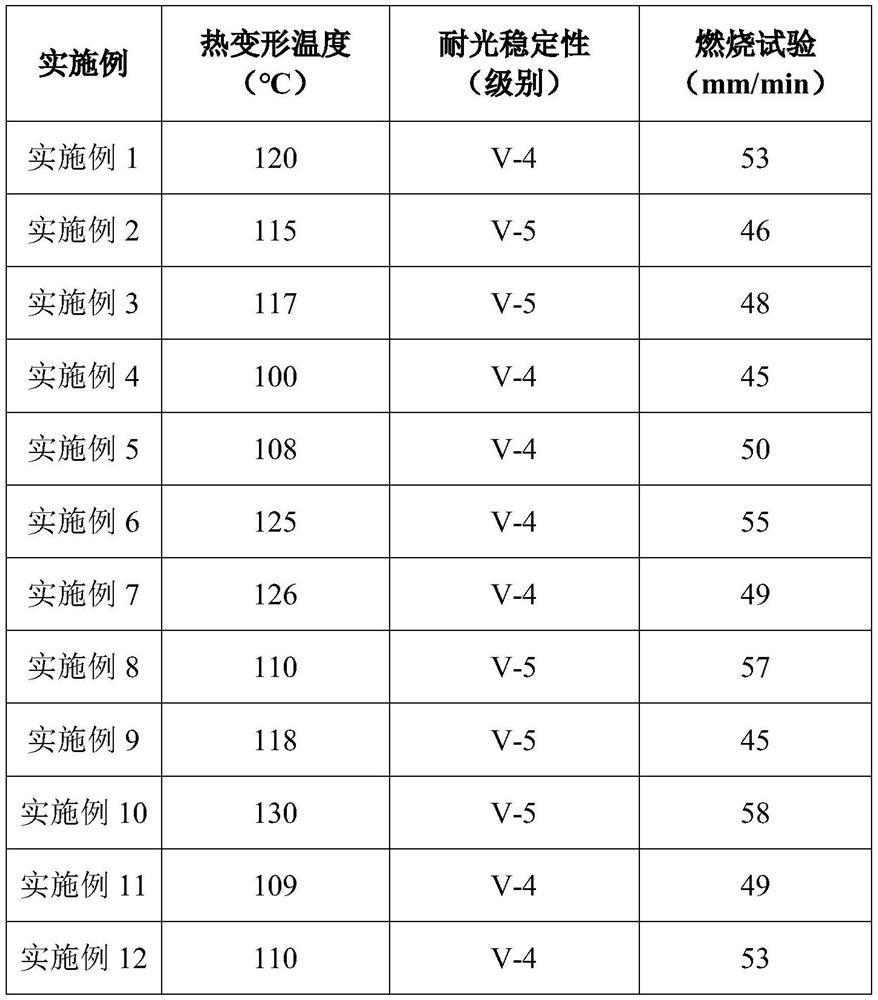

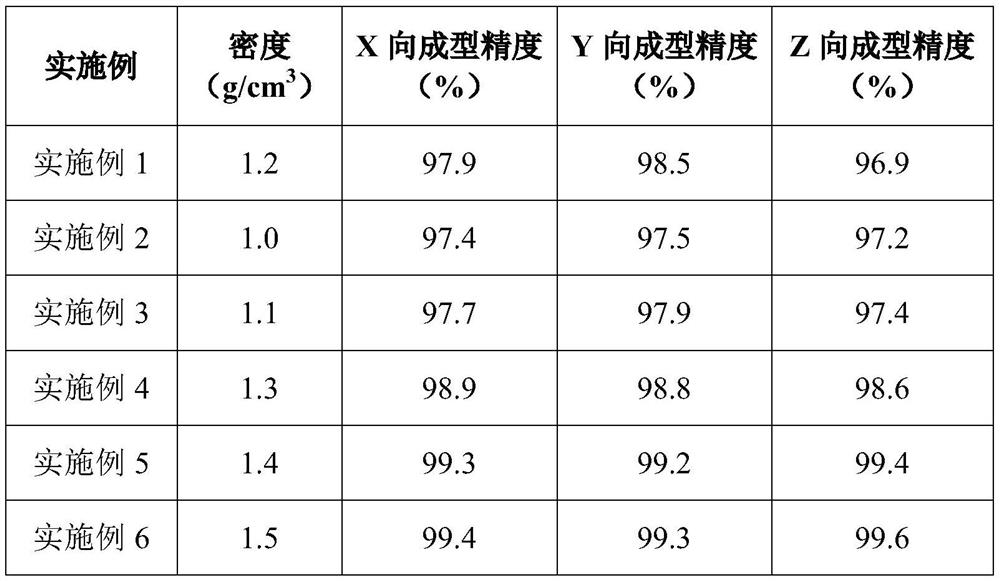

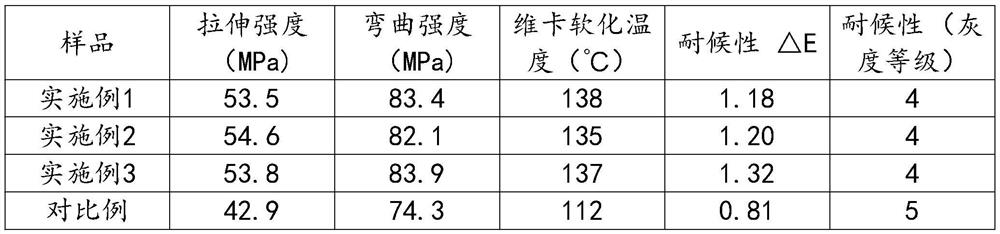

Functionalized TPU special powder for SLS molding anti-impact anti-exposure automobile instrument panel and preparation method of functionalized TPU special powder

The invention provides a functional TPU special powder for an SLS molding anti-impact anti-exposure automobile instrument panel and a preparation method of the functional TPU special powder. The method comprises the following steps: selecting TPU powder as a base material, wherein the particle size of the TPU powder is preferably 100-150 [mu]m; selecting functional fillers, wherein the functionalfillers comprise an impact-resistant filler, an anti-exposure filler, a flow aid, an antioxidant, a stabilizer, a coupling agent, a weather-resistant agent and the like; putting the base material andthe functional fillers into a high-speed mixer according to a certain ratio, and conducting mechanical mixing; characterizing the mixed TPU composite powder; and analyzing data, and drawing conclusions. The preparation method of the functionalized TPU special powder material for the SLS molding anti-impact anti-exposure automobile instrument panel is simple to operate and high in flexibility, andthe molded automobile instrument panel has good impact resistance, exposure resistance and the like, and has a wide application prospect in the field of automobile industry.

