High-wearable extrusion roller of roller press and manufacture process thereof

A technology of extrusion rollers and roller presses, which is applied in the field of extrusion rollers of high wear-resistant roller presses, can solve the problems that the wear resistance cannot meet the requirements of use, and achieve improved equipment utilization, good impact resistance, and reduced replacement The effect of times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

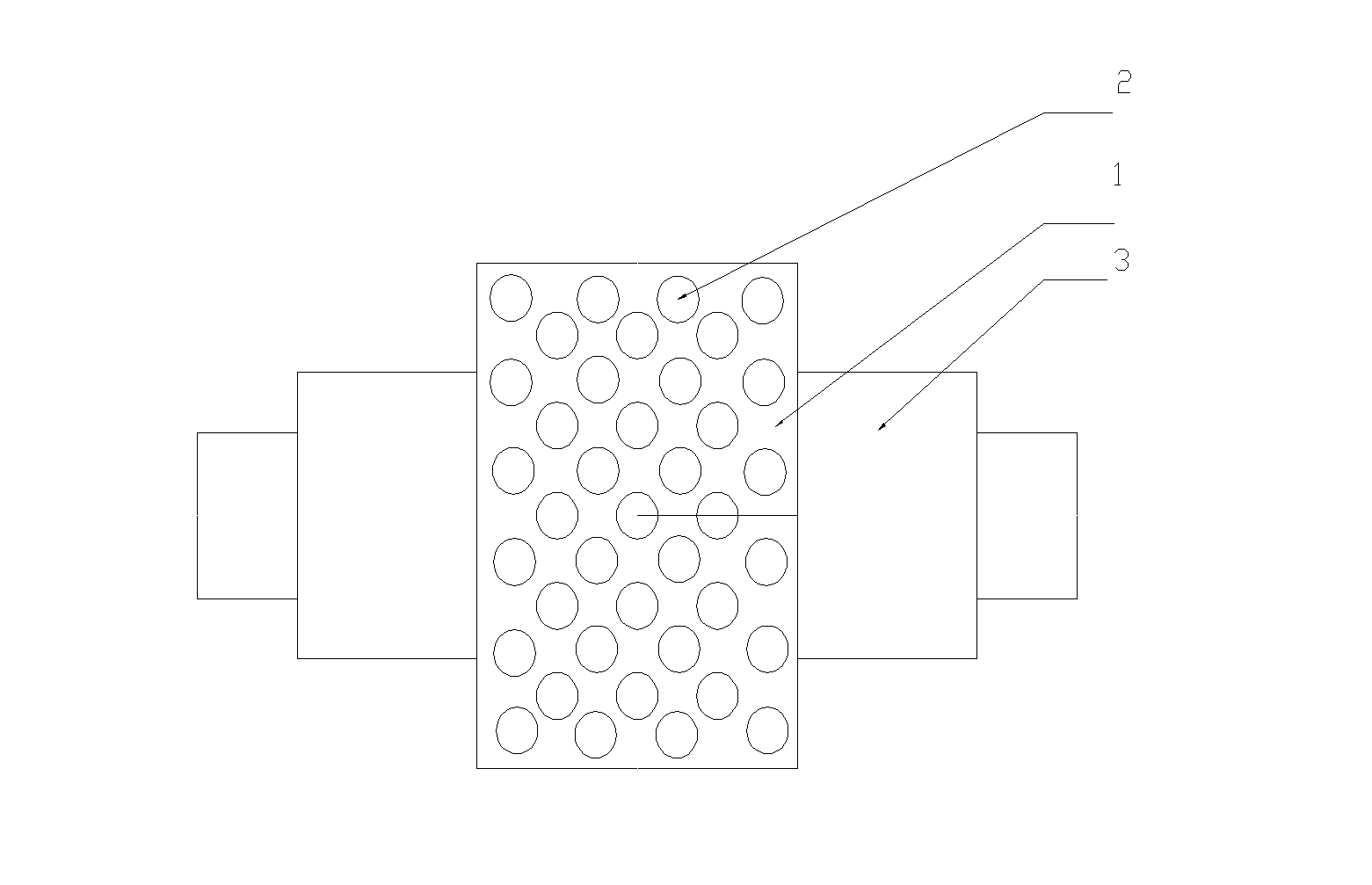

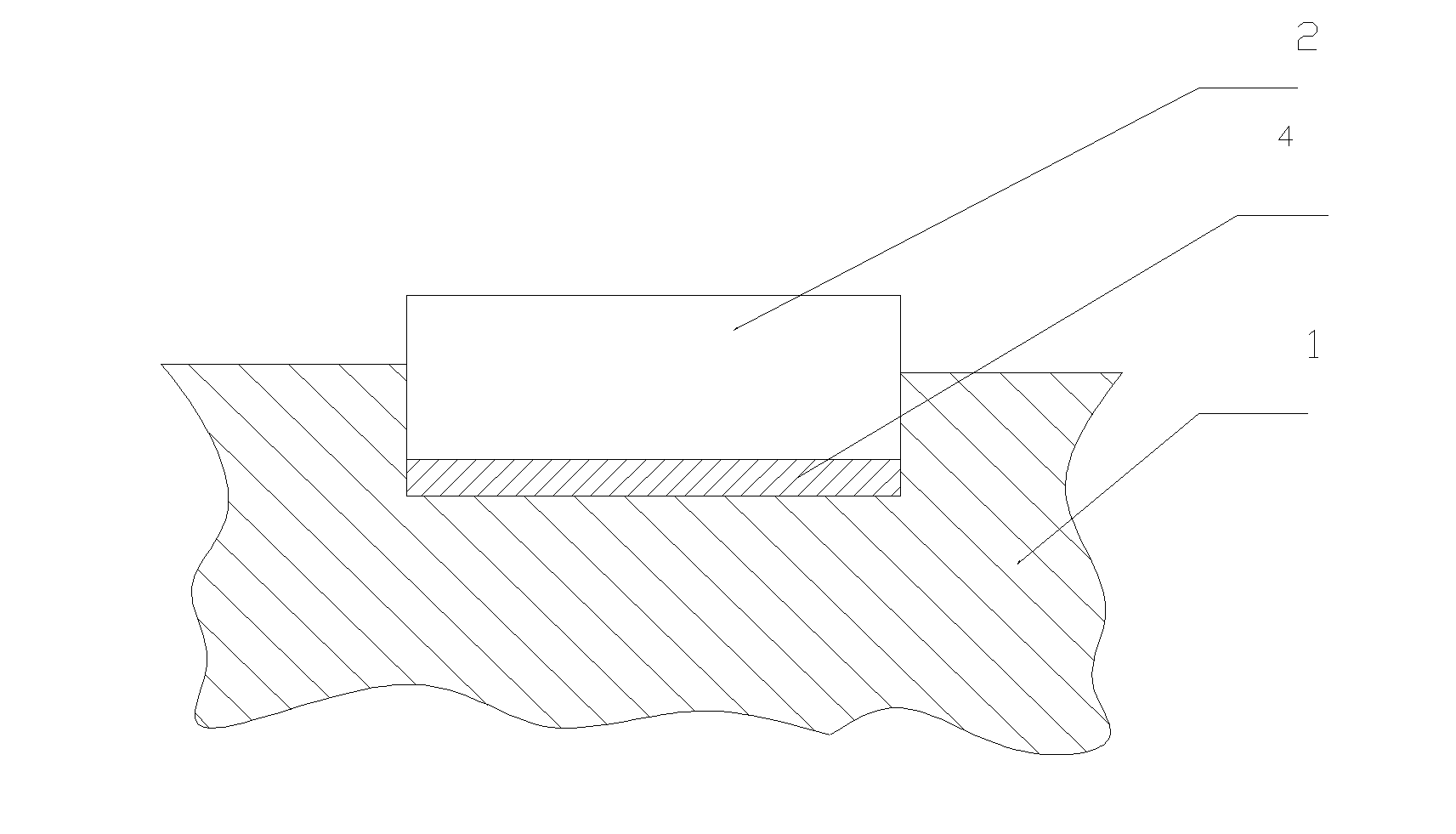

[0017] The pressure roller of the roller press machine has a diameter of 400mm and a length of 400mm. A circular groove is processed on the surface of the extrusion roller. The diameter of the groove is 8mm, the depth is 6mm, and the distance between the grooves is 3mm. The arrangement of circular slots is as follows figure 1 shown. Carbide is made of a round table with a diameter of 8mm and a height of 10mm. The cemented carbide composition is WC 66%; TiC 30%; Co 3.9%; Cr 0.1%. Place brazing solder in the circular groove of the extrusion roller, the brazing filler metal is a copper-based brazing filler metal and its composition is Cu85%; Mn15%. Put the cemented carbide cylinders into all the grooves of the extrusion roller respectively, and braze in the vacuum brazing furnace. After the brazing is completed, a layer of cemented carbide is welded on the surface of the extrusion roller.

Embodiment 2

