Flexible commutator for automobile rearview mirror

A technology of automobile rearview mirror and commutator, which is applied in vehicle parts, optical observation devices, transportation and packaging, etc., can solve the problem of mechanical rotating mechanism with poor vibration resistance, poor impact resistance, complex composition of hydraulic rotating mechanism, vibration resistance, vibration resistance, etc. Poor impact resistance and other problems, to achieve the effect of compact structure, low motion noise and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

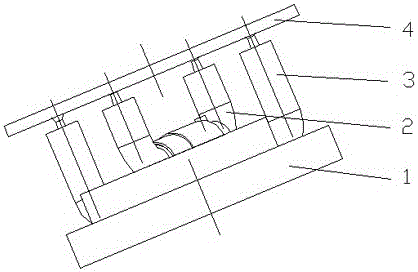

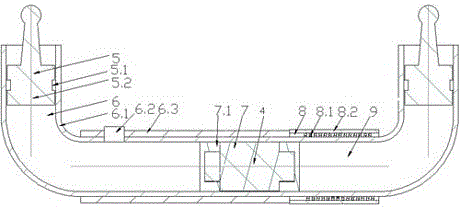

[0007] Such as figure 1 , figure 2 As shown, The present invention is a flexible commutator for automobile rearview mirrors. The first degree of freedom transmission mechanism 2 and the second degree of freedom transmission mechanism 3 are fixed on the base 1 through the vertical position of the space. The floating platform 4 passes through the top column 5.2 The ball joint is connected with the first degree of freedom transmission mechanism 2 and the second degree of freedom transmission mechanism 3, and the top column assembly 5 in the first degree of freedom transmission mechanism 2 and the second degree of freedom transmission mechanism 3 is placed by the moving pair At both ends of the pipeline assembly 6, the ferromagnetic core assembly 7 is placed inside the pipeline assembly 6 by a moving pair, the coil assembly 8 is fixed on the outer wall of the pipeline 6.1, and the first magnetic field shielding layer 6.3 and the second magnetic field shielding layer 8.2 are fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com