Owner:OECHSLER PLASTIC PROD TAICANG +1

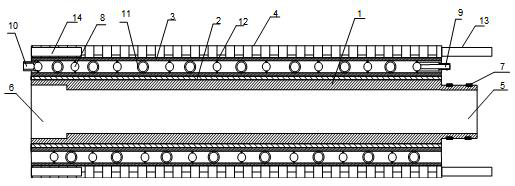

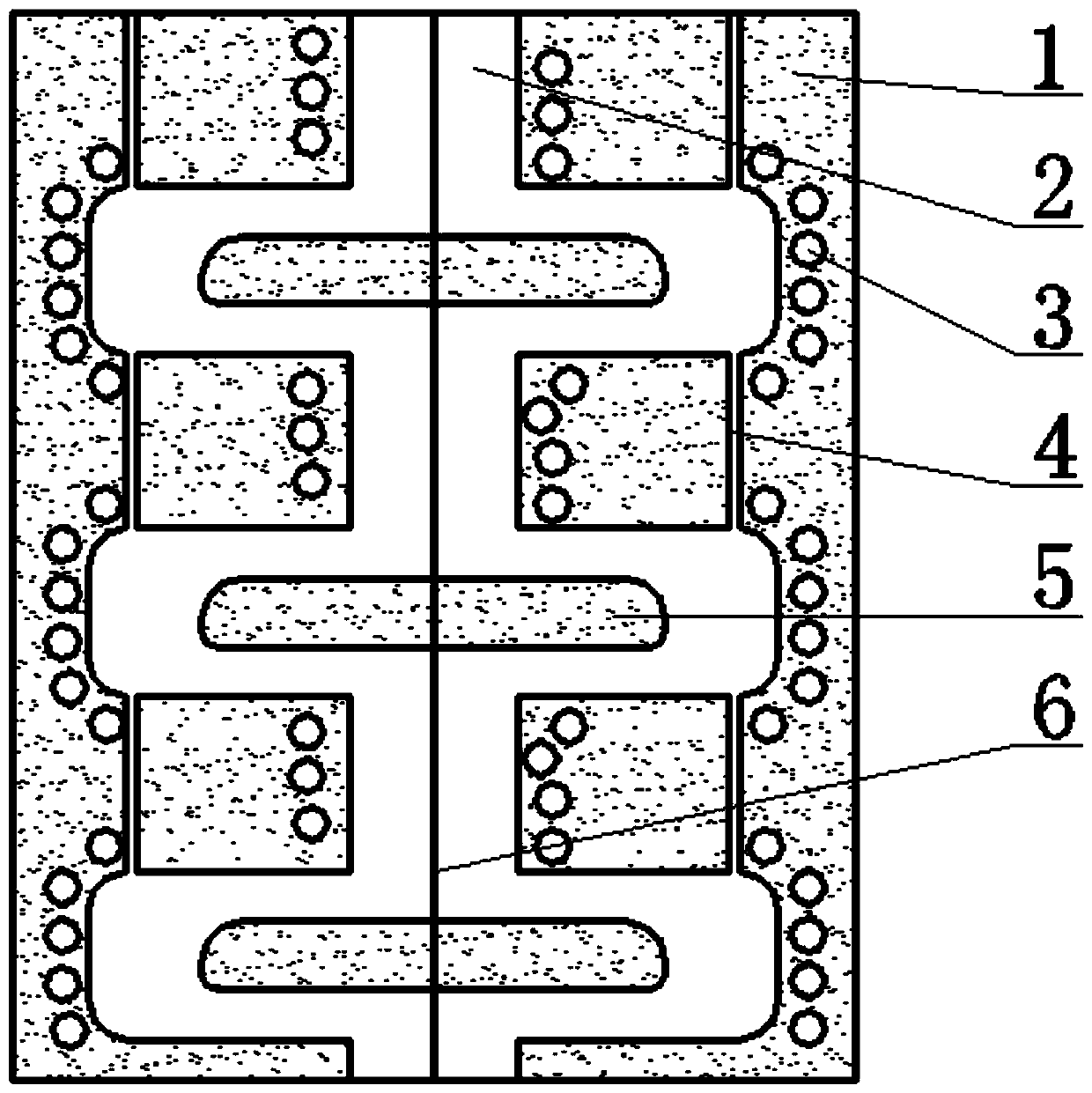

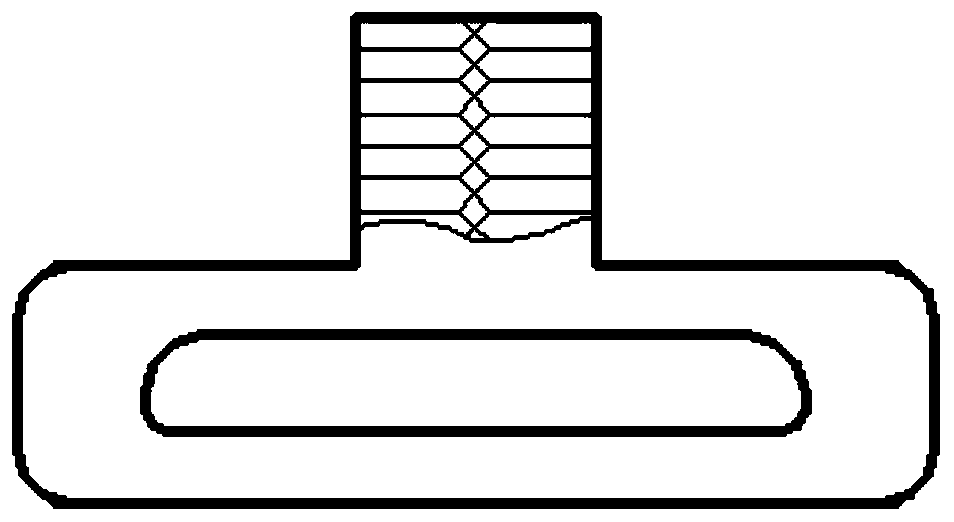

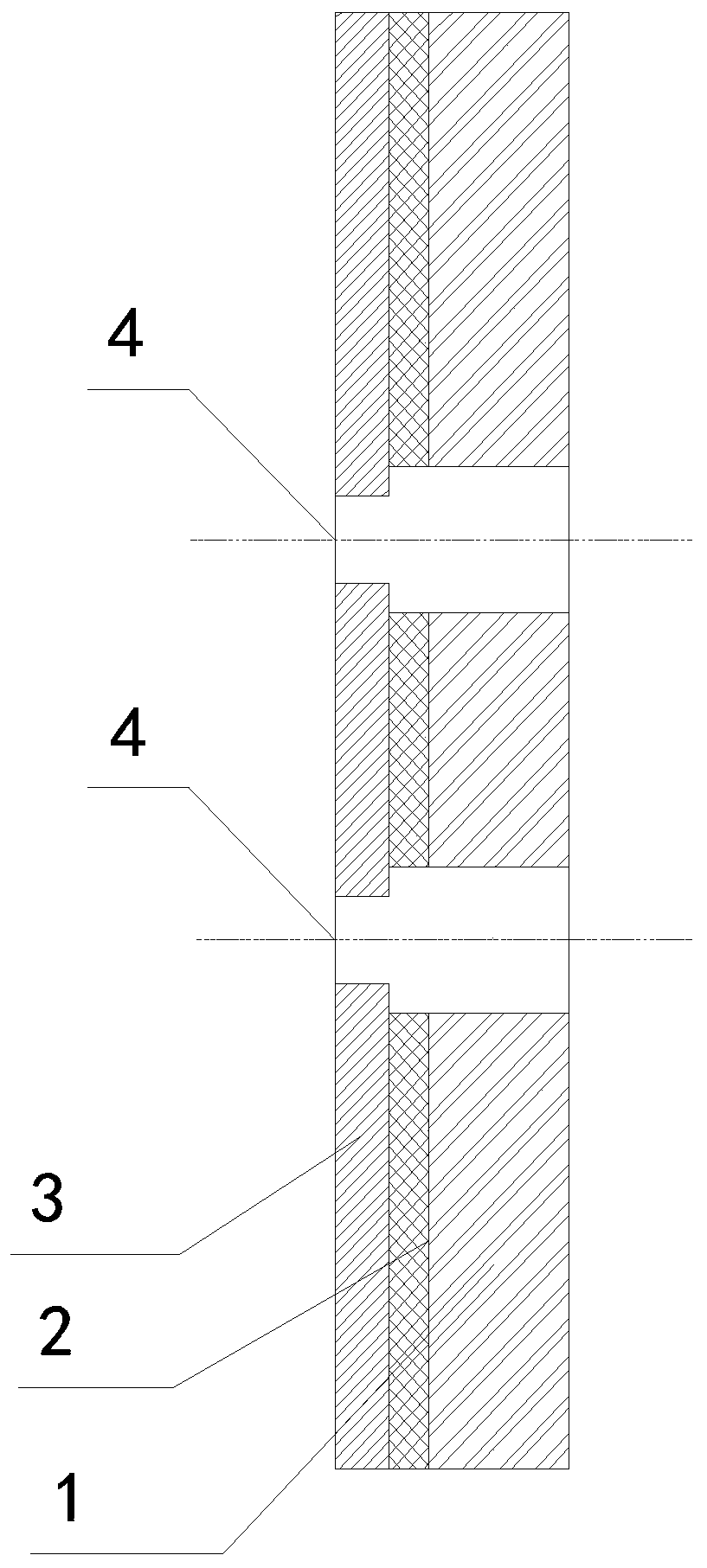

Novel glass fiber reinforced plastic lining concrete combined pipe

PendingCN111853378AImprove deformation abilityStrong impact resistanceThermal insulationPipe heating/coolingGlass fiberPipe

The invention discloses a novel glass fiber reinforced plastic lining concrete combined pipe. The novel glass fiber reinforced plastic lining concrete combined pipe comprises a glass fiber reinforcedplastic lining layer and a concrete layer, wherein an inserting opening is formed in one end of the glass fiber reinforced plastic lining pipe, a bellmouth is formed in the other end of the glass fiber reinforced plastic lining pipe, a groove is formed in the inserting opening to install a sealing ring, and a functional layer is further arranged between the glass fiber reinforced plastic lining layer and the concrete layer; and the functional layer comprises an annular hollow cylinder made of a steel material. A spiral pipe coaxial with an annular cylinder body is arranged in the annular cylinder body, one end of the spiral pipe is an inserting end extending out of one end of the annular hollow cylinder body, the other end of the spiral pipe is a bearing end extending out of the other endof the annular hollow cylinder body, an annular groove is formed in the outer wall of the bearing end of the spiral pipe and provided with a sealing ring, and when two combined pipes are connected, the spiral pipes of the two combined pipes are connected in an inserting manner; a plurality of second reinforcing ribs are arranged between the spiral pipe and the inner wall of the annular hollow cylinder body to support the spiral pipe; and a first reinforcing rib is arranged between two corresponding inner walls of the annular hollow cylinder.

Owner:德阳市卿发建材物资有限公司

High-strength and high-wear-resisting plastic valve element and preparation method thereof

The invention discloses a high-strength and high-wear-resisting plastic valve element and a preparation method thereof. The high-strength high-wear-resisting plastic valve element is prepared from, by weight, 60-80 parts of PFA, 10-20 parts of ETFE, 3-5 parts of nano attapulgite, 3-5 parts of nano dolomite powder, 2-5 parts of nano ceramic powder, 2-4 parts of nano silicon nitride, 1-2 parts of glass fibers, 1-3 parts of antiager, 0.5-0.8 part of antioxidant, 0.8-1.5 parts of coupling agent and 1-3 parts of liquid paraffin. The high-strength and high-wear-resisting plastic valve element is high in strength and resistant to impacts and wear, and has high temperature resistance, self-lubrication performance and excellent dimension stability.

