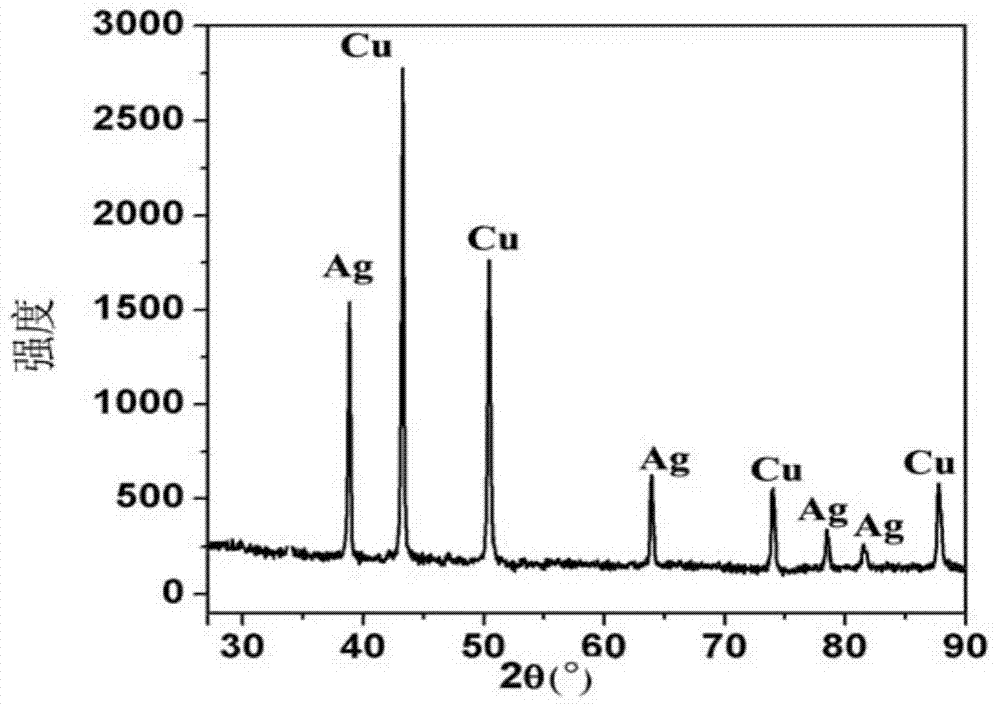

Preparation method for copper/silver heterojunction nano-particles

A nanoparticle and heterojunction technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as high price, and achieve the effect of solving difficult applications and simple and easy preparation methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

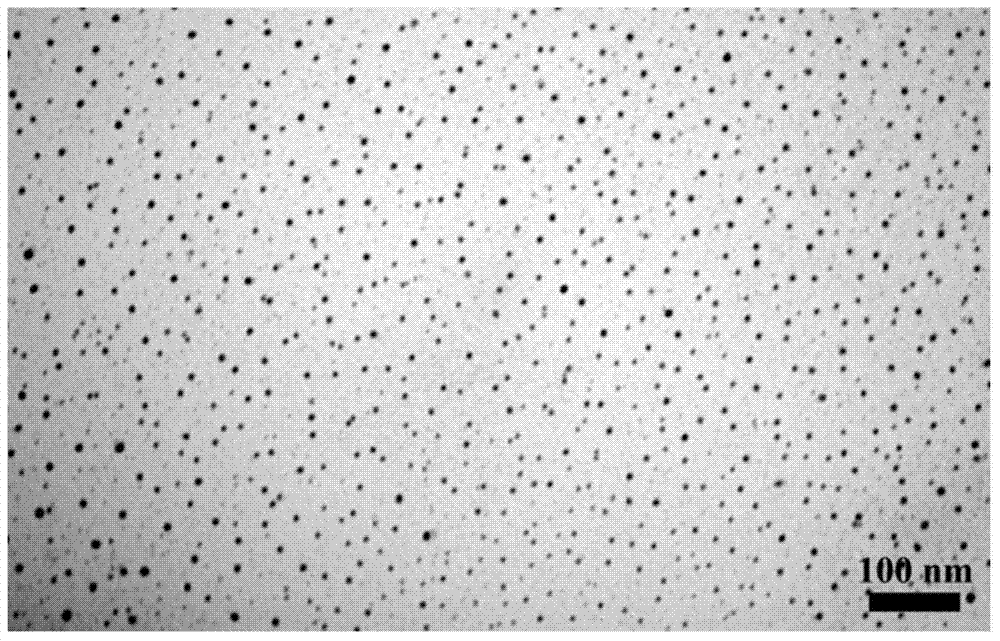

[0032] A preparation method of copper / silver heterojunction nanoparticles, comprising the following steps:

[0033] (1) Under the condition of magnetic stirring (30 rpm), add 0.2L of 0.01mol / L sodium borohydride to 0.001L of 0.1mol / L CuCl at a rate of 1.5mL / min 2 2H 2 In the O solution, react for 1 hour; after the reaction, centrifuge the reaction solution, get the precipitate, and then wash the precipitate with absolute ethanol and distilled water successively to obtain a nano-copper sample;

[0034] (2) Ultrasonically disperse 2 grams of the nano-copper sample obtained in step (1) (120W, time 15 minutes) in glycerol to obtain a nano-copper solution with a mass fraction of 10%; then 5ml of 0.02mol / L AgNO 3 The solution was added to the nano-copper solution, and heated to 150 ° C for 2 hours to react. After the reaction, the reaction solution was centrifuged and the precipitate was taken, and the precipitate was washed with absolute ethanol and distilled water in sequence to ...

