Patents

Literature

37results about How to "Antioxidant performance is stable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

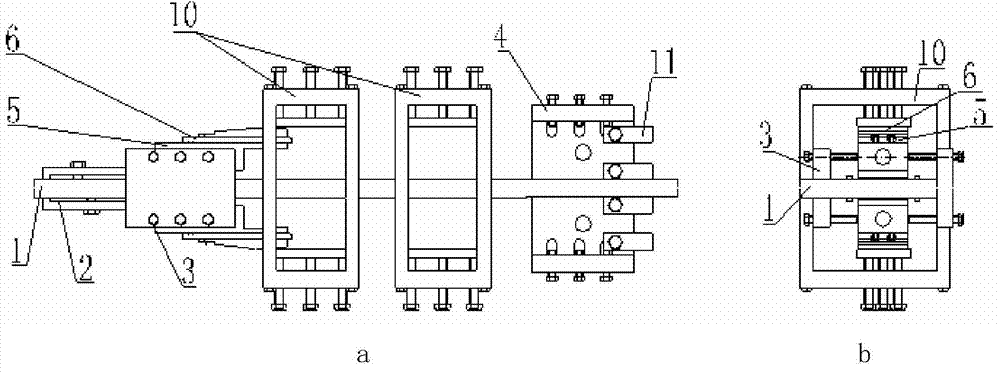

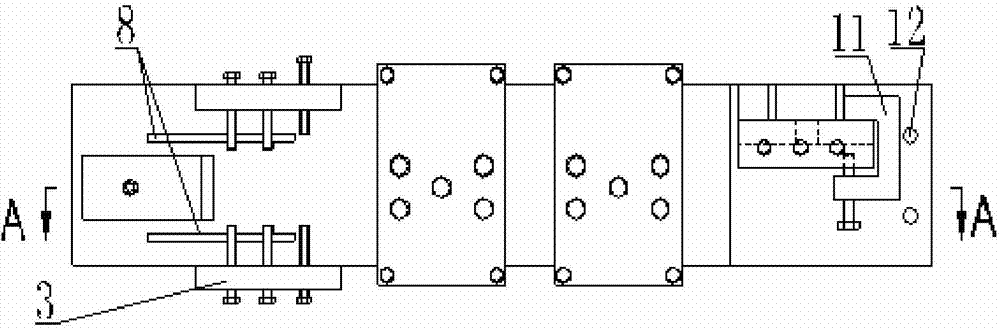

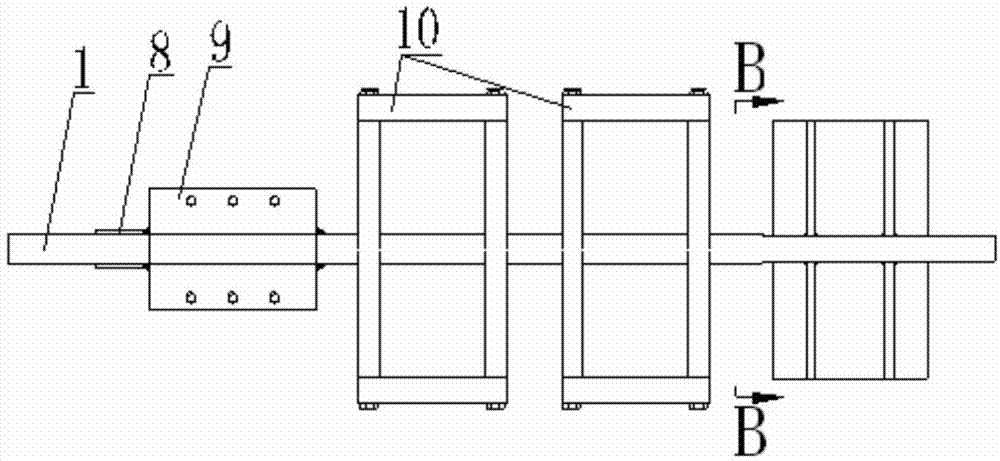

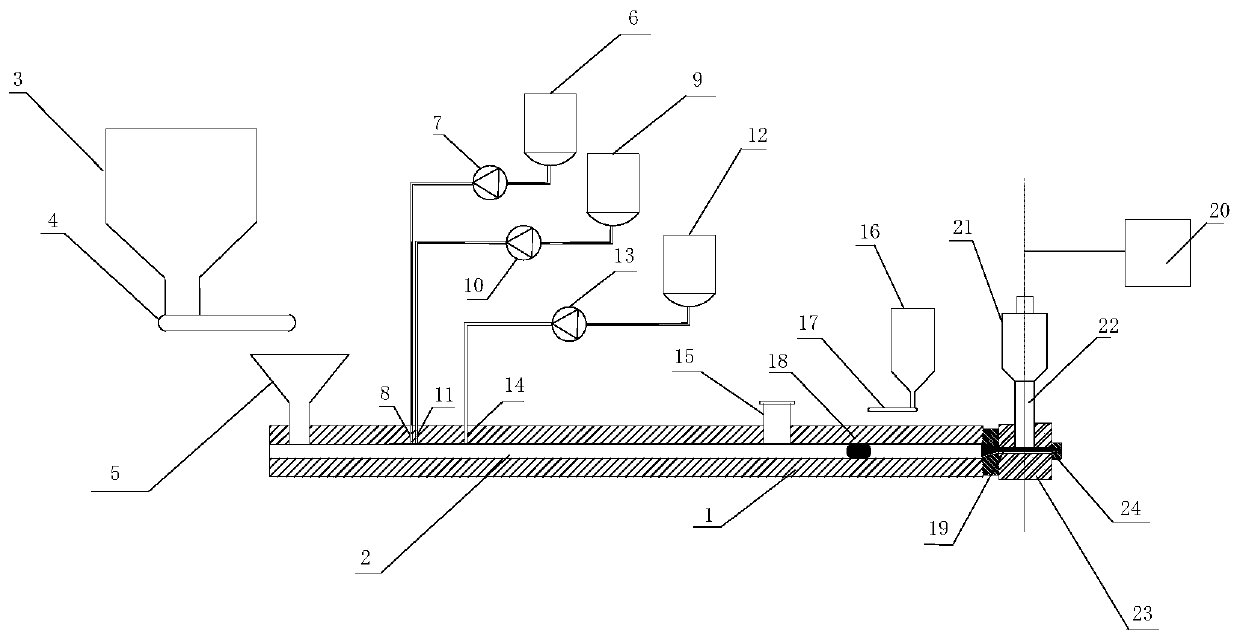

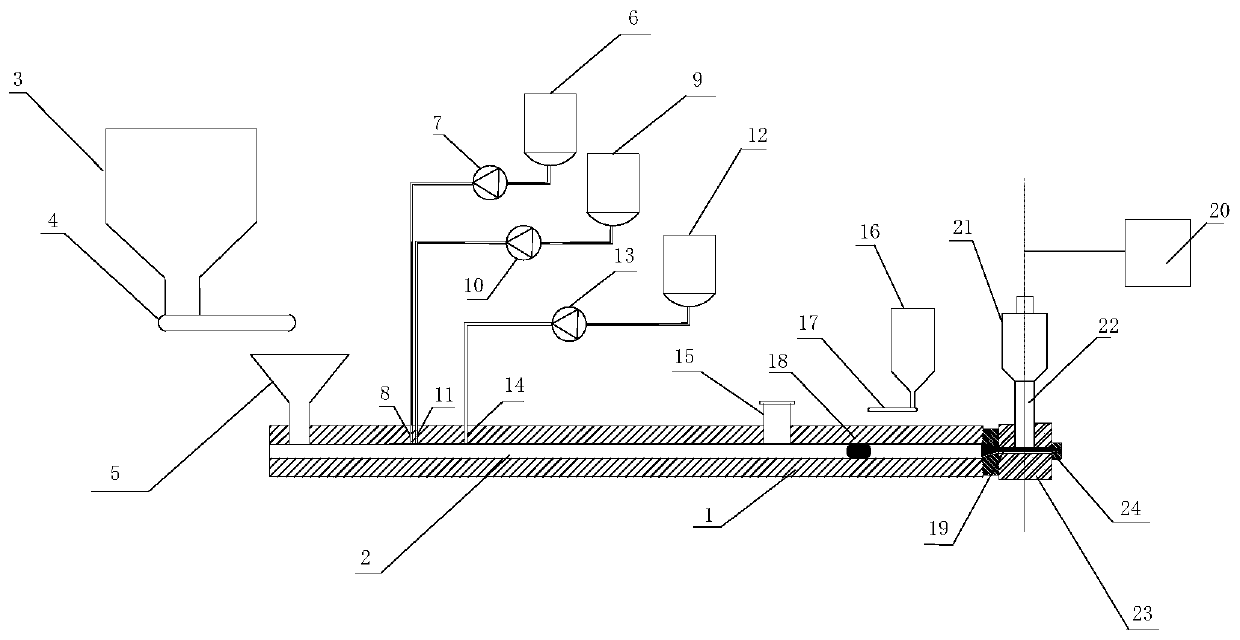

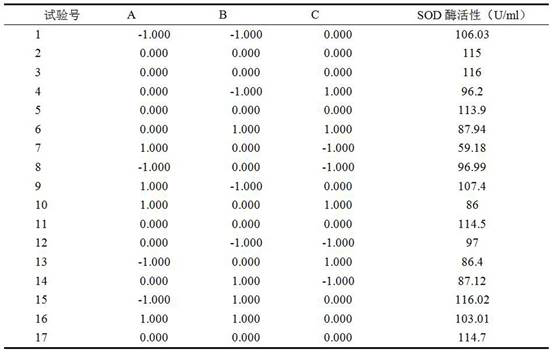

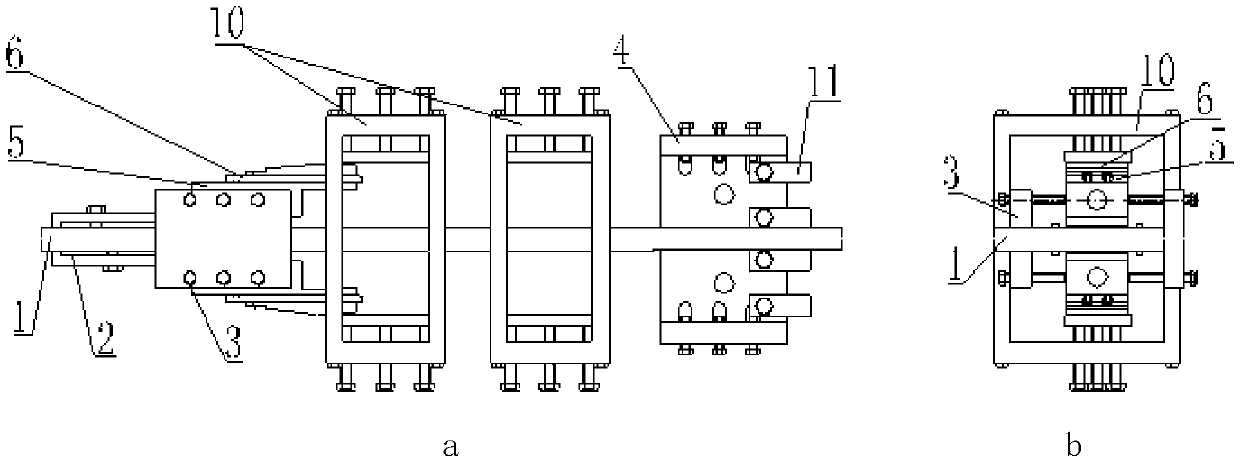

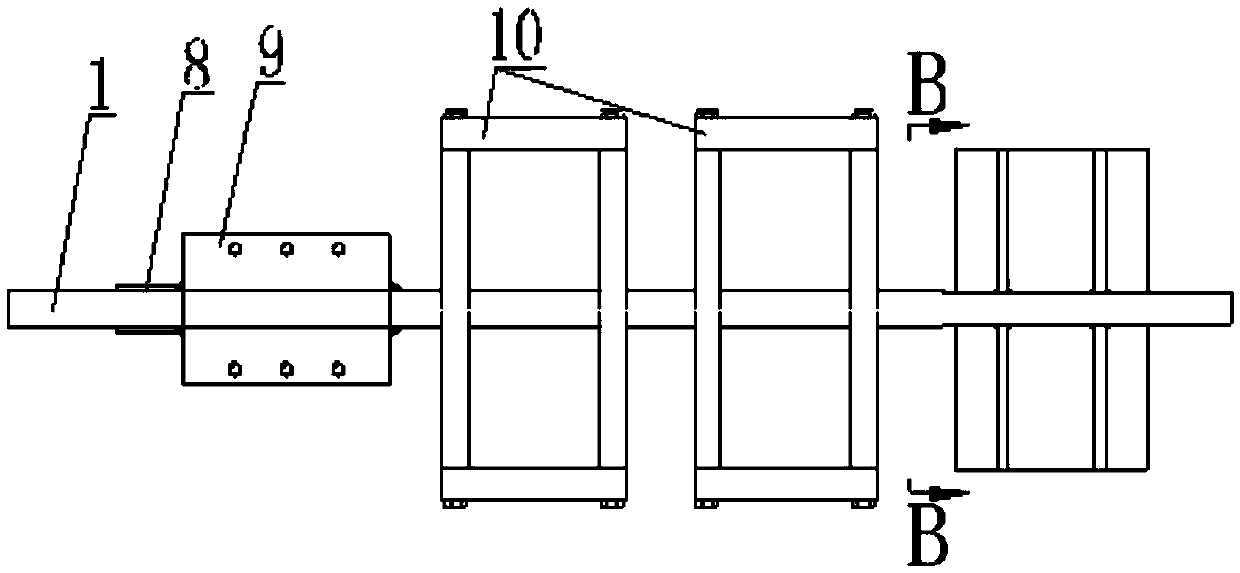

Device for heat shaping of thin-walled titanium alloy parts

The invention relates to a device for heat shaping of thin-walled titanium alloy parts. A first pressing mechanism is fixed at one end of a body, and a second pressing mechanism is fixed at the other end of the body. Two clamping mechanisms are mounted in the middle of the body. Two clamping plates of a lateral ejection mechanism are fixed on two lateral surfaces of the body respectively and located between the first pressing mechanism and the clamping mechanisms. A width inner-supporting mechanism is located between the two clamping plates of the lateral ejection mechanism, one end of the width inner-supporting mechanism is mounted in a to-be-shaped part, and cavity inner-supporting mechanisms are mounted on the upper surface and the lower surface of the width inner-supporting mechanism. One ends of the cavity inner-supporting mechanisms are mounted in the clamping mechanisms, so that a support body with a wedge-shaped inner cavity is formed in the to-be-shaped part. By the device, utilization rate of a heat treatment furnace is increased, and cost of vacuum heat shaping is lowered. Since the to-be-shaped parts are clamped symmetrically, main stresses of a tooling are symmetric in direction and offset each other, stress state of the tooling is improved, and deformation resistance of the tooling is enhanced indirectly.

