Patents

Literature

78results about How to "Not prone to plastic deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

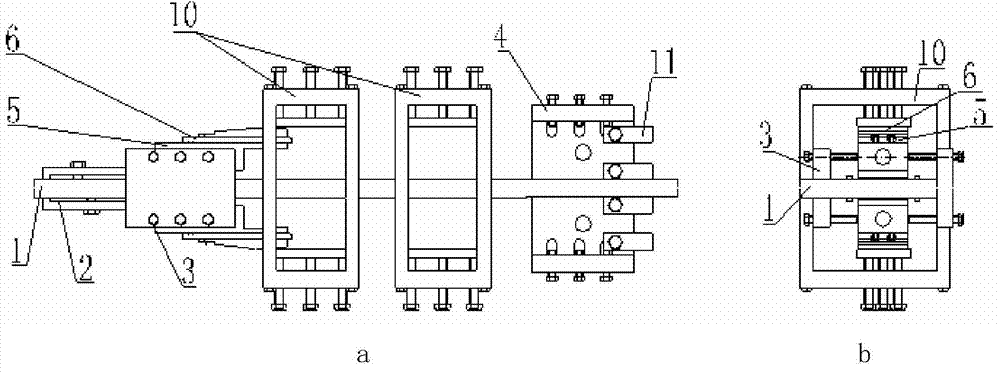

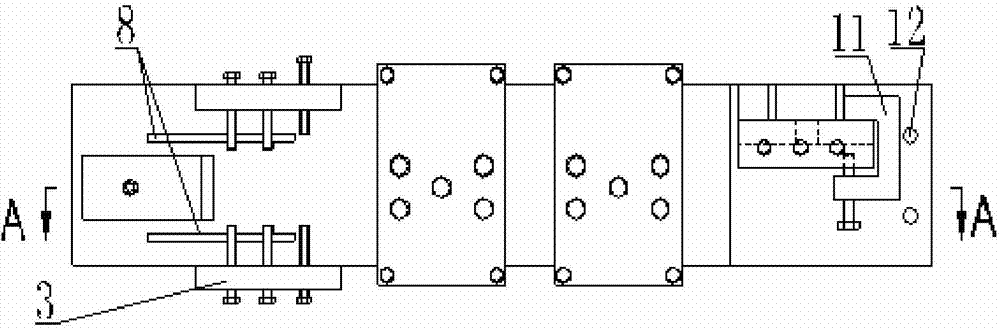

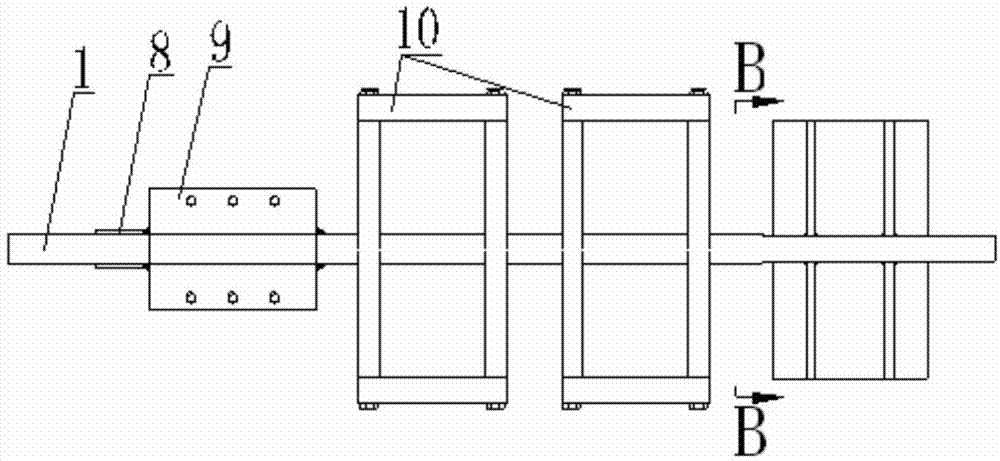

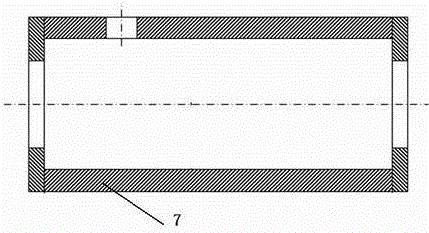

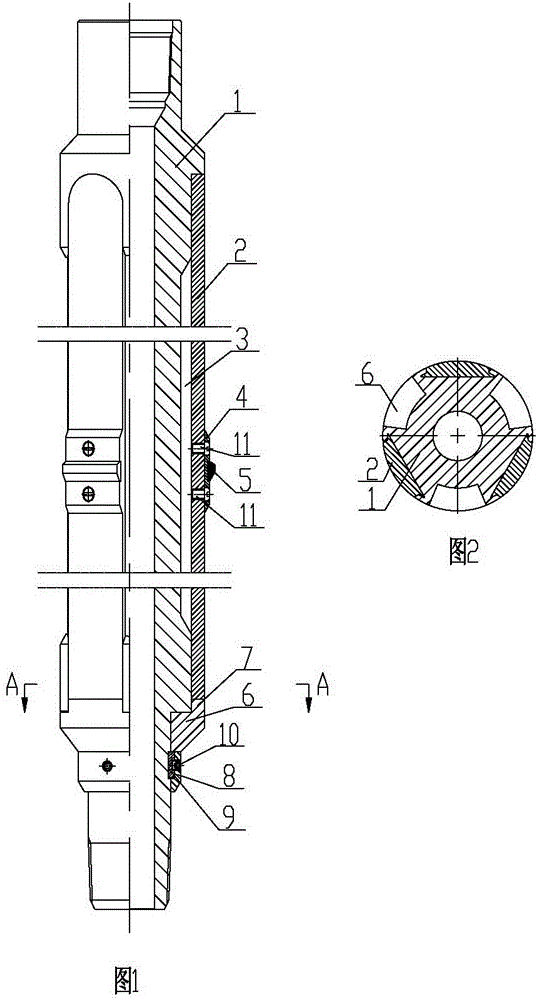

Device for heat shaping of thin-walled titanium alloy parts

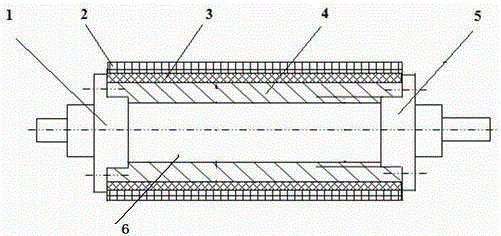

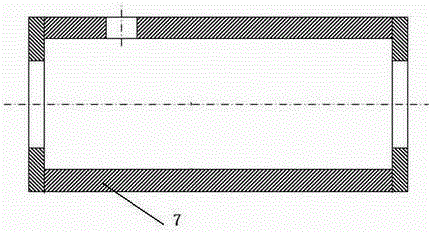

The invention relates to a device for heat shaping of thin-walled titanium alloy parts. A first pressing mechanism is fixed at one end of a body, and a second pressing mechanism is fixed at the other end of the body. Two clamping mechanisms are mounted in the middle of the body. Two clamping plates of a lateral ejection mechanism are fixed on two lateral surfaces of the body respectively and located between the first pressing mechanism and the clamping mechanisms. A width inner-supporting mechanism is located between the two clamping plates of the lateral ejection mechanism, one end of the width inner-supporting mechanism is mounted in a to-be-shaped part, and cavity inner-supporting mechanisms are mounted on the upper surface and the lower surface of the width inner-supporting mechanism. One ends of the cavity inner-supporting mechanisms are mounted in the clamping mechanisms, so that a support body with a wedge-shaped inner cavity is formed in the to-be-shaped part. By the device, utilization rate of a heat treatment furnace is increased, and cost of vacuum heat shaping is lowered. Since the to-be-shaped parts are clamped symmetrically, main stresses of a tooling are symmetric in direction and offset each other, stress state of the tooling is improved, and deformation resistance of the tooling is enhanced indirectly.