Embodiment 2

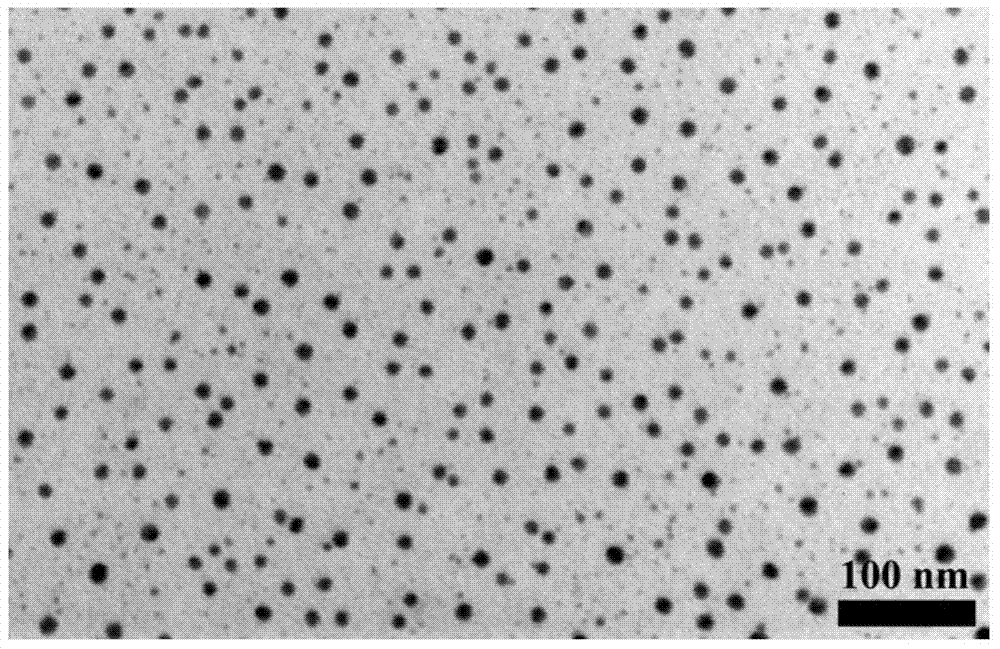

[0038] A preparation method of copper / silver heterojunction nanoparticles, comprising the following steps:

[0039] (1) Under the condition of magnetic stirring (150 rpm), add 0.2L of 0.01mol / L ascorbic acid solution to 0.1L of 0.5mol / L CuSO at a rate of 2ml / min 4 ·5H 2 In the O solution, react for 1 hour; after the reaction, centrifuge the reaction solution, get the precipitate, and then wash the precipitate with absolute ethanol and distilled water successively to obtain a nano-copper sample;

[0040] (2) Ultrasonically (120W, 15 minutes) disperse 3 grams of the nano-copper sample obtained in step (1) in ethylene glycol to obtain a nano-copper solution with a mass fraction of 3%; then 10ml of 0.01mol / L AgNO 3 The solution was added to the nano-copper solution, and heated to 100°C to react for 3 hours. After the reaction, the reaction solution was centrifuged and the precipitate was taken, and the precipitate was washed with absolute ethanol and distilled water in sequence t...

Embodiment 3

[0043] A preparation method of copper / silver heterojunction nanoparticles, comprising the following steps:

[0044] (1) Under the condition of magnetic stirring (120 rpm), add 0.02L0.01mol / L hydrazine hydrate solution to 0.1L0.2mol / L CuSO at a rate of 2ml / min 4 ·5H 2In the O solution, react for 1 hour; after the reaction, centrifuge the reaction solution, get the precipitate, and then wash the precipitate with absolute ethanol and distilled water successively to obtain a nano-copper sample;

[0045] (2) Ultrasonically (120W, 15min) disperse 0.3 g of the nano-copper sample obtained in step (1) in ethylene glycol to obtain a nano-copper solution with a mass fraction of 36%; then 30ml of 0.01mol / L AgNO 3 The solution was added to the nano-copper solution, and heated to 70°C for 6 hours to react. After the reaction, the reaction solution was centrifuged and the precipitate was taken, and the precipitate was washed with absolute ethanol and distilled water in sequence to obtain th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com