Owner:XIAN AEROSPACEMOTOR MACHINE FACTORY

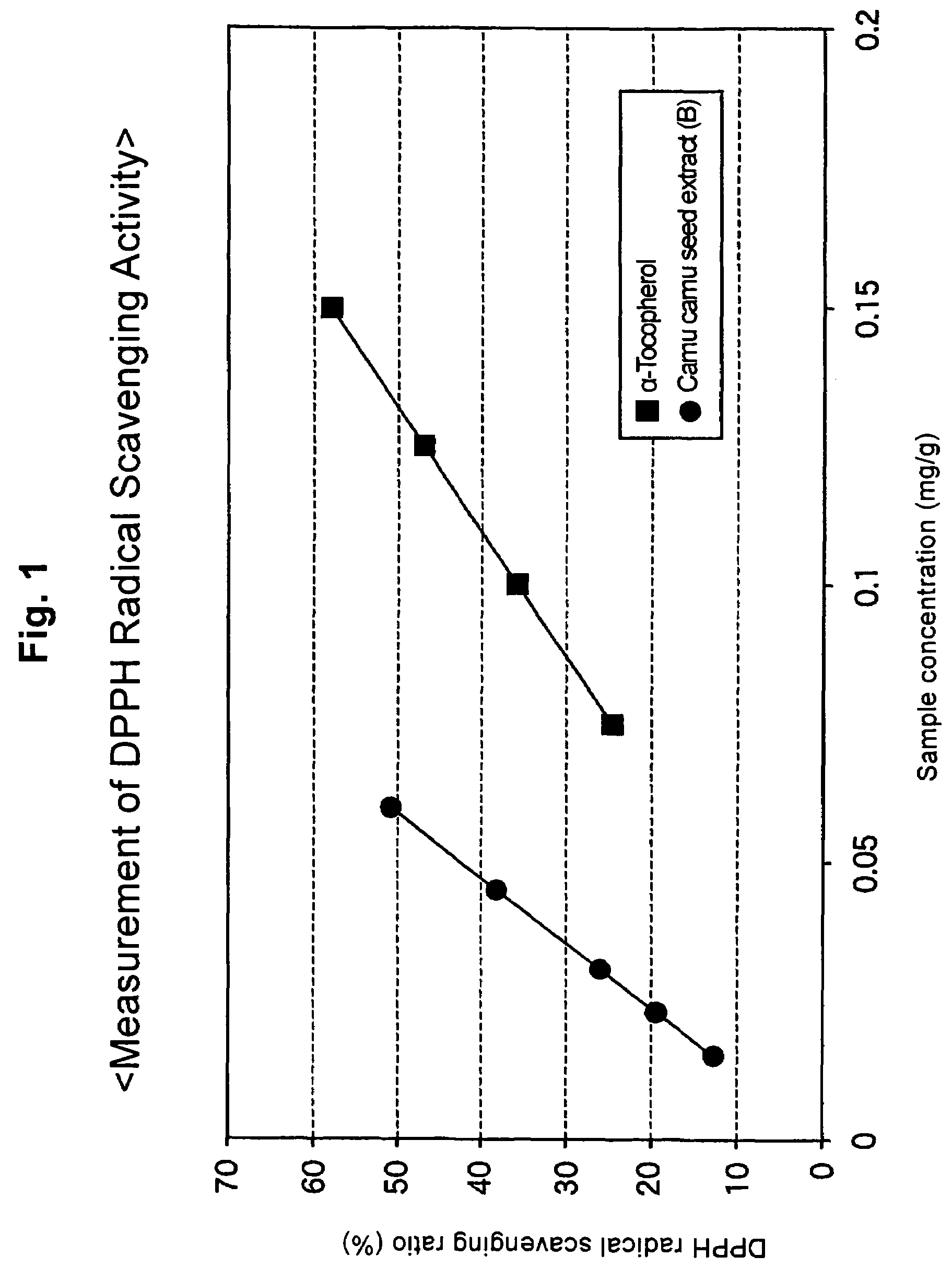

Whitening agent, skin preparation for external use and cosmetic

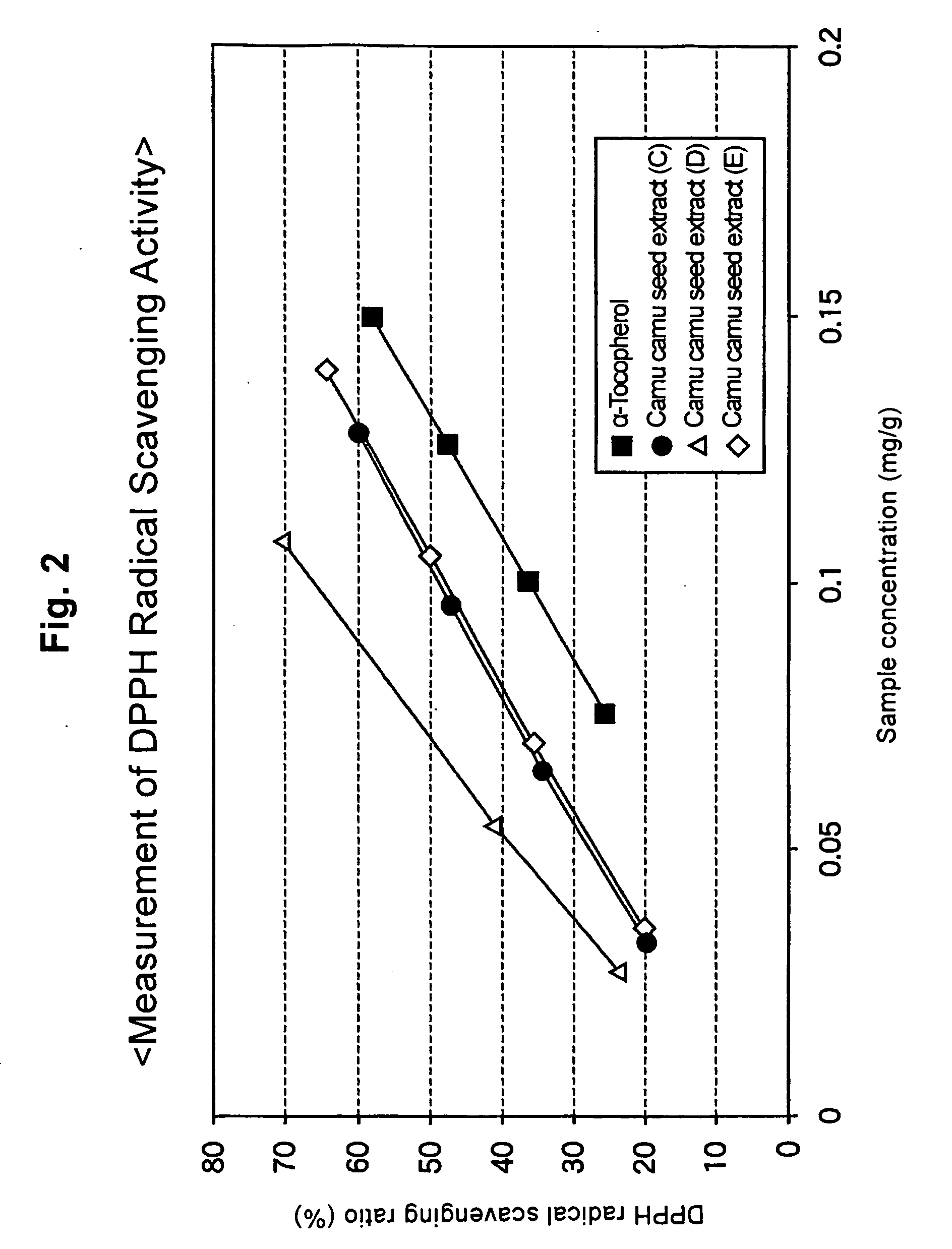

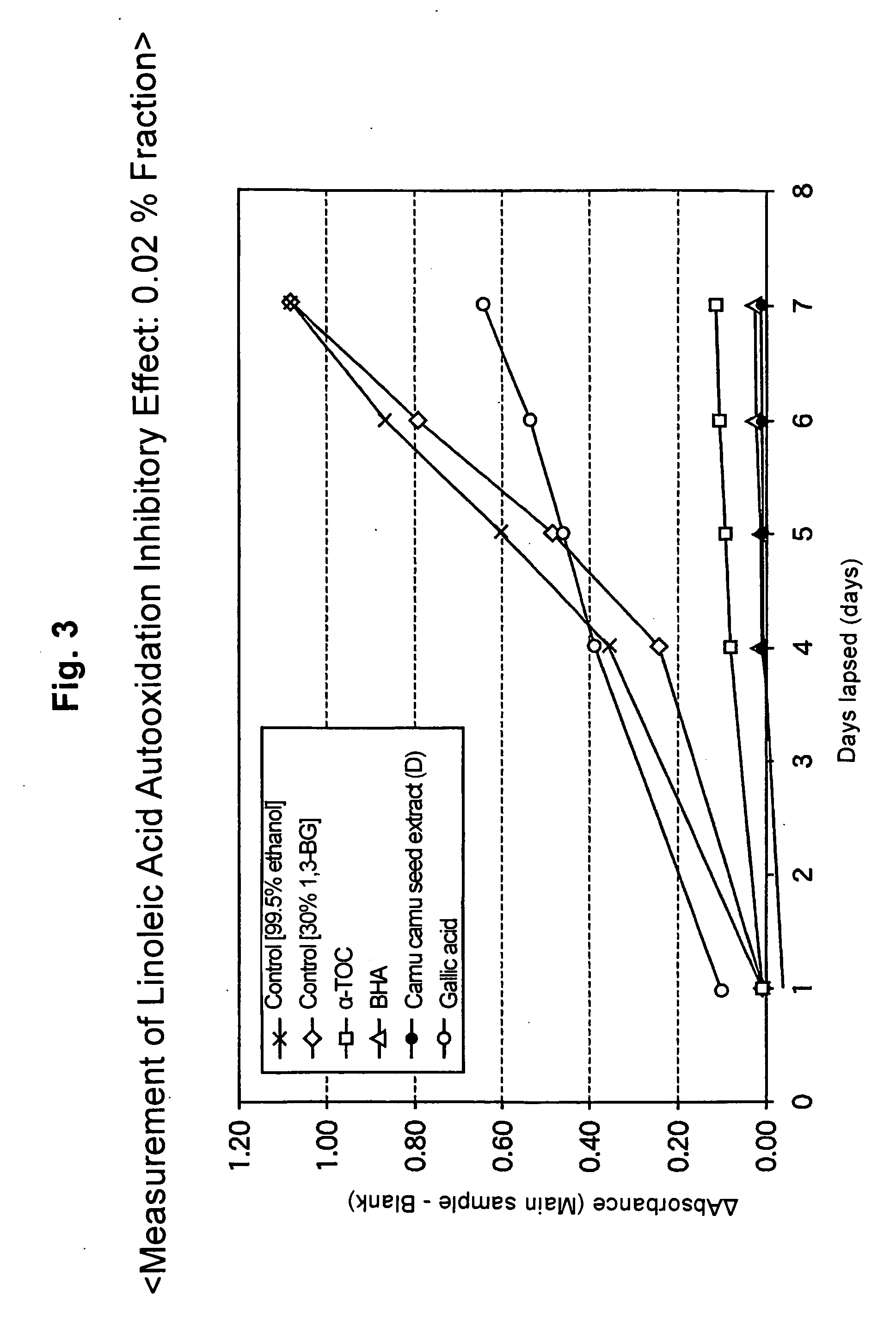

ActiveUS7192617B2High effectImprove securityBiocideCosmetic preparationsActive componentWhitening Agents

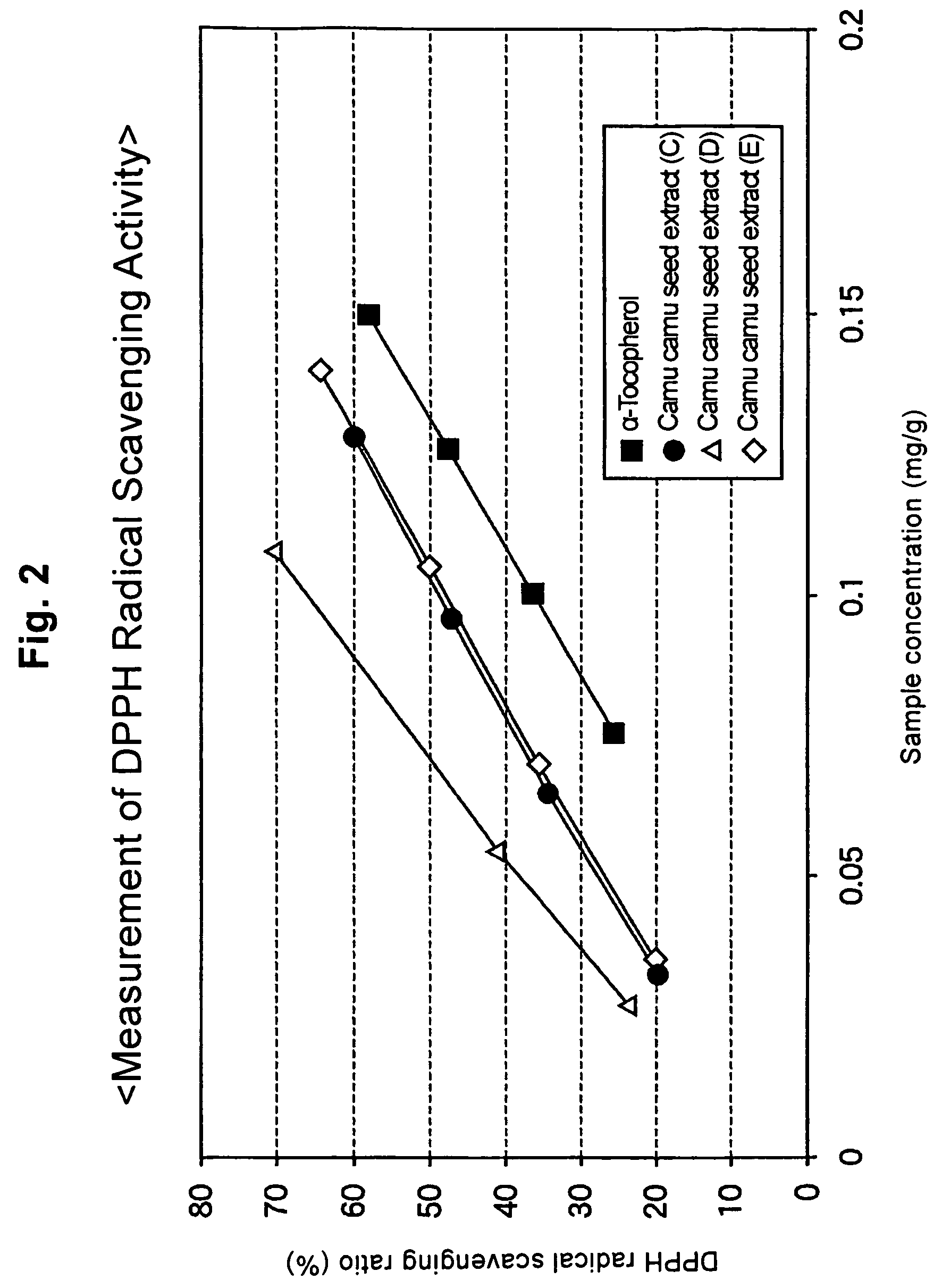

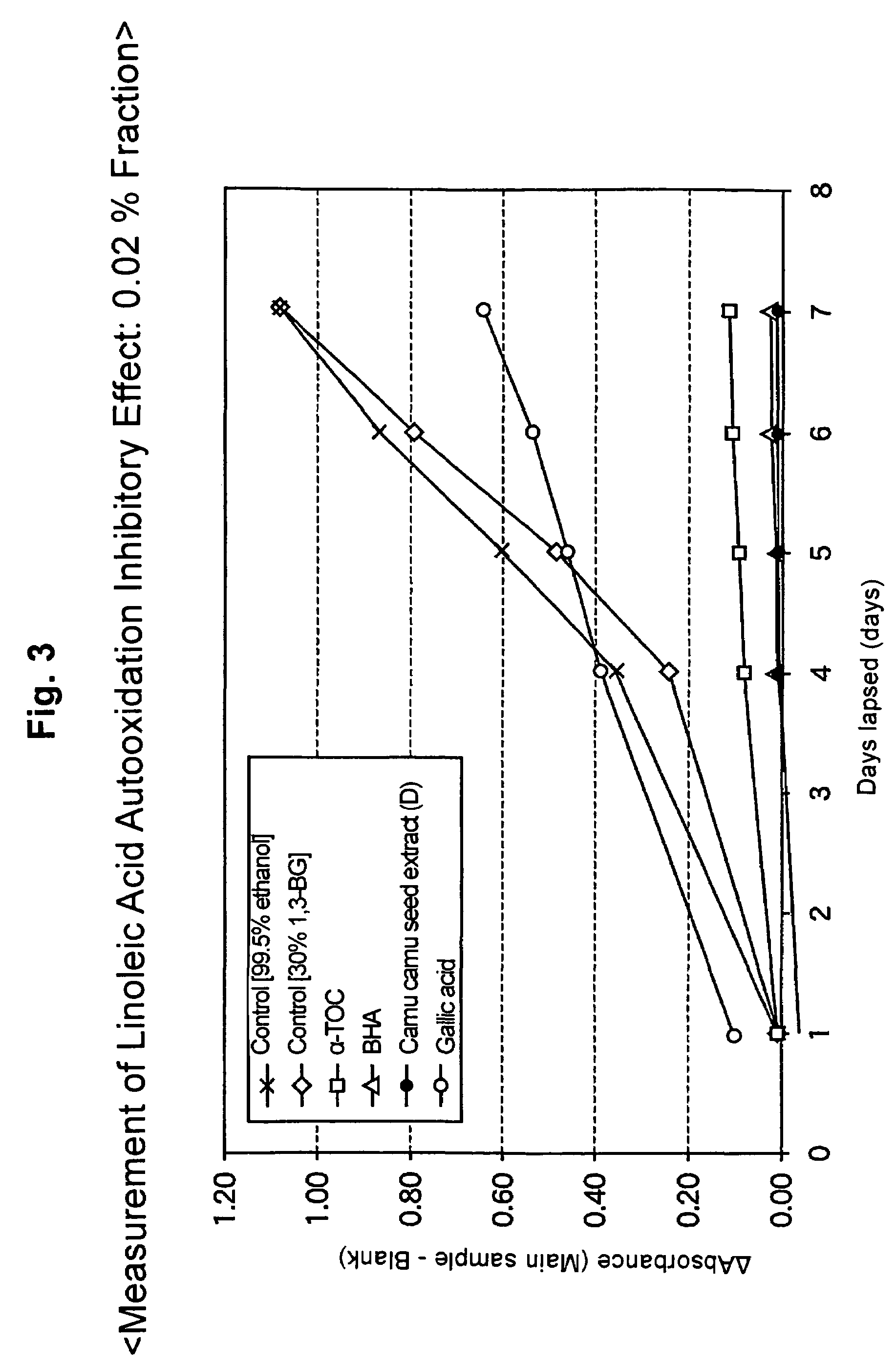

The invention relates to a whitening agent that makes effective use of camu camu seeds, which have conventionally been discarded, and that has high safety and whitening effect useful in cosmetics and the like, as well as skin preparations for external use and cosmetics containing the whitening agent. The whitening agent of the present invention contains camu camu seed extract as an active component, and the skin preparations for external use and cosmetics of the present invention contain the whitening agent.