Owner:TONGLING BAIRUI EQUIP PARTS CO LTD

Casting-forging combined torsion-resistant anti-impact vehicle steering knuckle and manufacturing method thereof

The invention discloses a casting-forging combined torsion-resistant anti-impact vehicle steering knuckle and a manufacturing method thereof. The porosity of the steering knuckle is 0-0.2%, the overall grain grow direction is the horizontal direction from the outermost side to the axis center, and the steering knuckle is made of cast low-alloy steel. The steering knuckle adopts the casting and forging combined one-time forming mode and is good in compactness, high in strength and resistant to torsion and impact, and the grains grow in the radial direction.

Owner:湖北洪伯车辆有限公司

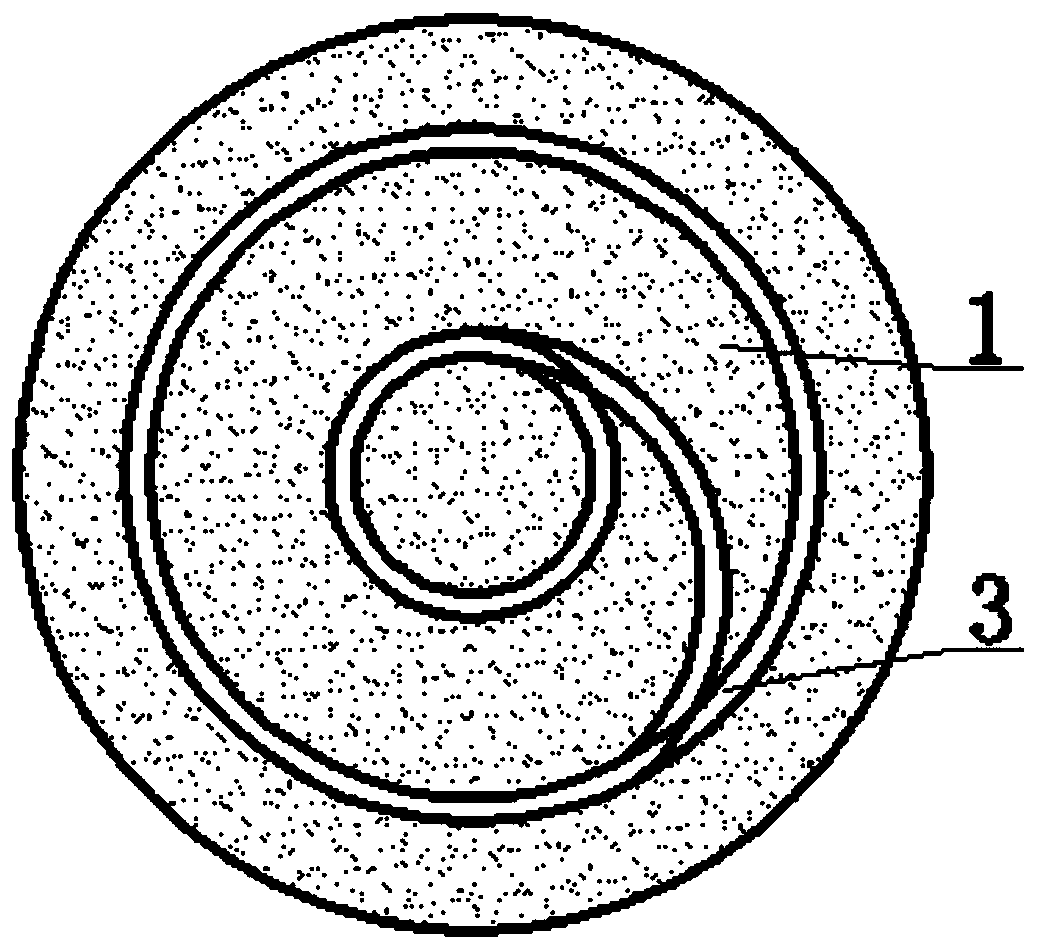

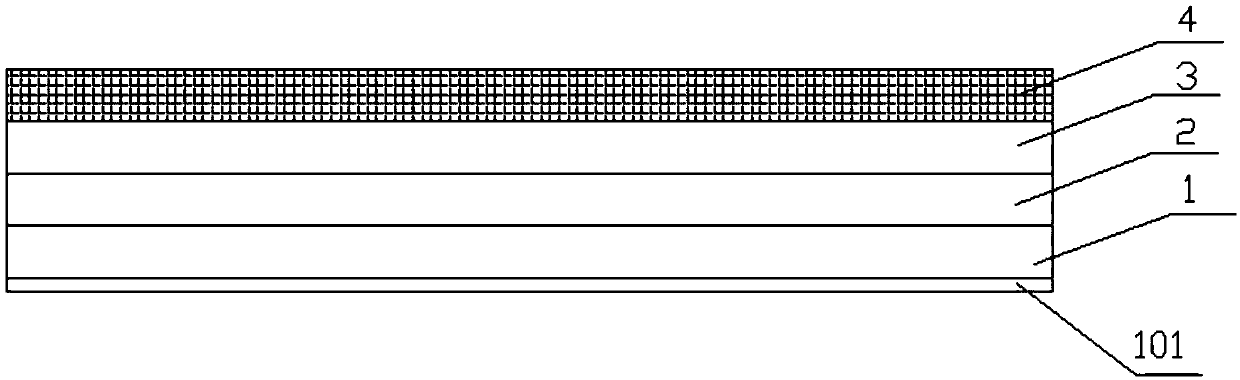

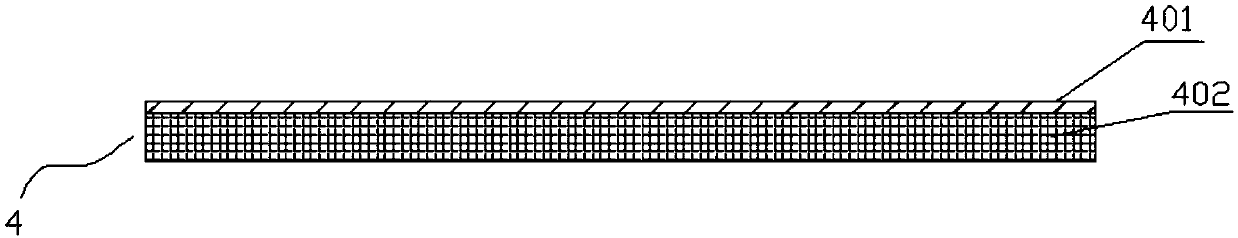

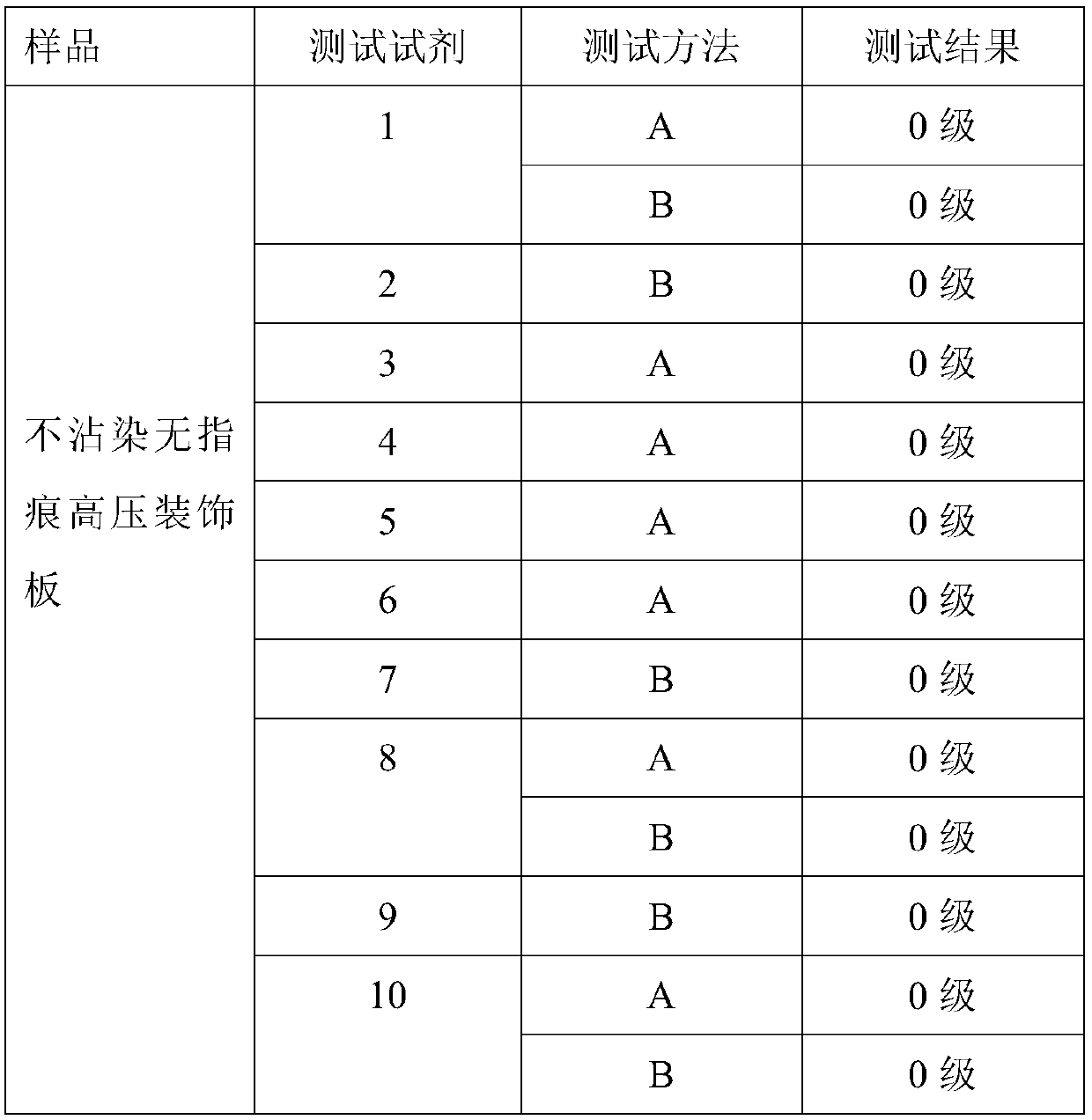

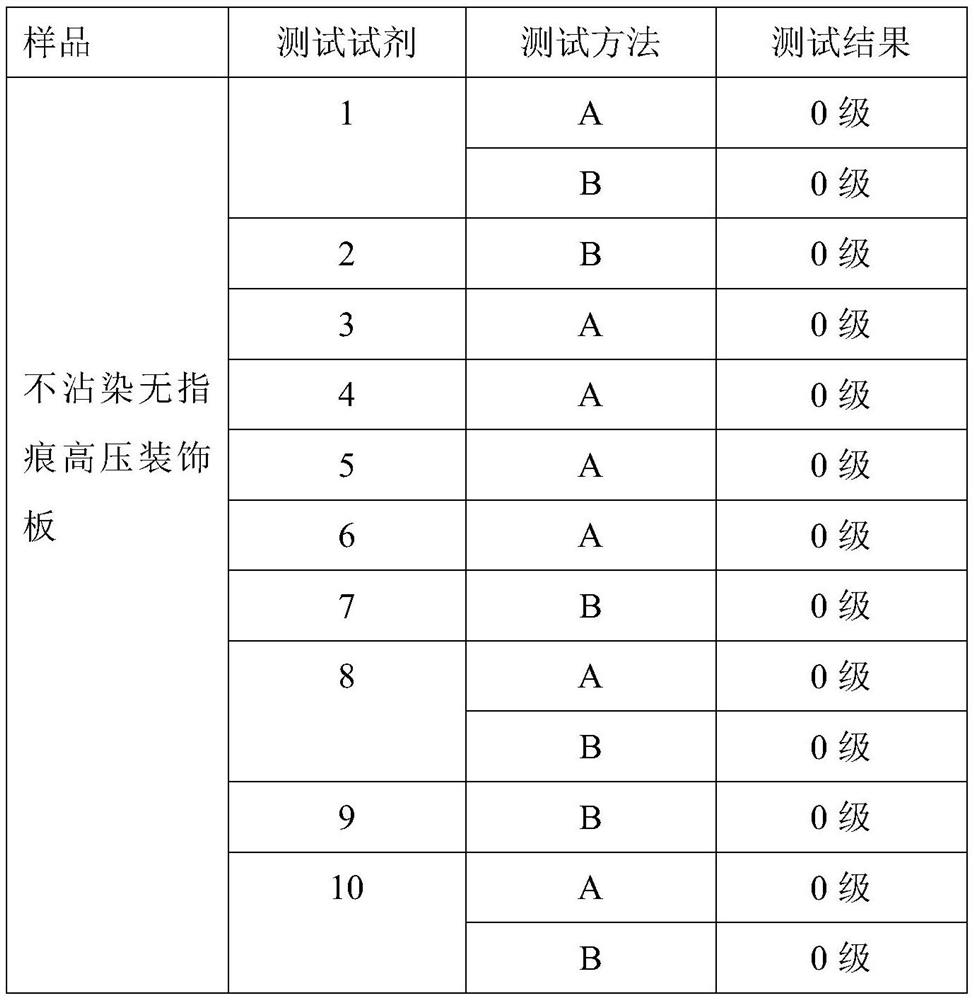

Non-staining non-finger mark high-pressure decorative board and preparation method thereof

ActiveCN109532180APollution resistantPollution resistance reachesLamination ancillary operationsLaminationSilica particleWater vapor

The invention discloses a non-staining non-finger mark high-pressure decorative board and a preparation method thereof. The high-pressure decorative board is formed by a balance layer, a substrate layer, an adhesive layer and a non-staining non-finger mark decorative layer through high-temperature and high-pressure moulding. The non-staining non-finger mark decorative layer is a resin-coated decorative paper, the decorative paper is coated with the fluoroalkylsilane resin composite resin with addition of silica particles. The mass percentage of the silica particles in the composite resin is 20% to 30%, and the particle size is 10 to 20 nm. The obtained high-pressure decorative board forms a protective film with high pollution resistance, fingerprint staining resistance and graffiti resistance, and has strong anti-adhesion property; can effectively block the damage of the decorative layer by ultraviolet rays and oxygen, acid corrosive gas, water vapor, and the like, and can keep the good stability of the decorative effect of the decorative board for a long time. Therefore, the decorative board can be better used for exterior wall decoration, beach tables and chairs, outdoor furniture decoration, and the like, can better protect the decorative objects from damage, which greatly expands the decorative board.

Owner:河南永威复合新材料有限公司

Special automobile exterior trim part material added with waste mask melt-blown material