Owner:XIAN AEROSPACEMOTOR MACHINE FACTORY

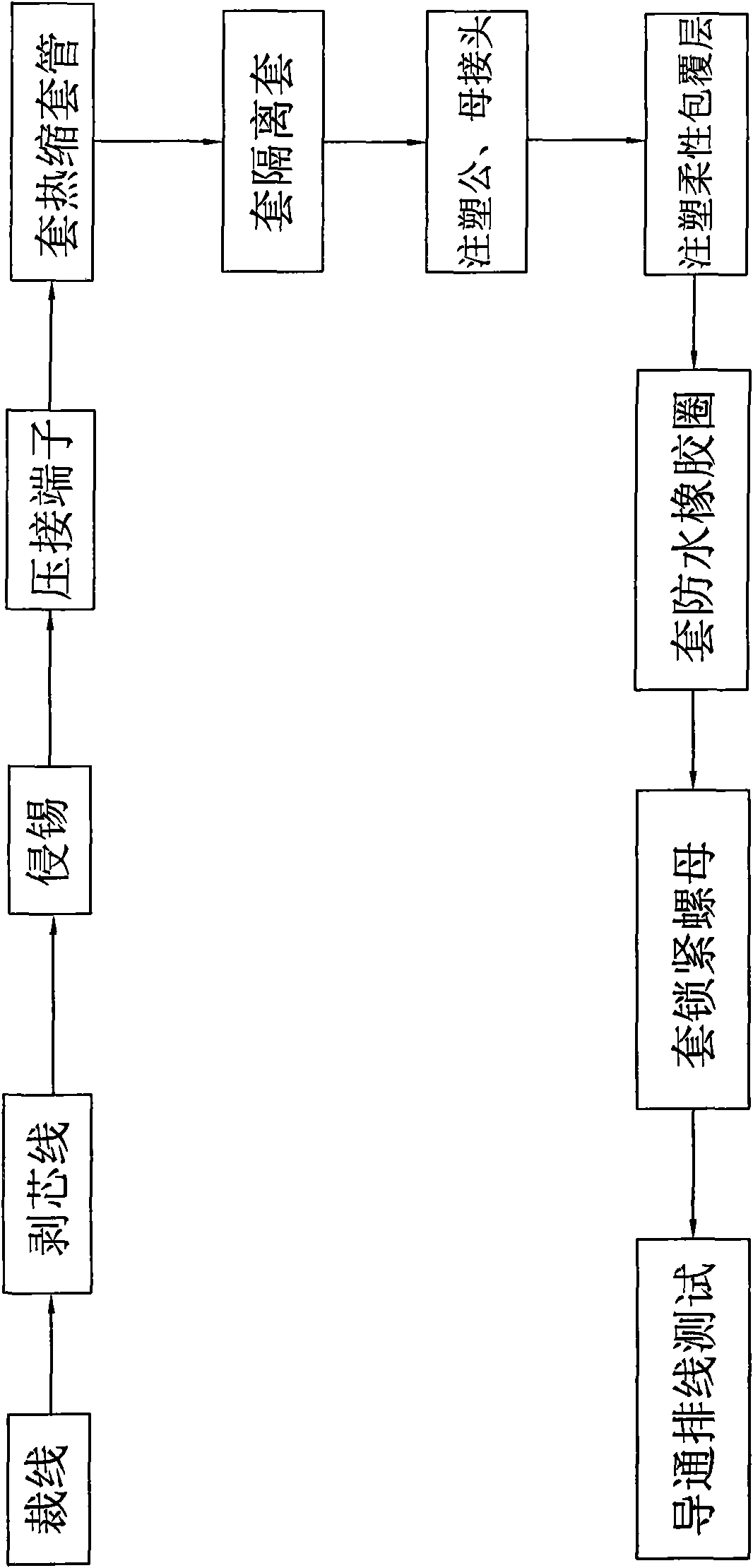

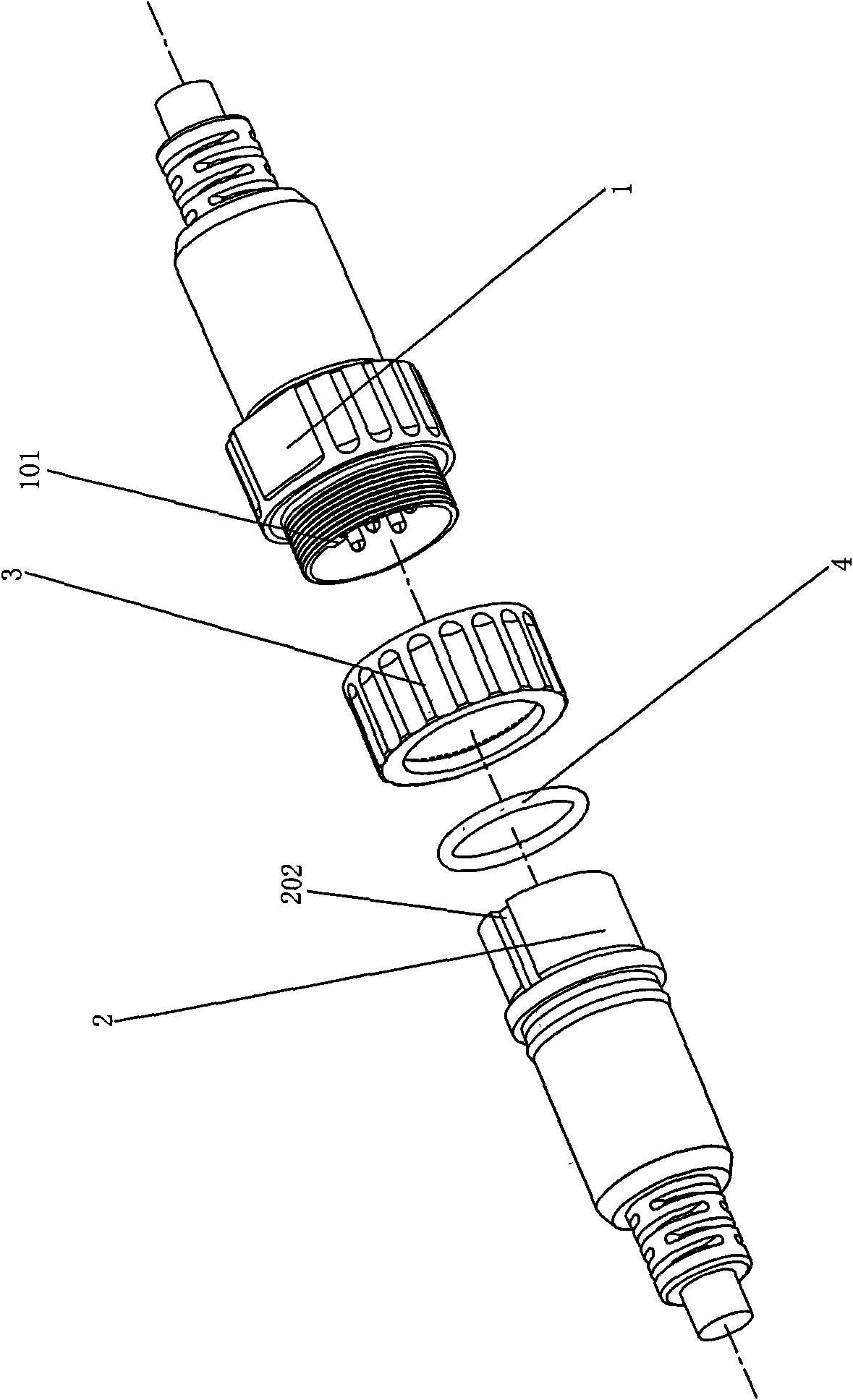

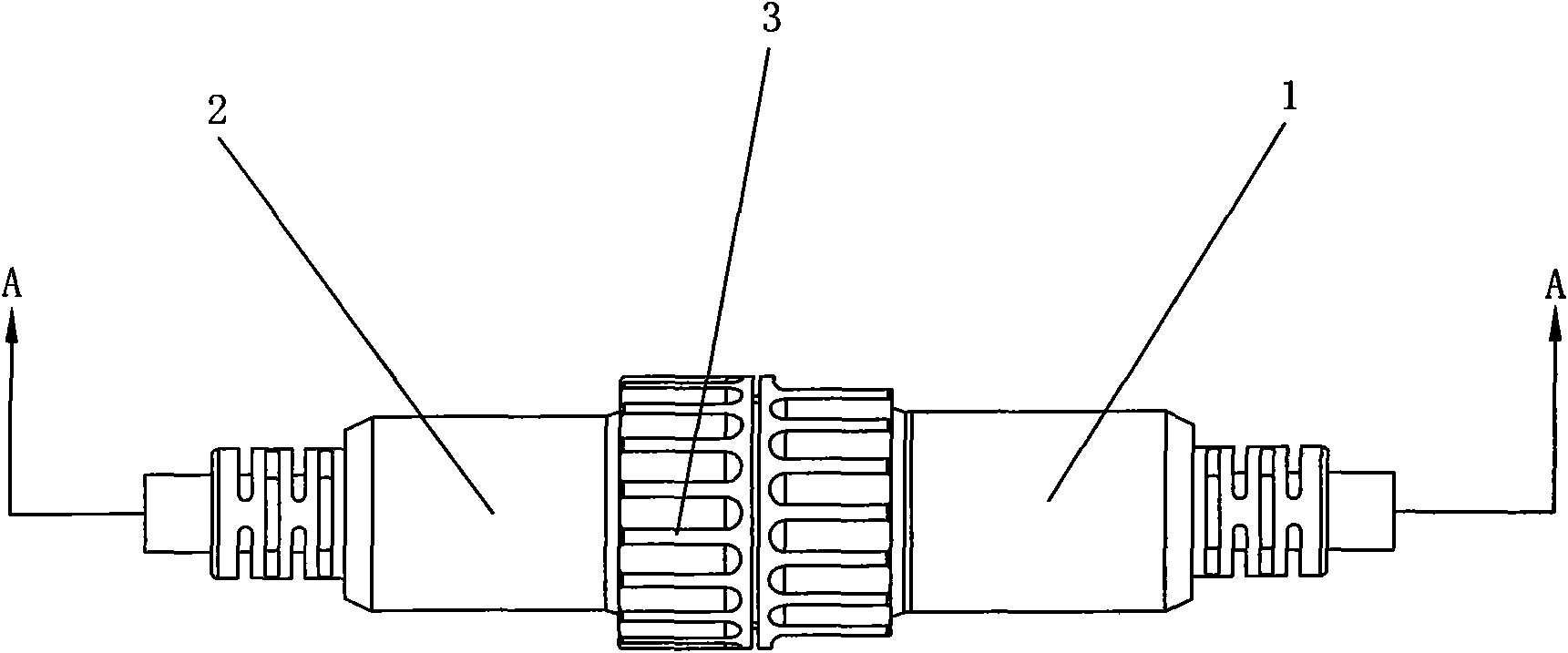

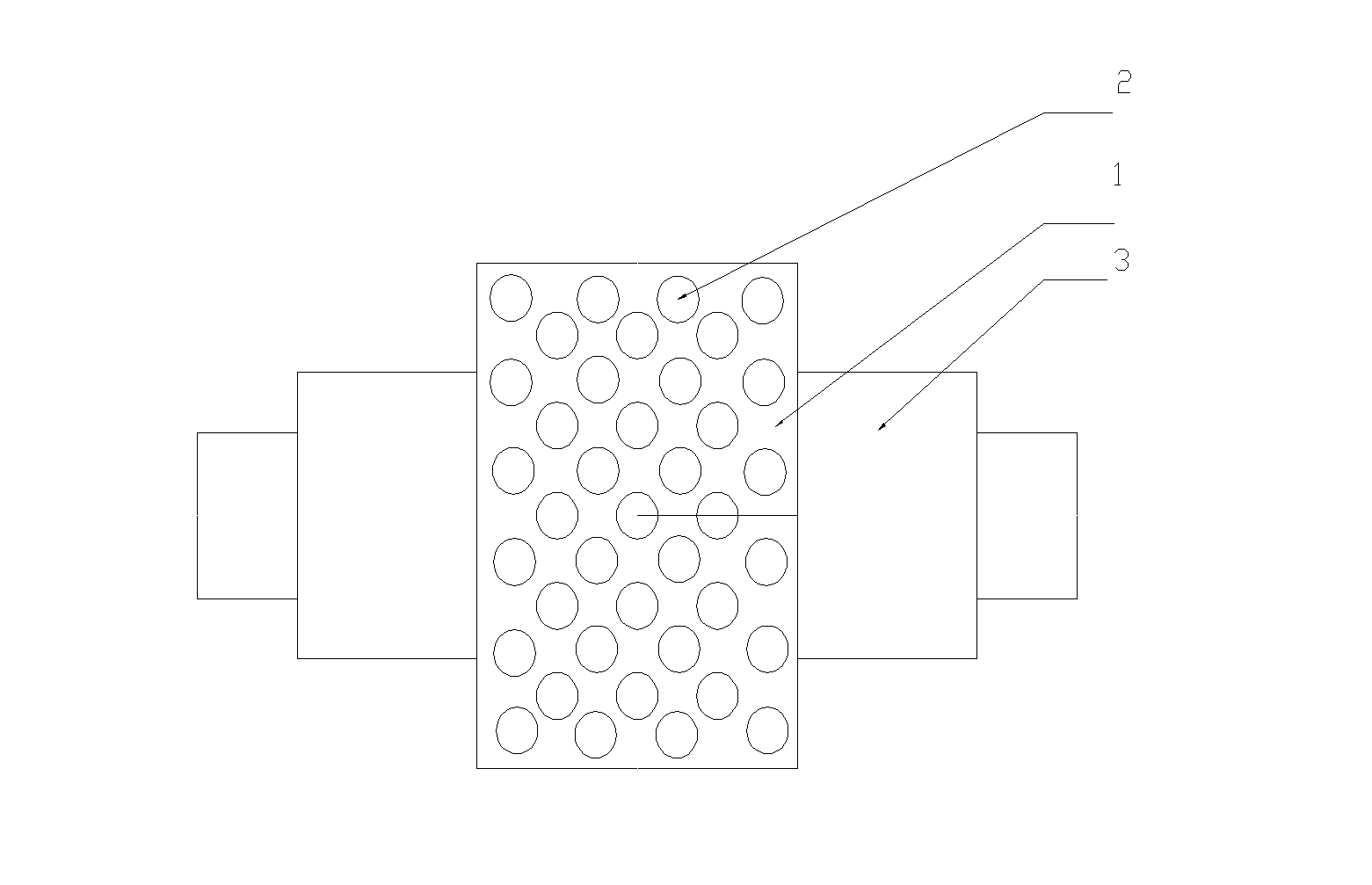

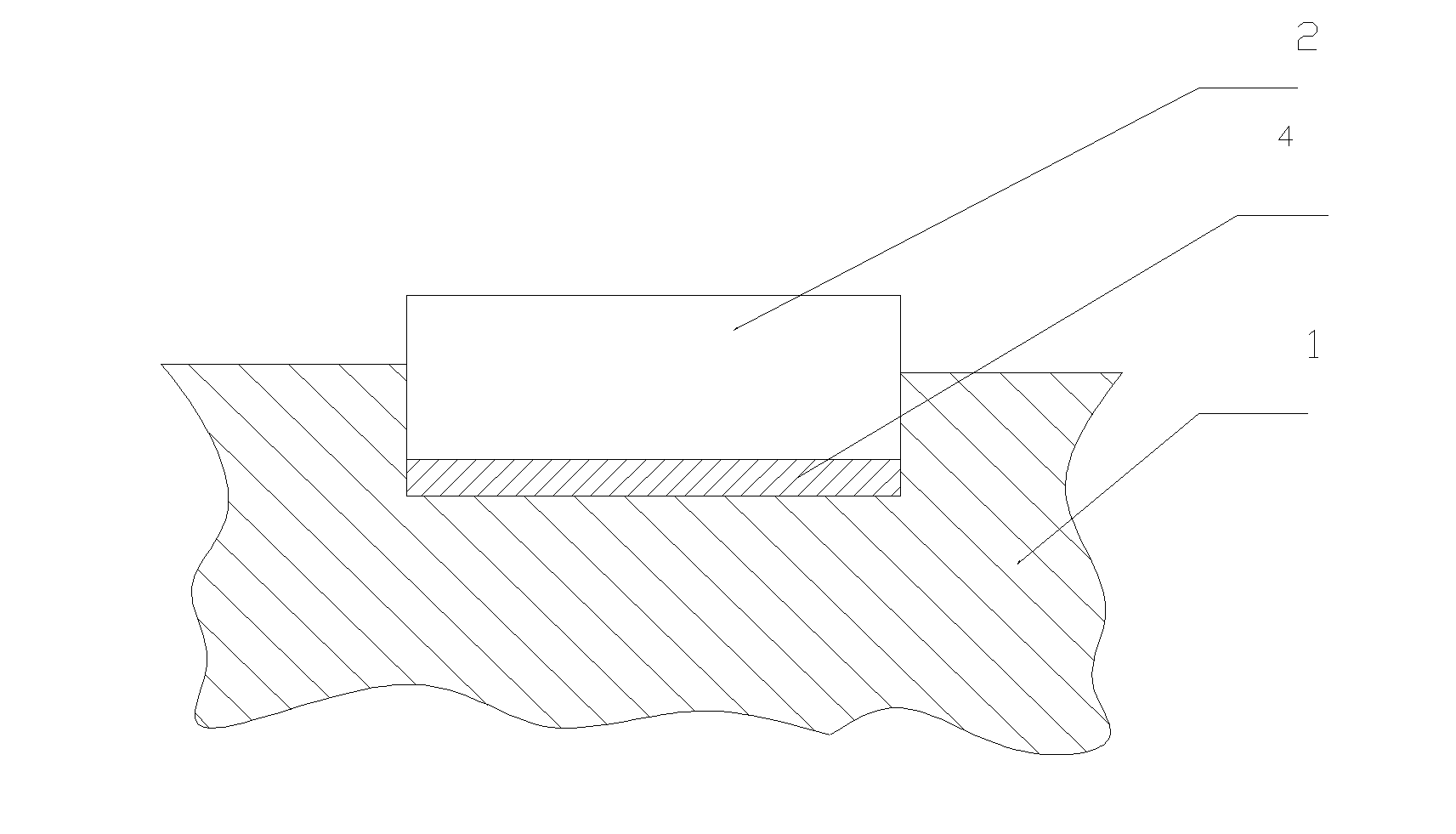

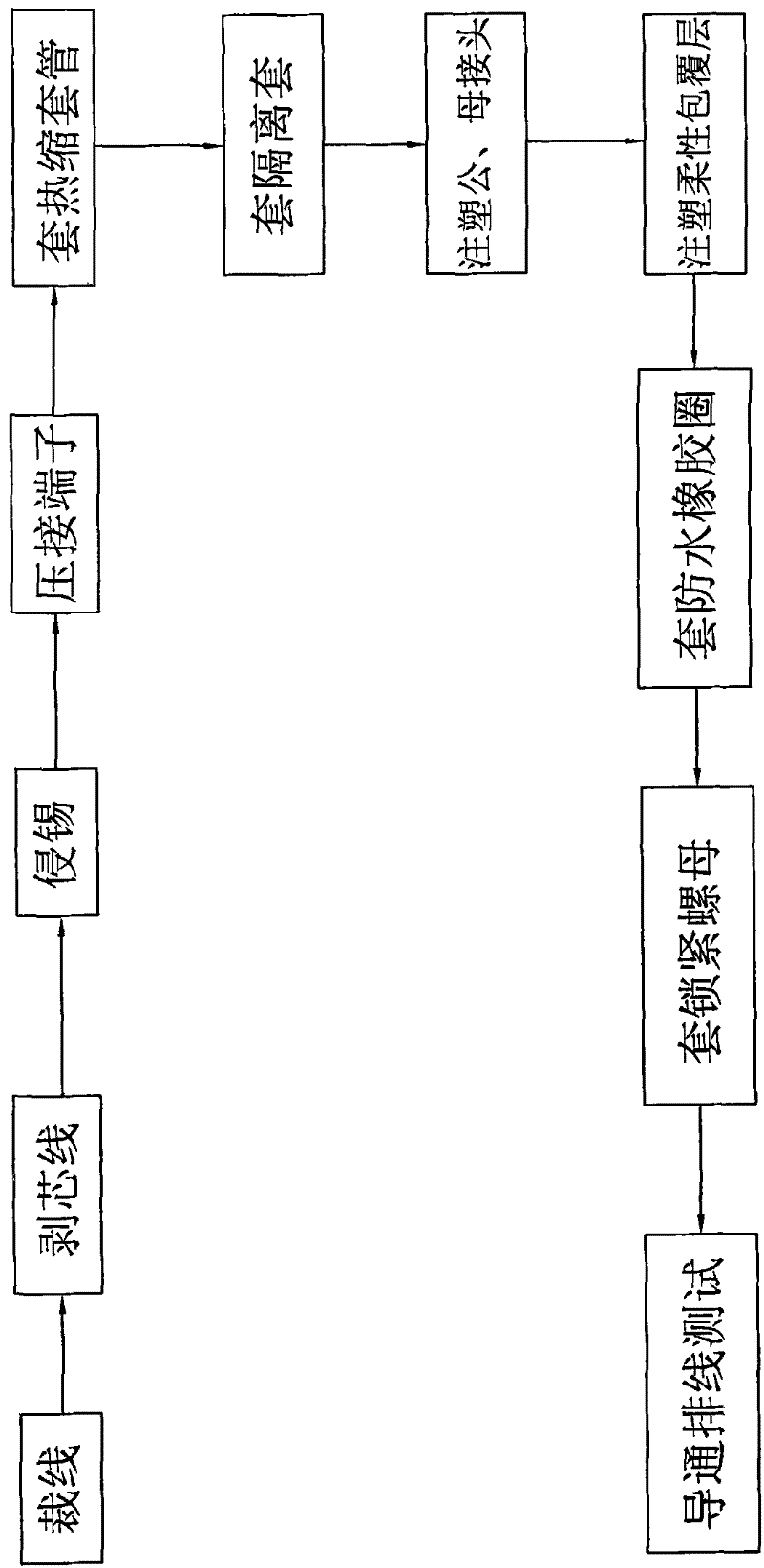

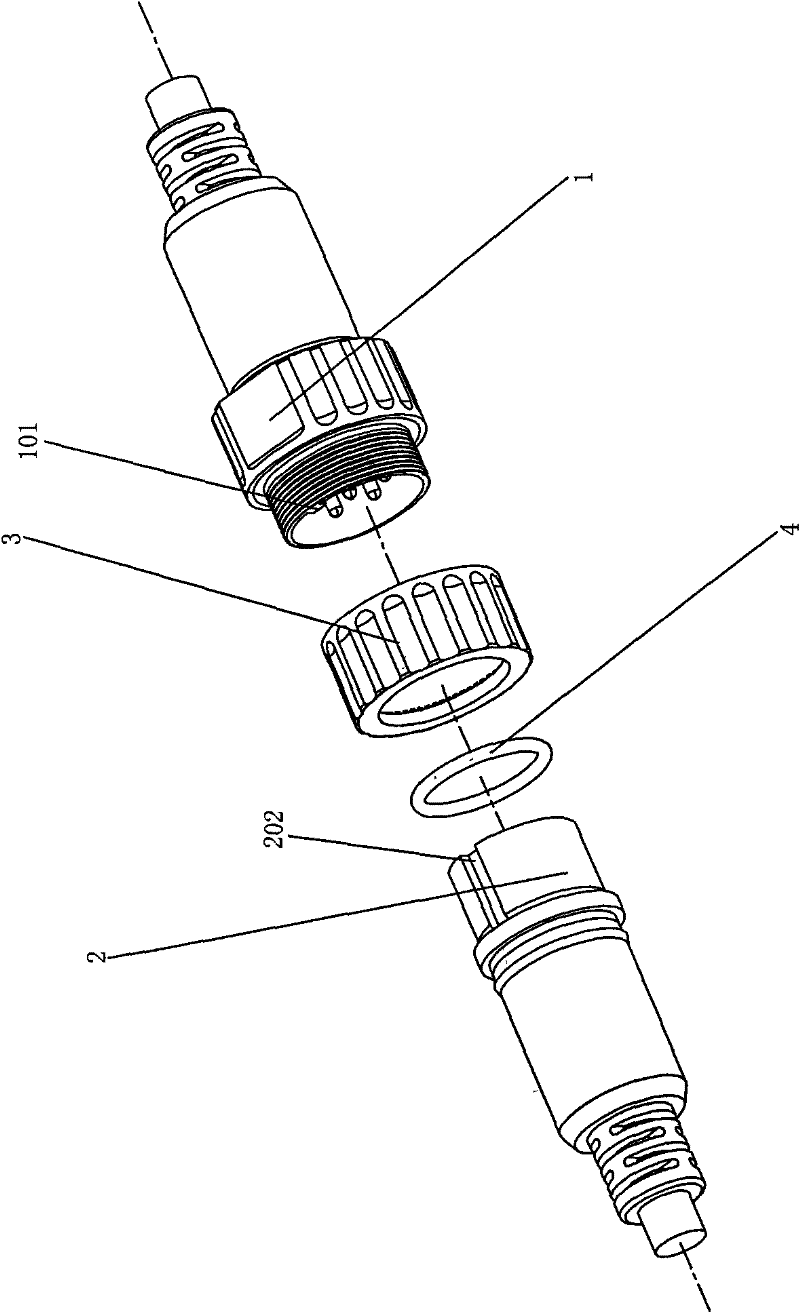

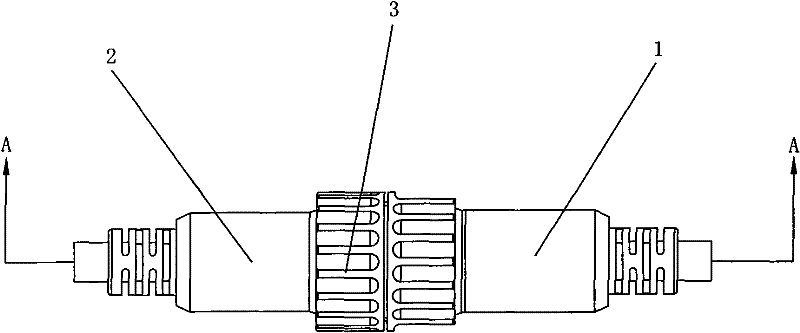

Manufacture method of waterproof power connector and waterproof connector adopting same

InactiveCN101609955AImprove tensile propertiesImprove sealingRelieving strain on wire connectionContact member assembly/disassemblyState of artPlastic injection molding

The invention discloses a manufacture method of a waterproof power connector, comprising the following steps: firstly, cutting a power cord with needed length; then peeling off the skin of a core cord at one end of the power cord so that a metal conducting wire is exposed to the outside; then placing the metal conducting wire into a terminal machine and respectively performing compression joint to a metal male terminal and a metal female terminal; next, sleeving a hard insulating sleeve outside the metal female terminal; and then placing the power cord of the connected metal male terminal into a male connector mould, placing the power cord of the connected metal female terminal into a female connector mould, injecting and molding a male connector and a female connector by an injection molding way, and selecting hard plastic as the material of the male connector and the female connector. By adopting a hard plastic injection molding way to manufacture the connector, the invention has simple process and good waterproof effect compared with a combined waterproof connector in the prior art.

Owner:HE SHAN LIDE ELECTRONICS ENTERPRISE CO LTD

High-wearable extrusion roller of roller press and manufacture process thereof

InactiveCN102441462AHigh strengthFatigue resistance hasGrain treatmentsManufacturing technologyAlloy

The invention relates to a high-wearable extrusion roller of a roller press and a manufacture process thereof, belonging to the technical field of extrusion rollers; circular grooves are machined on the surface of the extrusion roller every 3-6 mm; a hard alloy cylinder is embedded in the groove; the hard alloy cylinder is 2 mm higher than the surface of the extrusion roller; then, hard alloy is connected with the extrusion roller through a brazing method; the hard alloy contains the following components in percentage by weight: 66-92% of WC, 0-30% of TiC, 3.9-8% of Co and 0.1-0.3% of Cr; compared with the overlaying welding method, after the extrusion roller is brazed with the hard alloy, the wearable property is greatly increased; the service life is long; the replacement time of the extrusion roller is reduced; and the equipment utilization rate is increased.