Owner:NICHIREI BIOSCIENCE INC

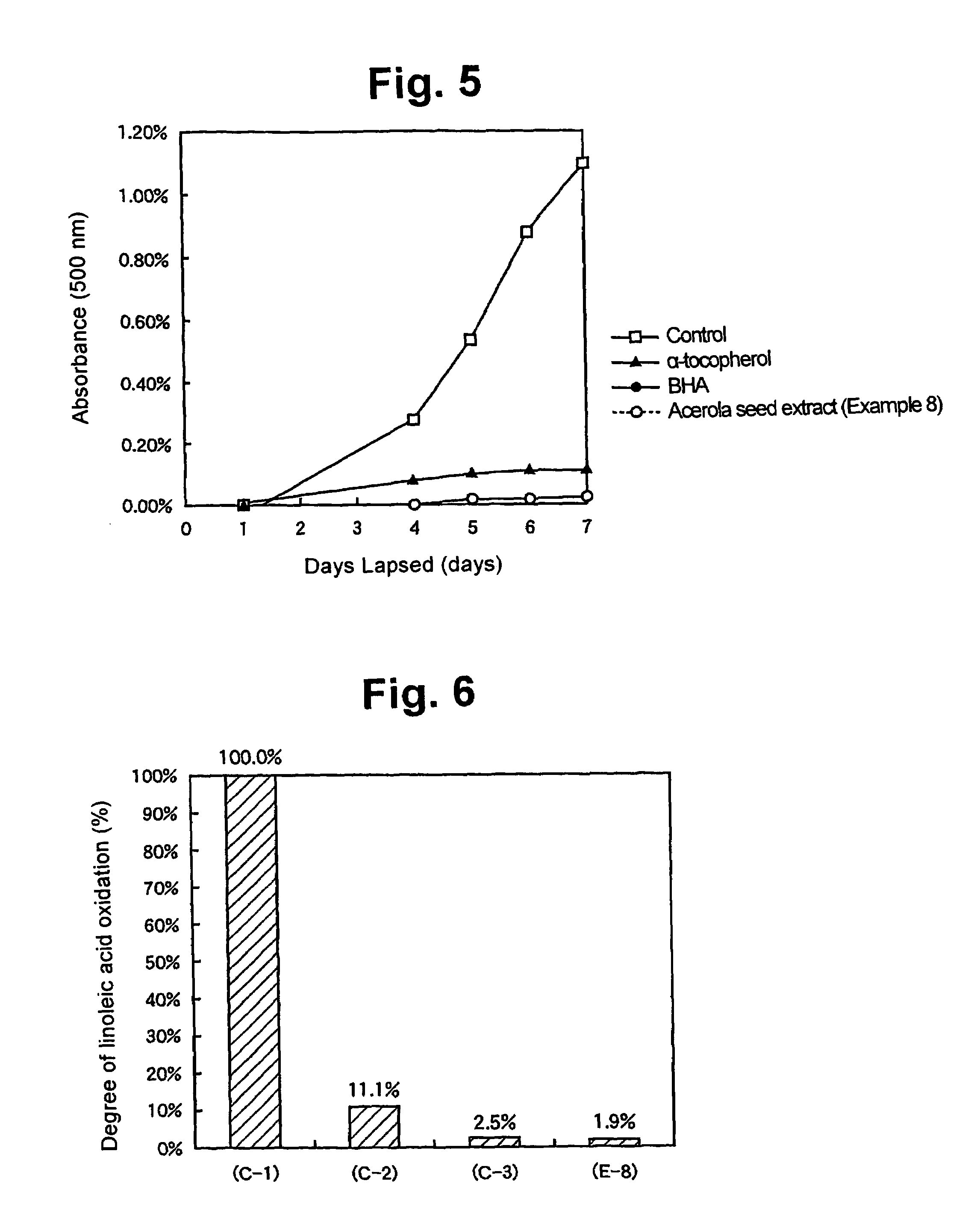

Antioxidant, skin preparation for external use, cosmetic and food

Owner:NICHIREI BIOSCIENCE INC

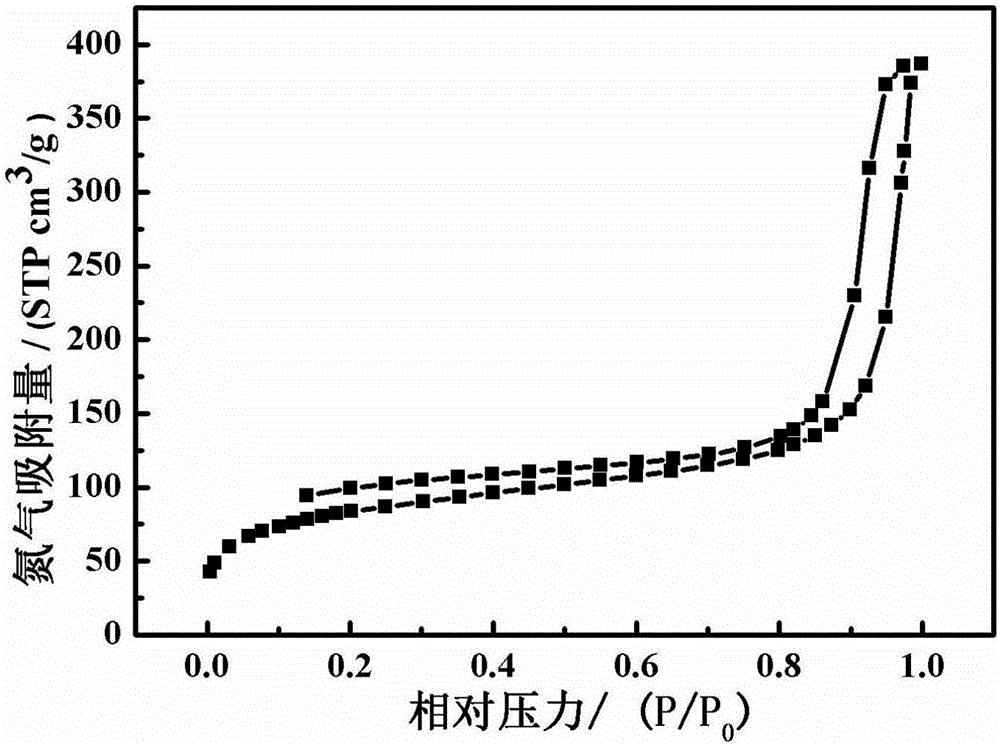

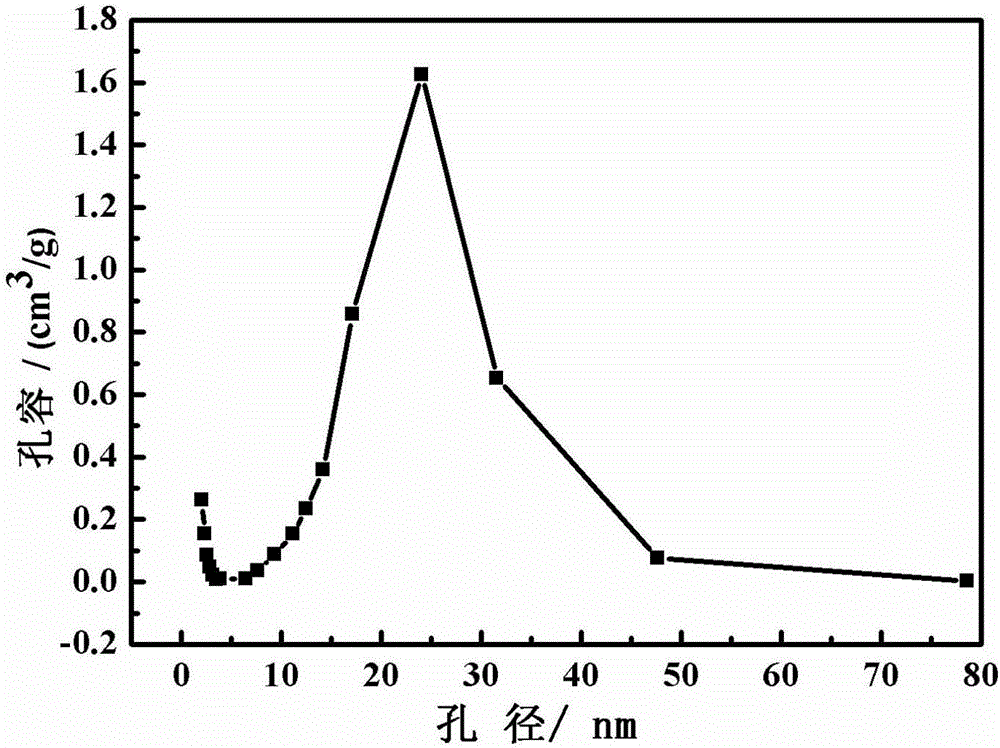

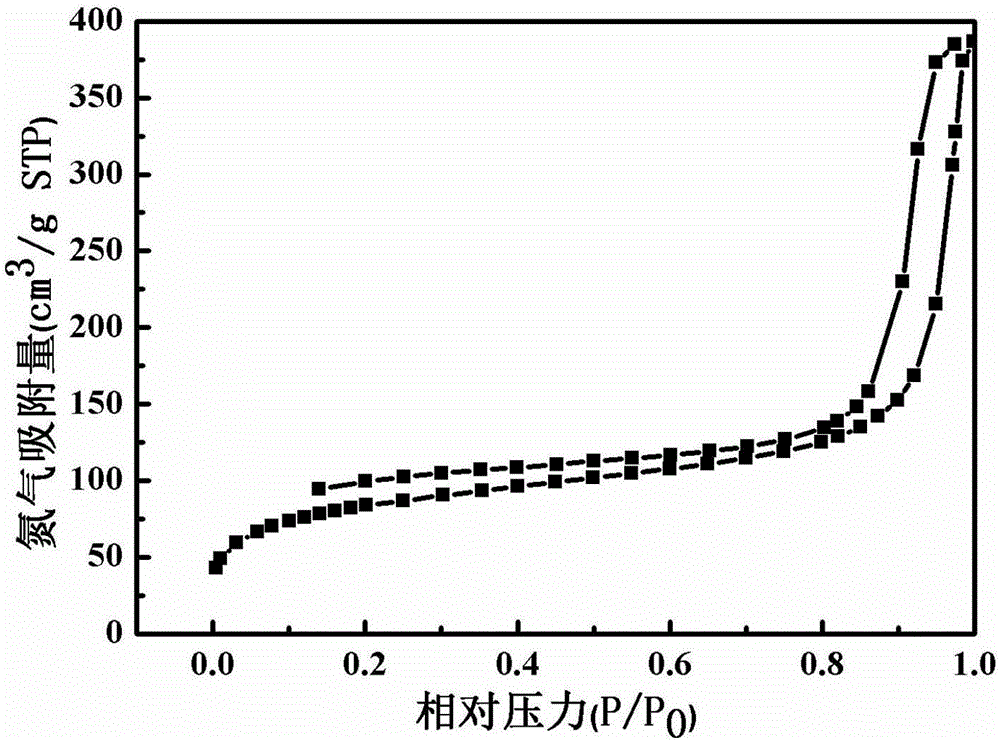

Preparation method of SiOC ceramic aerogel

InactiveCN106242610AHigh specific areaNarrow pore size distributionCeramicwareSupercritical dryingArgon atmosphere

Provided is a preparation method of SiOC ceramic aerogel. The invention relates to an aerogel material preparation technology, in particular to a preparation method of the SiOC ceramic aerogel. The problem that for an existing method for preparing the SiOC ceramic aerogel, the aperture is difficult to control is solved. The method comprises the steps that hydrogen-containing polymethylsiloxane, 2,4,6,8-tetramethyl-2,4,6,8-tetravinylcyclotetrasiloxane, chloroplatinic acid and acetone are mixed to be uniform and then put into a hydrothermal reaction kettle for reacting, and gel is obtained; the gel is soaked with acetone and ethyl alcohol in sequence, supercritical drying treatment is conducted, the temperature is increased to 700 DEG C to 1,300 DEG C under a nitrogen or argon atmosphere, heat preservation is conducted for 1 h to 3 h, natural cooling is conducted to room temperature, and the SiOC ceramic aerogel is obtained. The SiOC ceramic aerogel has the advantages of being high in specific surface area, narrow in pore diameter distribution, stable in structure and stable in temperature resistance and oxidation resistance and can be applied to the fields of thermal insulation, energy storage and the like.

Owner:HARBIN INST OF TECH

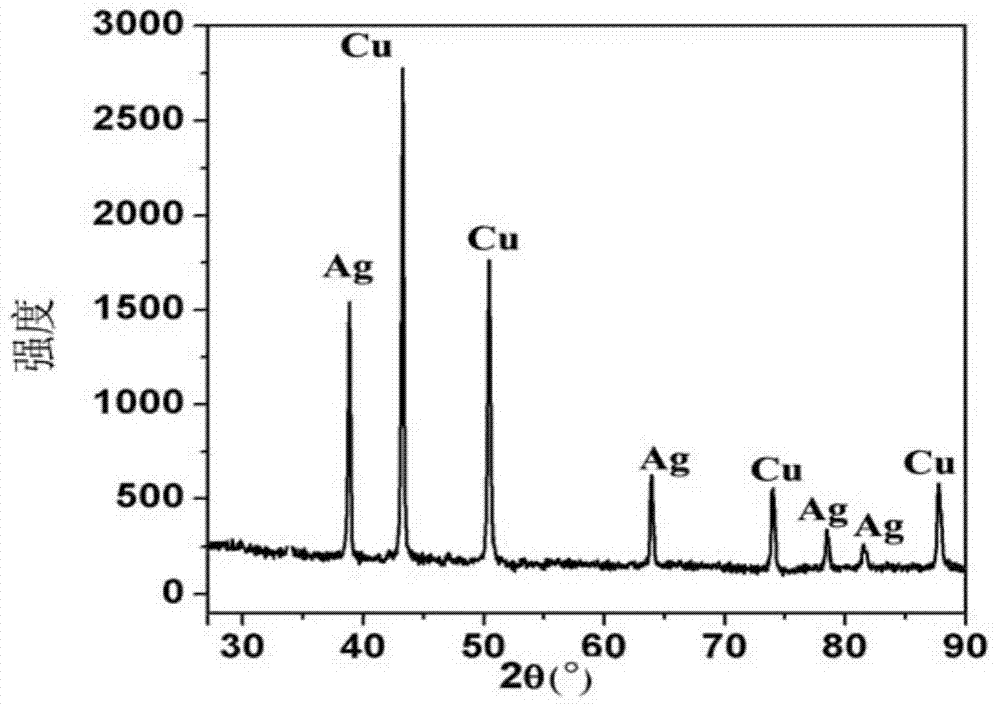

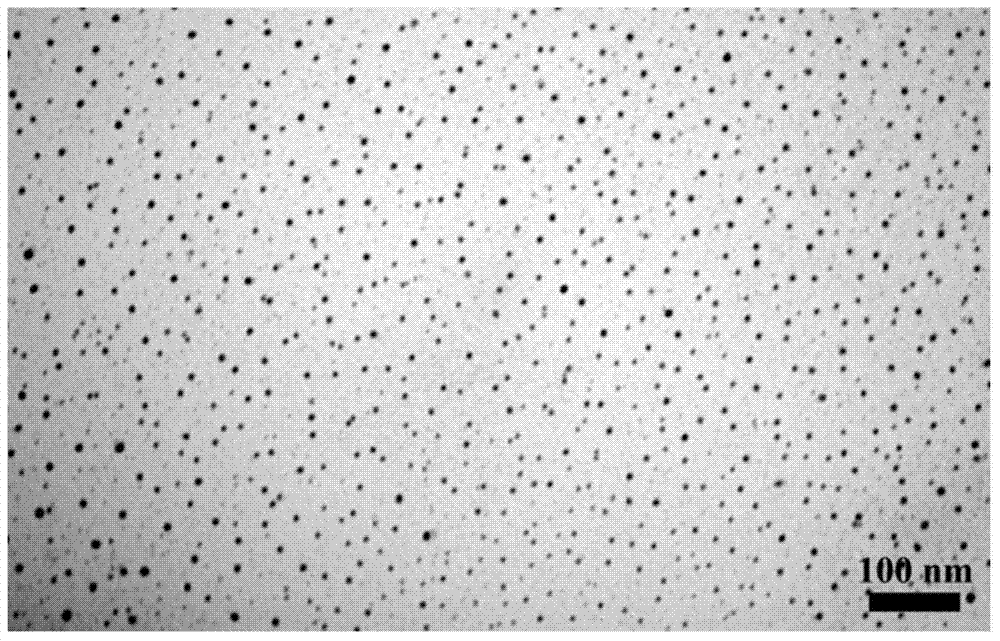

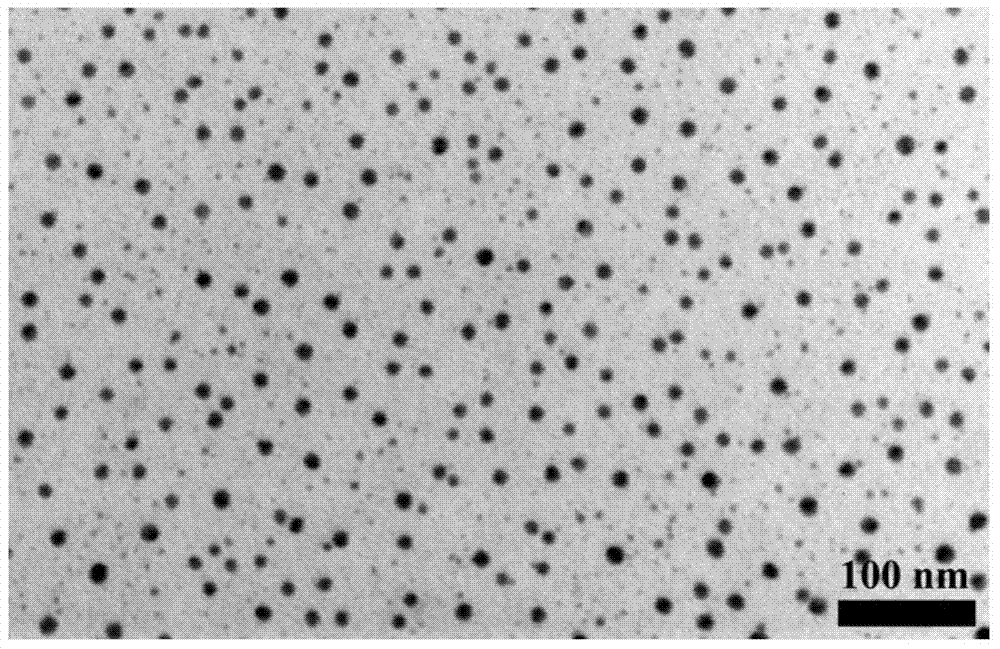

Preparation method for copper/silver heterojunction nano-particles

InactiveCN103691965ASolve technical problems that are difficult to disperseAntioxidant performance is stableMaterial nanotechnologyHeterojunctionSolvent

The invention discloses a preparation method for copper / silver heterojunction nano-particles. The preparation method comprises the following steps of: (1) adding a reducer in copper salt solution with stirring, and reacting for 1-3 hours; performing centrifugal separation and precipitate extraction on the reaction solution after the reaction is concluded, so as to obtain nano-copper samples; (2) dispersing the nano-copper samples obtained in the step (1) in a solvent, so as to obtain nano-copper solution; then adding silver salt solution in the nano-copper solution, heating to 70-180 DEG C and reacting for 1-6 hours, and performing centrifugal separation and precipitate extraction on the reaction solution after the reaction is concluded, so as to obtain the copper / silver heterojunction nano-particles. According to the preparation method disclosed by the invention, the copper / silver heterojunction nano-particles are prepared by performing a replacement reaction on the surface layer of copper, and the reducer is added to disperse nano-copper during the preparation process, thus solving the technical problem that nano-copper powder is difficult to disperse; moreover, the preparation method is simple in process and low in preparation cost.

Owner:SOUTH CHINA UNIV OF TECH

High-flame retardation solar energy cell organosilicon pouring sealant and preparation method thereof

InactiveCN107384305AHigh transparencyGood flexibilityNon-macromolecular adhesive additivesMacromolecular adhesive additivesCross-linkAcrylic resin

The invention relates to a high-flame retardation solar energy cell organosilicon pouring sealant and a preparation method thereof. The high-flame retardation solar energy cell organosilicon pouring sealant comprises the following raw materials in parts by weight: 40 parts of methyl phenyl vinyl silicone rubber, 20 parts of room-temperature sulfured phenylene silicone rubber, 20 parts of addition-type heat vulcanized nitrile silicone rubber, 20 parts of phosphate silicone oil, 20 parts of polyoxypropylene glycerol ether silicone oil, 10 parts of mercapto silicone oil, 5 parts of low-molecular hydroxy silicone oil, 5 parts of hydrogen-containing silicone oil with hydrogen containing amount accounting for 0.5% of mass content, 10 parts of an ethene-vinyl acetate copolymer, 10 parts of otcamethylcyclotetrasiloxane-modified acrylic resin, 7 parts of hydrogenated castor oil, 1-3 parts of an adhesion agent, 1-3 parts of a strengthening agent, 0.1-0.4 parts of a catalyst, 1-3 parts of a silicon nitrogen cross-linking agent, 0.5-2.5 parts of an inhibitor, and 1-2 parts of a flame-retardation filling material.

