A shock-resistant and wear-resistant material for laser manufacturing

A technology of impact resistance, wear resistance and laser, which is applied in the coating process of metal materials, coatings, etc., can solve the problems of decreased impact resistance, deterioration of impact resistance, and affecting the service life of workpieces, so as to improve service life and reduce maintenance and maintenance time, the effect of reducing manpower loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

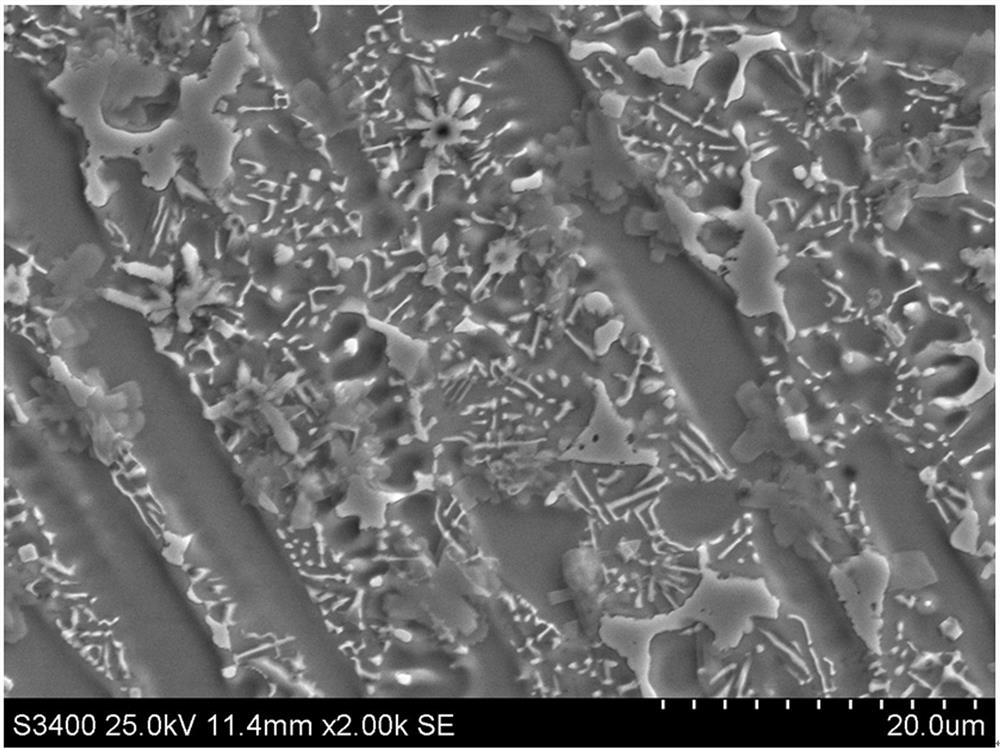

[0015] Use 6KW fiber laser to develop and design wear-reducing and heat-resisting iron-based alloy powder. The material composition ratio is as follows: by weight percentage, including C: 3.0%, Cr: 19%, Si: 1.00%, Ni: 0.55%, Mn: 1.3%, W: 2.4%,: V: 16.2%, B: 1.0%, Nb: 8%, Y: 0.9%, the balance is Fe and unavoidable impurities, and laser manufacturing is performed on the ball mill liner. Firstly, determine the base material of the trial sample block to be 35CrMo, and the size of the sample block is 100mm×100mm×20mm. Firstly, the surface of the sample is cleaned, and the oil is removed by cleaning with acetone; the impact-resistant and wear-resistant alloy powder is baked at 200°C for 1.5h Dry processing. Surface heating equipment is used to rapidly heat the workpiece surface to 200°C and laser equipment is heated synchronously. After the laser cladding conditions are met, the cladding process parameters are adopted: power 3800W, spot circle diameter 3.4mm, scanning speed 1100mm / m...

Embodiment 2

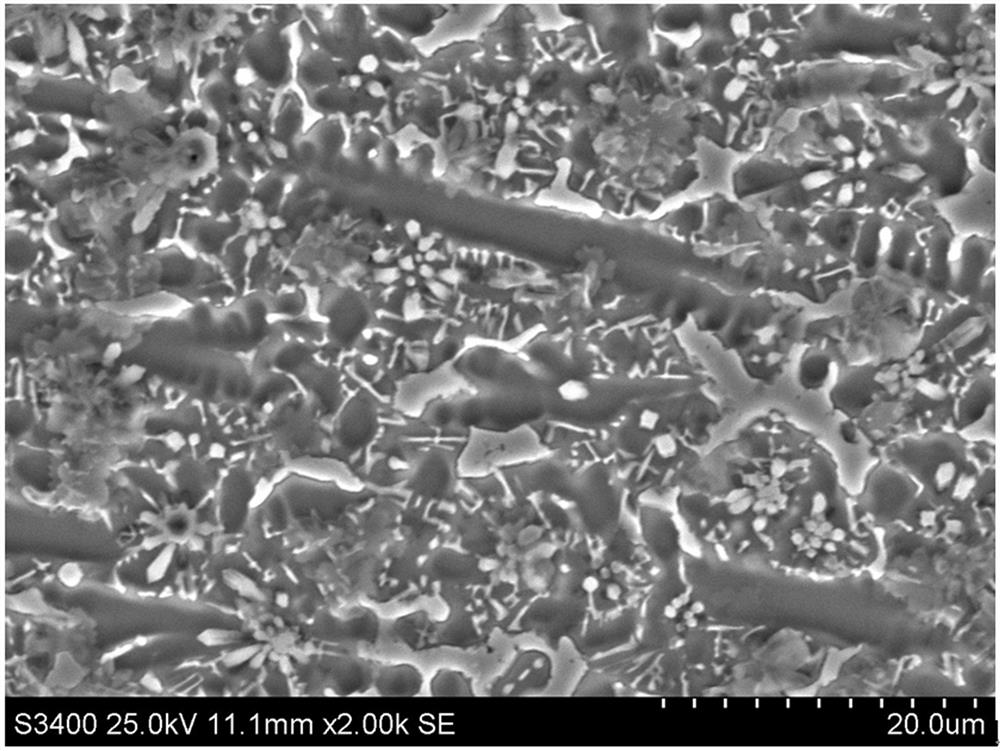

[0018] Using a 4KW solid-state laser, the wear-reducing and heat-resistant cobalt-based alloy powder is developed and designed. The material composition ratio is as follows: by weight percentage, C: 3.4%, Cr: 17%, Si: 1.20%, Ni: 0.8%, Mn: 0.95%, W: 3.5%, V: 19%, B: 1.3%, Nb: 8.20%, Y: 0.9%, and the balance is Fe and unavoidable impurities. Firstly, it is determined that the base material of the trial sample block is 45 steel, and the size of the sample block is 100mm×100mm×20mm. First, the surface of the sample is cleaned, and the oil is removed by cleaning with acetone; the impact-resistant and wear-resistant alloy powder is kept at 200°C for 1.5h Drying process. The surface heating equipment is used to inductively and rapidly heat the workpiece surface to 230°C and the laser equipment is heated synchronously. After the laser cladding conditions are met, the cladding process parameters are adopted: power 4000W, spot circle diameter 4.0mm, scanning speed 1000mm / min, lap rate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com