Owner:BEIJING UNIV OF TECH

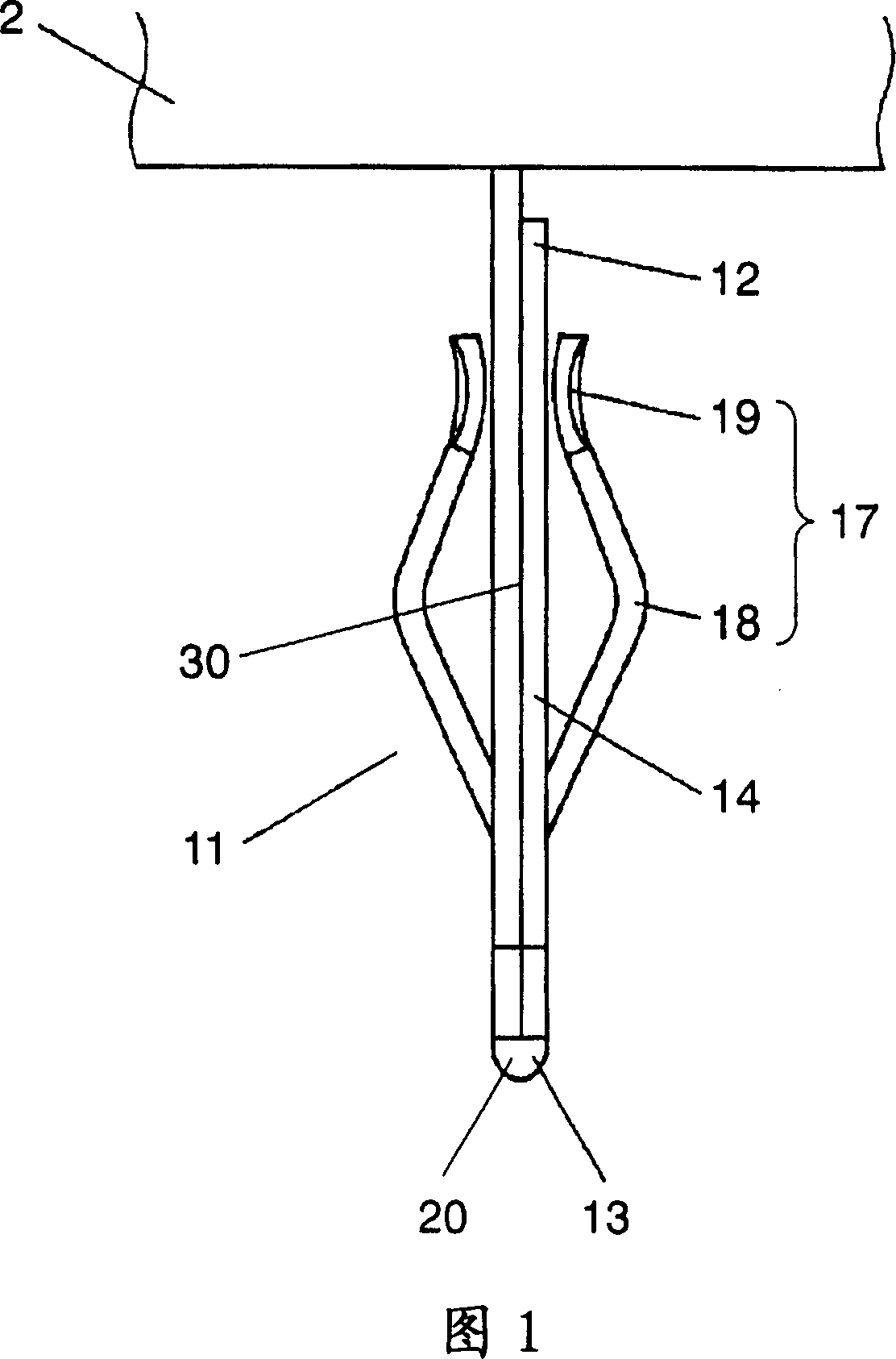

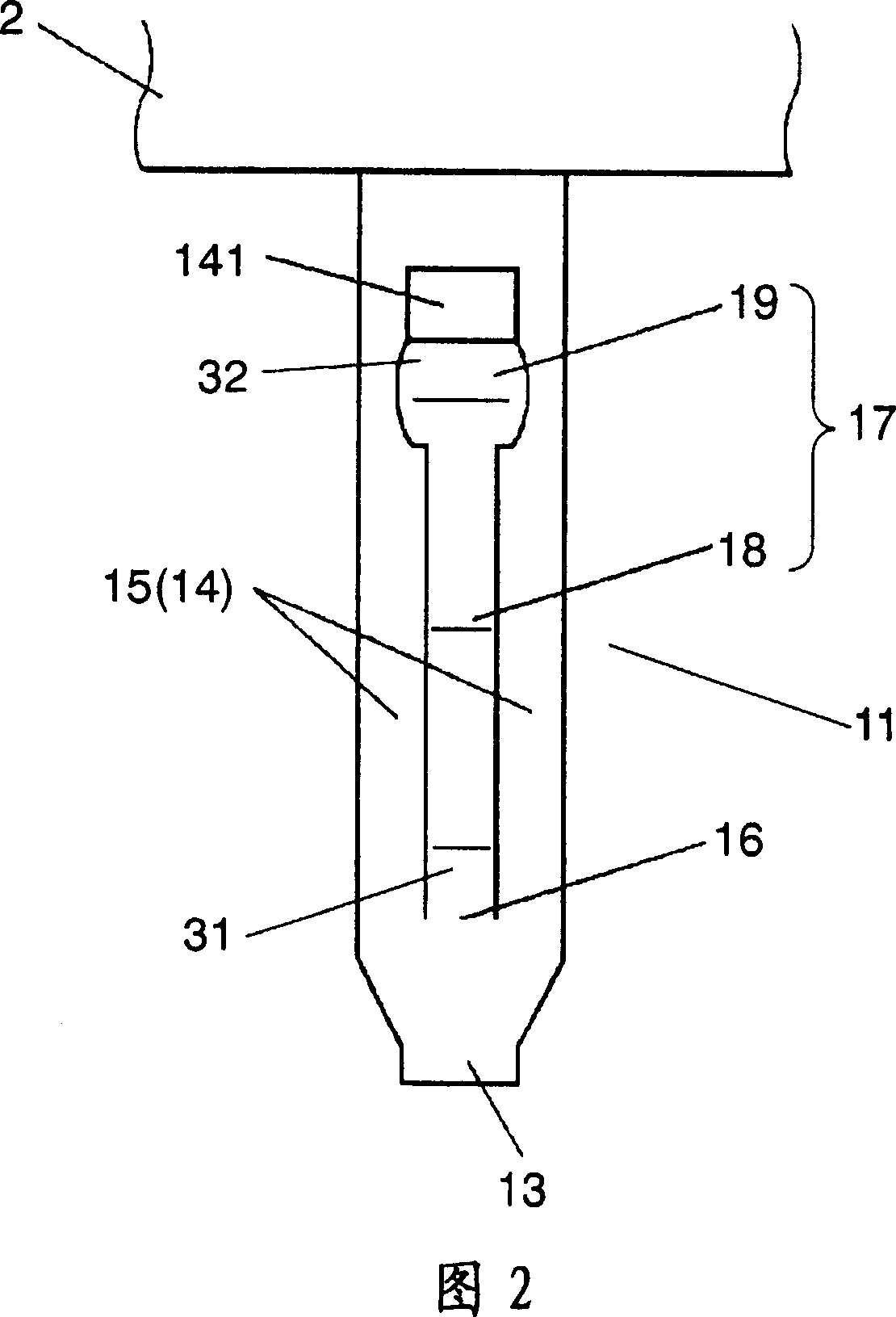

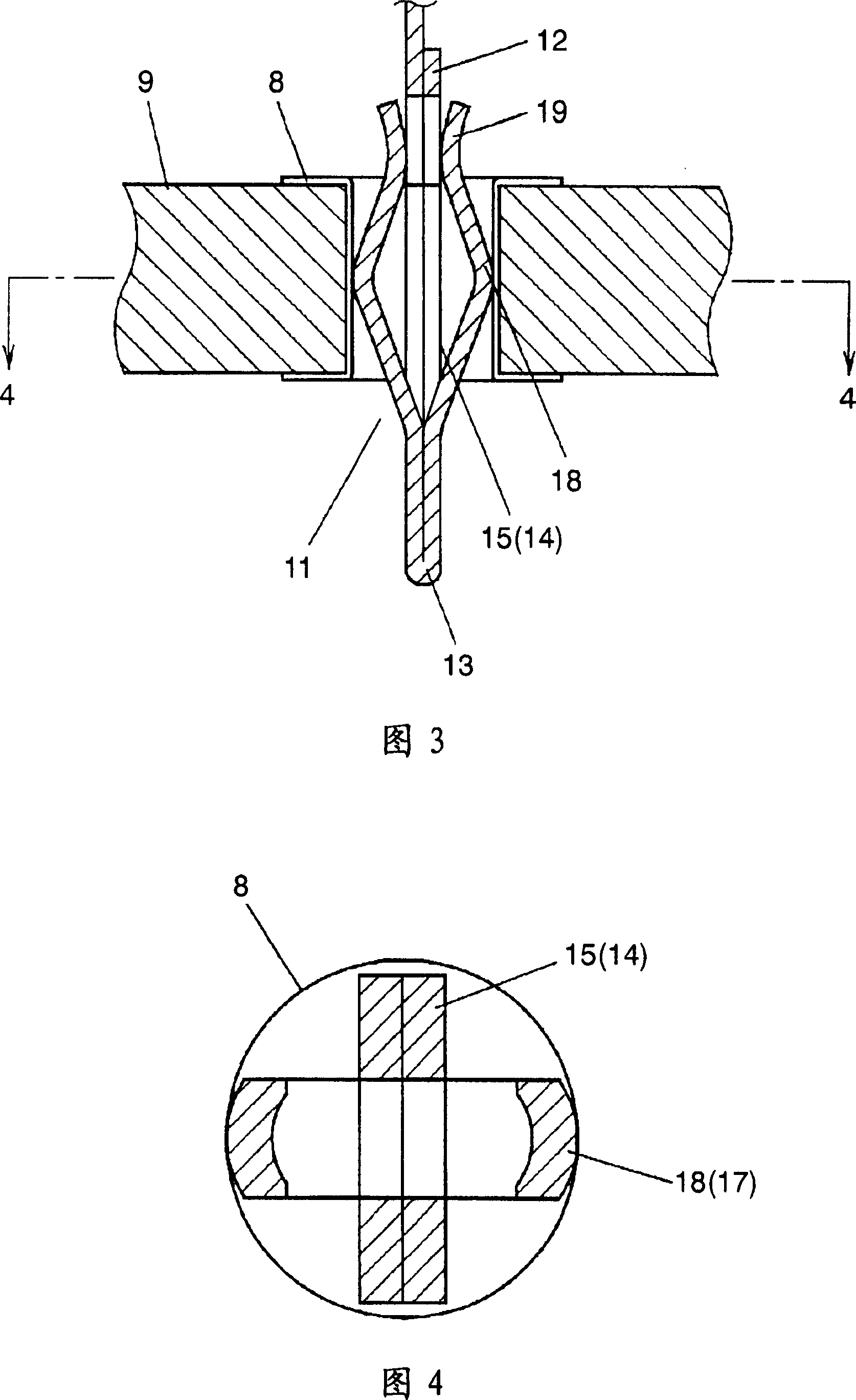

Press-fit fixing terminal, and electronic component having the same terminal

InactiveCN1964140ANot prone to plastic deformationCrimp firmlyPrinted circuit aspectsPrinted circuit manufactureEngineeringElectronic component

A press-fit fixing terminal is mountable to a wiring board by being inserted into a through-hole of the wiring board, and includes a flat plate section and a resilient contacting section. The flat plate section is made of metal thin plate and double-backed such that an end of the flat plate section is placed on a root side and a bent point works as an insertion tip when the terminal is inserted into the through-hole. The resilient contacting sections sandwich the double-backed portion of the flat plate section such that they are placed symmetrically with respect to the double-backed portion and both of the ridges of the resilient contacting section face outward viewed from the double-backed portion, so that each one of the resilient contacting sections forms a V-shape including an obtuse angle.

Owner:PANASONIC CORP

Method for preparing steel lining washing rollers

The invention provides a method for preparing steel lining washing rollers, which includes the following steps: firstly preparing a steel lining roller; then winding the steel lining roller with a carbon fiber layer, wherein during the winding process, frictioning is performed manually while winding to increase the content of carbon fiber; placing the steel lining roller wound with the carbon fiber layer in a curing box for heating and curing; performing the skim coating on the roller surface subjected to curing; finally preparing the finished steel lining composite carbon fiber washing roller. The finished steel lining composite carbon fiber washing roller prepared through adopting the method provided by the invention has the advantages of light weight, antifatigue, excellent rigidity, corrosion resistance and long service life.

Owner:JIANGSU YINGYOU TEXTILE MACHINERY

Rigid layer of fixed abrasive polishing roll for Roll-to-Roll chemical-mechanical polishing machine and preparation method of rigid layer

InactiveCN105150120AGuaranteed surface flatnessGuaranteed removal rateAbrasion apparatusGrinding devicesSocial benefitsPolishing

The invention discloses a rigid layer of a fixed abrasive polishing roll for a Roll-to-Roll chemical-mechanical polishing machine and a preparation method of the rigid layer. The rigid layer comprises components in percentage by weight as follow: 0.5%-10% of the abrasive, 5%-45% of light-cured resin, 5%-41% of a reactive diluent, 4%-7% of a photoinitiator, 0.05%-5% of an accelerant, 0.05%-3% of a surface performance regulator, 0.05%-5% of an adjuvant, 1%-4% of filler and 0.02% of pigments. The rigid layer of the fixed abrasive polishing roll for the Roll-to-Roll chemical-mechanical polishing machine and the preparation method of the rigid layer have the advantages of simple operation process, low cost, broad market prospect and remarkable economic and social benefits, and facilitates industrialization, popularization and application.

Owner:HENAN INST OF SCI & TECH

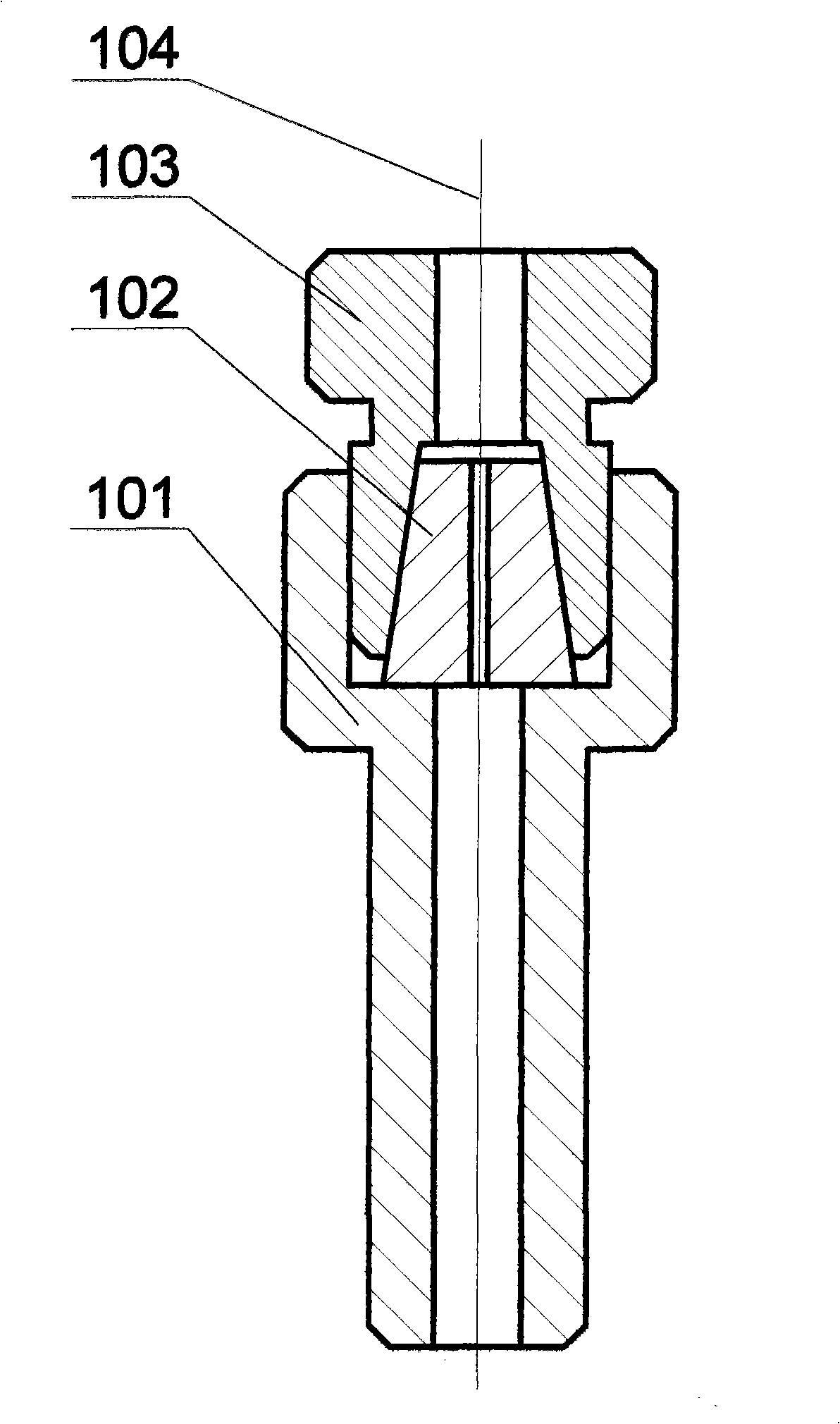

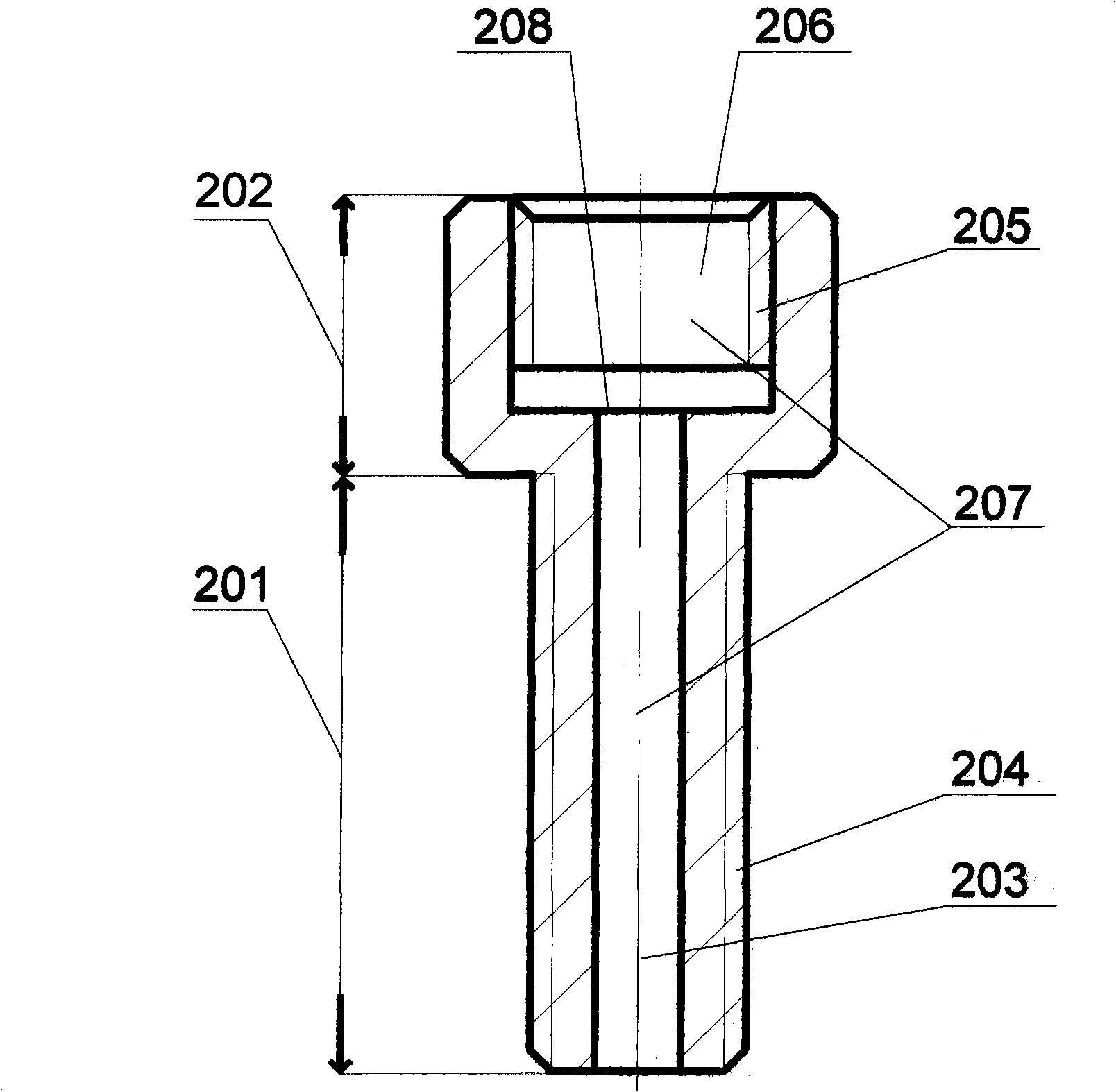

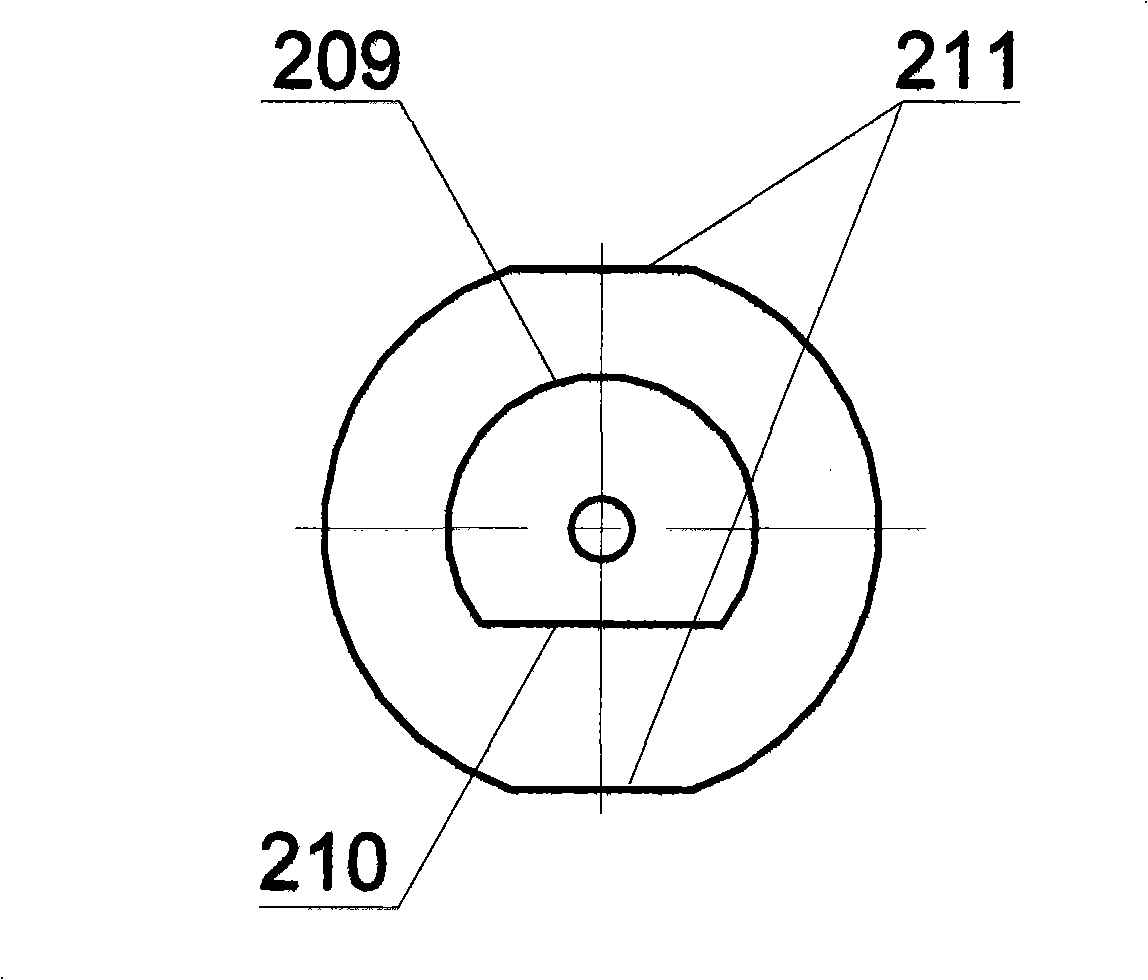

Thin wire locking method and device thereof

InactiveCN101245828ALarge locking forceRealize locking fasteningRopes and cables for vehicles/pulleyTextile cablesEngineeringScrew thread