Owner:NINGBO HUASHUN SOLAR ENERGY TECH

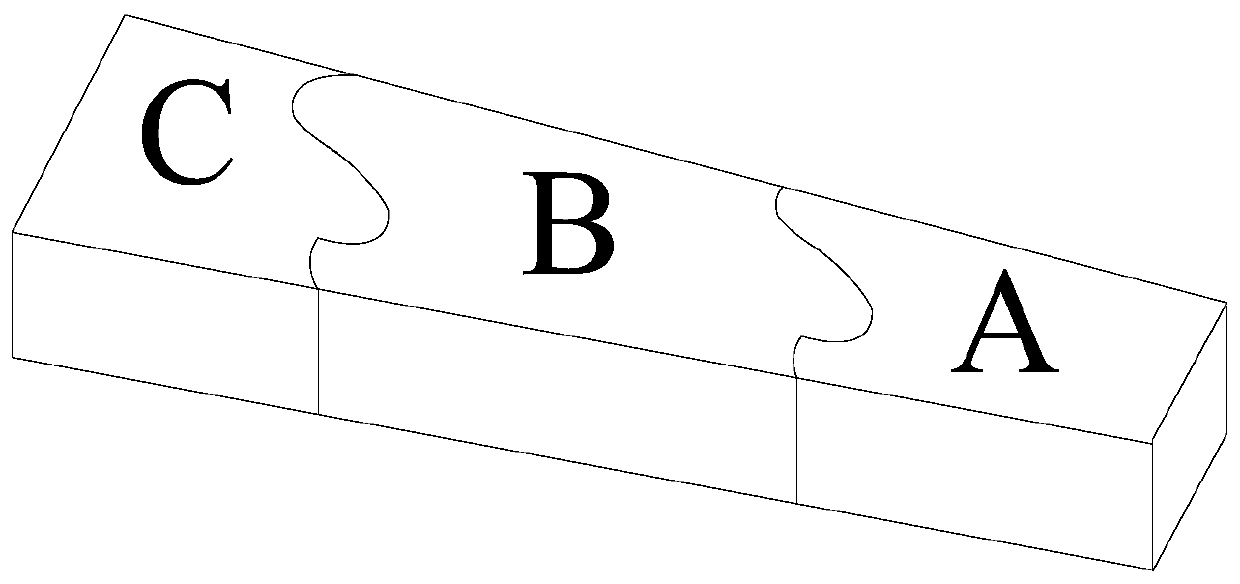

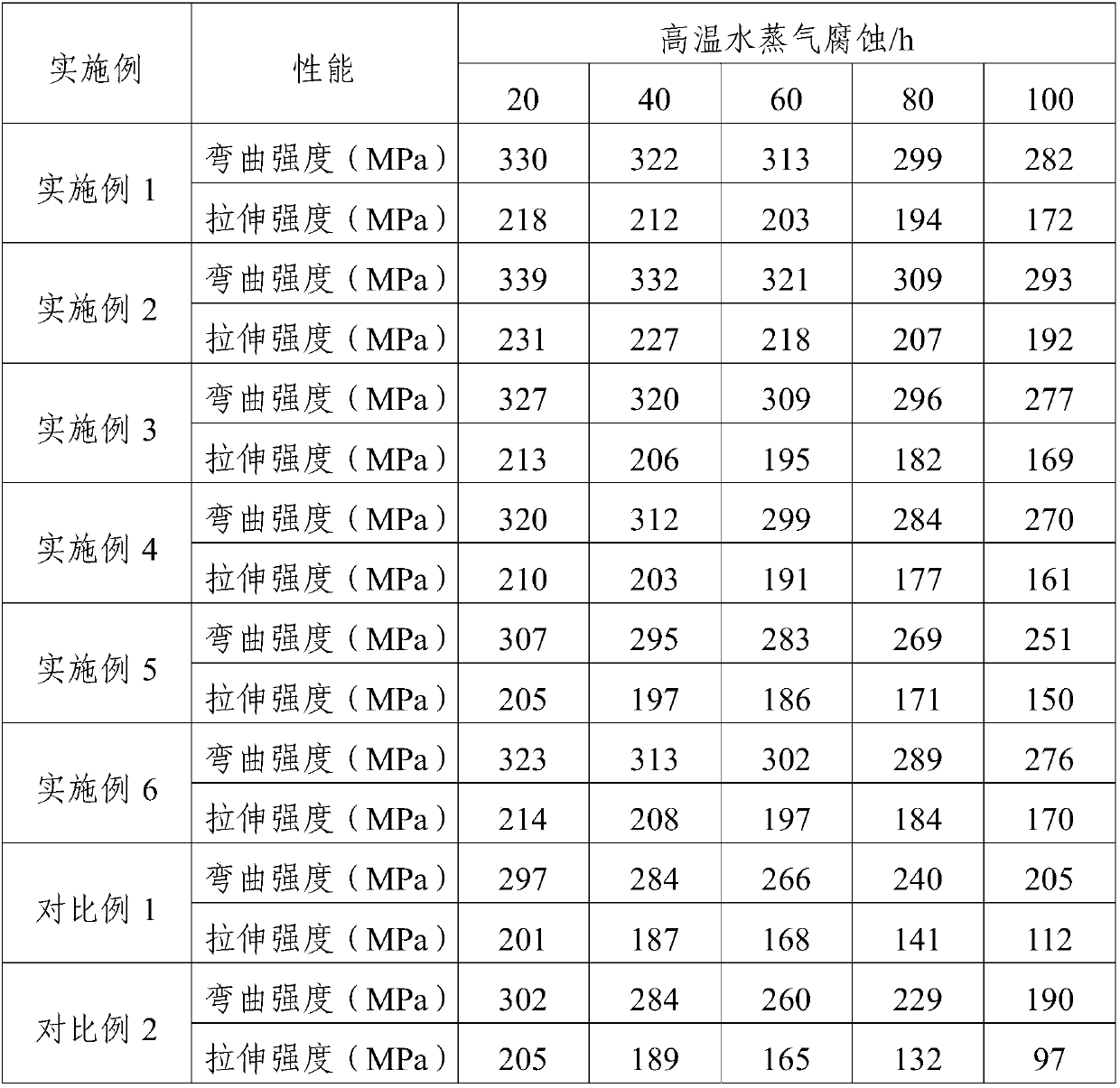

Composite converter magnesia-carbon brick and preparation method thereof

InactiveCN110423125AImprove mechanical propertiesAntioxidant performance is stableManufacturing convertersProcess efficiency improvementMagnesiumMaterials science

The invention discloses a composite converter magnesia-carbon brick and a preparation method thereof, and belongs to the technical field of steel making. The magnesia-carbon brick comprises an A part,a C part, and a B part positioned between the A part and the C part; one side surface of the B part is serrated and is tightly engaged with one side surface of the A part, and the other side surfaceof the B part is also serrated and is tightly engaged with one side surface of the C part. The part A is used as a working layer, wherein a high-quality fused magnesia raw material is adopted to forma stable internal network structure with a carbonaceous raw material and a bonding agent, so that integral high-temperature resistance of the magnesia-carbon brick is improved; the B part is used as atransition between the working layer and a non-working area, wherein a high-quality fused magnesia raw material and regenerated magnesia carbon bricks are adopted, so that integral high-temperature resistance of the magnesia-carbon brick is ensured; and the C part is used as a non-working area, wherein the whole C part is prepared by regenerated magnesia-carbon bricks are adopted, so that production cost is reduced. The composite converter magnesia-carbon brick is suitable for popularization and use by enterprises.