[0019] The extrusion roller of the roller press has a diameter of 800 mm and a length of 600 mm. A circular groove is processed on the surface of the extrusion roller. The diameter of the groove is 18 mm; the depth of the groove is 10 mm, and the distance between the grooves is 4 mm. The arrangement of circular slots is as follows figure 1 shown. The cemented carbide is made of a round platform with a diameter of 18mm and a height of 12mm. The cemented carbide composition is WC 79%; TiC 15%; Co 5.8%; Cr 0.2%. Place brazing solder in the circular groove on the surface of the squeeze roller, the solder is copper-based solder, and its composition is Cu85%, Mn15%. Put the cemented carbide round tables into all the grooves of the extrusion roller respectively, and braze in the vacuum brazing furnace. After the brazing is completed, a layer of cemented carbide is welded on the surface of the extrusion roller.

Embodiment 3

[0021] The diameter of the pressing roller of the roller press is 800mm, and the length is 600mm. A circular groove is processed on the surface of the extrusion roller. The diameter of the groove is 25mm; the depth of the groove is 12mm, and the distance between the grooves is 6mm. The circular slots are arranged as shown in the figure. The cemented carbide is made of a round table with a diameter of 25mm and a height of 15mm. The cemented carbide composition is WC 92%; TiC 0%; Co 7.7%; Cr 0.3%. Place brazing solder in the circular groove of the extrusion roller, the solder is copper-based solder, and its composition is Cu85%; Mn15%. Put the cemented carbide round tables into all the grooves of the extrusion roller respectively, and braze in the vacuum brazing furnace. After the brazing is completed, a layer of cemented carbide is welded on the surface of the extrusion roller.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com