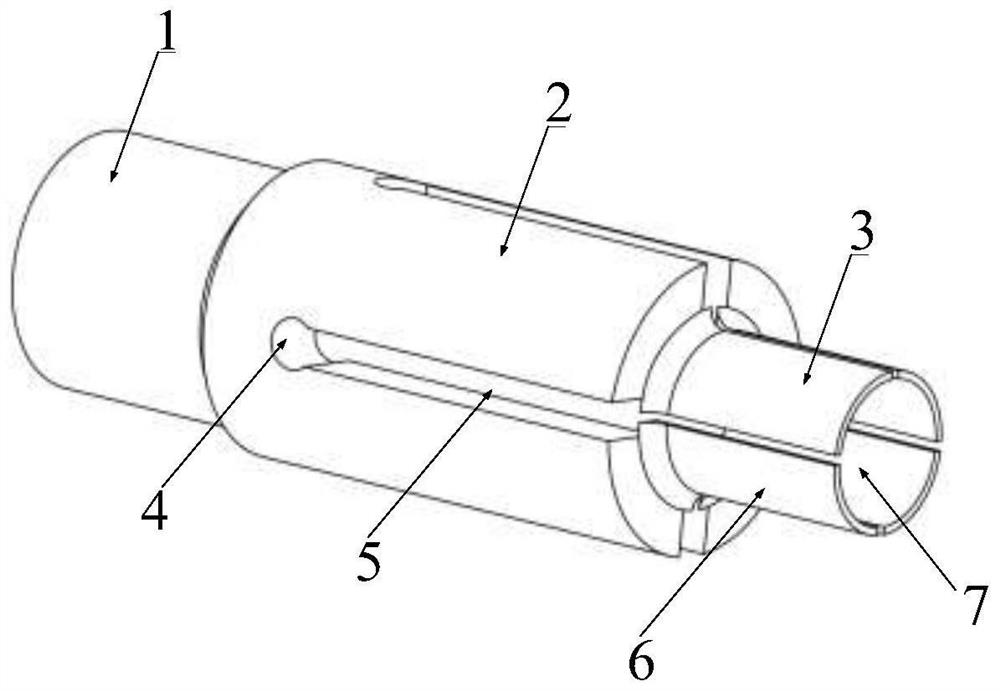

The invention discloses a locking method of a filament and the device, aiming at providing the filament locking method and the mechanical device which can be disassembled and repeatedly used and can provide large locking force after being screwed. The key point of the technical proposal is that the device consists of a fixed bolt, a clamping sleeve and a locking cap. The clamping sleeve is arranged inside the locking cap which is arranged at the upper end of the fixed bolt. The fixed bolt and the locking cap are mutually locked by an internal thread and an external thread. The locked filament passes through the central axis line of the locking device; the fixed bolt is used for containing the locking cap and the clamping sleeve and fixing the whole device. The clamping sleeve guides and clamps the filament; the fixed bolt, the clamping sleeve and the locking cap are matched with each other so as to lock the filament. By rotating the locking cap, the mutual action of the force is formed between the filament and each part of the locking device, thus realizing the locking of the filament. The locking method generates large locking force, can lock wire material with various diameters, not only can lock a single filament, but also can lock a plurality of filaments at the same time. The locking device has simple structure, convenient installation, easy processing and manufacture, easy disassembly and repeated application.

Owner:TIANJING UNIV OF TECH & EDUCATION +2

Aluminum magnesium alloy pattern ring of radial tire segmented mold

The invention relates to an aluminum magnesium alloy pattern ring of a radial tire segmented mold. The production method of the aluminum magnesium alloy pattern ring comprises the steps that the pattern ring comprises the components in percentage by weight as follows: 99.80% of pure aluminum, 0.003% of copper, 0.01% of magnesium, 0.002% of zinc, 0.003% of silicon, 0.001% of manganese and 0.001% of titanium alloy powder T15.2; a gas melting furnace is used, and pure aluminum is put into a graphite crucible for warming and melting; the temperature is raised to 950 DEG C, copper wires and a manganese agent in the proportion are put into melted pure aluminum; the temperature is lowered to 730 DEG C, magnesium, zinc, silicon, and the titanium alloy T15.2 powder in the proportion are put into an aluminum alloy; and after refining and deslagging, aluminum magnesium alloy liquid is poured into a model fitted with pattern blocks for natural solidification cooling through casting ladle pouring and gravity casting, the mold is opened, punching is performed, and the plaster model is removed, so that tire pattern blocks meeting the requirements are obtained. Compared with other commonly-used aluminum, the produced aluminum magnesium alloy pattern ring has the benefits that a novel casting tire mold pattern ring (block) aluminum material with high stability and reliability is used, the energy is saved, and the cost is reduced.

Owner:SHANDONG HENGYI MOLD

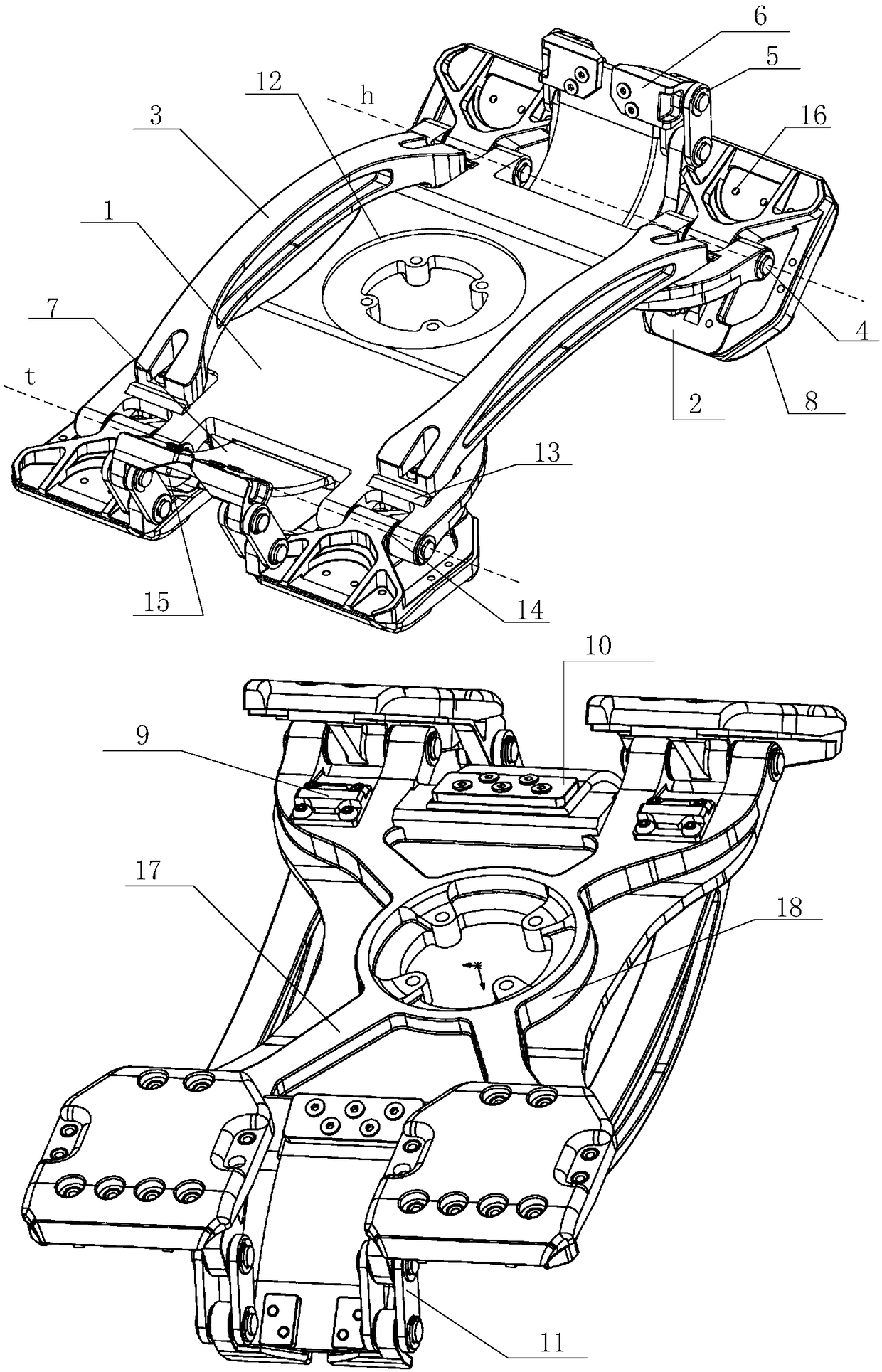

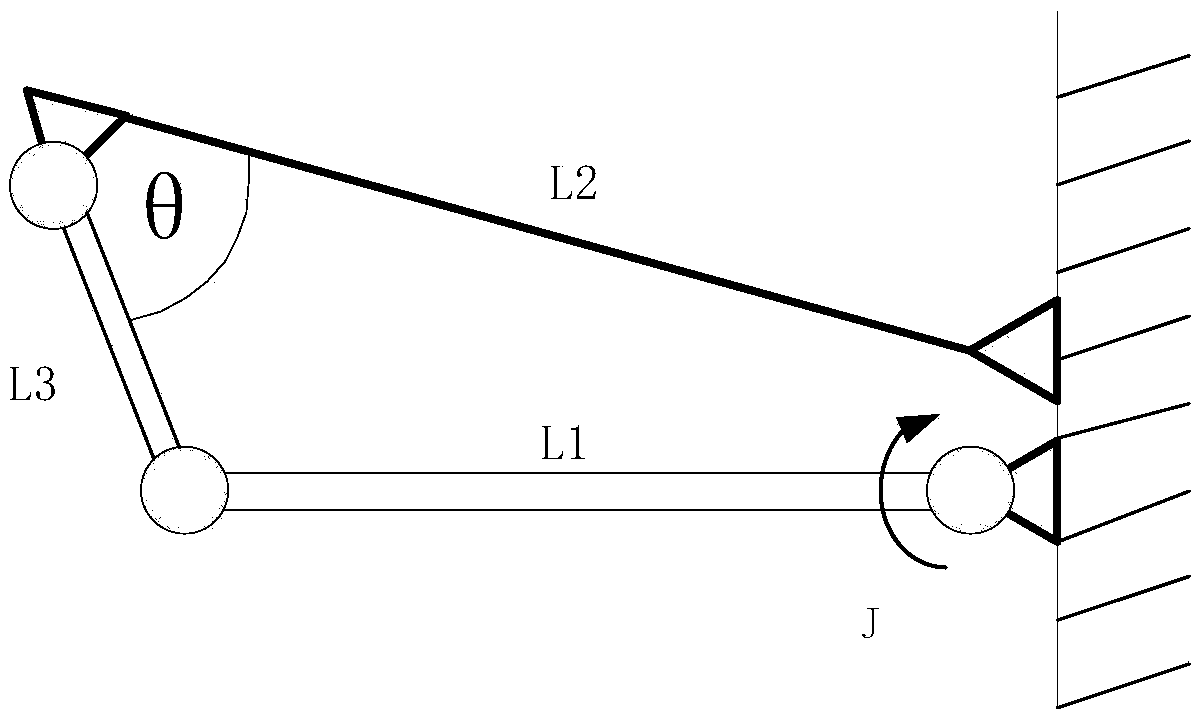

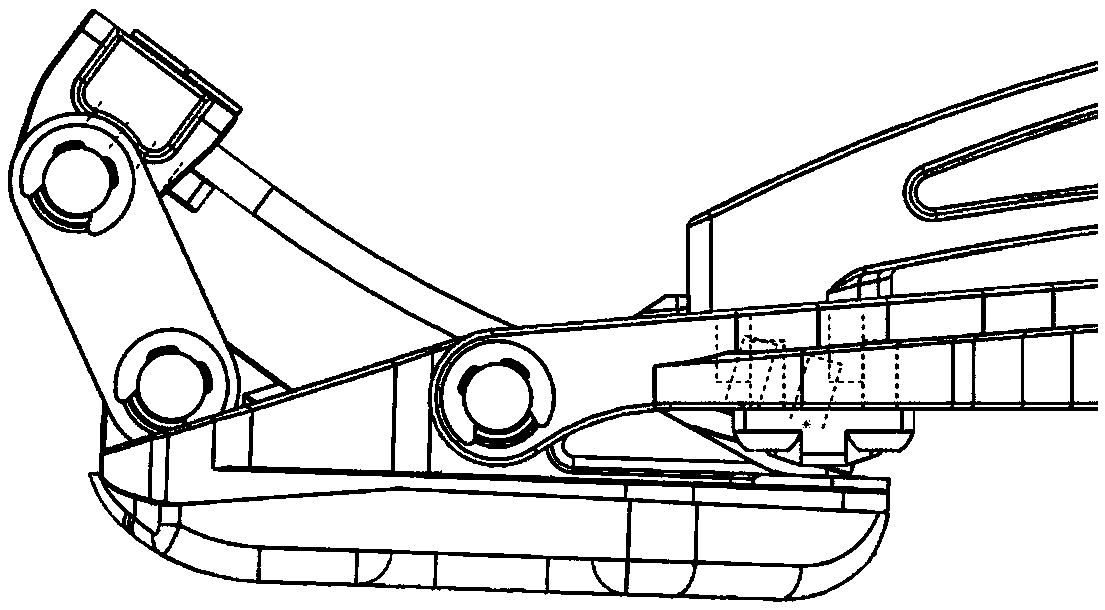

Bionic foot with variable stiffness toe and heel joints

ActiveCN109292021AIncreased bending stiffnessNot prone to plastic deformationVehiclesTurn angleVariable stiffness

The invention provides a bionic foot with variable stiffness toe and heel joints. The bionic foot with the variable stiffness toe and heel joints comprises a structural main body, a first connecting mechanism and a second connecting mechanism, wherein the structural main body comprises a sole, toes and heels; the toes and the heels can pivot relative to the sole; the first connecting mechanism isconnected between the sole and the toes and / or between the sole and the heels; the first connecting mechanism comprises an elastic part; the elastic part can generate elastic bending with the rotatingof the toes and / or the heels so as to provide a reverse moment for the rotation; and the second connecting mechanism is connected between the sole and a leg of a bionic robot, wherein the stiffness of the elastic part changes in a non-linear manner with the bending angle. According to the bionic foot with the variable stiffness toe and heel joints, by using a connecting rod mechanism, the rotations of the toe and / or heel joints are converted into bending of a glass fiber plate; the bending stiffness is enhanced with increasing of the turning angle of the toes and / or the heels; and therefore,plastic deformation is uneasy to generate.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Spring sheet type collar locator

ActiveCN104989384ALarge elastic resistanceLifting force data changes significantlySurveyDrilling rodsEngineeringMechanical engineering

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

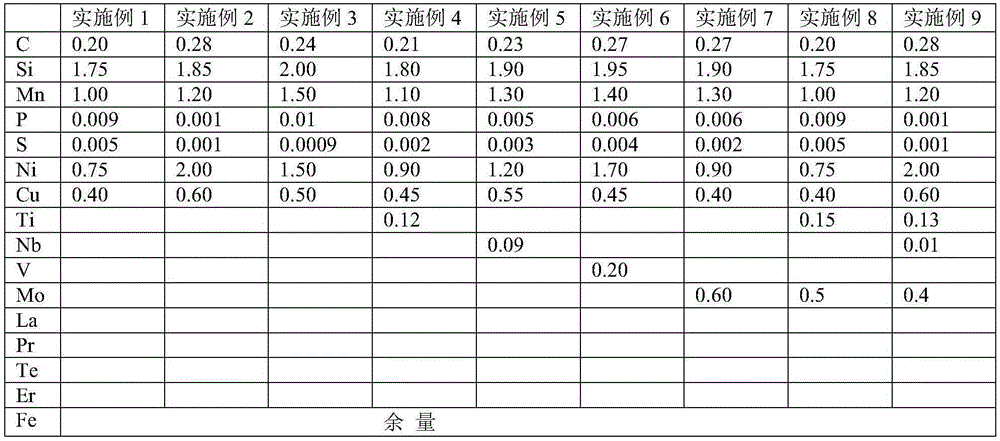

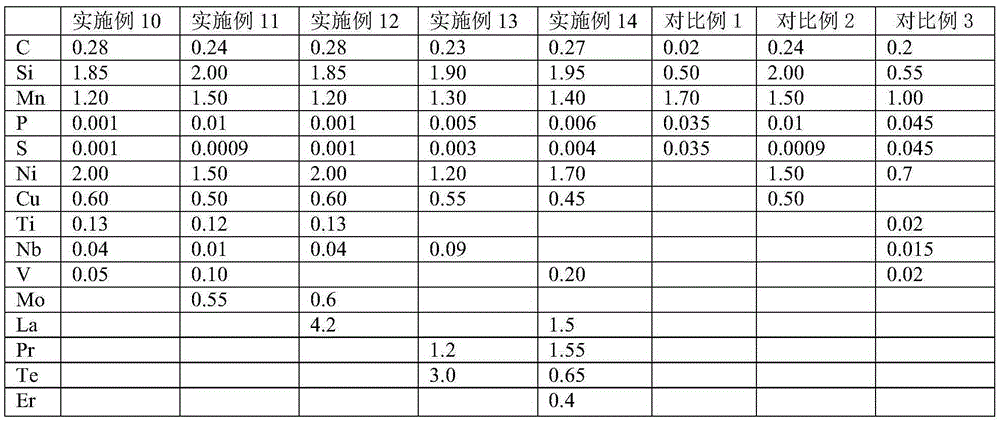

Electric tower high-strength steel special for extra-high voltage

The invention belongs to the field of steel production, and particularly relates to an electric tower high-strength steel special for extra-high voltage. The electric tower high-strength steel special for extra-high voltage comprises, by weight, 0.20-0.28% of carbon, 1.75-2.0% of silicon, 1.0-1.5% of manganese, smaller than or equal to 0.01% of phosphorus, smaller than or equal to 0.005% of sulfur, 0.75-2.0% of nickel, 0.4-0.6% of copper and the balance iron and inevitable impurities. A manufacturing method for the high-strength steel for an extra-high voltage line tower includes the steps of raw material treatment, smelting, refining, die casting, forging, cooling and tempering. The high-strength steel manufactured through the manufacturing method is high in strength, long in service life and high in corrosion resistance, oxidation resistance and high temperature resistance, the manufacturing method is simple, and production cost is low.