Owner:WUGANG REFRACTORY CO LTD

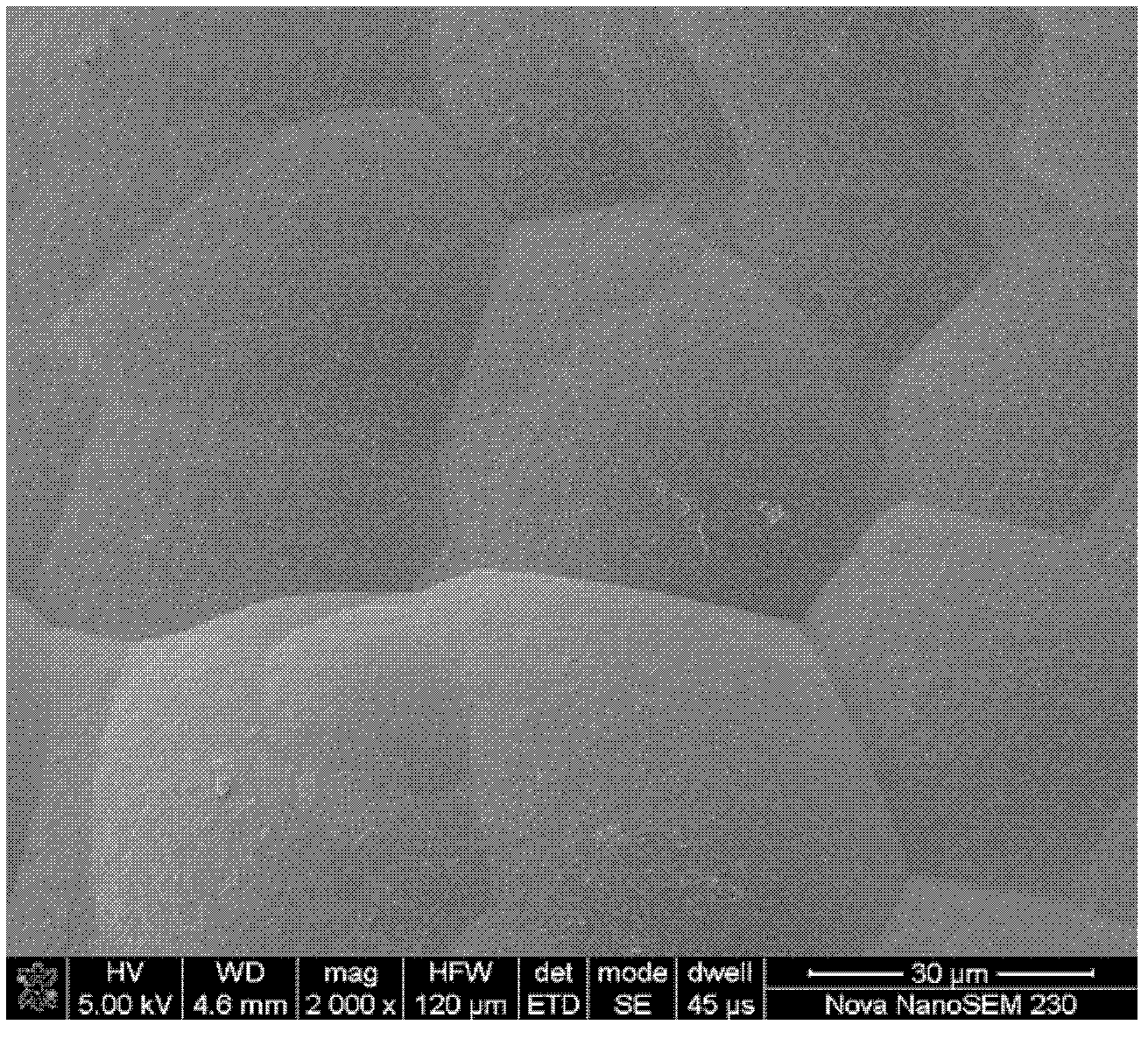

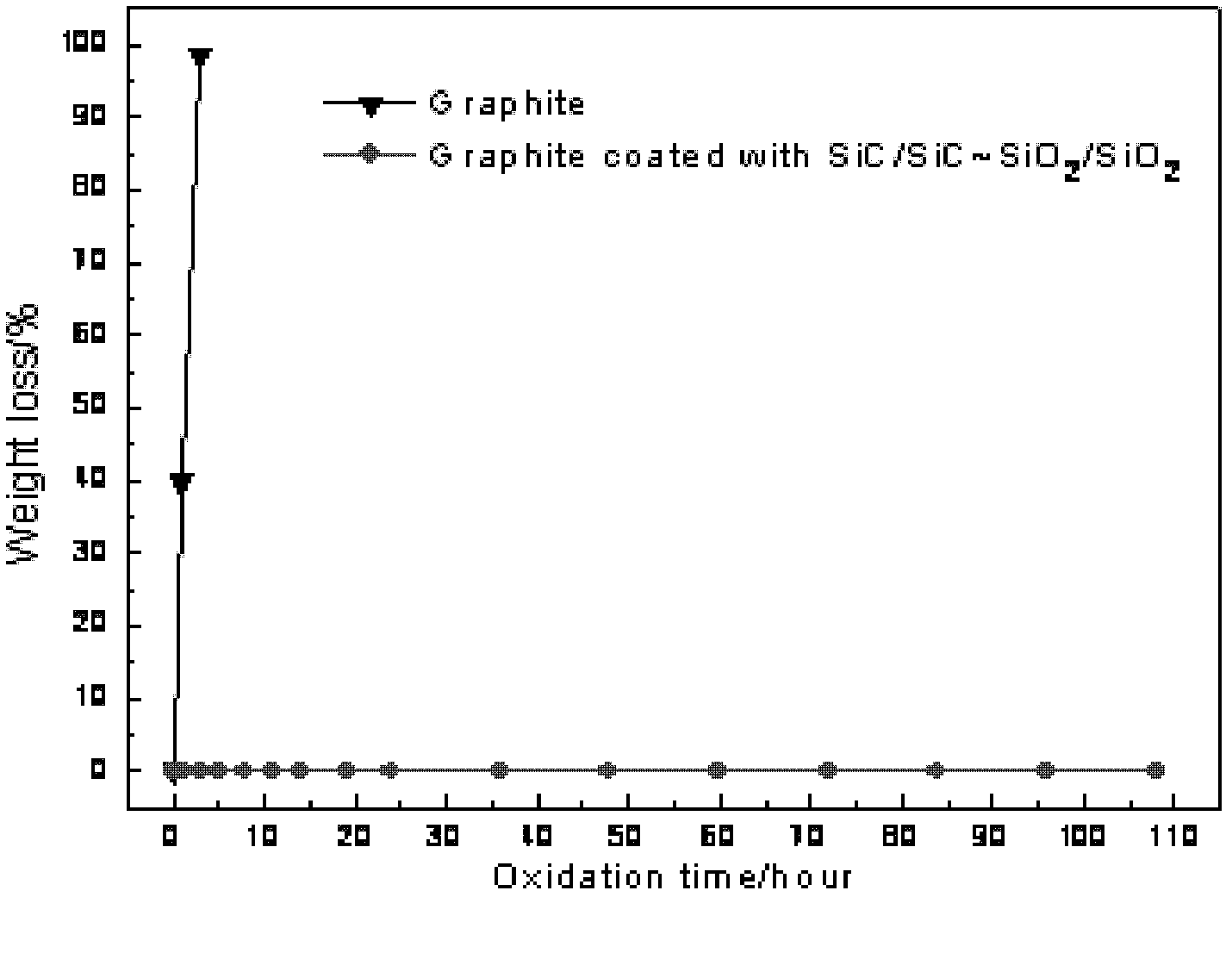

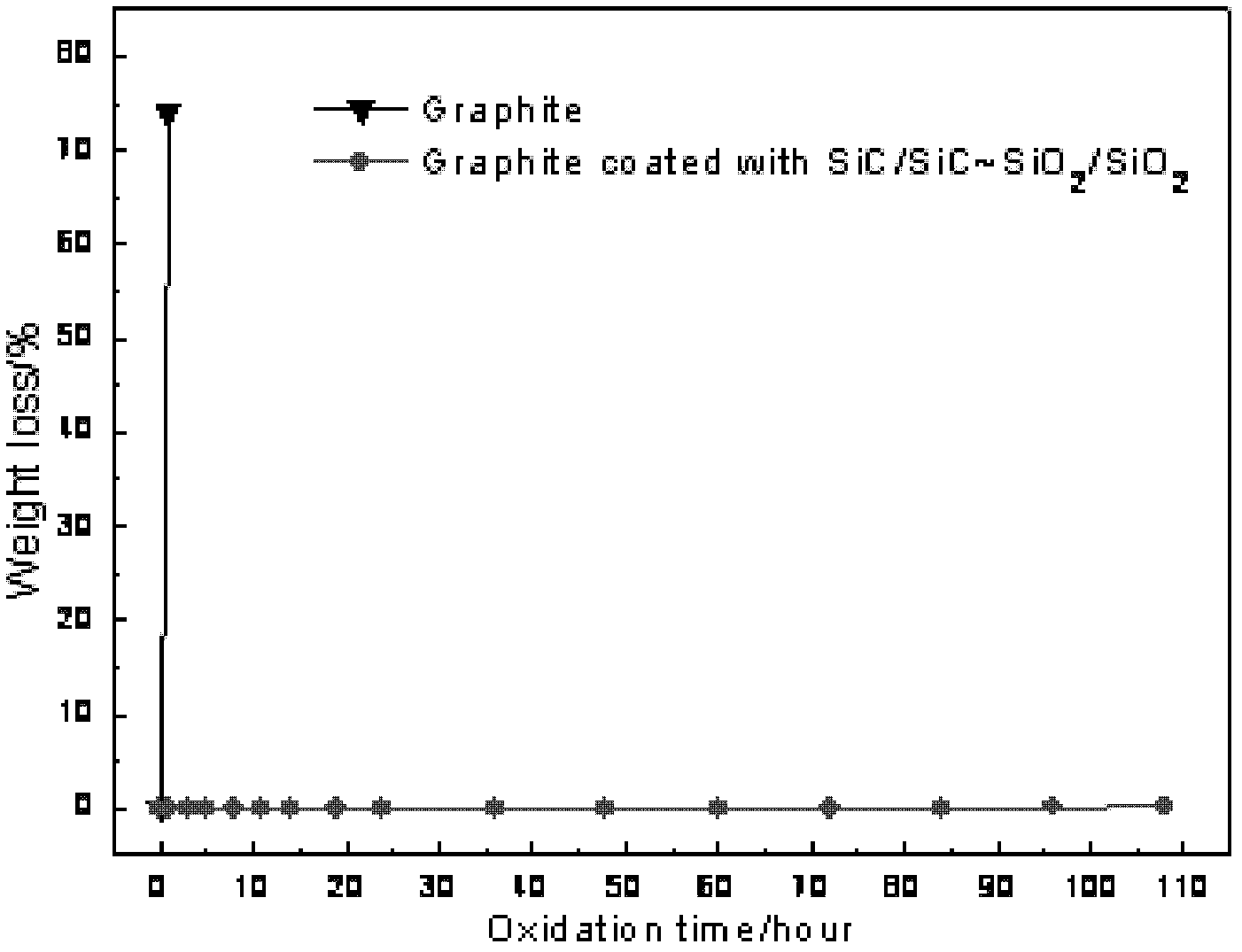

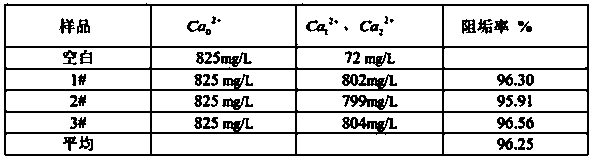

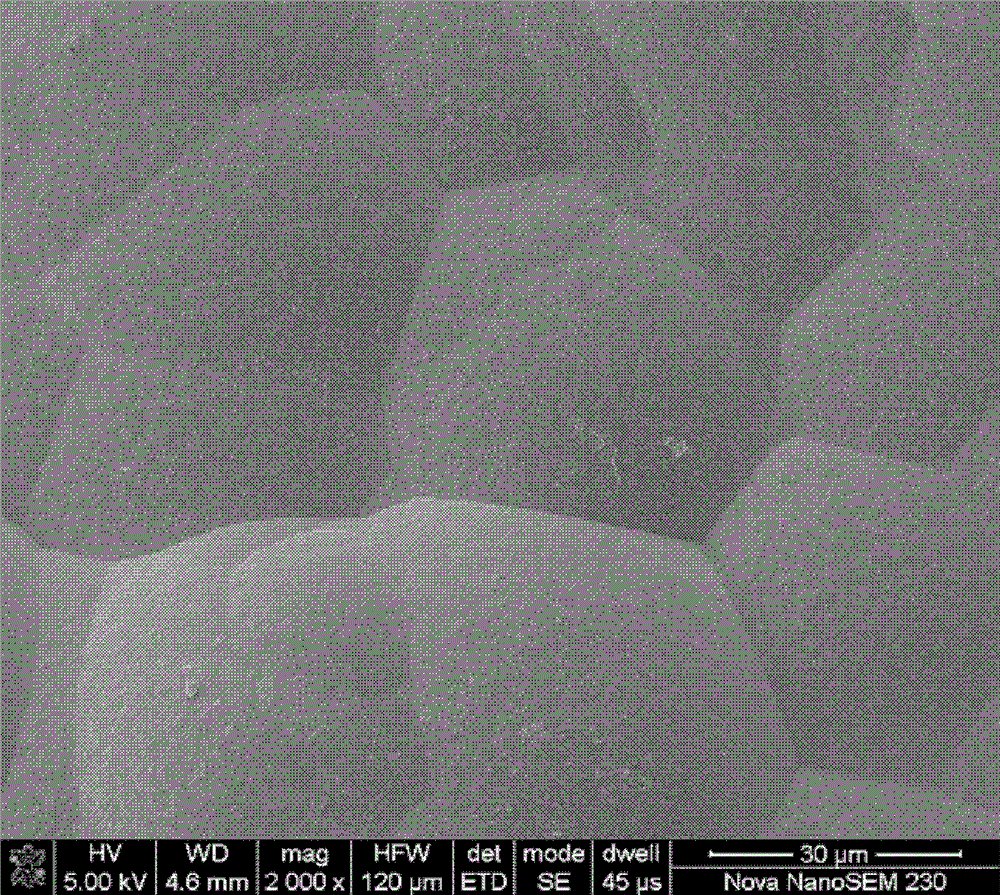

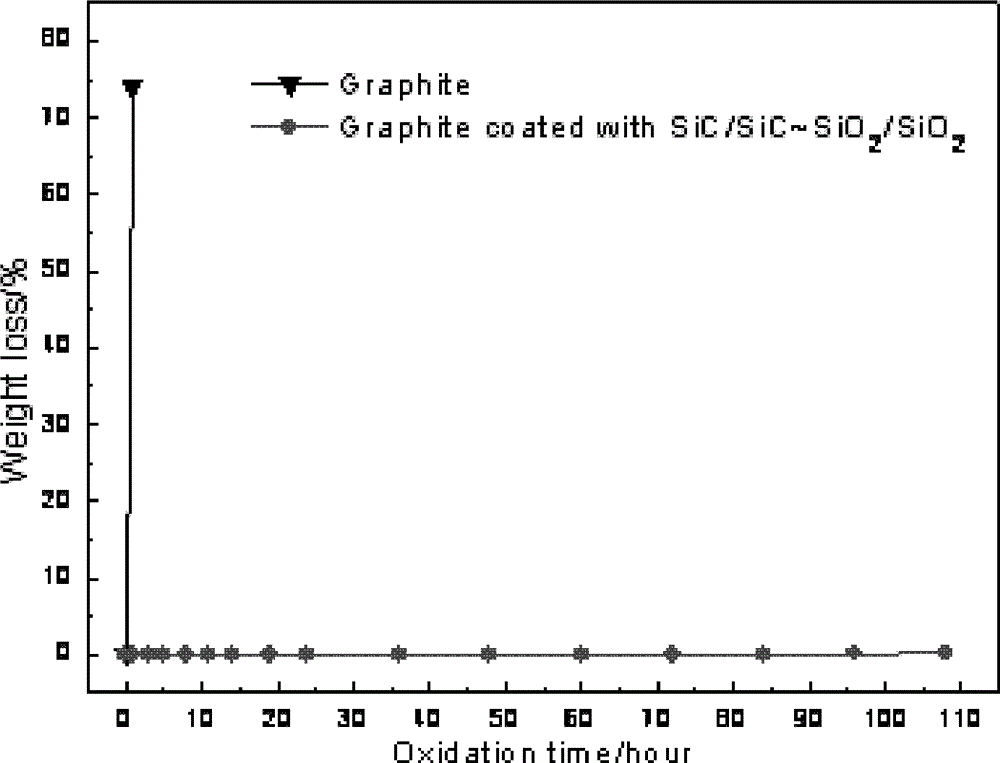

CVD (Chemical Vapor Deposition) SiC/SiO2 gradient antioxidant composite coating and preparation method thereof

ActiveCN102659451ACompact structureGood controllabilityChemical vapor deposition coatingCeramic compositeRoom temperature

The invention discloses a CVD SiC / SiO2 gradient antioxidant composite coating and a preparation method thereof. The CVD (Chemical Vapor Deposition) SiC / SiO2 gradient antioxidant composite coating is mainly used for long-time antioxidant protection of graphite, a C / C composite material and an easily oxidized ceramic-based material (such as a C / C-ceramic composite material, C / ceramic composite material, carbide ceramics and the like). The coating is prepared by adopting a chemical vapor deposition (CVD) method and has good controllability and designability. The coating comprises a SiC coating, a SiO2 coating and a SiC and a SiO2 co-deposition coating. The coating is formed by a gradient or is a multilayer composite gradient coating which is formed by multiple gradients; the multilayer composite gradient coating is sequentially SiC / SiC-SiO2 / SiO2 coating from inside to outside, or sequentially SiC / SiC-SiO2 / SiC-SiO2 / SiC-SiO2 / SiO2 coating, or sequentially SiC / SiC-SiO2 / SiO2 / SiO2-SiC / SiC / SiC-SiO2 / SiO2......SiC / SiC-SiO2 / SiO2, or SiC / SiC- SiO2 / SiO2-SiC / SiC-SiO2 / ...... / SiO2-SiC / SiC-SiO2 / SiO2, or SiC / SiC-SiO2 / SiC-SiO2 / SiO2- SiC / SiC-SiO2 / ....... / SiC-SiO2 / SiC-SiO2 / SiO2, or is only a SiC-SiO2 codepostion coating. The prepared gradient composite coating has good long-time oxidation resistance at the temperature of from a room temperature to 1700 DEG C.

Owner:CENT SOUTH UNIV

Nickel-Coated Copper Powder and Method for Producing the Nickel-Coated Copper Powder

InactiveUS20080090092A1Improve adhesionImprove uniformityConductive materialMetal-working apparatusConductive pasteHydrazine compound

Objects of the present invention are to provide oxidation resistant nickel-coated copper powder for conductive paste capable of forming a conductive wiring part for an electronic circuit, and to provide a method for producing the same. In order to achieve the objects, there is provided nickel-coated copper powder which is characterized in that it comprises nickel-coated copper particles in which a core material is copper particles, a catalyst for plating is fixed to a surface of the copper-particles by reduction reaction and electroless plated nickel is applied to the outermost surface. The reduction reaction is characterized in that hydrazine is used as a reducing agent.

Owner:MITSUI MINING & SMELTING CO LTD

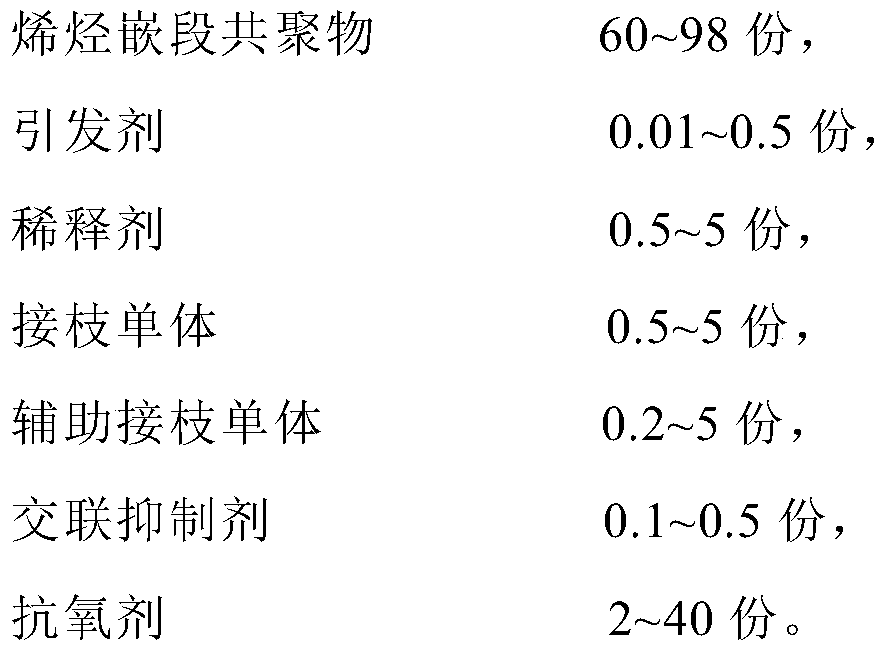

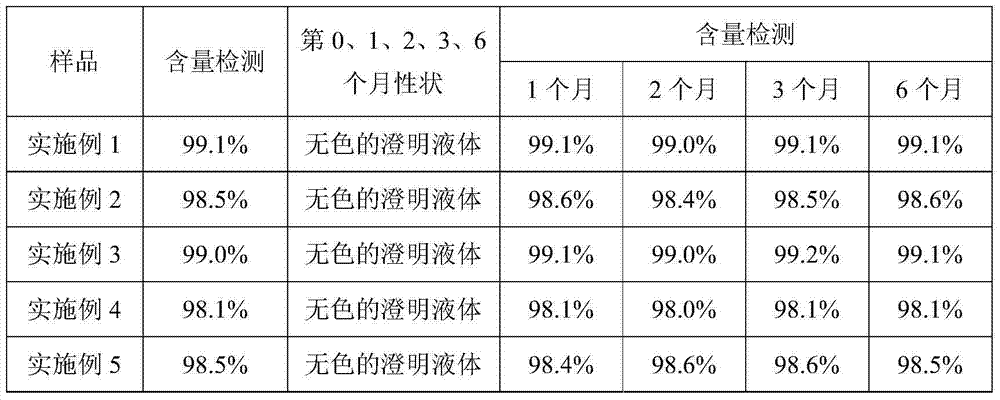

Functional OBC (olefin block copolymer) antioxidant masterbatch as well as preparation method thereof

ActiveCN110041470AImprove the use temperatureReduce the steps of adding antioxidantsMasterbatchCross-link

The invention discloses a functional OBC (olefin block copolymer) antioxidant masterbatch as well as a preparation method thereof. The antioxidant masterbatch is prepared from 60-98 parts of an OBC, 0.01-0.5 part of an initiator, 0.5-5 parts of a diluent, 0.5-5 parts of a graft monomer, 0.2-5 parts of an auxiliary graft monomer, 0.1-0.5 part of a cross-linking inhibitor and 2-40 parts of an antioxidant. The OBC is mixed with the cross-linking inhibitor, and the mixture is added from a main feeding port, the graft monomer, the auxiliary graft monomer and the diluent are respectively added to different locations of an extruding machine for participating a reaction, residues are removed by vacuumizing after the reaction, the antioxidant is added to a side feeding port on the back side of vacuum removal, an ultrasonic enhancing dispersion effect is implemented at a die head, and finally granulation is performed. The OBC is selected as matrix resin and functionalized by means of reactive extrusion, the antioxidant is further added, the antioxidant masterbatch with reactive polarity is produced by a one-step method, and functionality, stability and convenience of the antioxidant masterbatch are highlighted in applications.

Owner:FINE BLEND COMPATILIZER JIANGSU CO LTD

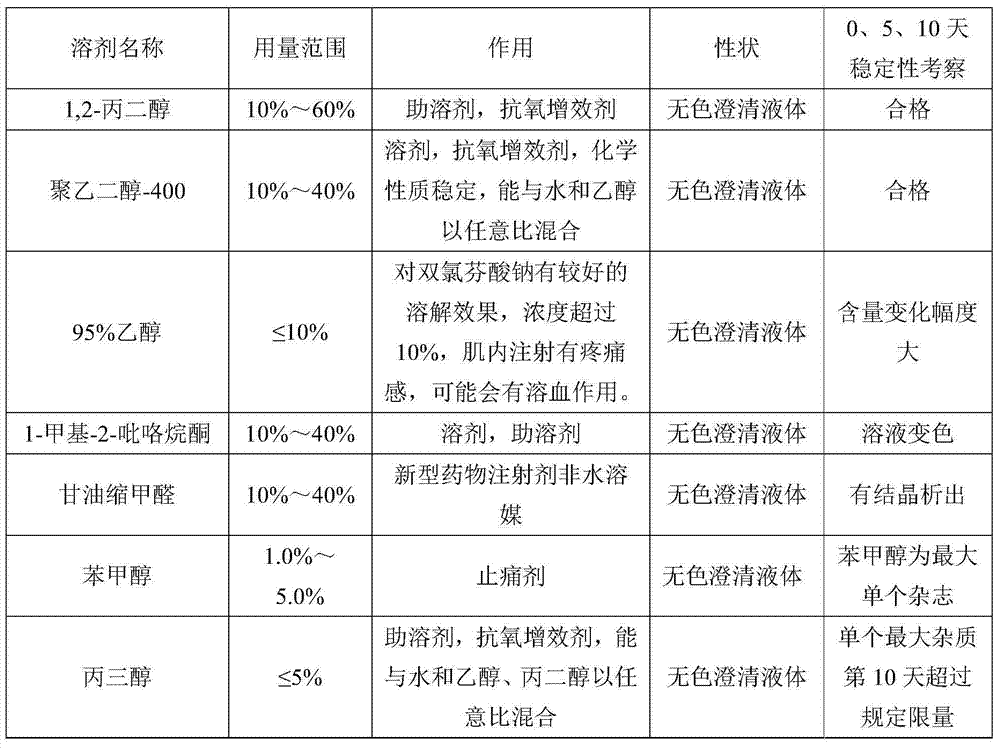

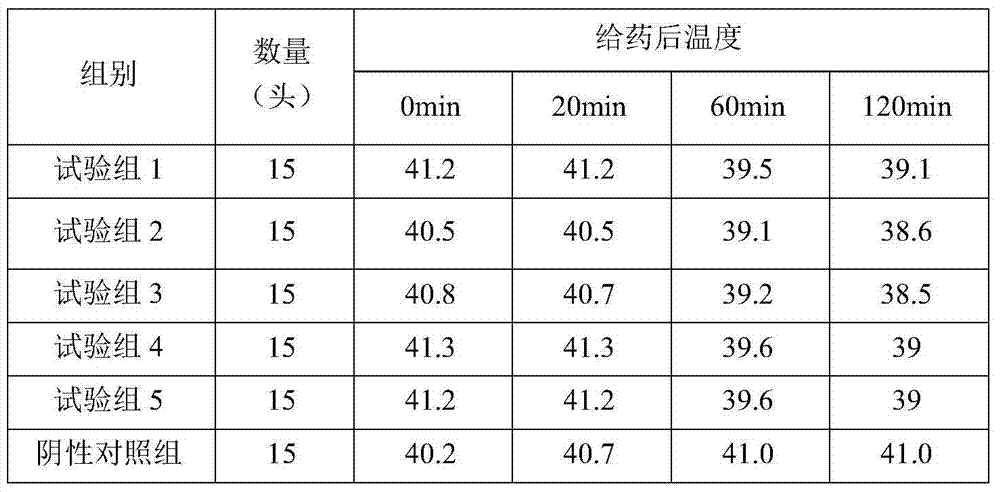

Injection for treating pyrexia and hoof disease of dairy cows, and its preparation method

InactiveCN104288096AImprove solubilityImprove stabilityOrganic active ingredientsAntipyreticEthylenediamineSolubility

The invention discloses an injection for treating pyrexia and the hoof disease of dairy cows, and its preparation method, and belongs to the technical field of veterinary western medicines. Every 100 ml of the injection is composed of 2-10g of diclofenac sodium, 0.1-0.5g of an antioxidant, 0.01-0.05g of a stabilizer, 20-80 ml of a cosolvent, and the balance of water for injection. The injection meets the veterinary drug market's demands on new antipyretic analgesic drugs, and has the advantages of good curative effect, small side effects and no accumulation in the clinical use process. Propylene glycol or polyethylene glycol-400 adopted as a cosolvent and the stabilizer disodium ethylenediaminetetraacetate synergistically enhance the dissolvability of diclofenac sodium in water, so the stability of the injection is increased. Anhydrous sodium sulfite has a stable anti-oxidation effect in alkaline environment with the pH value of 7.5-9.0. The preparation method of the diclofenac sodium injection has the advantages of simple and convenient preparation, low production cost, and suitableness for large-scale industrial production.