The invention discloses a special automobile exterior trim part material added with a waste mask melt-blown material. The special automobile exterior trim part material is prepared from the followingraw materials in parts by weight: 80-100 parts of PC resin, 50-60 parts of waste mask reclaimed material, 10-20 parts of flame-retardant filler, 10-15 parts of modified montmorillonite, 5-10 parts ofbasalt fiber, 1-5 parts of flexibilizer, 1-3 parts of light stabilizer and 1-3 parts of coupling agent. The flame-retardant filler is added to endow the composite material with excellent flame retardancy and heat resistance, the modified montmorillonite and the flexibilizer endow the composite material with excellent toughness and impact resistance in inorganic and organic aspects, and the titanium dioxide can scatter and absorb ultraviolet rays, thereby enhancing the aging resistance of the composite material. The melt-blown material in waste masks is utilized to implement secondary high-efficiency utilization of the waste and reduce pollution, so that the special material for the automobile exterior trim part has the characteristics of impact resistance, high-temperature resistance, flame retardancy, low cost, environment friendliness, health and the like.

Owner:ANHUI GUANHONG PLASTIC IND

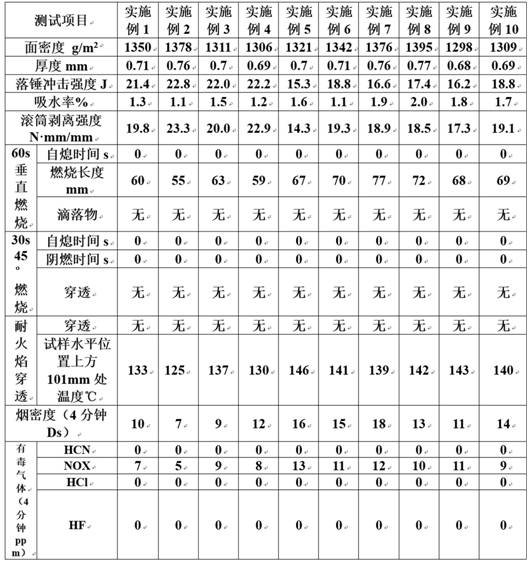

A kind of impact-resistant, flame-retardant liner and its preparation method

ActiveCN113635630BImpact resistance hasImprove flame retardant performanceLamination ancillary operationsLaminationFiberPolymer science

Owner:北京玻钢院复合材料有限公司

A kind of preparation method of composite tungsten-based tubular electrode hard surface material

ActiveCN105033509BImprove wear resistanceImpact resistance hasWelding/cutting media/materialsSoldering mediaManganeseSingle crystal

The invention discloses a preparation method of a compound tungsten-base tubular welding rod hard-face material. The preparation method of the compound tungsten-base tubular welding rod hard-face material is characterized in that the raw materials comprise, by weight, 50-65 parts of cemented carbide pellets, 10-12 parts of spheroidal tungsten carbide, 10-30 parts of casting granular tungsten carbide, 6-8 parts of single crystal granular tungsten carbide, 1-2 parts of silicon nitride ceramic particles, 2.5-4.5 parts of silicon-manganese powder and 0.5 part of phenolic resin; the method comprises the steps that the raw materials of the cemented carbide pellets, the spheroidal tungsten carbide, the casting granular tungsten carbide, the single crystal granular tungsten carbide, the silicon nitride ceramic particles and the silicon-manganese powder are mixed for 1-4 h in a mixing machine according to the proportions, and a mixture is obtained; after the mixture obtained in the first step is discharged, the phenolic resin is added in the mixture according to the proportion for even stirring and drying in a drying box, the mixture is maintained for 3 h at 100 DEG C, the mixture is maintained for 3 h at 150 DEG C, and the finished product tubular welding rod hard-face material is obtained after the processed product is taken out of the drying box. The preparation method of the compound tungsten-base tubular welding rod hard-face material is mainly used for preparing the compound tungsten-base tubular welding rod hard-face material.