Owner:STATE GRID CORP OF CHINA +1

Segmental mold aluminum-titanium-boron aluminum-magnesium alloy pattern block casting material and production method thereof

The invention relates to a segmental mold aluminum-titanium-boron aluminum-magnesium alloy pattern block casting material and a production method thereof. According to the technical scheme, the casting material is prepared from the following components in parts by weight: 99.85% of pure aluminum ingots, 0.20% of silicon, 0.10% of iron, 0.10% of copper, 0.10% of manganese, 3.80% of magnesium, 0.01% of chrome, 0.0050% of nickel, 0.0047% of zinc, 0.000108% of beryllium, 0.0032% of bismuth, 0.0108% of lithium, 0.00063% of sodium, 0.0030% of titanium alloy powder T15.2, and 0.0025% of aluminum-titanium-boron ALTi5B1. The casting material has the beneficial effects that: 1, a die casting is precise in cooling shrinkage contour curved surface and good in surface precision, and has no defects such as pinholes, shrinkage porosity, cold shut, and the like; 2, pattern edges and corners are clear, and the surface smoothness is good; 3, the casting material is corrosion-resistant, does not stick scourings, and resists blast cleaning; 4, the casting material is high in strength, good in toughness, and uneasy to have plastic deformation after being machined; 5, the casting material is wear-resistant, long in service life, and resists die opening-closing impact; and 6, an aluminum-titanium-boron aluminum-magnesium alloy is taken as an independent ingredient, the element proportioning of the alloy is accurate, and the rate of finished products is high, thereby reducing the cost spending of enterprises.

Owner:SHANDONG HENGYI MOLD

Ferrite heat-resisting cast steel, preparation method thereof and applications thereof

ActiveCN103820739AImprove thermal fatigue performance and high temperature oxidation resistanceGood high temperature oxidation resistanceExhaust apparatusSilencing apparatusRoom temperatureOxidation resistance

The invention relates to ferrite heat-resisting cast steel and a preparation method thereof. The preparation method comprises following steps of: melting an alloy, tapping molten steel, casting and performing thermal processing. The alloy comprises following components by weight: 0.10-0.25% of C, 0.6-1.5% of Si. 0.2-0.6% of Mn, not more than 0.05% of P, 0.03-0.12% of S, 14.1-20% of Cr, 0.8-1.35% of Ni, 0.01-0.06% of N, 0.01-0.1% of Re, 0.15-3.0% of Nb and 0.01-0.8% of Al, with the balance being iron and unavoidable impurities. The ferrite heat-resisting cast steel has high high-temperarure oxidation resistance, high-temperature fatigue resistance and high room-temperature toughness, and is low in production cost and suitable for production of components of engine discharging systems.

Owner:CRRC QISHUYAN INSTITUTE CO LTD +1

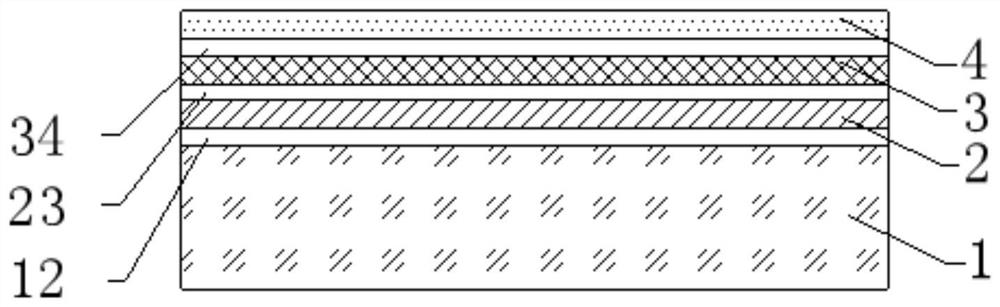

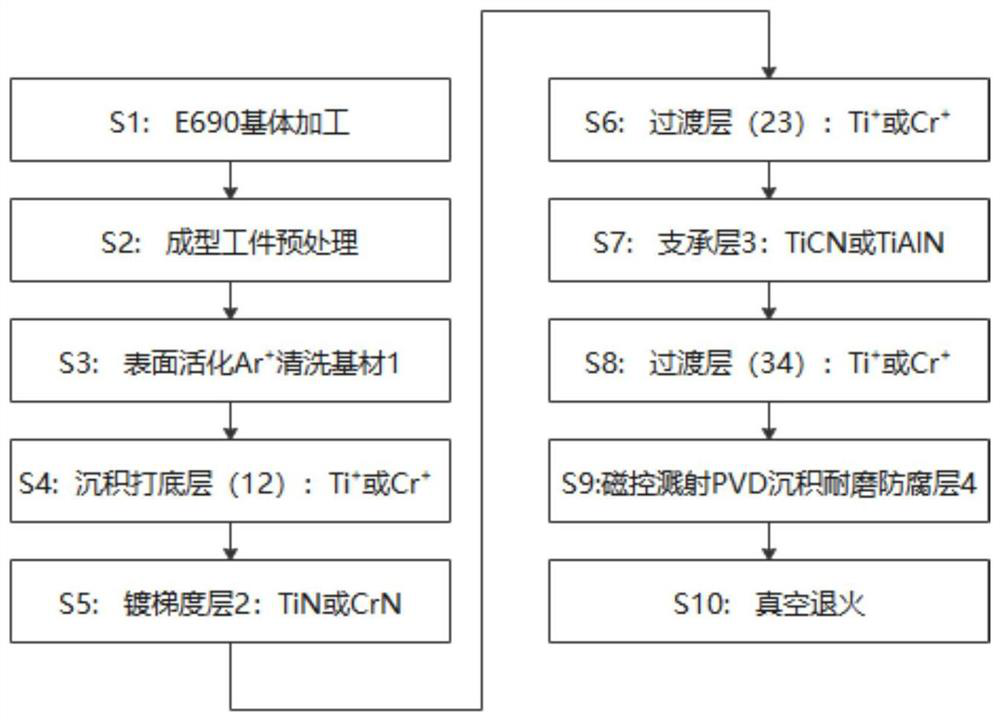

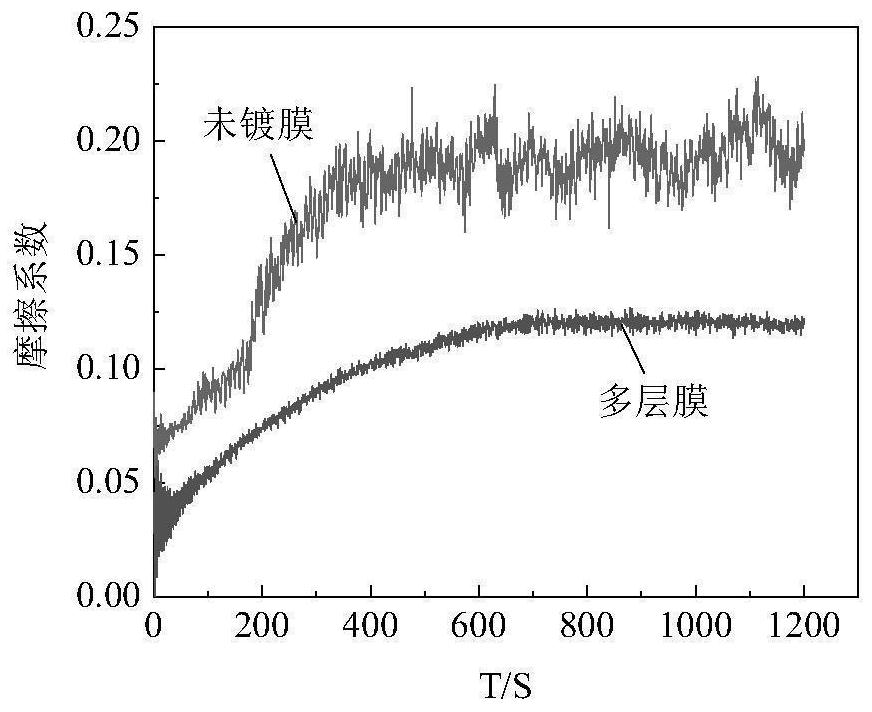

Structure and method for improving tribological performance of E690 steel

ActiveCN113073293AImprove bindingImprove toughnessVacuum evaporation coatingSputtering coatingComposite filmHeat treated

The invention discloses a structure and method for improving tribological performance of E690 steel for maritime work, and belongs to the technical field of surface modification. According to the structure, E690 steel serves as a matrix, a multi-layer composite film is deposited on the matrix, the multi-layer composite film comprises a base layer, a gradient layer, a supporting layer and a wear-resistant and anti-corrosion layer which are arranged from inside to outside, the micro-hardness of the base layer, the gradient layer and the supporting layer is increased layer by layer from inside to outside, the micro-hardness of the supporting layer is larger than that of the base layer, and the micro-hardness of the supporting layer is the same as that of the abrasion-resistant and anti-corrosion layer. The method comprises the following steps of performing heat treatment, rough machining and finish machining on a matrix material, depositing the multi-layer film by adopting a plasma enhanced magnetron sputtering technology, then depositing a surface film by adopting the magnetron sputtering technology, and finally annealing the coated E690 steel in a vacuum annealing furnace. The multi-layer composite film prepared by the method is well combined with the E690 steel matrix, and has lower friction coefficient and good wear resistance and corrosion resistance.

Owner:NANTONG UNIVERSITY

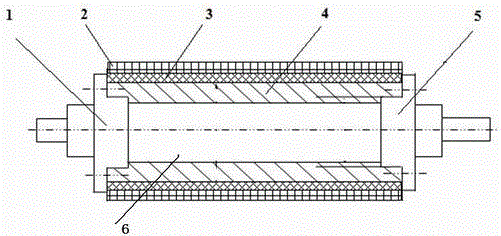

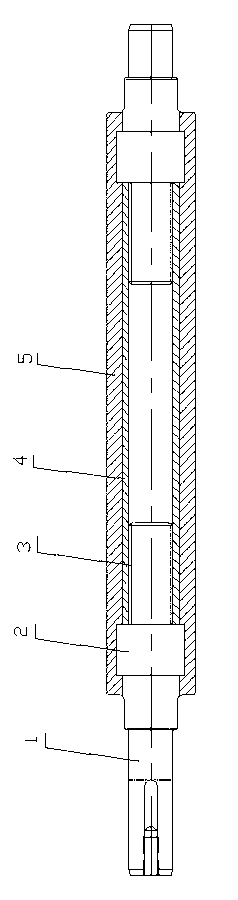

Fixed abrasive polishing roll for Roll-to-Roll chemical mechanical polisher and preparation method for fixed abrasive polishing roll

InactiveCN105215865AGuaranteed surface flatnessGuaranteed surface qualityAbrasion apparatusGrinding devicesMaterial removalPolishing

The invention discloses a fixed abrasive polishing roll for a Roll-to-Roll chemical mechanical polisher and a preparation method for the fixed abrasive polishing roll. According to the technical scheme, a polishing roll left-end supporting mechanism and a polishing roll right-end supporting mechanism are arranged on the two sides of the fixed abrasive polishing roll respectively; the fixed abrasive polishing roll is provided with a fixed abrasive polishing roll base body layer; an elastic layer is arranged in the exterior of the fixed abrasive polishing roll base body layer; a rigid layer is arranged in the exterior of the elastic layer. The surface of the fixed abrasive polishing roll is not liable to be deformed plastically; pore spaces in the surface of the fixed abrasive polishing roll are not liable to be blocked; the capacities for containing a polishing solution and removing scraps of the fixed abrasive polishing roll are not decreased with time; the material removal rate is even and uniform. In addition, a polishing pad does not need to be repaired and maintained, so that the polishing efficiency is improved.

Owner:HENAN INST OF SCI & TECH

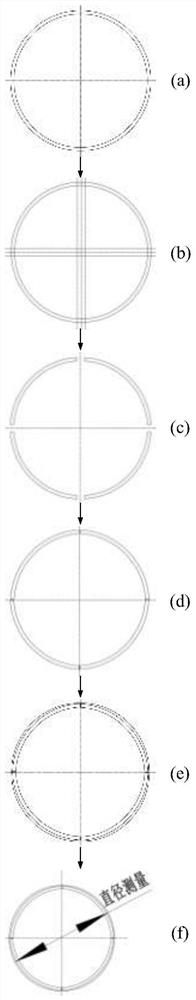

Machining method for multi-slotted lining

The invention provides a machining method for a multi-slit lining. The machining method comprises the following steps of: (1) selecting a material 0Cr17Ni7Al used for preparing the multi-slit lining; (2) conducting blanking on ta e 0Cr17Ni7Al bar based on structural parameters of an extruded workpiece; (3) conducting rough machining on the blanked 0Cr17Ni7Al bar with reference to the design size of the multi-slotted lining; (4) conducting heat treatment on the roughly machined bar by using a TH565 heat treatment system; (5) drilling the 0Cr17Ni7Al bar subjected to heat treatment to form the lining; and (6) grooving the lining to form the multi-slotted lining. The machining method is high in production efficiency and machining precision and can improve the surface quality of the wall of an assembly hole of the extruded workpiece and the fatigue performance of the extruded workpiece.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

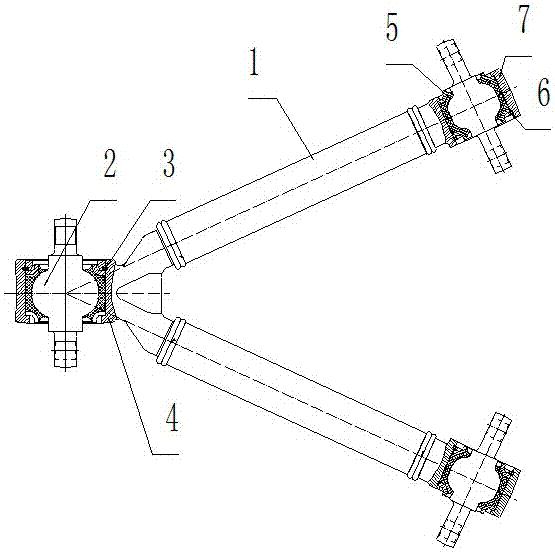

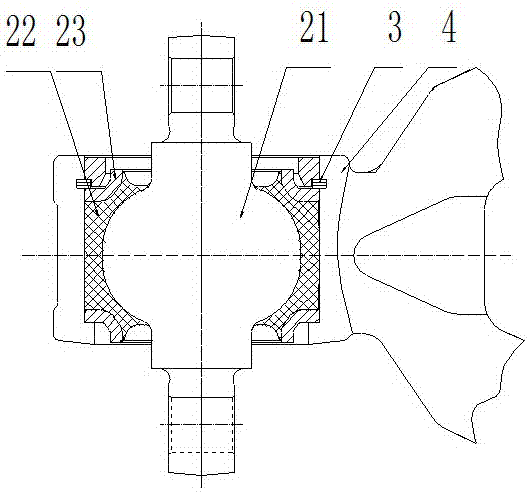

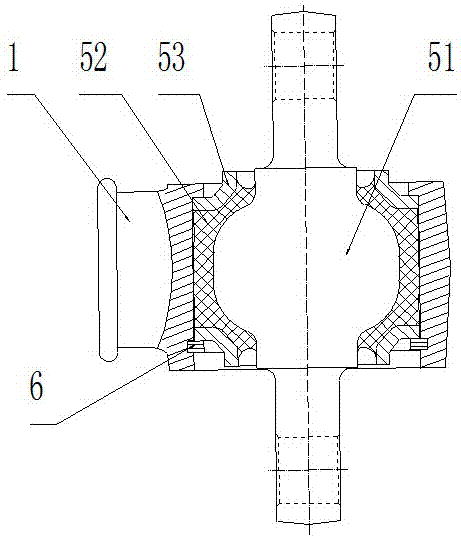

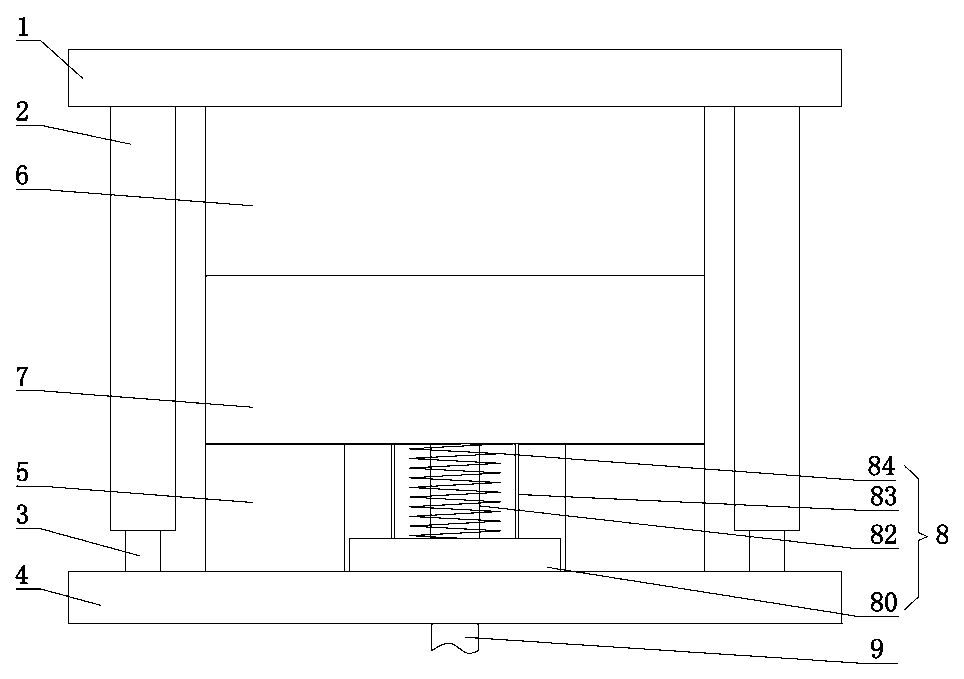

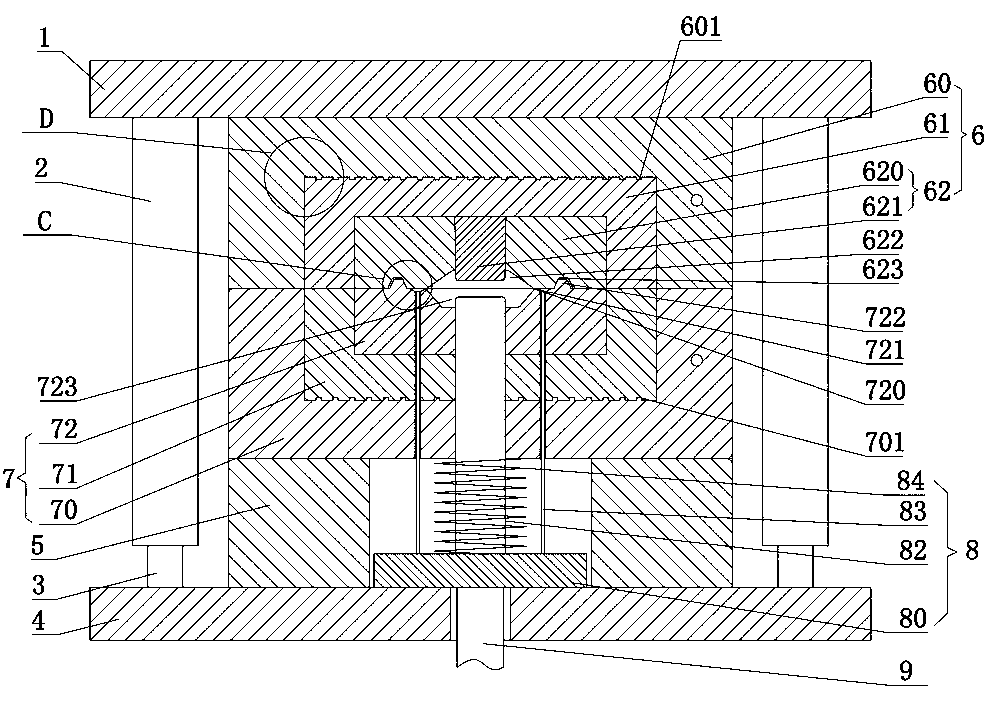

Heavy type commercial vehicle V-shaped thrust rod assembly and assembly method thereof