Owner:ZHENGZHOU BARY ANIMAL PHARMA

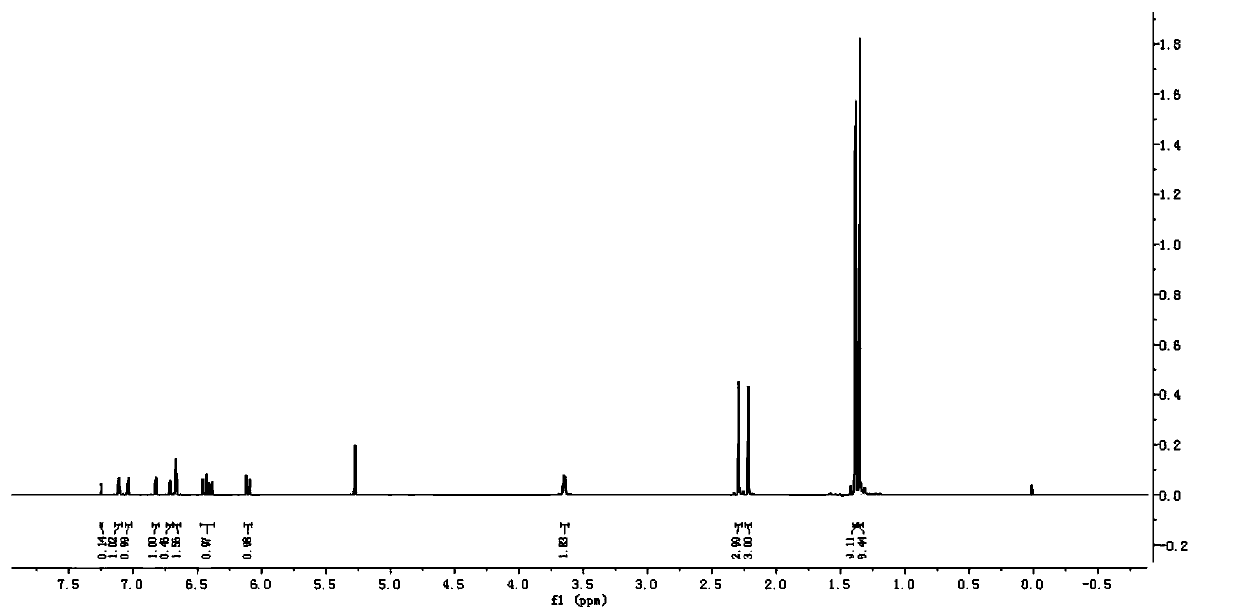

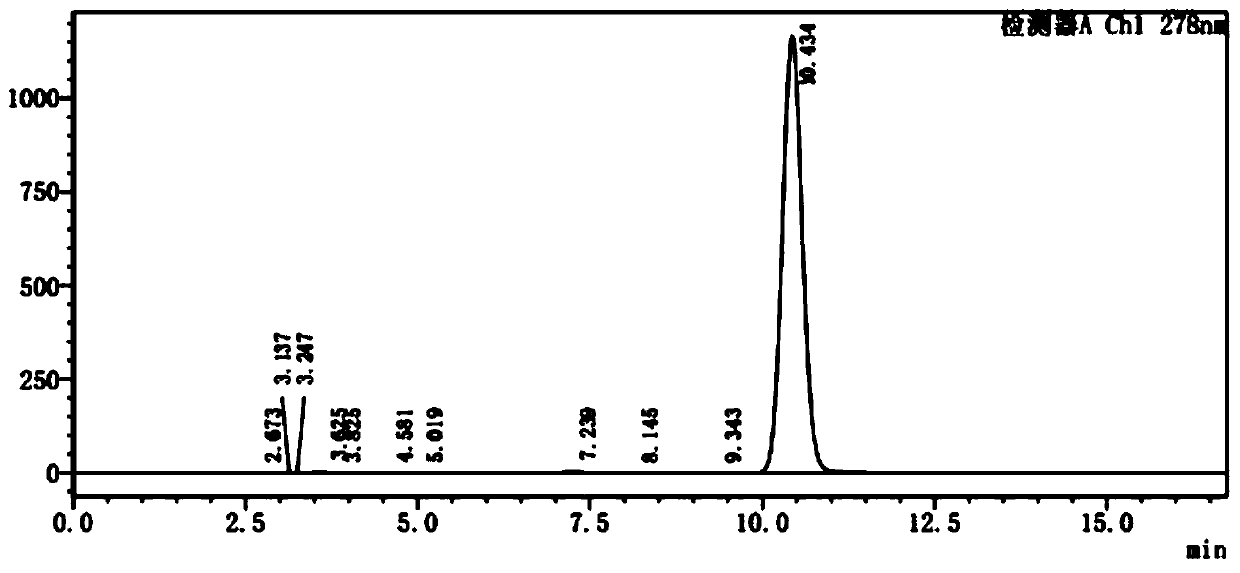

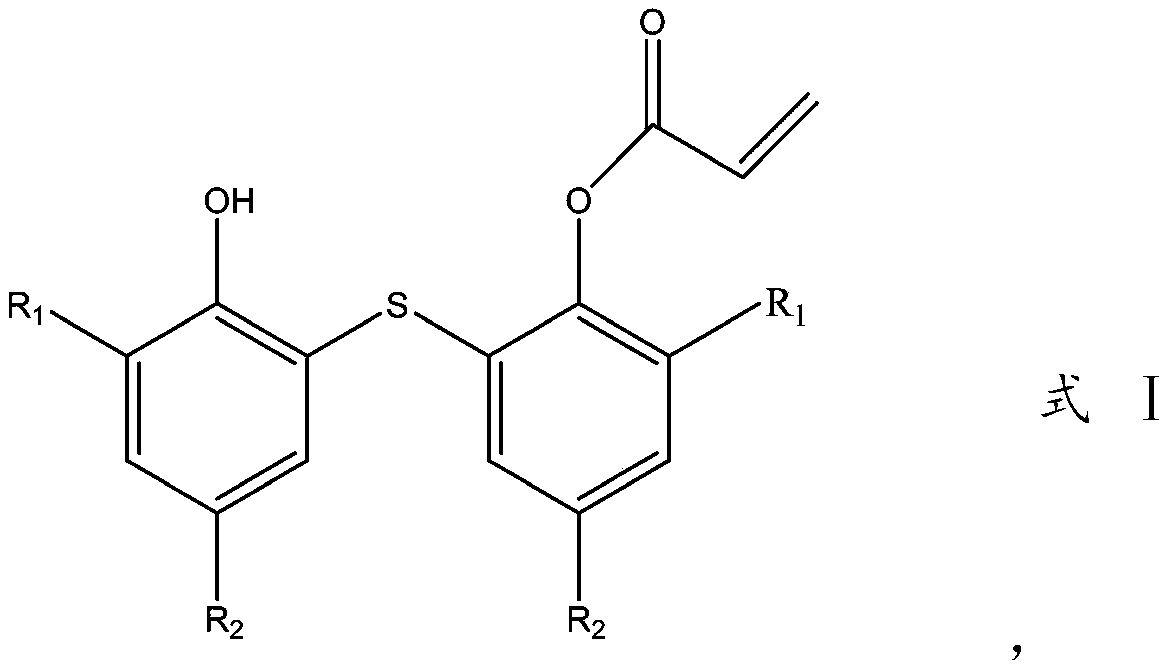

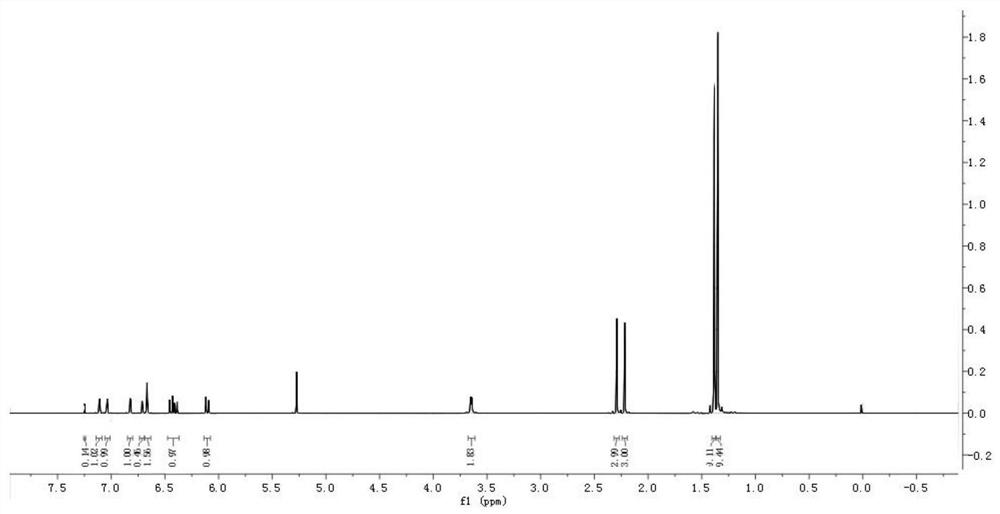

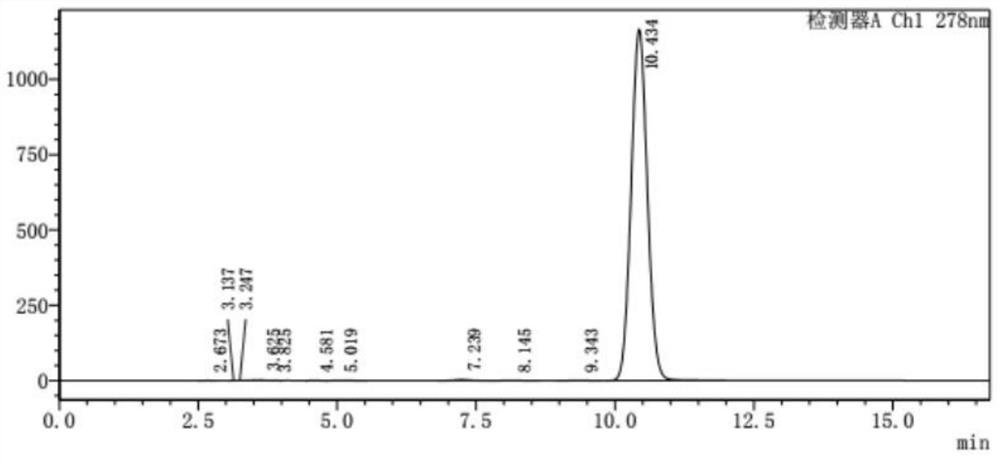

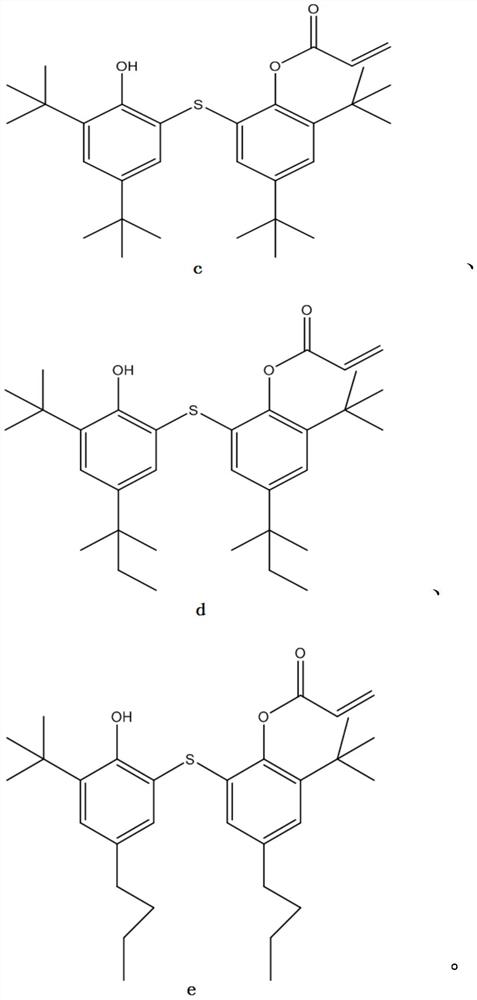

Thioether bisphenol acrylate multi-effect antioxidant and preparation method thereof

ActiveCN110183364AImprove protectionAntioxidant performance is stableOrganic compound preparationSulfide preparationFiltrationReaction temperature

The invention discloses a thioether bisphenol acrylate multi-effect antioxidant, which has the molecular structure shown as the following formula: the formula is shown in the description. The moleculeof the thioether bisphenol acrylate multi-effect antioxidant of the invention contains both hindered phenol functional groups as a main antioxidant and thioether bonds as an auxiliary antioxidant, also contains an acrylic acid phenolic ester structure having a carbon free radical trapping function, can play a three-in-one antioxidant effect in the processing and use of a polymer material, can better protect the polymer material, avoids degradation and aging of products, and solves the problem of poor anti-oxidation effect of single-function antioxidants on the polymer material; in addition, the corresponding preparation process has the advantages of low reaction temperature and low energy consumption; the byproducts can be removed by filtration, no waste water is produced, the solvent canbe recycled, and the green and environment protection are realized.

Owner:烟台新特路新材料科技有限公司

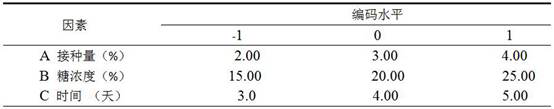

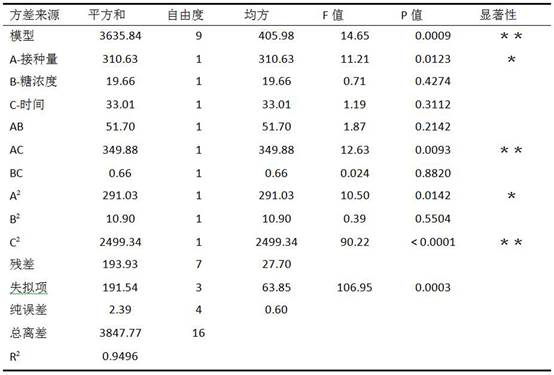

Preparation technology for high antioxidant activity zizyphus mauritiana enzymes

The preparation technology includes taking zizyphus mauritiana as a raw material, blending the zizyphus mauritiana and syrup with a ratio being 1 : 2 after boiling, color protecting and sterilization,inoculating microzyme, lactobacillus bulgaricus and streptococcus thermophilus to perform constant temperature incubation for 4 d, and performing clarification, filtering, disinfection and other technologies so that a high antioxidant activity zizyphus mauritiana enzyme stock solution can be prepared. Prepared zizyphus mauritiana enzymes have characteristics of strong in fragrance, smooth and fine in juice and mellow in taste; the zizyphus mauritiana enzymes can effectively adjust human body metabolism and maintain the balance of human intestinal flora; and the zizyphus mauritiana enzymes arerich in vitamin C, flavone, polyphenol, SOD, polypeptide and other antioxidant active substances which can delay aging and enhancing human immune functions.

Owner:山西师范大学

Alkyl-substituted disiloxane and preparation method thereof

InactiveCN102731559AOptimal Control StructureThe reaction process is simpleGroup 4/14 element organic compoundsDisiloxaneDistillation

The invention discloses alkyl-substituted disiloxane shown by a chemical formula (I), and a preparation method thereof. The preparation method of the compound comprises the steps that: raw materials are adopted according to a molar ratio of magnesium to bromoalkane to silicon tetrachloride of 3-3.5:3-3.3:1; magnesium is added into a reaction vessel; bromoalkane-tetrahydrofuran or an anhydrous diethyl ether solution and a silicon tetrachloride-ligroin solution are added under the protection of nitrogen gas; the mixture is subjected to a reaction for 2-6h under a temperature of 20-60 DEG C; an ammonium chloride solution or dilute hydrochloric acid is mixed into the mixture for stopping the reaction; an organic phase is separated from an aqueous phase; the aqueous phase is extracted by using an organic solvent, and the organic phases are combined; the mixture is washed by using deionized water, and is dried by using a drying agent; the material is subjected to pump-filtration; the filtrate is subjected to distillation concentration, and is dehydrated for 3-4h under a temperature of 160-260 DEG C; the material is then subjected to silica gel column chromatography, such that the alkyl-substituted disiloxane is obtained. The alkyl-substituted disiloxane provided by the invention has good thermal stability, good oxidation resistance, and high flash point. The compound is suitable to be used in hydraulic oil, diffusion pump oil, and heat conduction oil.