Owner:株洲金韦硬质合金有限公司

A kind of preparation method of impact-resistant film for automatic access control

ActiveCN108928090BGood dispersionHigh impact strengthLamination ancillary operationsLaminationPolyurethane adhesiveCarbon nanotube

Owner:安徽菲勒自动门制造有限公司

Shock resisting material for grinding machine

The invention discloses a shock resisting material for a grinding machine. The shock resisting material for the grinding machine is prepared from, by weight, 80-87 parts of iron, 40-45 parts of chromium, 23-28 parts of aluminum, 11-14 parts of manganese, 8-12 parts of vanadium, 6-10 parts of tantalum, 13-17 parts of boron and 15-19 parts of silicon. The shock resisting material is prepared from iron, chromium, aluminum, manganese, vanadium, tantalum, boron and silicon, and has the beneficial effects of being high in hardness and strength, resistant to abrasion and shocks and long in service life.

Owner:SUZHOU CITY XIANGCHENG DISTRICT MINGDA COMPOSITE MATERIAL FACTORY

High elasticity and high strength steel and its producing method

An impact-resistant, wear-resistant high-elasticity, high-strength steel, wherein the steel contains 0.26-0.48 wt % C, 1.4-2.5 wt % Si, 0.5-1.0 wt % Mn, 1.4-2.4 wt % % Cr, 0.01-0.1 wt % Ni, 0.01-0.5 wt % Mo, 0.005-0.04 wt % Al, 0.05-0.1 wt % V, 0.0025-0.02 wt % N, remaining Fe and unavoidable of impurities. The impact-resistant and wear-resistant high-elasticity and high-strength steel of the present invention has high hardness, high strength, high toughness and high elasticity, and the steel has weldability, low temperature tempering resistance, high temperature tempering resistance, hardening energy, Mechanical properties such as abrasion resistance, impact toughness and tensile strength are very good, so model life and component life are much longer than previous steels when used under severe conditions.

Owner:CF +2

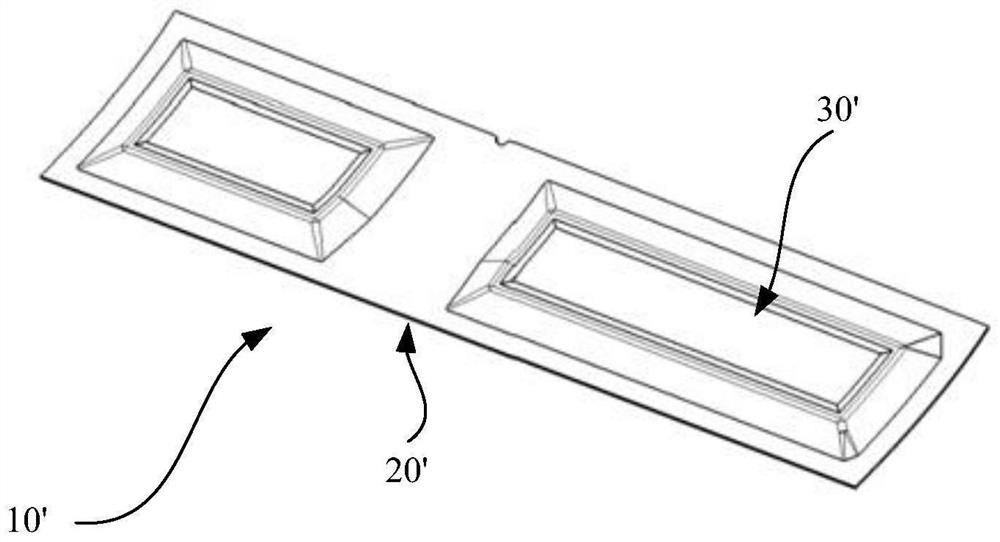

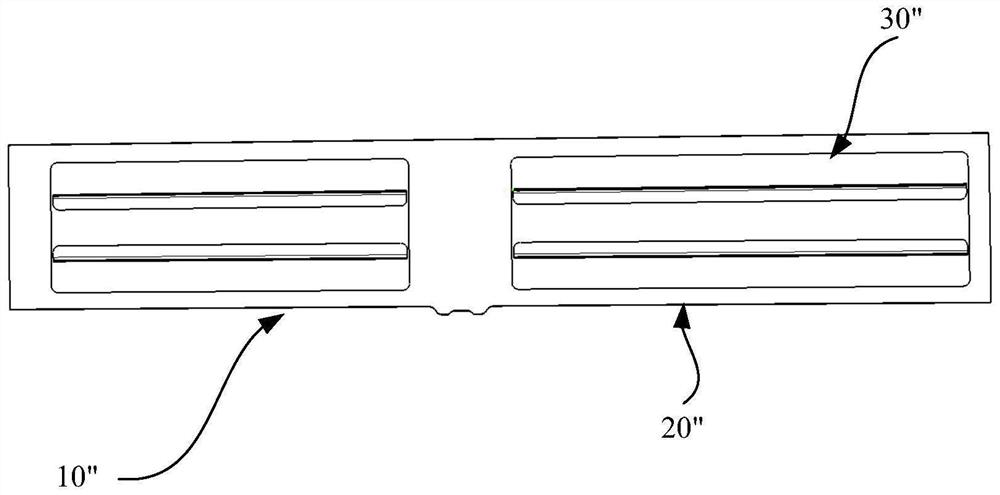

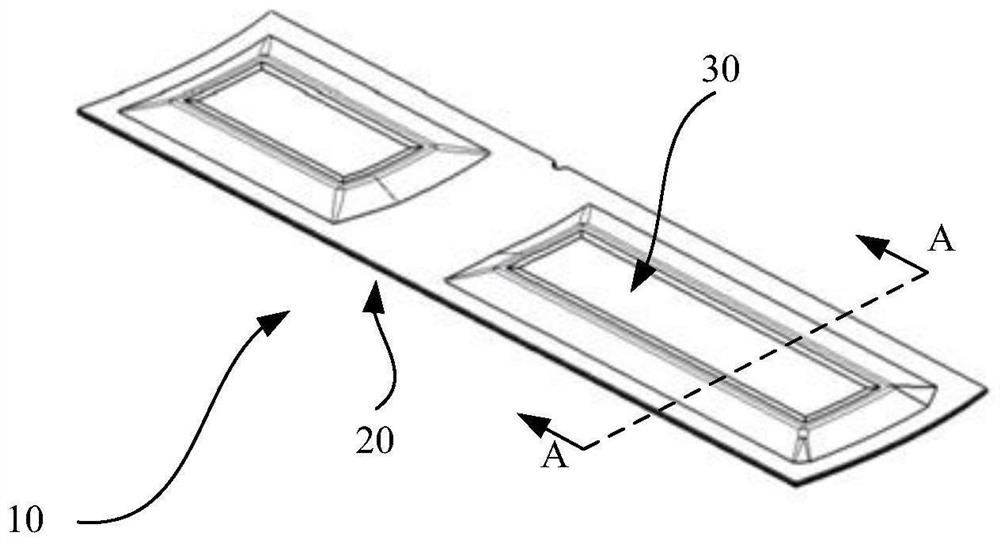

Aircraft arresting bed arresting unit top cover and preparation method thereof

ActiveCN106751348BHigh strengthImprove flame retardant performanceArresting gearDispersityBenzoyl peroxide

The invention provides an airplane blocking bed blocking unit top cover and a preparation method thereof, and aims to provide the airplane blocking bed blocking unit top cover which is stable in mechanical strength, low in dispersity, high in weather resistance, and high in flame retardant property. Through the technical scheme, dicyclopentadiene type unsaturated polyester resin is adopted as matrix resin, a polybutadiene-styrene copolymer is adopted as a low shrinkage agent, benzopinacole silicon alkyl ether is respectively or commonly used with benzoyl peroxide tert-butyl ester, peroxide-2-ethylhexoic acid tert-butyl ester to form an initiator, an unsaturated polyester glass fiber modeling piece SMC prepared from an ultraviolet absorbent is added, then the SMC resin paste is used for steeping and rolling an upper resin paste film layer, a middle chopped glass fiber layer and a lower resin paste film layer through a coating machine, and the SMC material containing 8 to 12 parts by weight of chopped glass fiber is prepared through curing; and then the product is molded through compression and cooled to room temperature in a laminated top cover mold with required thickness.