ActiveCN107415615AIncrease stiffnessImprove carrying capacityPivoted suspension armsMetal working apparatusFriction weldingStructural engineering

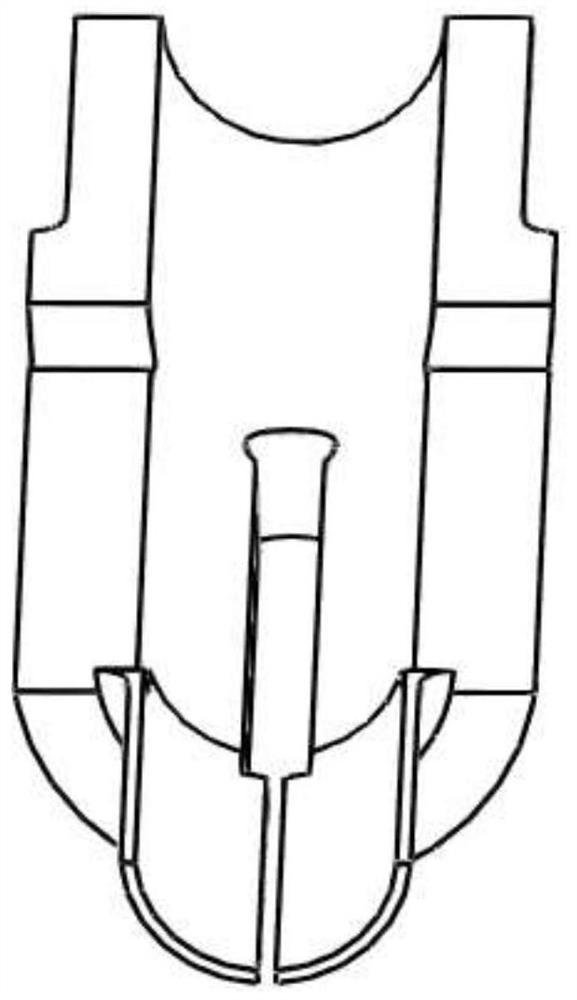

The invention discloses a heavy type commercial vehicle V-shaped thrust rod assembly and an assembly method thereof. The V-shaped thrust rod assembly comprises a V-shaped end socket assembly, a small end socket assembly and a connecting rod; the V-shaped end socket assembly comprises a V end reinforcing type spherical hinge, a V end spring collar and a V-shaped end socket; and the small end socket assembly comprises a small end spherical hinge, a small end spring collar and a small end socket. The assembly method of the heavy type commercial vehicle V-shaped thrust rod assembly includes the steps that firstly the V-shaped end socket and the small end socket are connected with each other through the connecting rod in a frictional welding mode, then the V-shaped end socket assembly and the small end socket assembly are assembled, and the heavy type commercial vehicle V-shaped thrust rod assembly is formed. In the assembly method of the heavy type commercial vehicle V-shaped thrust rod assembly, both the V end spring collar and the small end spring collar are pressed into a clamping groove of the V-shaped end socket or the small end socket through a specialized pressing device, and the specialized pressing device is composed of a guide mechanism, an upper pressing plate, a pressing head, a transition taper sleeve and a positioning seat. According to the technical scheme of the heavy type commercial vehicle V-shaped thrust rod assembly and the assembly method thereof, the weight of a V-shaped thrust rod can be reduced by 10-15%, the fatigue resistant strength of the heavy type commercial vehicle V-shaped thrust rod assembly and the power of a heavy type commercial vehicle are improved, the service life of the thrust rod assembly is prolonged, the fuel consumption is reduced, and the exhaust pollution is lowered.

Owner:ANQING HUITONG AUTOMOTIVE PARTS

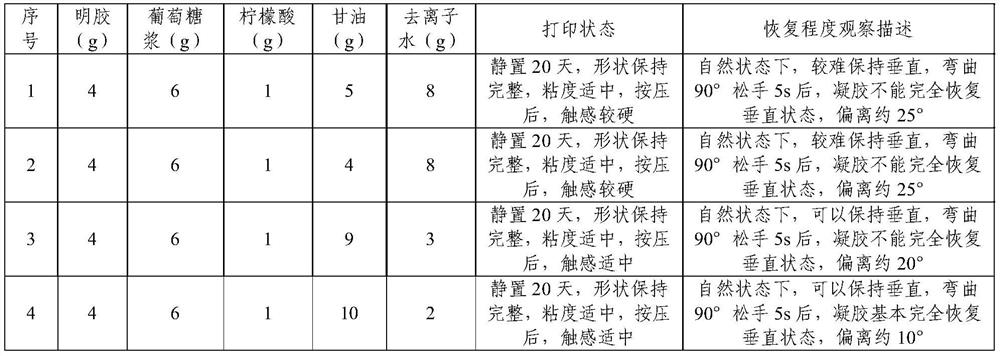

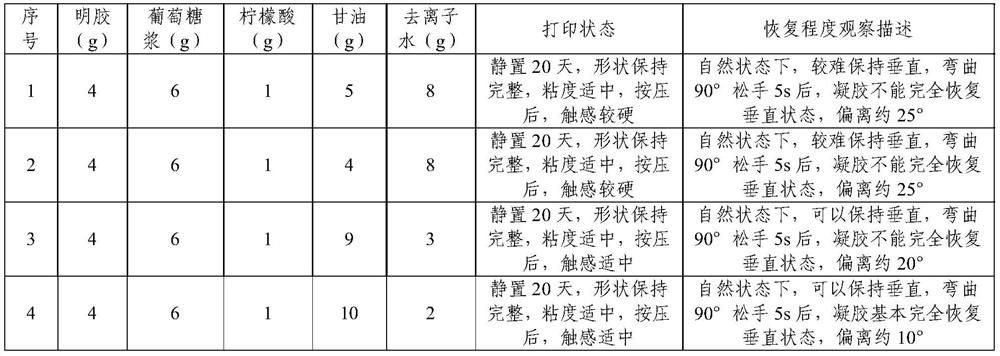

Preparation, product and application of a biodegradable 3D printing gel

ActiveCN112194802BEasy to processAdjust the elasticityAdditive manufacturing apparatusBiotechnologyGlycerol

The present invention proposes the preparation of a biodegradable 3D printing gel, its product and its application. The preparation method includes operations: citric acid, glycerin and water are prepared as a solution, wherein the mass ratio of citric acid, glycerin and water is 1: (2-10): (2-10); mix the glucose syrup with the solution obtained in (1), the mass ratio of the glucose syrup to citric acid is (5-9): 1; add to step (2) Gelatin is added to the obtained solution, and the mass ratio of the gelatin to citric acid is (6-12):1. The preparation method of the 3D printing gel proposed by the present invention realizes the stable processing performance and processing conditions of the gel by adjusting the ratio of water and glycerin, that is, the adjustment of the mechanical strength; the addition of citric acid can adjust the pH environment of the gel, and at the same time It can inhibit the growth of microorganisms; all selected materials are food grade, environmentally friendly and easy to degrade.

Owner:CHINA AGRI UNIV

Wear-resistant steel rod and production method thereof

InactiveCN105018704AExtended service lifeExcellent grinding abilityFurnace typesHeat treatment furnacesPearliteDecarburization

Owner:郑州赫芃新材料科技有限公司

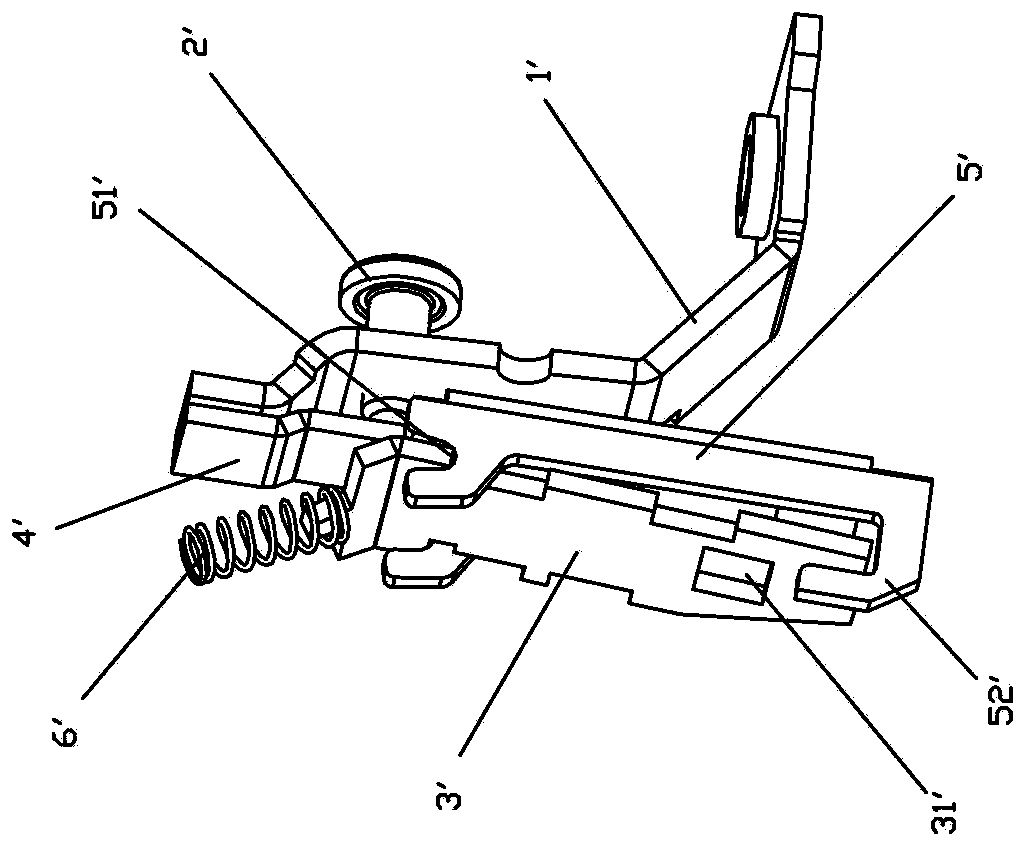

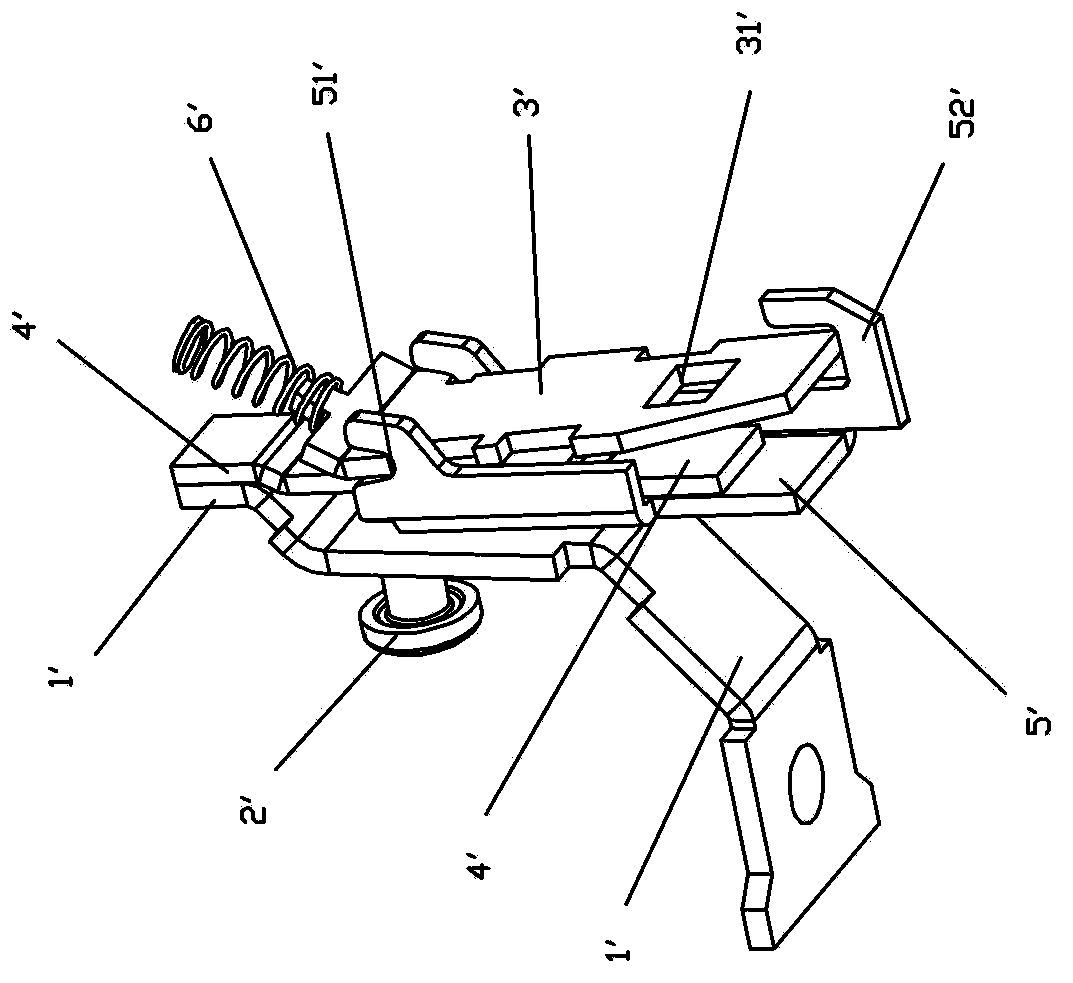

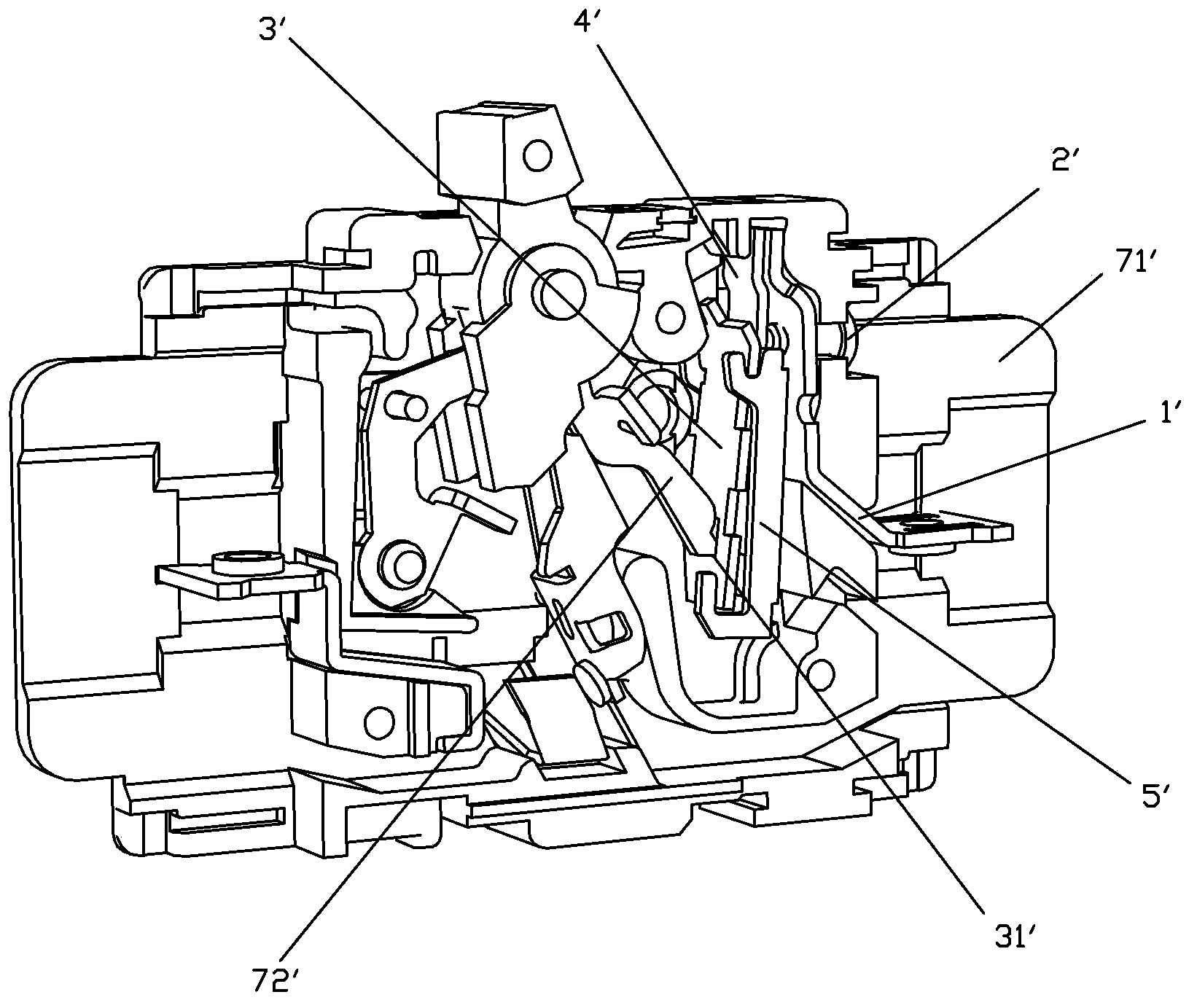

Thermo-magnetic protection device and electric protection device of thermo-magnetic protection device

InactiveCN103578880ANo changeNot easy to moveProtective switch operating/release mechanismsEngineeringCopper

The invention discloses a thermo-magnetic protection device and an electric protection device of the thermo-magnetic protection device. The thermo-magnetic protection device comprises a wiring board, an adjusting screw, an armature, a bimetallic element, a magnet yoke, a counter-force spring and a strand line. The wiring board is fixed on a supporting body, the armature is hung on the magnet yoke and fixed through the counter-force spring, one end portion of the magnet yoke is clamped on the preset supporting body, the other end portion of the magnet yoke is elastically bent to enable a preset included angle a to be formed between the other end portion of the magnet yoke and the one end portion of the magnet yoke, the adjusting screw is connected to the one end portion of the magnet yoke in a screwed mode, and the tail end of the adjusting screw abuts against the other end portion, provided with the elastic force, of the magnet yoke, and therefore the preset included angle a is adjusted through the adjusting screw. The bimetallic element is arranged in the other end portion of the magnet yoke, the bimetallic element and the other end portion of the magnet yoke are fixed, and the bimetallic element is connected with the wiring board through the strand line. The thermo-magnetic protection device and the electric protection device of the thermo-magnetic protection device have the advantages of being simple in design, high in reliability, less in copper using quantity and low in manufacturing cost.