Owner:SOUTHWEAT UNIV OF SCI & TECH

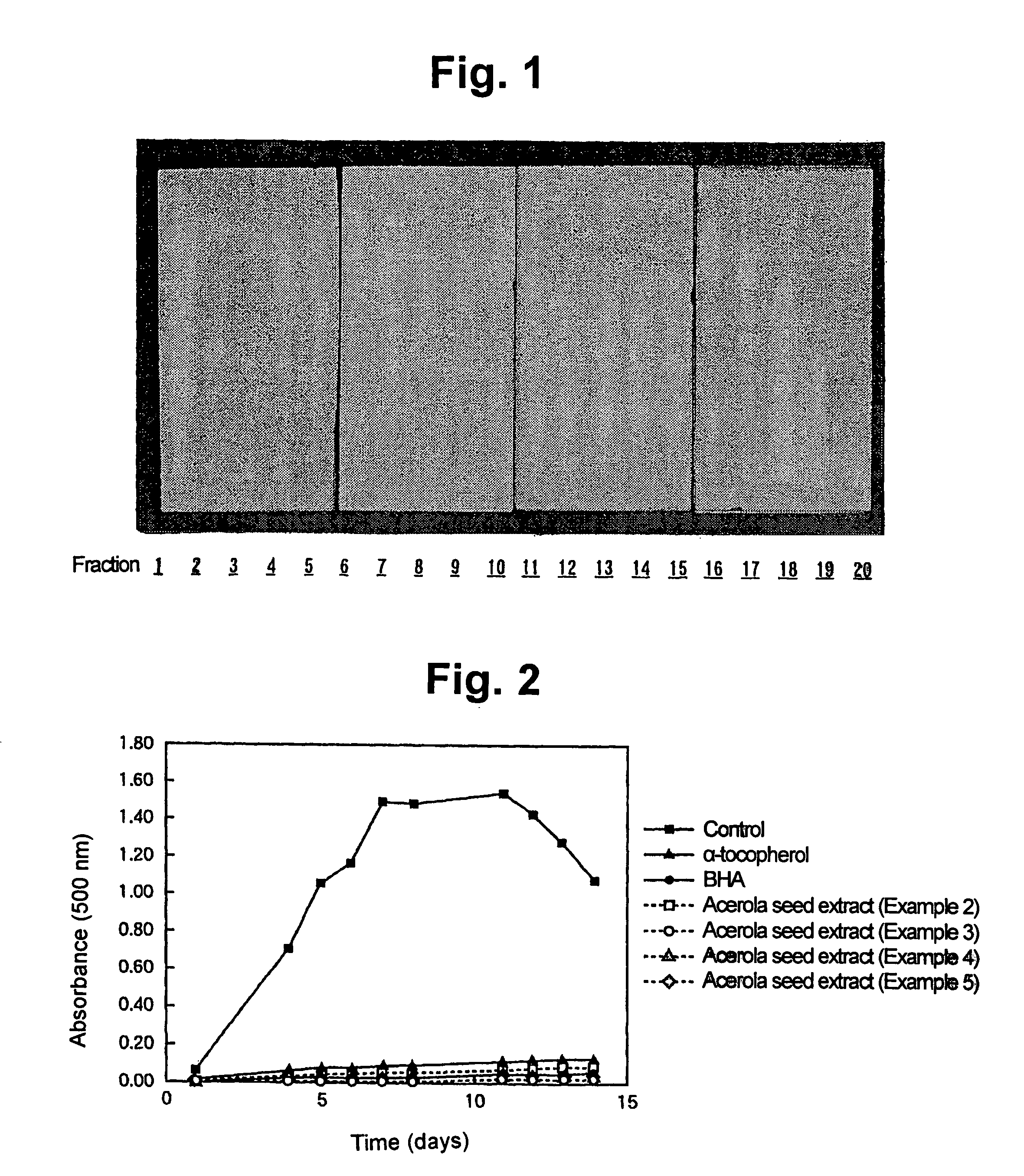

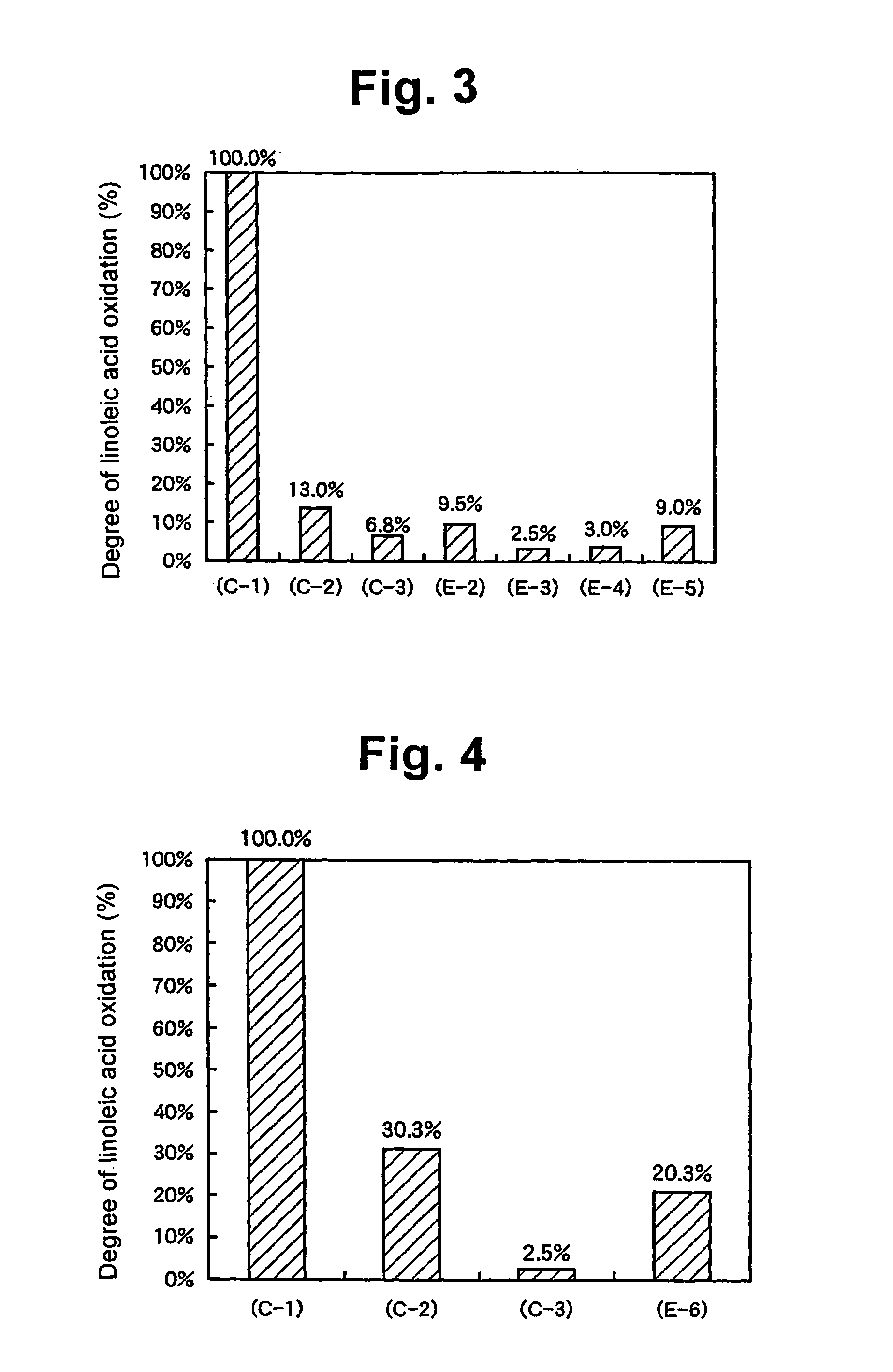

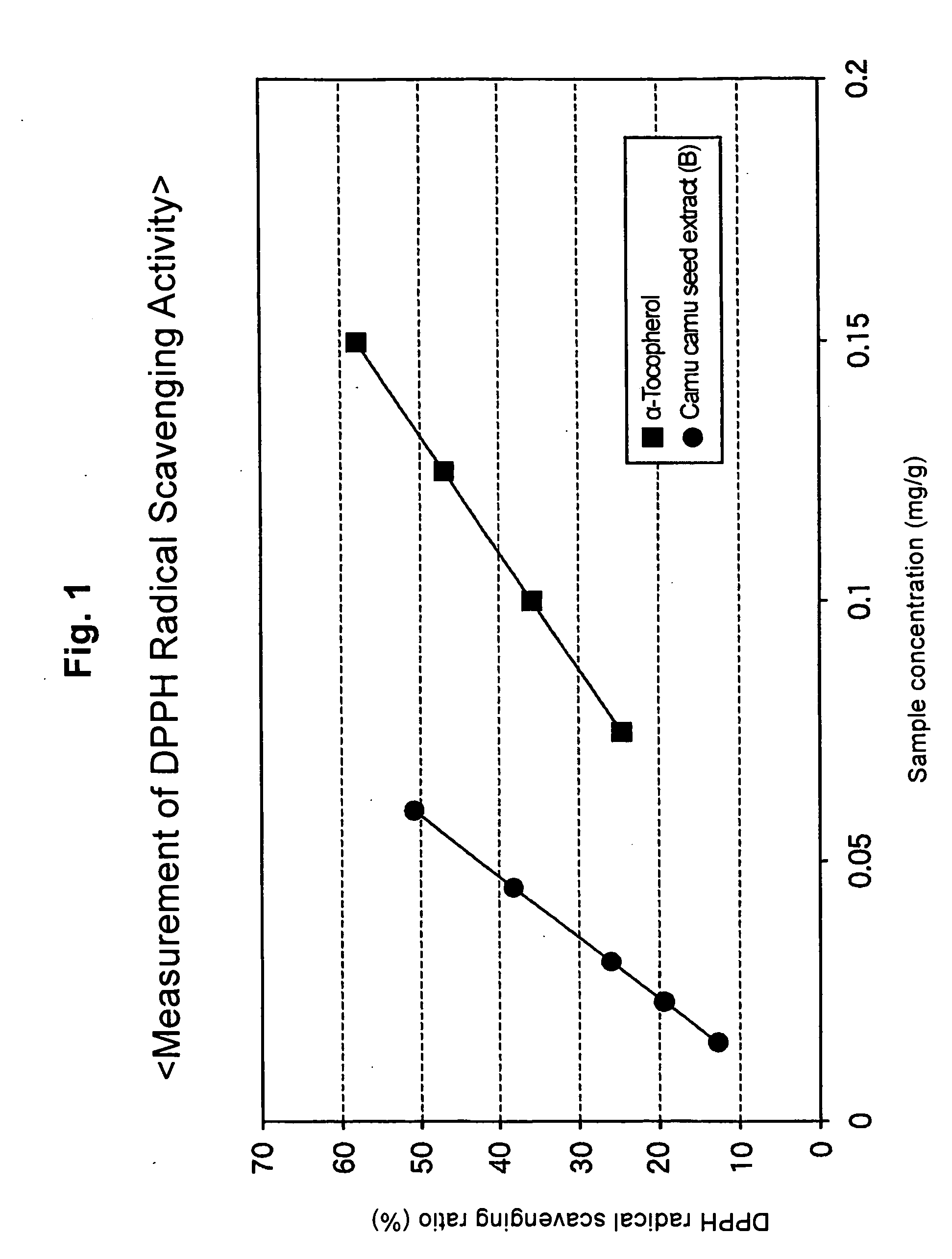

Whitening agent, skin preparation for external use and cosmetic

ActiveUS20060104926A1High safety effectHigh whitening effectCosmetic preparationsBiocideWhitening AgentsActive component

The invention relates to a whitening agent that makes effective use of camu camu seeds, which have conventionally been discarded, and that has high safety and whitening effect useful in cosmetics and the like, as well as skin preparations for external use and cosmetics containing the whitening agent. The whitening agent of the present invention contains camu camu seed extract as an active component, and the skin preparations for external use and cosmetics of the present invention contain the whitening agent.

Owner:NICHIREI BIOSCIENCE INC

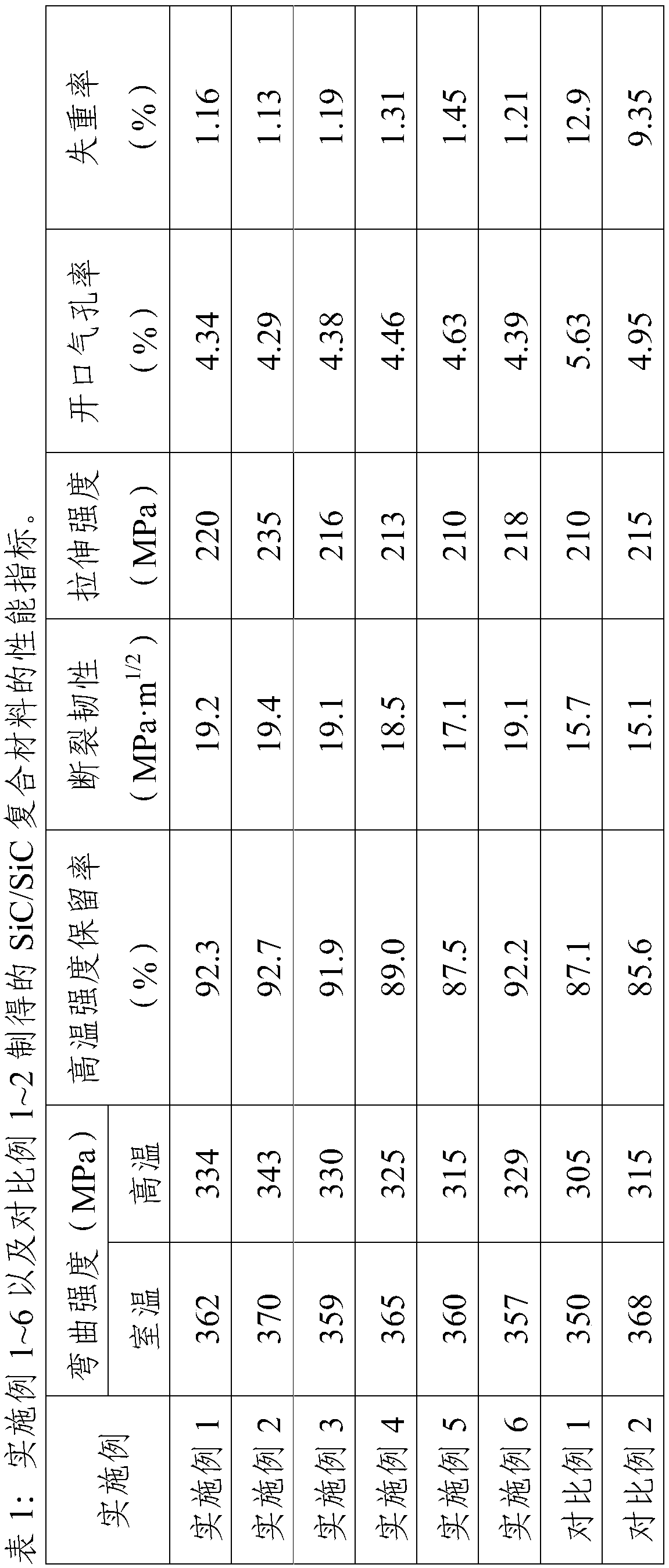

Tungsten carbide interface layer modified silicon carbide fiber-reinforced silicon carbide composite material and preparation method thereof

The invention relates to a tungsten carbide interface layer modified silicon carbide fiber-reinforced silicon carbide composite material and a preparation method thereof. The method comprises the following steps of: (1) depositing a tungsten carbide interface layer and a silicon carbide interface layer on the surface of a silicon carbide fiber prefab in sequence through a chemical vapor depositionmethod, so as to prepare a modified silicon carbide fiber prefab; (2) steeping the modified silicon carbide fiber prefab prepared in the step (1) by using precursor solution of carbon, and carrying out solidification and pyrolysis on the steeped modified silicon carbide fiber prefab in sequence; (3) repeating the step (2) for at least once so as to obtain a porous silicon carbide fiber prefab; and (4) carrying out liquid silicon infiltration reaction on the porous silicon carbide fiber prefab to obtain the tungsten carbide interface layer modified silicon carbide fiber-reinforced silicon carbide composite material. The prepared tungsten carbide interface layer modified silicon carbide fiber-reinforced silicon carbide composite material is excellent in comprehensive properties such as high-temperature oxidation resistance, thermal shock resistance, vapor corrosion resistance and the like.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

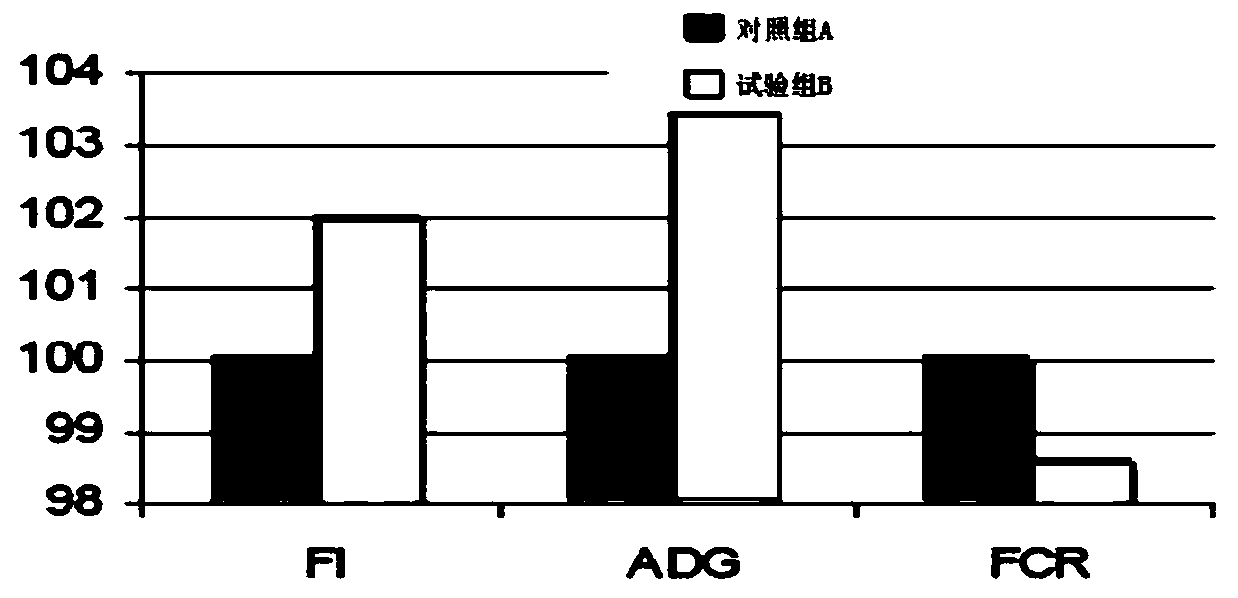

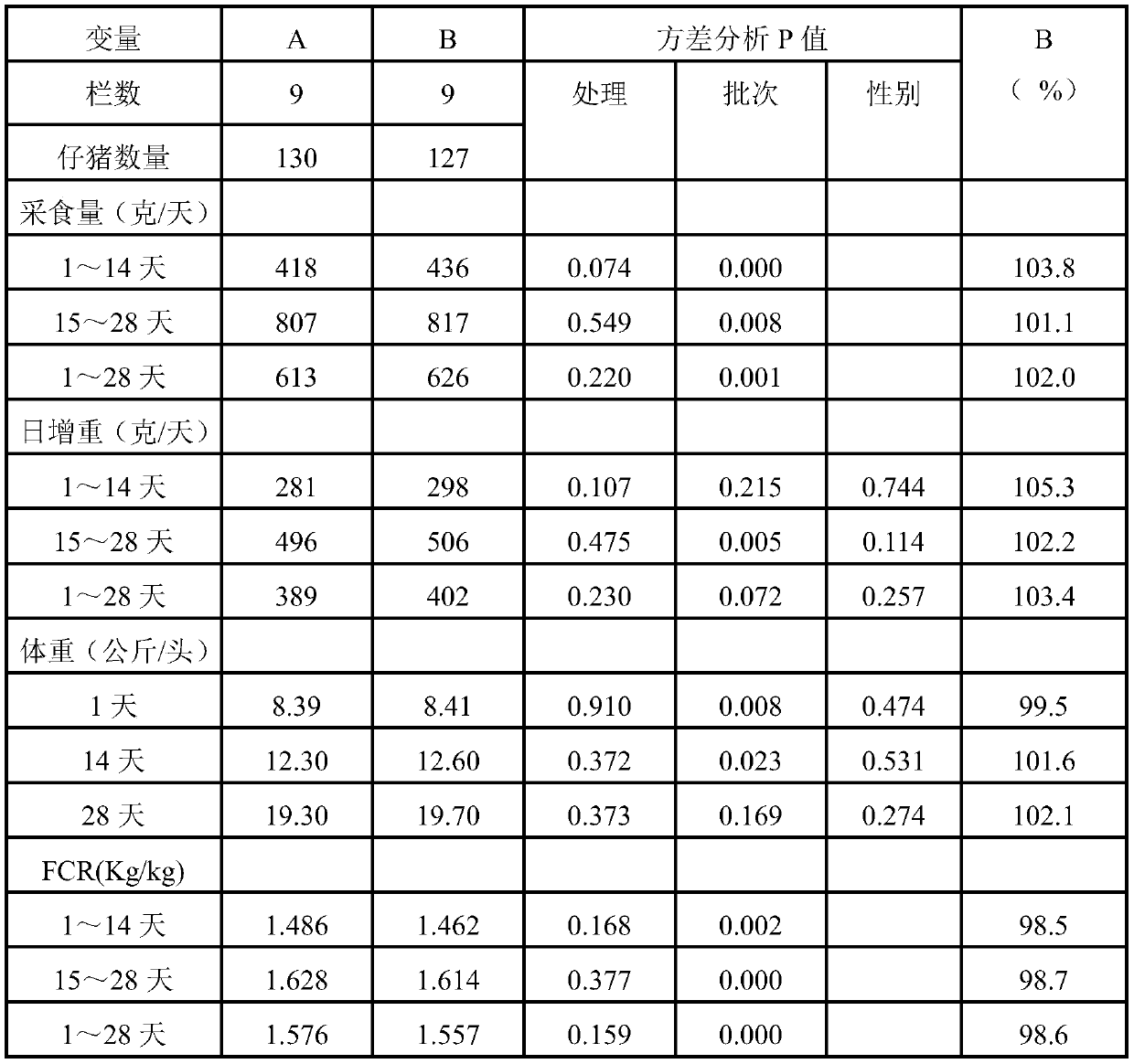

Natural compound antioxidant for animal feed and preparation method thereof

PendingCN111011601APrevent or delay oxidative rancidityImprove stabilityAnimal feeding stuffAccessory food factorsVitamin CAstaxanthin

The invention discloses a natural compound antioxidant for animal feed and a preparation method thereof. The natural compound antioxidant comprises the following raw materials in percentage by weight:1-5% of astaxanthin, 1-10% of a rosemary extract, 5-20% of lipoic acid, 1-7% of vitamin C, 2-6% of citric acid and the balance of a carrier. The antioxidant disclosed by the invention solves the problem of poor antioxidant effect of the existing feed antioxidant, and can prevent or delay oxidative rancidity of fat in the feed, improve the stability of the feed and prolong the storage period afterbeing added into the high-fat feed.

Owner:南京泛成生物科技有限公司

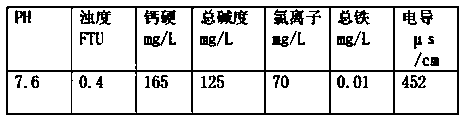

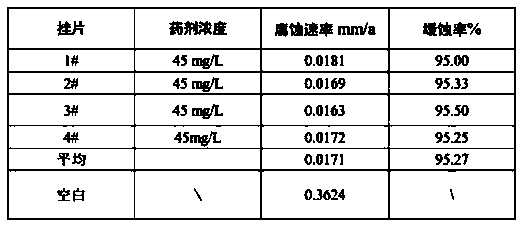

Phosphorus-free corrosion and scale inhibition all-in-one agent for treating circulating cooling water and preparation method

InactiveCN110028169ALow costSimple corrosion and scale inhibition control effectScale removal and water softeningIonEnvironmental chemistry

The invention discloses a phosphorus-free corrosion and scale inhibition all-in-one agent for treating circulating cooling water. The agent is prepared from the following components in percentage by mass: 15-20% of polyepoxysuccinic acid (sodium salt), 20-30% of hydrolyzed polymaleic acid, 20-30% of 2-acrylamide-2-methylpropanesulfonic acid, 5-10% of zinc sulfate and the balance of deionized water. Accroding to the invention, the agent is free of organic phosphonates and inorganic phosphates, is a phosphorus-free product, can be completely biodegraded, cannot cause deterioration of natural environment and biological death or secondary pollution of the ecological environment after discharged into the natural environment along with wastewater of a circulating cooling water system, and is quite environmentally friendly. Compared with an existing mainstream phosphorus formula and a formula requiring for separated adding of a phosphorus-free corrosion inhibitor and a scale inhibitor, the agent of the invention has the advantages that the release amount is small, the release is simple and convenient, the scale inhibition rate is 96% or above, and the corrosion inhibition rate is 95% or above, so that the treatment cost of the circulating cooling water is greatly reduced.