Owner:周志亮

A steering knuckle for a cast-forged combined anti-torsion and impact-resistant vehicle and its manufacturing method

ActiveCN110202108BHigh densityHigh strengthSteering linkagesEngine componentsUltimate tensile strengthImpact

Owner:湖北洪伯车辆有限公司

Skin structure for wing, aircraft having skin structure and method for mounting skin structure

PendingCN114056544AGuaranteed structural strengthGuaranteed StrengthWingsMetal layered productsThermal breakThermal insulation

The present invention relates to a skin structure for a wing, the skin structure comprising: a skin forming a part of an aerodynamic configuration of the wing; and a skin body which is internally attached to the skin skin with respect to the wing and protrudes toward the interior of the wing, in which the skin skin includes an outer surface layer and a thermal insulation layer, the skin body is internally attached to the thermal insulation layer with respect to the wing, and the thermal insulation layer is internally attached to the outer surface layer with respect to the wing, wherein the thermal conductivity of the material of the insulating layer is lower than that of the material of the skin body, and wherein the hardness of the material of the outer skin layer is higher than that of the material of the insulating layer. The invention further relates to an aircraft with the skin structure and a method for mounting the skin structure.

Owner:COMAC +1

Impact-resistant zirconium-aluminum wear-resistant plate

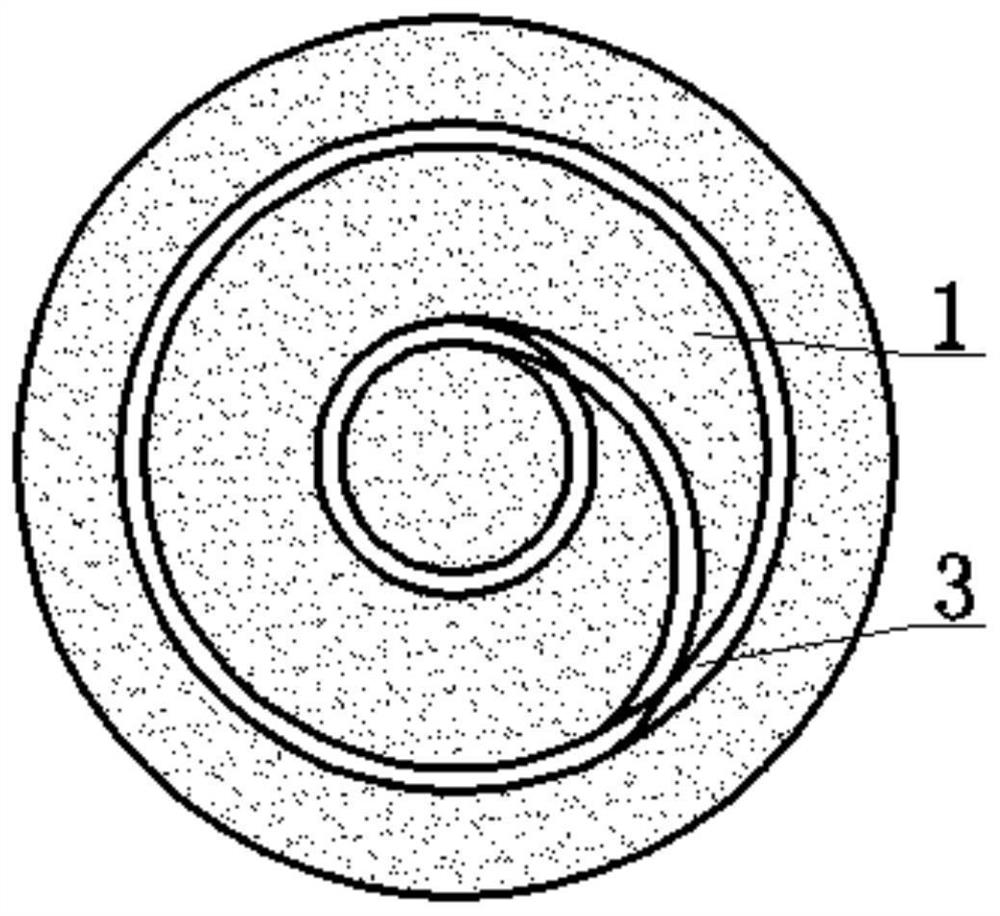

InactiveCN110978670ANot easily deformedReliable operationRubber layered productsMetal layered productsManufacturing lineManufacturing engineering

The invention discloses an impact-resistant zirconium-aluminum wear-resistant plate, which comprises an upper-layer zirconium-aluminum plate (1) capable of bearing material impact, a lower-layer connecting plate (3) used for being connected with a mounting surface, and a middle-layer buffer plate (2) located between the upper-layer zirconium-aluminum plate (1) and the lower-layer connecting plate(3). The upper-layer zirconium-aluminum plate (1), the middle-layer buffer plate (2) and the lower-layer connecting plate (3) are connected in a bonding mode. The impact-resistant zirconium-aluminum wear-resistant plate can be applied to key equipment and facilities of a coking area coke treatment system of an iron mill, can completely achieve baking and impacting of high-temperature coke, and iscorrosion-resistant, high-temperature-resistant, wear-resistant, not easy to deform, reliable in operation, long in service life, convenient to mount and low in maintenance operation intensity. A chute and the mounting surface of a buffer table are effectively protected, the production efficiency of a coke conveying line can be improved, the intensity of operators can be reduced, spare part resources can be saved, the use cost can be reduced, and powerful support can be provided for a coke oven production line.

Owner:攀钢集团西昌钢钒有限公司

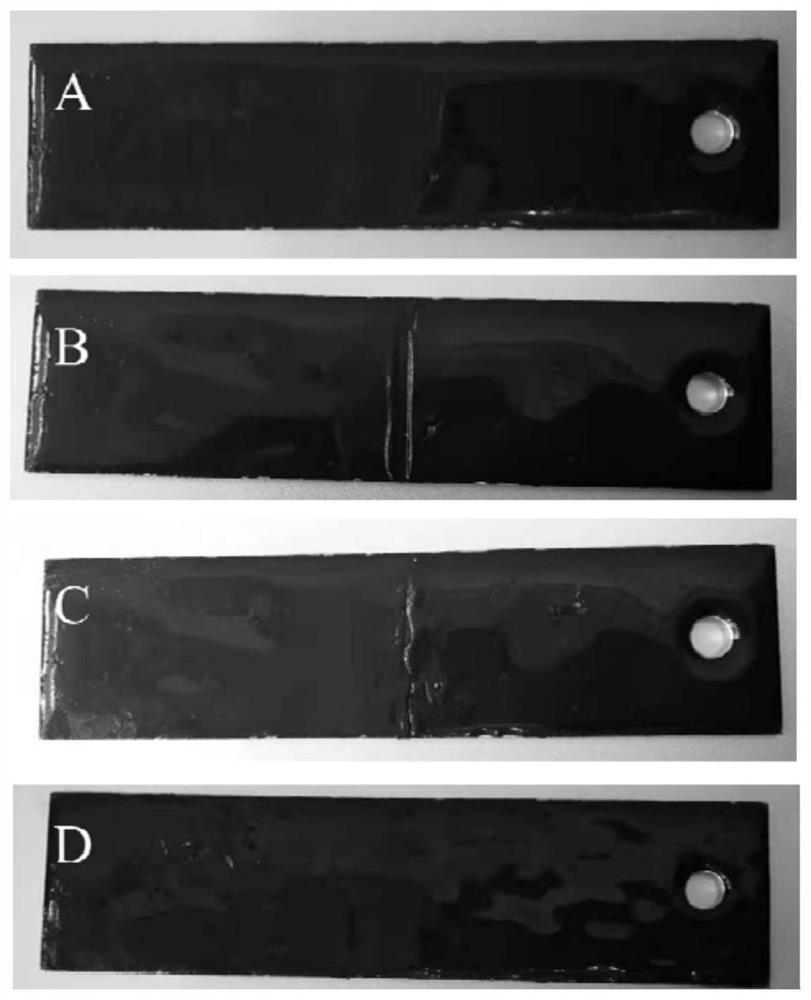

Lignin/polyether polyol impact-resistant and self-healing coating and preparation method thereof

ActiveCN112646495AAdjustable impact resistanceAdjustable compound performancePolyether coatingsLignin material coatingsPolymer sciencePolyol

The invention belongs to the technical field of impact-resistant and self-healing coating materials, and particularly relates to a lignin / polyether polyol impact-resistant and self-healing coating and a preparation method thereof. The method comprises the steps: taking industrial lignin as a raw material, and obtaining purified lignin with high purity and a specific molecular weight range through purification and molecular weight grading; mixing part of purified lignin with high purity and the specific molecular weight range with styrene, and carrying out micro-nanocrystallization to obtain lignin-styrene micro-nano particles; and blending the rest purified lignin with high purity and the specific molecular weight range, lignin-styrene micro-nano particles and polyether polyol in the presence or absence of a solvent to obtain the lignin / polyether polyol impact-resistant self-healing coating. The coating has good adhesion performance and functions of impact resistance, self-healing and the like, the preparation process is simple, efficient, green and environmentally friendly, the raw materials are cheap and easy to obtain, and the green characteristic can be greatly improved.