Owner:XIAMEN HONGFA ELECTRICAL SAFETY & CONTROLS CO LTD

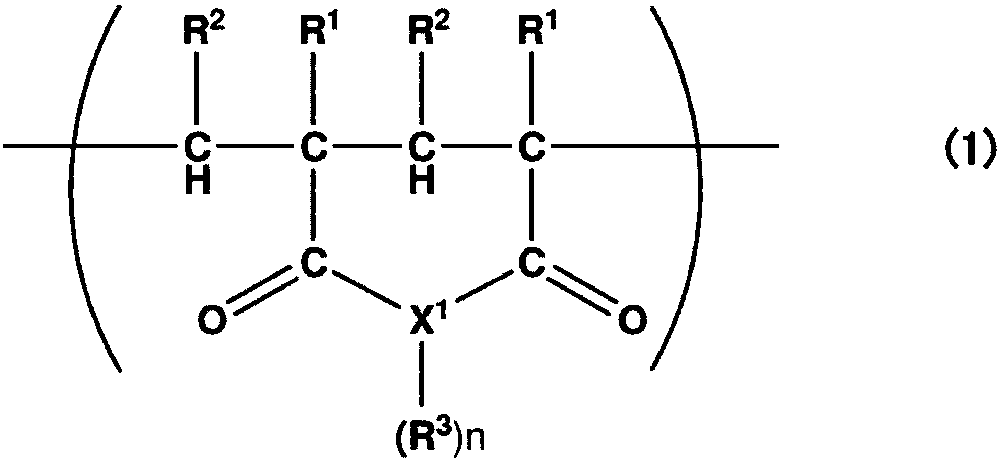

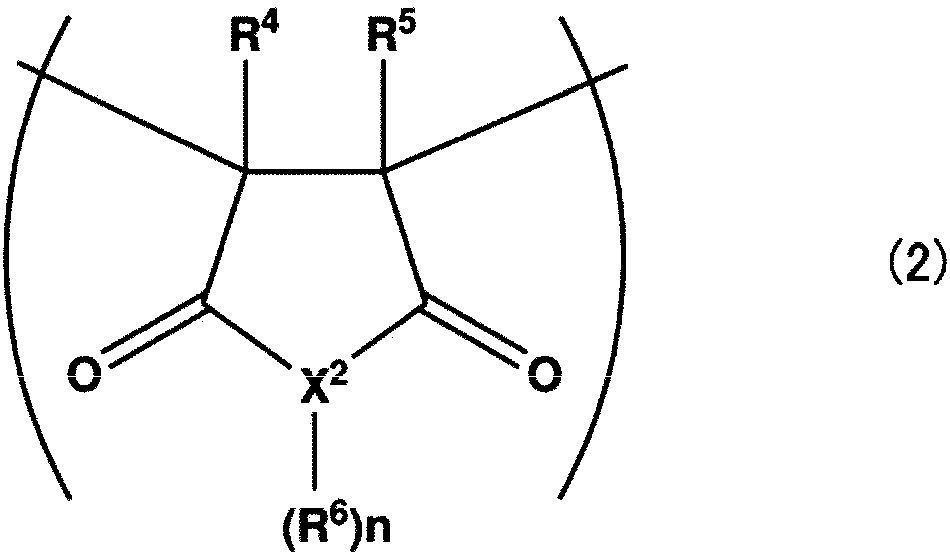

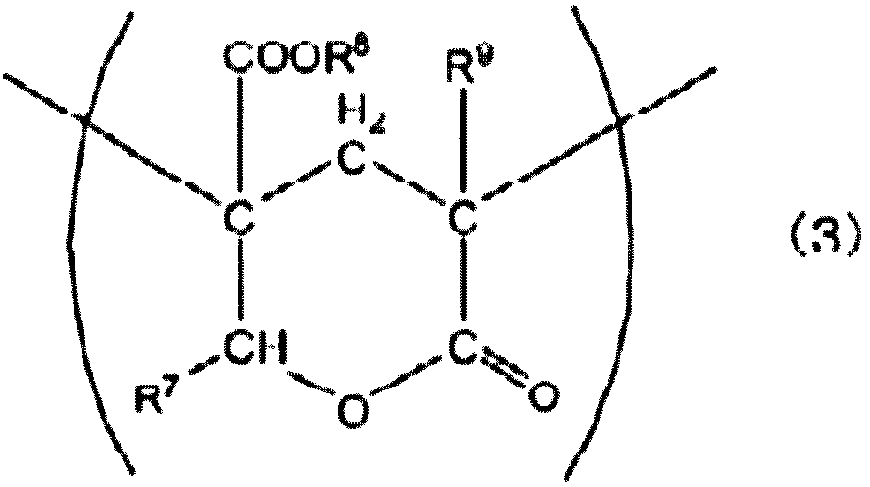

Block copolymer

ActiveCN107849201AIncrease or improve strengthIncrease or improve heat resistancePolarising elementsNon-linear opticsPolymer scienceSIS block copolymer

Provided are a novel block copolymer having a (meth)acrylic acid ester as a polymer component, and a film composed of the block copolymer. The novel block copolymer is a block copolymer containing a (meth)acrylic acid ester as the polymer component and having a ring structure on the main chain.

Owner:NIPPON SHOKUBAI CO LTD

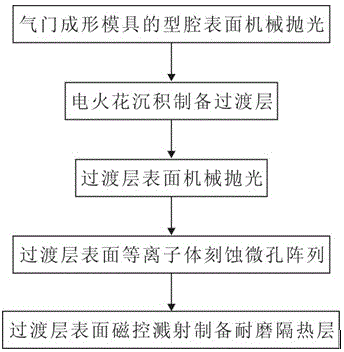

Valve forming mould covered with wear-resistant heat insulation film layer and manufacturing method of valve forming mould

InactiveCN102912346AExtended service lifeNot prone to plastic deformationVacuum evaporation coatingSputtering coatingWear resistantPlasma etching

The invention provides a manufacturing method of a valve forming mould covered with a wear-resistant heat insulation film layer. The wear-resistant heat insulation film layer covers the surface of a cavity of the valve forming mould and comprises a transition layer and a wear-resistant heat insulation layer; and the transition layer is positioned between the cavity of the valve forming mould and the wear-resistant heat insulation layer. The manufacturing method comprises the steps as follows: (1), mechanically polishing the surface of the cavity of the valve forming mould covered with the wear-resistant heat insulation film layer; (2), preparing the transition layer by using electric spark deposition; (3), mechanically polishing the surface of the transition layer; (4), conducting plasma etching on the surface of the transition layer to prepare a micropore array; and (5), conducting magnetron sputtering on the surface of the transition layer to prepare the wear-resistant heat insulation layer. The manufacturing method of the valve forming mould covered with a wear-resistant heat insulation film layer can make a guide for production of the valve forming mould covered with the wear-resistant heat insulation film layer.

Owner:HUBEI UNIV OF TECH

Fuzzing roller rolled by carbon fiber composite material in two-step method

The invention discloses a fuzzing roller rolled by a carbon fiber composite material in a two-step method. The fuzzing roller comprises a roller body of the fuzzing roller and shaft heads, wherein the shaft heads are arranged at the two ends of the roller body. A preparation method for the fuzzing roller comprises the following steps of: firstly, winding a carbon fiber preimpregnated cloth on a designed mould core rod to make a carbon fiber inner lining tube for later use; coating an adhesive in adhesion sections of the shaft heads; inserting the adhesion sections into the carbon fiber inner lining tube for adhering; and finally winding the carbon fiber preimpregnated cloth again by using the carbon fiber inner lining tube as a core rod and covering reinforcing shaft shoulders of the shaft heads into the carbon fiber inner lining tube at the same time to perform the steps of curing coarse processing, refine processing and coating to finally prepare the fuzzing roller serving as a finished product. The fuzzing roller is light in weight, and good in linearity degree, fatigue resistance and rigidity, so that the binding of the carbon fibers and resin is high, and the compactness is high; and because the binding strength of the fuzzing roller is greatly higher than that manufactured in a one-step method, and the service life of the fuzzing roller is prolonged. The carbon fiber composite material and the metal shaft heads are adhered by coating for twice, so that a contact surface of a carbon fiber tubular wall and the metal shaft heads is enhanced, the adhesion is firm, and the integral strength of the fuzzing roller of the carbon fiber composite material is greatly improved.

Owner:常州神鹰碳塑复合材料有限公司

Method for preparing foam metal through resin microsphere stacking

The invention belongs to the technical field of foam metal material preparing and provides a method for preparing foam metal through resin microsphere stacking. The method includes the steps that firstly, hollow PMMA glass microspheres are prepared and then are stacked, then metal powder and water are mixed and stirred to prepare metal pulp, then the metal pulp flows into the stacking clearance formed by the hollow microspheres and fill the stacking clearance, and porous foam metal is obtained after drying and sintering curing. Compared with a traditional method, the technological process is simplified in the adopted method, the production cost is reduced, meanwhile, the foam hole size, the porosity, the volume weight and the like of the foam metal are effectively controlled, the compression resistance capability of the obtained product is high, plastic deformation is not likely to happen when the product is compressed, the use performance is good, energy conservation and environment friendliness are achieved in the whole preparing process, and the method can be widely applied.

Owner:钱陈

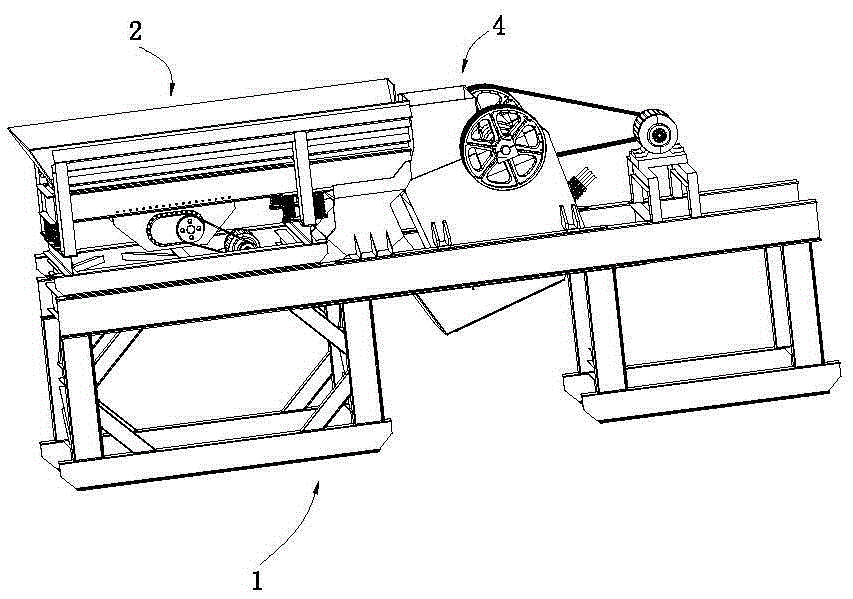

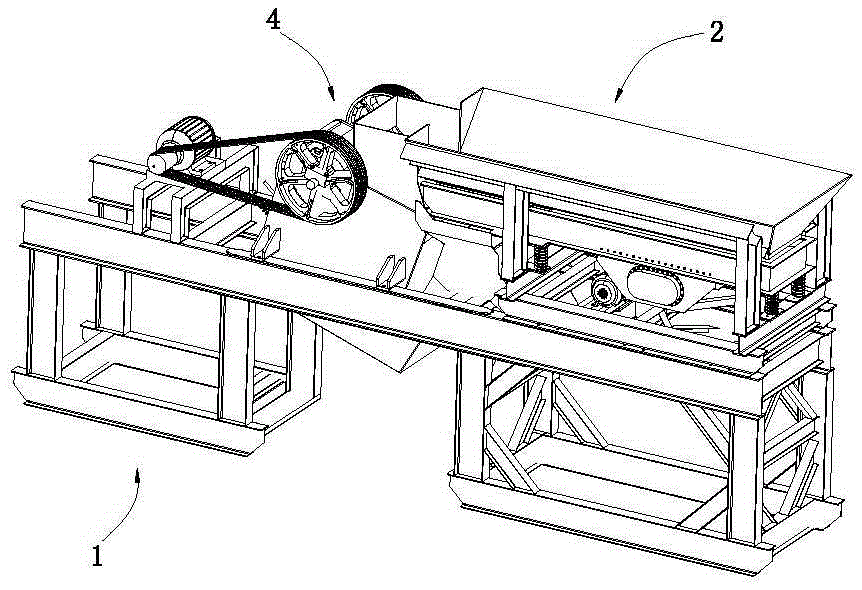

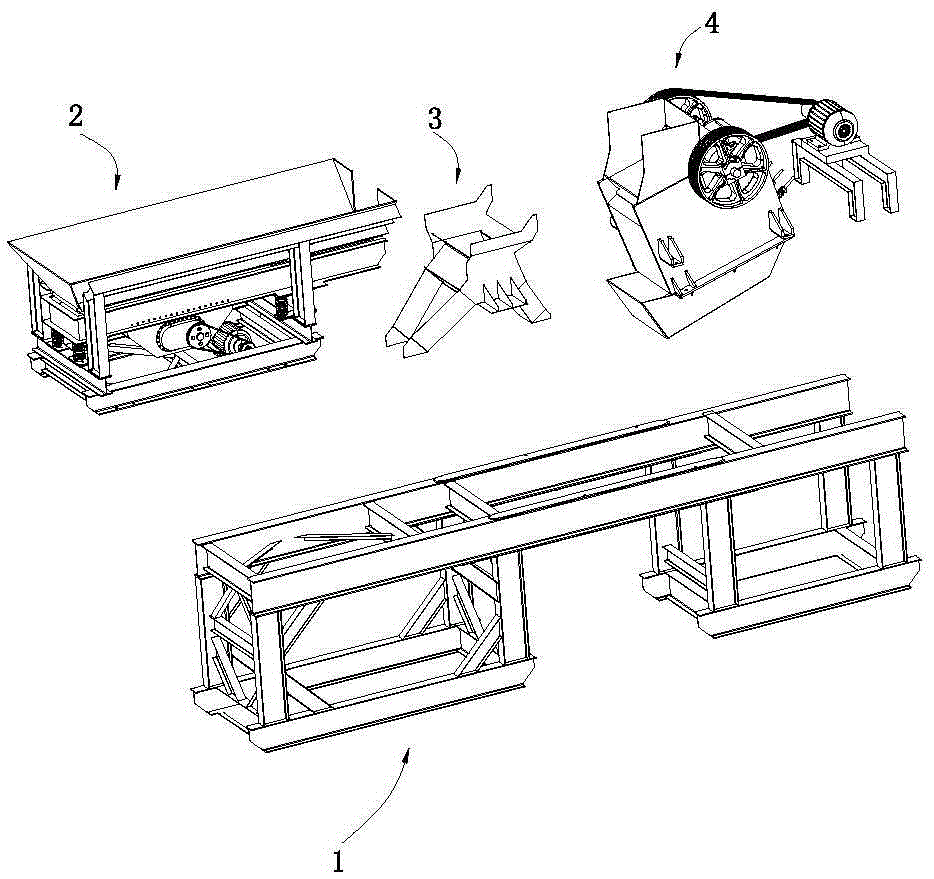

Vibration conveying elastic device of powder coating pulverizer

The invention discloses a vibration conveying elastic device of a powder coating pulverizer. The vibration conveying elastic device comprises a vibration conveying fixed mount and an elastic device, wherein the vibration conveying fixed mount comprises a third beam, a third longitudinal beam, a third upper longitudinal beam, a third inclined strut and a motor fixing beam; the elastic device comprises two left elastic assemblies and two right elastic assemblies; each left elastic assembly comprises a left lower base, a left spring and a left upper base, wherein the left spring is arranged between the left lower base and the left upper base; and each right elastic assembly comprises a right lower base, two right springs and a right upper base, wherein the two right springs are transversely arranged, and are arranged between the right lower base and the right upper base. According to the vibration conveying elastic device, strength can be improved, structural stability can be improved, and amount of elastic deformation can be increased; continuous and reliable conveying for materials can be realized, elastic force of two left springs can be balanced better, and the right lower bases are not liable to have plastic deformation.