Owner:SUZHOU ANFENG ENVIRONMENT PROTECTION TECH CO LTD

Aluminum welding powder and preparation method thereof

InactiveCN107790915AAntioxidant performance is stableAccelerated corrosionWelding/cutting media/materialsSoldering mediaLithium sulphateCopper oxide

The invention relates to aluminum welding powder and a preparation method thereof. The aluminum welding powder comprises the following raw materials of, by weight, 20-35 parts of barite, 2-5 parts ofsilicon dioxide, 4-10 parts of copper oxide, 4-10 parts of vanadium oxide, 2-5 parts of lithium sulfate, 2-6 parts of calcium fluoride, 1-5 parts of sodium nitrate and 50-70 parts of aluminum powder.The aluminum welding powder has stable oxidation resistance, corrosion resistance and adhesiveness and is free of collapse.

Owner:广西塔锡科技有限公司

Jet smelting NiCrWRe alloy powder for dual-phase flow work piece and its preparation process

The spouting melting NiCrWRe alloy powders used in two phase current workpieces and its preparation method, whose purpose is to improve wear and corrosion resistance and using longevity of liquid state and solid state current wearable and corrosion-resistant workpieces at high temperature. The components counted by weight percent is as follows: Ni 50-79%, Cr13-25%, W1-6%, Re 0.1-2.5%, Si 2.0-6.0%, B 2.0-6.0%, C 0.2-2.0%, Fe is less than or equal to 1%. Mixing the raw materials according to the above alloy components, after preheating the mixing raw materials appending the raw materials into electric furnace to melt, when temperature rises to 1450-1550 deg.C adding deoxidized, exhaust air, clear residues, then adding rare earth alloy, after stirring keeping quiescence for 3-5 min, and then clearing residues, analyzing in front of the furnace, adjusting components, taking out of furnace if conformity, injecting the eligible alloy liquid into milling device, atomizing the alloy under the preservation of inertia gas or vacuum state, finally preparing the alloy into powders of 100-350 orders.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

CVD (Chemical Vapor Deposition) SiC/SiO2 gradient antioxidant composite coating and preparation method thereof

ActiveCN102659451BCompact structureStrong designabilityChemical vapor deposition coatingCeramic compositeRoom temperature

The invention discloses a CVD SiC / SiO2 gradient antioxidant composite coating and a preparation method thereof. The CVD (Chemical Vapor Deposition) SiC / SiO2 gradient antioxidant composite coating is mainly used for long-time antioxidant protection of graphite, a C / C composite material and an easily oxidized ceramic-based material (such as a C / C-ceramic composite material, C / ceramic composite material, carbide ceramics and the like). The coating is prepared by adopting a chemical vapor deposition (CVD) method and has good controllability and designability. The coating comprises a SiC coating, a SiO2 coating and a SiC and a SiO2 co-deposition coating. The coating is formed by a gradient or is a multilayer composite gradient coating which is formed by multiple gradients; the multilayer composite gradient coating is sequentially SiC / SiC-SiO2 / SiO2 coating from inside to outside, or sequentially SiC / SiC-SiO2 / SiC-SiO2 / SiC-SiO2 / SiO2 coating, or sequentially SiC / SiC-SiO2 / SiO2 / SiO2-SiC / SiC / SiC-SiO2 / SiO2......SiC / SiC-SiO2 / SiO2, or SiC / SiC- SiO2 / SiO2-SiC / SiC-SiO2 / ...... / SiO2-SiC / SiC-SiO2 / SiO2, or SiC / SiC-SiO2 / SiC-SiO2 / SiO2- SiC / SiC-SiO2 / ....... / SiC-SiO2 / SiC-SiO2 / SiO2, or is only a SiC-SiO2 codepostion coating. The prepared gradient composite coating has good long-time oxidation resistance at the temperature of from a room temperature to 1700 DEG C.

Owner:CENT SOUTH UNIV

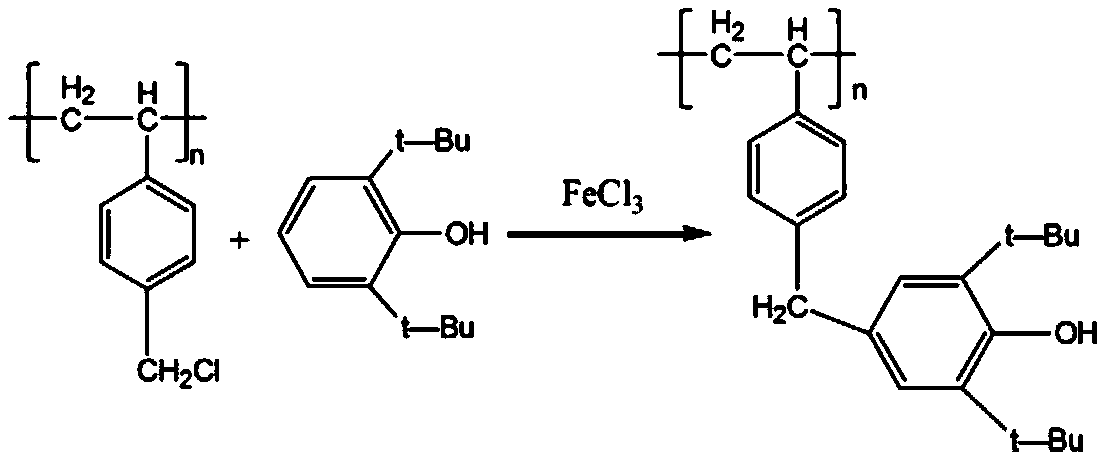

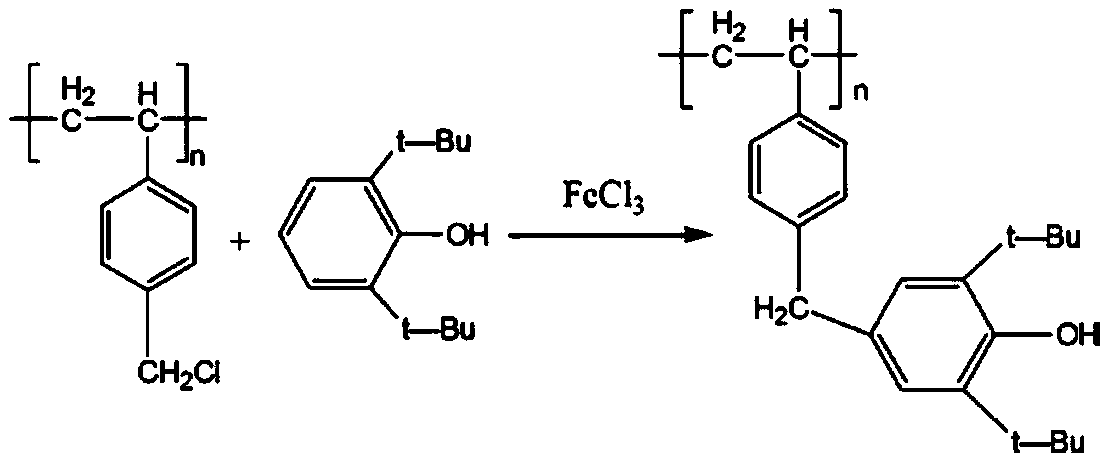

A kind of method and product thereof for preparing 2,6-di-tert-butylphenol antioxidant resin

ActiveCN107226873BLarge specific surface areaAntioxidant performance is stableTert butyl phenolFiltration

The invention discloses a method for preparing 2,6-di-tert-butyl phenol antioxidant resin and a product thereof. The synthetic method comprises the following steps: firstly, swelling chloromethyl polystyrene resin; then adding a catalyst and 2,6-di-tert-butyl phenol, performing graft modification reaction under a specific environment and performing suction filtration to obtain polystyrene-supported 2,6-di-tert-butyl phenol resin; then sequentially soaking the polystyrene-supported 2,6-di-tert-butyl phenol resin by a hydrochloric acid solution and a sodium hydroxide solution, removing impurities and performing water containing storage. The synthesized antioxidant resin disclosed by the invention has large specific surface area, can fully contact a liquid phase, has stable antioxidant property, further can be easily separated from the liquid phase and avoids the problem of surrounding solution pollution.

Owner:HUNAN NORMAL UNIVERSITY

Ganoderic spore extract and its production

InactiveCN101028305BPromote absorptionReasonable absorptionDigestive systemAntinoxious agentsSporeBiology

Owner:卢昶年 +1

Preparation technology of green jujube enzyme with high antioxidant activity

The scheme of the present invention uses green jujube as raw material, after steaming, color protection and sterilization, the ratio of green jujube to sugar water is 1:2, inoculated with yeast, Lactobacillus bulgaricus and Streptococcus thermophilus for constant temperature cultivation for 4 days, clarification and filtration , sterilization and other processes to make high antioxidant activity green jujube enzyme stock solution. The jujube enzyme prepared by this method has the characteristics of rich jujube fragrance, smooth and delicate juice, and mellow taste; it can effectively regulate human metabolism and maintain the balance of human intestinal flora; it is rich in vitamin C, flavonoids, polyphenols, SOD, polypeptides, etc. Antioxidant active substances can delay the aging process and improve human immune function.

Owner:山西师范大学

Efficient soldering tin protective agent

InactiveCN104551449AAntioxidant performance is stableOxidative stabilityWelding/cutting media/materialsSoldering mediaChemical industryTriolein

The invention relates to the technical field of chemical industry, in particular to an efficient soldering tin protective agent. The efficient soldering tin protective agent is prepared from, by weight, 5-20% of high-viscosity dimethicone, 5-10% of palmitoleic triolein, 5-10% of arachidonic acid, 5-10% of liquid polybutylene, 40-50% of vacuum residue and 0.5-2% of amine antioxidant. The raw materials are mixed and molten into uniform grease at the temperature of 100-140 DEG C. The efficient soldering tin protective agent is stable in performance.

Owner:戴留庆

Hot plating film liquid

InactiveCN108441927AImprove antioxidant capacityHigh strengthElectrolytic coatingsRare-earth elementOxidation resistant

The invention relates to hot plating film liquid. The hot plating film liquid at least consists of tin-contained nanoalloy powder and film plating medicine liquid; the tin-contained nanoalloy powder is uniformly dispersed in the film plating medium liquid; tin chloride in the tin-contained nanoalloy powder is a main resistance component; the oxidation resistance of the film plating liquid and thestabilization of the crystallizing strength are improved through chlorides of rare earth elements; the adjustment of resistance and expansion coefficients of the film plating liquid is realized through transitional metal; and through the tin chloride, the chlorides of the rare earth elements and nanoalloy powder of multiple metal, the effective reduction of the film forming temperature on a carrier is realized, the power use is reduced, and the film life is prolonged.

Owner:德阳利源节能科技有限公司

A device for thermal correction of thin-walled titanium alloy parts

The invention relates to a device for heat shaping of thin-walled titanium alloy parts. A first pressing mechanism is fixed at one end of a body, and a second pressing mechanism is fixed at the other end of the body. Two clamping mechanisms are mounted in the middle of the body. Two clamping plates of a lateral ejection mechanism are fixed on two lateral surfaces of the body respectively and located between the first pressing mechanism and the clamping mechanisms. A width inner-supporting mechanism is located between the two clamping plates of the lateral ejection mechanism, one end of the width inner-supporting mechanism is mounted in a to-be-shaped part, and cavity inner-supporting mechanisms are mounted on the upper surface and the lower surface of the width inner-supporting mechanism. One ends of the cavity inner-supporting mechanisms are mounted in the clamping mechanisms, so that a support body with a wedge-shaped inner cavity is formed in the to-be-shaped part. By the device, utilization rate of a heat treatment furnace is increased, and cost of vacuum heat shaping is lowered. Since the to-be-shaped parts are clamped symmetrically, main stresses of a tooling are symmetric in direction and offset each other, stress state of the tooling is improved, and deformation resistance of the tooling is enhanced indirectly.

Owner:XIAN AEROSPACEMOTOR MACHINE FACTORY

A kind of sulfide bisphenol acrylate multi-effect antioxidant and preparation method thereof

ActiveCN110183364BImprove protectionAntioxidant performance is stableOrganic compound preparationSulfide preparationPolymer sciencePhenol

The invention discloses a thioether-based bisphenol acrylate multi-effect antioxidant, which has a molecular structure shown in the following formula: the molecule of the thioether-based bisphenol acrylate multi-effect antioxidant contains both the main antioxidant The hindered phenol functional group of the agent and the thioether bond of the auxiliary antioxidant also contain the acrylate phenol ester structure with the function of capturing carbon free radicals, which can play a three-in-one antioxidant effect in the process of processing and using polymer materials , can better protect polymer materials, avoid product degradation and aging, solve the problem of poor anti-oxidation effect of single-functional antioxidants on polymer materials, and the corresponding preparation process has low reaction temperature, low energy consumption, and side effects The product can be removed by filtration, no waste water is generated, the solvent can be recycled, and it is environmentally friendly.

Owner:烟台新特路新材料科技有限公司

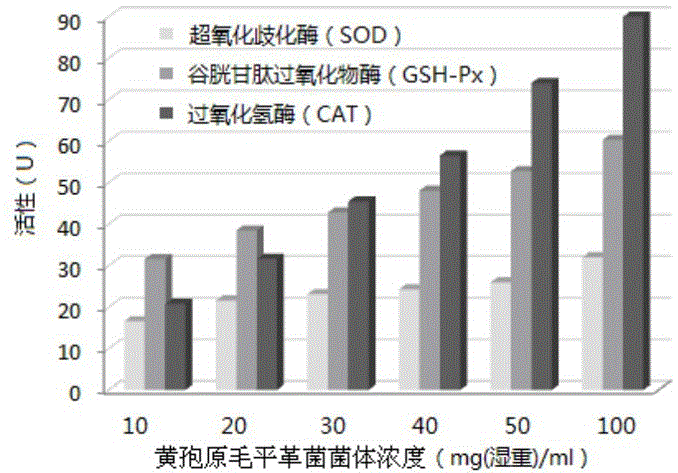

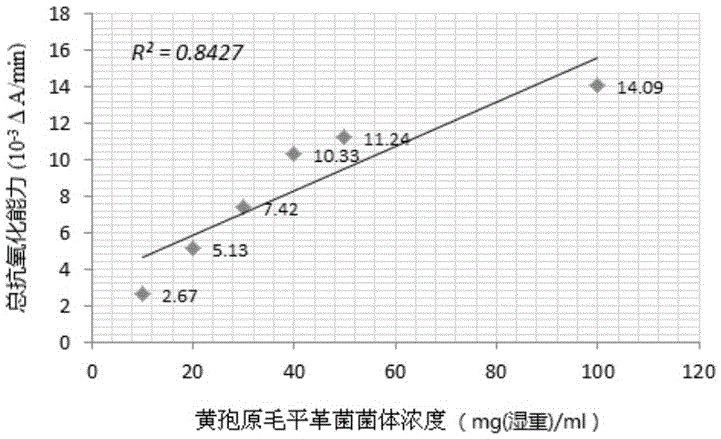

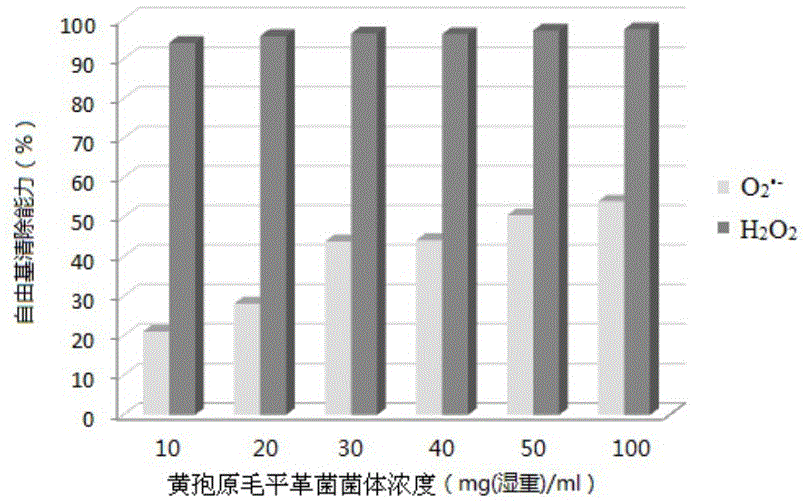

Phanerochaete chrysosporium extract containing antioxidant enzyme and preparation method

The invention relates to a panerochaete chrysosporium extracting solution with antioxidant enzyme. The panerochaete chrysosporium extracting solution with antioxidant enzyme is prepared by taking a panerochaete chrysosporium bacterium as an extracted substance, a phosphate buffer as an extracting agent, mixing up the panerochaete chrysosporium bacterium with the phosphate buffer, grinding and performing eccentric separation. The panerochaete chrysosporium extracting solution with antioxidant enzyme comprises superoxide dismutase, glutathione peroxidase and catalase. The panerochaete chrysosporium extracting solution is high in oxidation resistance. The invention further relates to a preparation method. The preparation method comprises the following steps: weighing the panerochaete chrysosporium bacterium, transferring into a glass homogenizer, adding the phosphate buffer, grinding, centrifuging to obtain the supernate, further adding the phosphate buffer into the glass homogenizer, grinding, centrifuging to obtain the supernate, and adding the phosphate buffer into the supernate until the constant volume is achieved. The panerochaete chrysosporium extracting solution is simple in process.

Owner:HUNAN UNIV

A kind of high-efficiency selective water shutoff agent for oil field and preparation method thereof

ActiveCN105273133BGood water blocking effectAvoid damageDrilling compositionStrong acidsNitrogen gas

The invention belongs to the technical field of oil-field applied chemistry, and provides an efficient selective water plugging agent for oil fields and a preparation method of the efficient selective water plugging agent for the oil fields. The preparation method comprises the following steps of sequentially adding 18.0 percent to 22.0 percent of nonionic monomers, 10.0 percent to 14.0 percent of anionic monomer 1#, 4.0 percent to 8.0 percent of anionic monomers 2# and 2.0 to 4.0 percent of cationic monomers into a flask containing deionized water under the protection of nitrogen, and stirring sufficiently; adding 0.1 percent to 0.2 percent of crosslinking agent 1# and 0.1 percent to 0.15 percent of crosslinking agent 2#, and stirring sufficiently; adding 0.2 percent to 0.3 percent of oxidizing agent and 0.1 percent to 0.2 percent of reducing agent; reacting at a normal temperature for 30 min to obtain water plugging agent gel; purifying the gel and drying, and grinding the agent into products with different particle sizes according to requirements so as to prepare an expansive organosilicon selective water plugging agent. The water plugging agent prepared according to the method provided by the invention has the advantages of higher water plugging efficiency and lower oil plugging ratio, stability in performance at the normal temperature, strong acid resistance and strong inoxidizability, and the water plugging agent can be prepared into products with different particle sizes according to the size of formation pores. The prepared water plugging agent can be used for plugging water from producing layers during the production process and plugging water during the water injection and profile control process.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com