Owner:SOUTH CHINA UNIV OF TECH

Composite material for interior decoration of automobiles and manufacturing method thereof

ActiveCN100354123CLow investment costLow costLamination ancillary operationsLaminationSurface layerIn vehicle

The invention relates to a composite material used in vehicle inner decoration and relative producing method. Said composite material is formed by five or six non-woven sheets as surface layer, de-molding layer, filled layer, de-molding layer and base material layer. Wherein, the filled layer can be formed by hot-melt felt (3a) and polypropylene felt (3b). The producing method comprises that using the de-molding layer (4) as lower layer, the filled layer (3) as intermediate layer and the de-molding layer (2) as upper layer to be piled and arranged between the upper and lower heating plates of heat device; adhering said three layers after low-pressure high-temperature heating into the frame of soft-sandwich type; moving said frame into the lower mould of molding mould and above the base material layer (5); coating the surface layer (1) on the frame; closing the mould to be pressurized and shaped; cutting the hole and edge; and lifting upper mould to attain the final product. The invention has the advantages of lower cost, un-deformed product, high strength, impact resistance, welding availability, short producing process and high efficiency.

Owner:上海汽车地毯总厂有限公司

Impact-resistant steel ball for ball mill

InactiveCN104120365BImpact resistance hasImprove performanceFurnace typesHeat treatment furnacesTemperingSteel ball

The invention discloses an impact-resistant steel ball for a ball mill. The weight percentages of the components are as follows: C: 0.6%-0.8%; Si: 0.2%-0.3%; Cr: 1.5%-2.3%; Mn: 0.6% ‑0.8%; Ni: 0.2%‑0.3%; Ti: 0.04%‑0.06%; Al: 0.6%‑1.2%; W: 0.05%‑0.1%; Mo: 0.15%‑0.25%; S: 0‑0.02% ; P: 0‑0.06%; the remaining material is Fe; in the preparation process, the impact-resistant steel balls for the ball mill are prepared according to the following process steps: S1: Weigh the raw materials according to the weight percentage of each component and smelt them. Refining in , and final deoxidation in the later stage of refining, pouring, casting and cleaning, to obtain castings; S2: The castings obtained in S1 are kept at 850-870°C for 2.5-3.5 hours, then water quenched, quenched The final casting is heated to 240-260°C for tempering treatment, and after 1-2 hours of heat preservation, it is moved into a slow cooling pit and slowly cooled to room temperature to obtain a finished wear-resistant steel ball.

Owner:NINGGUO SOUTHERN WEAR RESISTANT MATERIALS

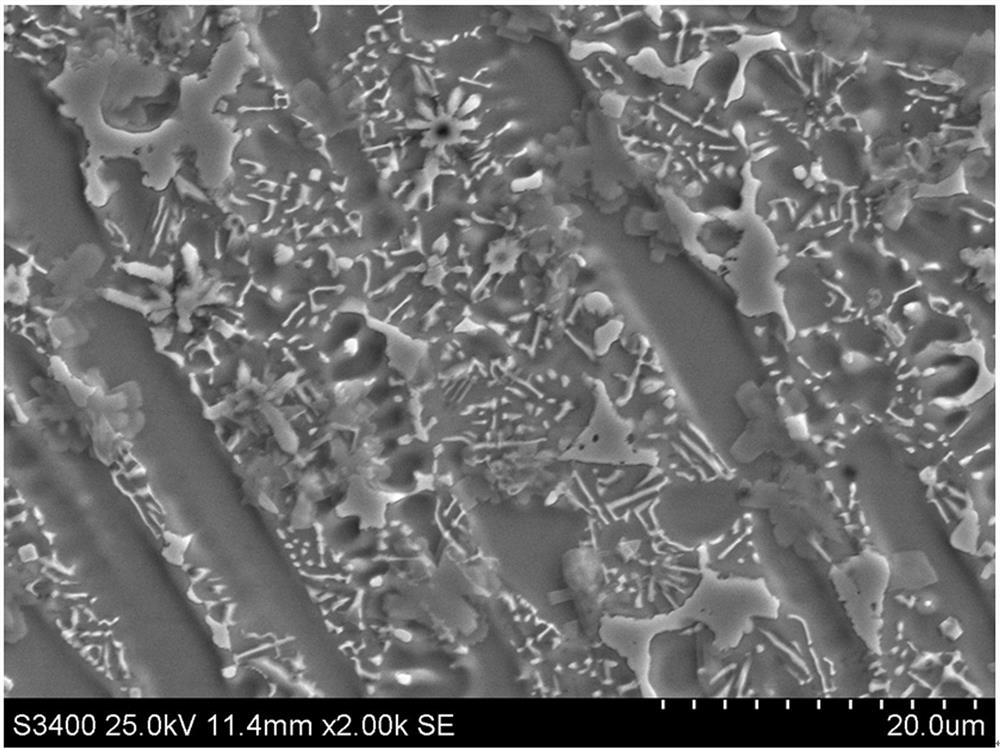

A shock-resistant and wear-resistant material for laser manufacturing

ActiveCN109576604BImpact resistance hasCorrosion resistanceMetallic material coating processesLaser fabricationCorrosion resistant

The invention provides an impact-resistant and wear-resistant material for laser manufacturing, which is composed of the following components in mass percentage: C: 2.9-3.8%, Cr: 15-23%, Si: 1.00-1.30%, Ni: 0.2-0.95 %, Mn: 0.9-1.5%, W: 2-5.5%, V: 14-21%, B: 0.8-1.8%, Nb: 5.50-10%, Y: 0.8-2.3%, the balance is Fe and not Avoid impurities. The impact-resistant and wear-resistant iron-based alloy powder for laser cladding provided by the invention has the properties of impact resistance, corrosion resistance and wear resistance, and can be used for laser manufacturing of large and medium-sized parts in complex working conditions such as large crushers. The composite wear-resistant parts prepared by laser can meet the needs of complex working conditions on the comprehensive mechanical properties of the work surface. At the same time, the matrix can be made of low-cost common materials, and the used matrix can be reused by laser manufacturing; this paper The invention can not only provide the utilization rate of the overall material of the parts, but also can improve the service life of a single time, reduce maintenance and overhaul time, increase resource utilization rate, and reduce manpower loss.