Owner:徐妍玲

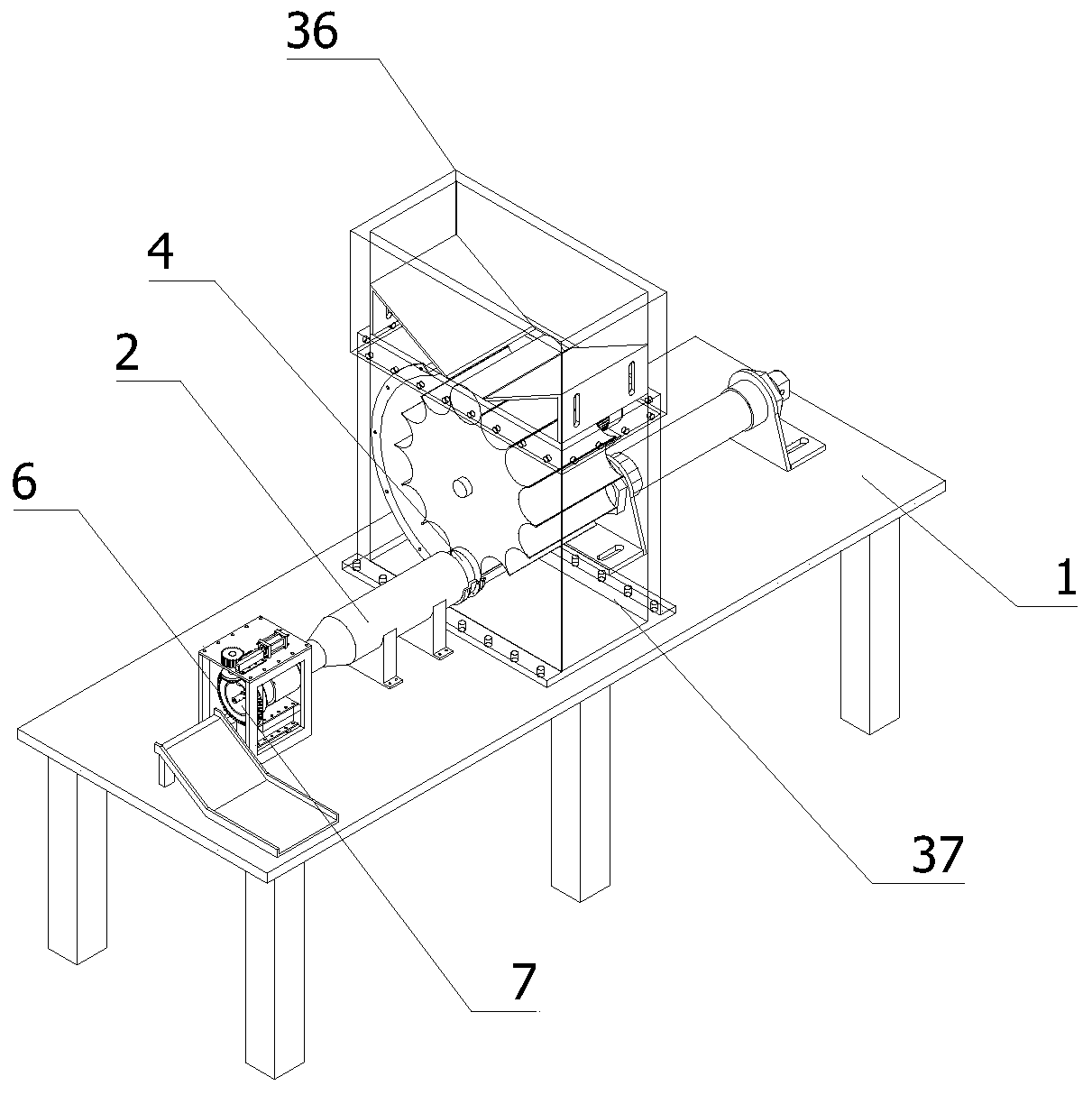

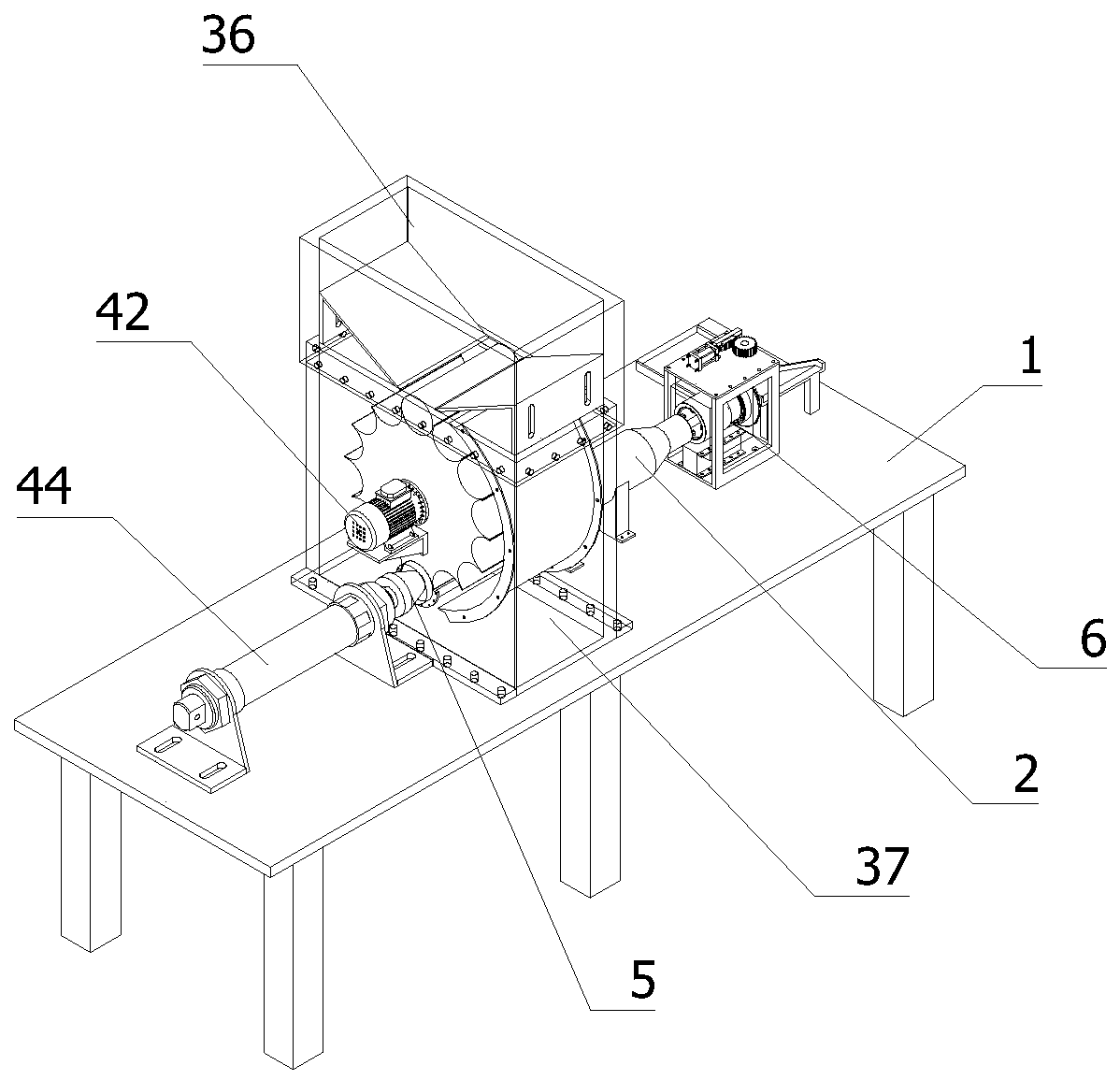

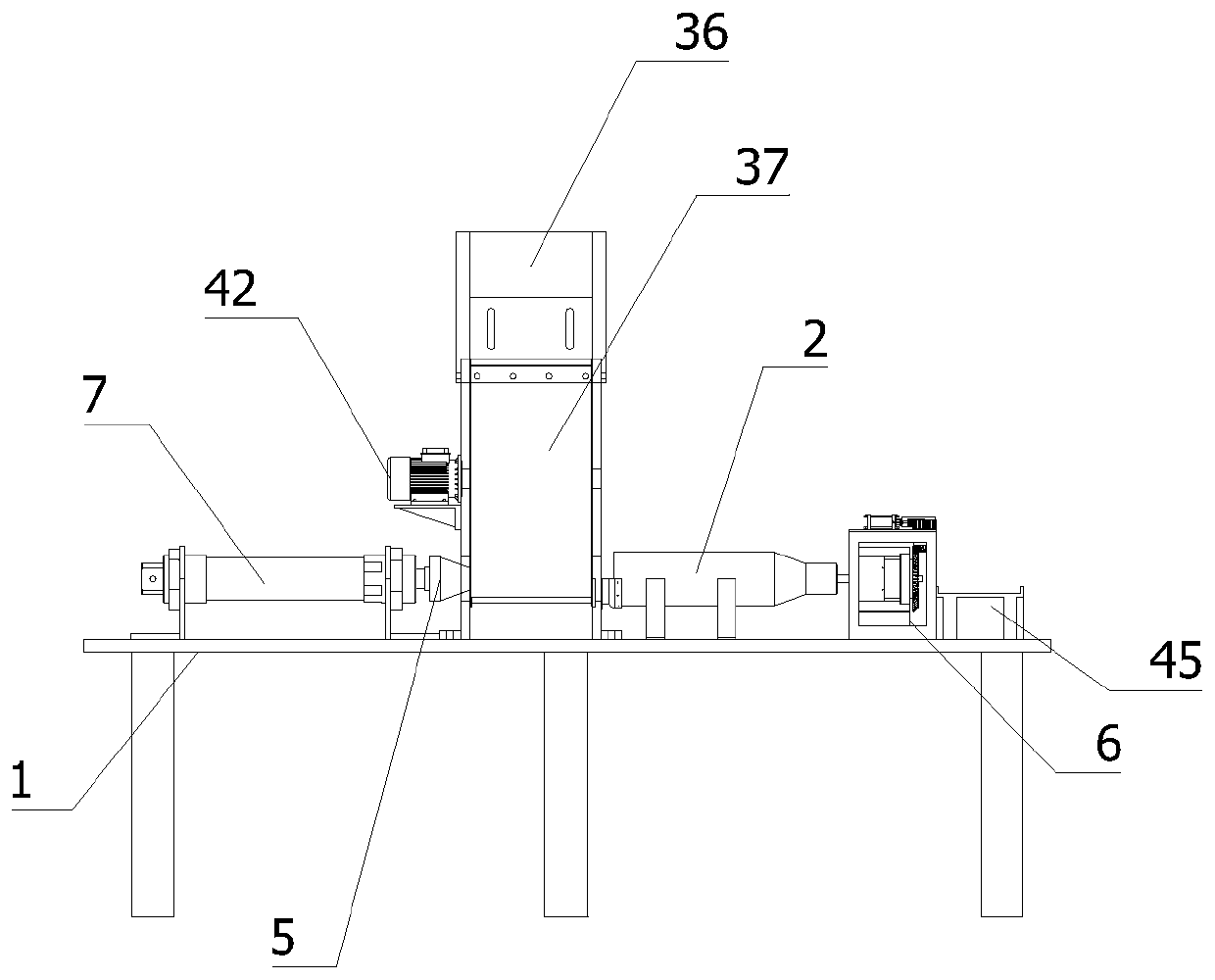

Hard alloy cutter with internal spiral cooling liquid hole and production equipment thereof

InactiveCN111468732AGood molding effectNice appearanceTurbinesOther manufacturing equipments/toolsEngineeringProcess engineering

The invention relates to the technical field of hard alloy cutters, in particular to a hard alloy cutter with an internal spiral cooling liquid hole and production equipment thereof. The production equipment comprises a machining table and further comprises a material supplying mechanism, an extrusion mold mechanism and a cooling discharging mechanism; the extrusion mold mechanism comprises a heating feeding sleeve and a forming mold; the heating feeding sleeve comprises a feeding inlet and a discharging outlet, and the forming mold is installed in the position, located at the discharging outlet, of the heating feeding sleeve; the material supplying mechanism comprises a material supplying bin, the material supplying bin is provided with a material guide opening, and the interior of the material supplying bin is provided with an extrusion head; the cooling discharging mechanism comprises a rotary cooling assembly and a discharging table; and the rotary cooling assembly comprises a cooling bin, the cooling bin is provided with a round through hole penetrating through two surfaces, and the interior of the round through hole is provided with cooling spray heads. According to the technical scheme, through the extrusion forming mold, the size stability of a hard alloy round bar product with the internal spiral hole can be improved, the appearance is attractive, the percent of pass is high, in addition, cooling can be automatically conducted, and the production quality is improved.

Owner:江西耀升钨业股份有限公司

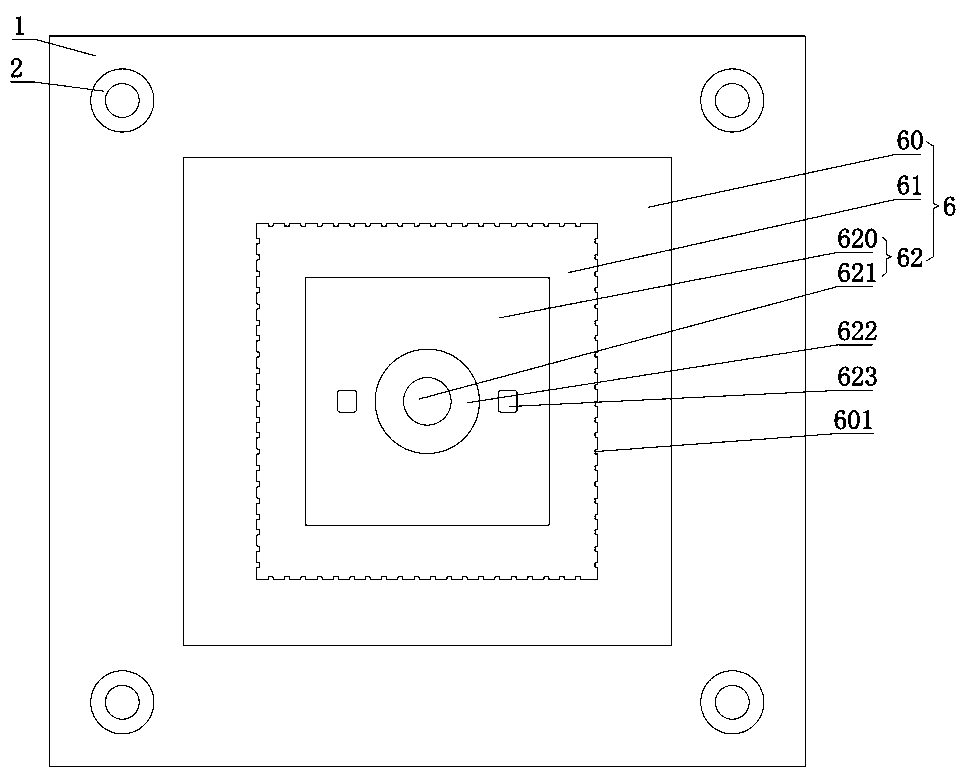

Forging and pressing die

ActiveCN111112532ASmall size deviationHigh precisionForging/hammering/pressing machinesEngineeringMechanical engineering

The invention relates to a forging and pressing die. The forging and pressing die comprises an upper die base, a fixing plate, an upper combination die, a lower combination die and an ejection device,wherein a guide sleeve is arranged on the bottom surface of the upper die base; a guide column is arranged in the guide sleeve in a penetrating mode; the guide column is fixed on a lower die base; athrough hole is formed in the center of the lower die base; an ejector rod movably penetrates into the through hole; the fixing plate is arranged on the top surface of the lower die base; the upper combination die comprises an upper outer die, an upper inner die and an upper die core; the upper die core is a combination body composed of an upper plate body and a round rod; the combination body isarranged in a second upper groove of the upper inner die; a frustum-shaped hole is formed in the bottom surface of the upper plate body; the lower end of the round rod extends out of a first through hole and is arranged in the frustum-shaped hole; the lower combination die comprises a lower outer die, a lower inner die and a lower die core; and an inverted frustum-shaped hole and a residual material groove are formed in the top surface of the lower die core. The forging and pressing die aims to solve the problems that in the prior art, according to a forging and pressing die, the size deviation of a forge piece is prone to being too large, a die cavity is prone to generating plastic deformation, the sudden change position of the inner wall of the die cavity is prone to cracking, and the forge piece is prone to deformation during discharging.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

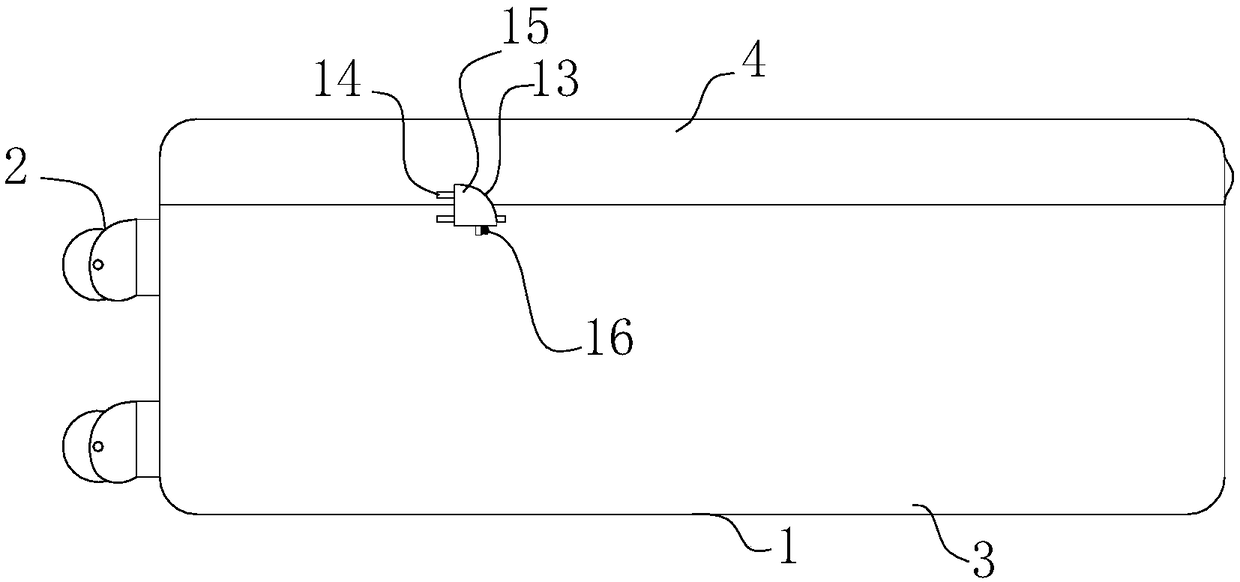

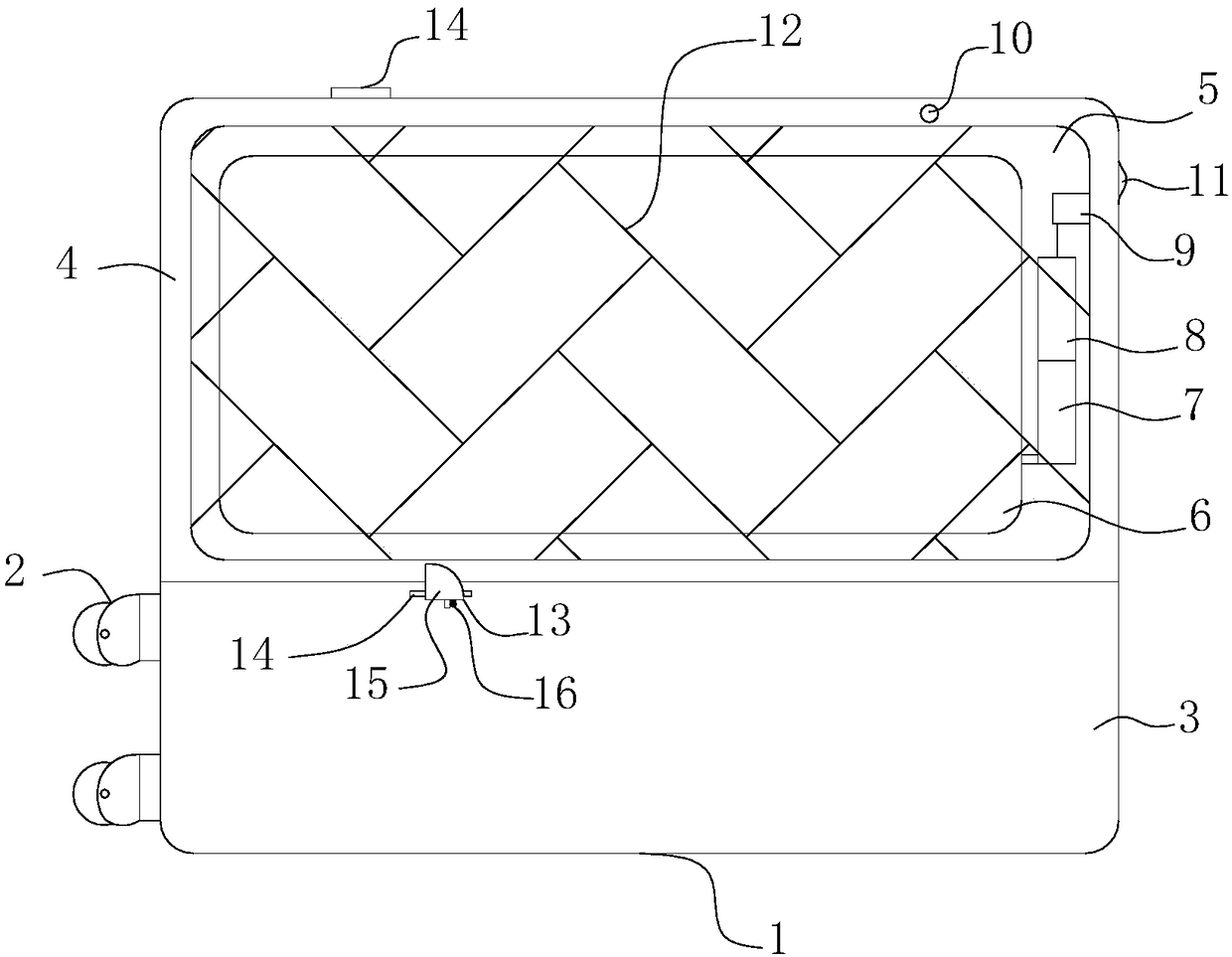

Metal traveling case

PendingCN108783802AImprove user experienceImprove performanceLuggageOther accessoriesEngineeringControl switch

The invention aims to provide a metal traveling case reasonable in structural design and capable of effectively positioning articles in the traveling case. The metal traveling case comprises a box body with a containing cavity and a box cover covering the containing cavity, wherein a cavity is formed in the box cover, an air bag is arranged in the cavity and is inflated by an air pump, a storage battery for supplying power for the air pump is also arranged in the cavity, a control switch and a touch switch are serially connected between the storage battery and the air pump, and the touch switch is triggered after the box cover is closed. After the control switch and the touch switch are triggered, the air pump works to supply air for the air bag, the air bag becomes large after the air pump supplies air for the air bag, accordingly the gap between the box cover and the containing cavity can be compensated, thus the articles in the containing cavity can be effectively positioned, and the use experience of the metal traveling case is optimized.

Owner:ZHEJIANG DEQING WANMEI LUGGAGE

Preparation, product and application of biodegradable 3D printing gel

ActiveCN112194802AEasy to processAdjust the elasticityAdditive manufacturing apparatusGlycerolBiology

The invention provides preparation, a product and application of biodegradable 3D printing gel. The preparation method comprises the steps of preparing a solution from citric acid, glycerin and water,wherein the mass ratio of citric acid to glycerin to water is 1: (2-10): (2-10); mixing glucose syrup with the solution obtained in the step (1), wherein the mass ratio of the glucose syrup to citricacid is (5-9): 1; and (3) adding gelatin into the solution obtained in the step (2), wherein the mass ratio of the gelatin to the citric acid is (6-12): 1. According to the preparation method of the3D printing gel provided by the invention, the stable processability and processing conditions of the gel are realized by adjusting the ratio of water to glycerol, that is, the adjustment of the mechanical strength is realized; the citric acid is added, so that the pH environment of the gel can be adjusted, and meanwhile, the growth of microorganisms can be inhibited; all the selected materials are food-grade, environment-friendly and easy to degrade.

Owner:CHINA AGRI UNIV

Manufacture method of waterproof power connector and waterproof connector adopting same

InactiveCN101609955BImprove tensile propertiesImprove sealingRelieving strain on wire connectionContact member assembly/disassemblyPlastic injection moldingMechanical engineering

Owner:HE SHAN LIDE ELECTRONICS ENTERPRISE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com