Owner:沈阳大陆激光工程技术有限公司

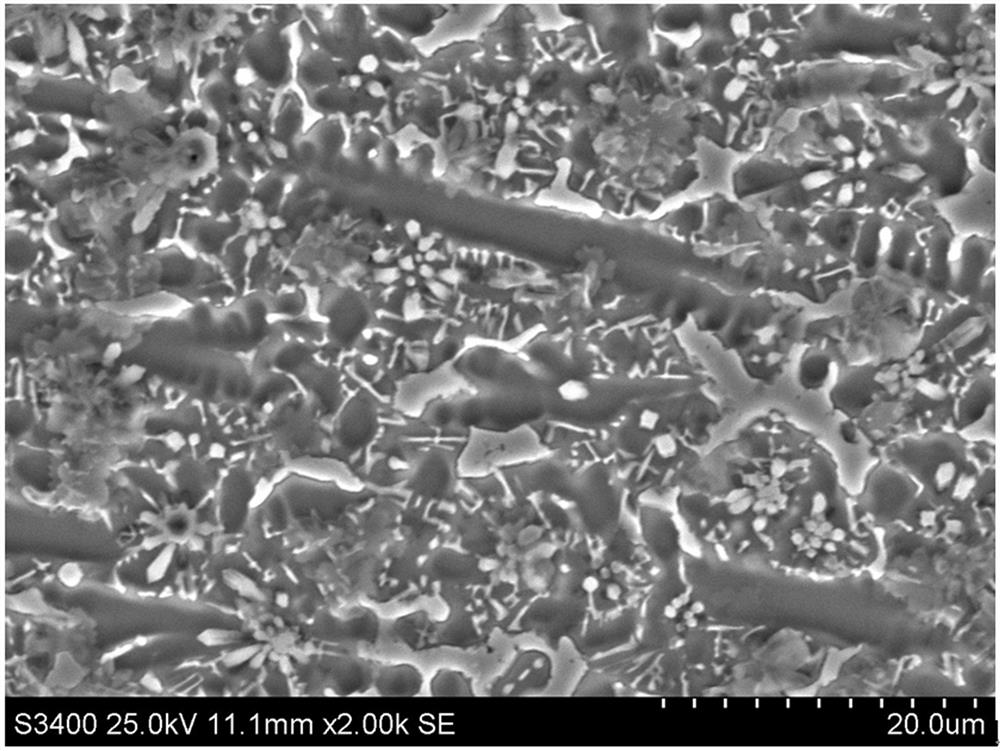

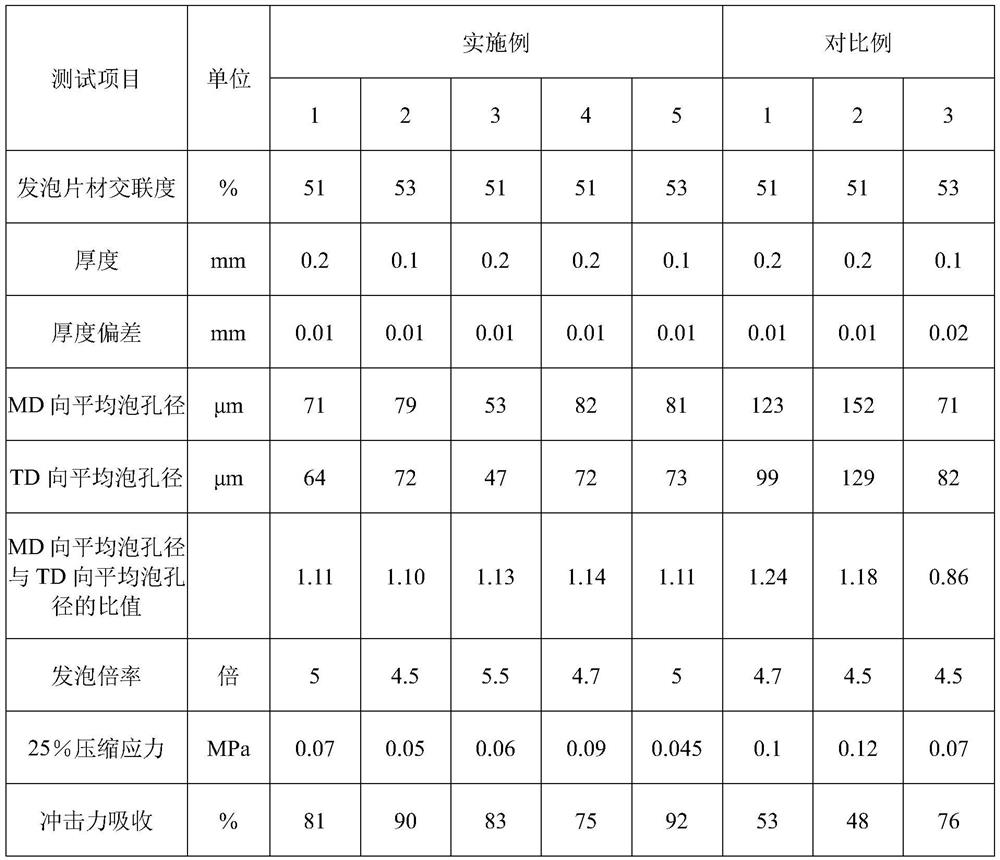

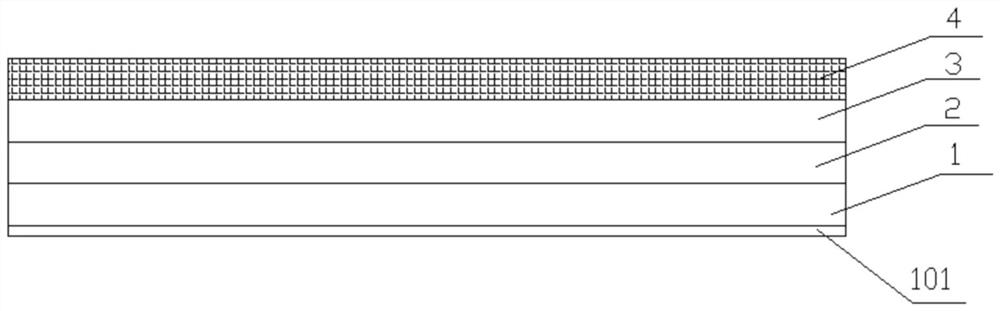

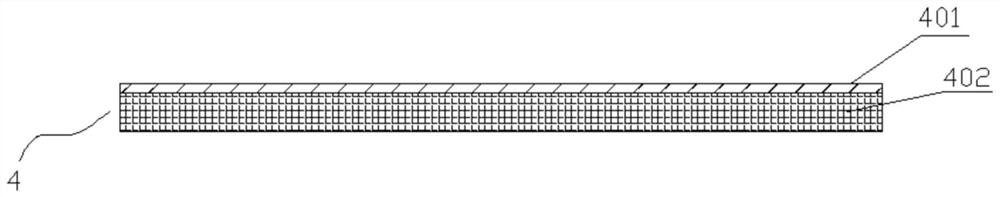

Impact-resistant ultra-thin polyolefin foaming sheet as well as preparation method and application thereof

PendingCN112778565AImpact resistance hasImprove waterproof performanceFilm/foil adhesivesClimate change adaptationThin membraneFilm material

The invention discloses an impact-resistant ultra-thin polyolefin foaming sheet, which is characterized in that the polyolefin foaming sheet is formed by foaming polyolefin resin, and has an independent cellular structure; fumed silica modified foaming agent particles are used in the foaming process, and the particle size of the modified foaming agent particles is less than 10 microns; the cross-linking degree of the foaming sheet ranges from 30% to 60%, the thickness ranges from 0.03 mm to 0.5 mm, the average foam pore size of the foaming sheet in each direction ranges from 20 micrometers to 100 micrometers, the ratio of the average foam pore size in the MD direction to the foam pore size in the TD direction ranges from 0.8 to 1.2, the foaming ratio ranges from 1.5 times to 6 times, the 25% compression stress is less than or equal to 0.1 MPa, and the impact force absorption is greater than or equal to 60%. The invention further provides a preparation method and application of the impact-resistant ultra-thin polyolefin foaming sheet, the process is simple, the impact-resistant ultra-thin polyolefin foaming sheet is suitable for industrial mass production, and the prepared foaming sheet has the advantages of impact resistance, good waterproofness, softer, lighter and thinner than a common thin film material and the like, and is suitable for being used as a sealing buffer material or an adhesive tape base material of an electronic product.

Owner:广德祥源新材科技有限公司

A kind of non-staining and finger marks-free high-pressure decorative board and preparation method thereof

ActiveCN109532180BPollution resistantPollution resistance reachesLamination ancillary operationsLaminationSilica particlePolymer science

The invention discloses a non-staining non-finger mark high-pressure decorative board and a preparation method thereof. The high-pressure decorative board is formed by a balance layer, a substrate layer, an adhesive layer and a non-staining non-finger mark decorative layer through high-temperature and high-pressure moulding. The non-staining non-finger mark decorative layer is a resin-coated decorative paper, the decorative paper is coated with the fluoroalkylsilane resin composite resin with addition of silica particles. The mass percentage of the silica particles in the composite resin is 20% to 30%, and the particle size is 10 to 20 nm. The obtained high-pressure decorative board forms a protective film with high pollution resistance, fingerprint staining resistance and graffiti resistance, and has strong anti-adhesion property; can effectively block the damage of the decorative layer by ultraviolet rays and oxygen, acid corrosive gas, water vapor, and the like, and can keep the good stability of the decorative effect of the decorative board for a long time. Therefore, the decorative board can be better used for exterior wall decoration, beach tables and chairs, outdoor furniture decoration, and the like, can better protect the decorative objects from damage, which greatly expands the decorative board.

Owner:河南永威复合新材料有限公司

An impact-resistant, high-strength ceramic for daily use

Owner:GUANGDONG YANHONG CERAMICS CO LTD

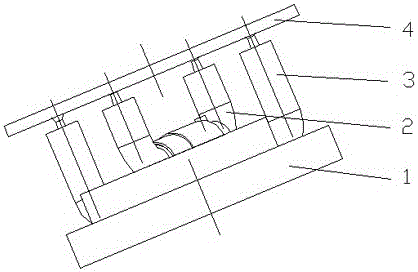

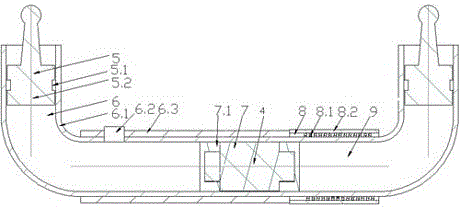

Flexible commutator for automobile rearview mirror

InactiveCN103600696BVibration resistance hasImprove flexibilityOptical viewingSpherical jointFloating platform

A flexible commutator for automobile rearview mirrors, the transmission mechanism of the first degree of freedom (2) and the transmission mechanism of the second degree of freedom (3) are fixed on the base (1) in a vertical manner through the space position, and the floating platform (4) The spherical joint pair of the top column (5.2) is connected with the first degree of freedom transmission mechanism (2) and the second degree of freedom transmission mechanism (3), and the characteristic is that the first degree of freedom transmission mechanism (2) and the second degree of freedom are respectively The top column assembly (5) in the degree of freedom transmission mechanism (3) is placed at both ends of the pipeline assembly (6) through the moving pair, and the ferromagnetic core assembly (7) is placed inside the pipeline assembly (6) through the moving pair , the coil assembly (8) is fixed on the outer wall of the pipe (6.1), the first magnetic field shielding layer (6.3) and the second magnetic field shielding layer (8.2) are fixed on the outside of the pipe (6.1) and the coil (8.1), the fluid (9) Located inside the pipeline (6.1).

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com