Preparation method of conductive glue solution for negative electrode of lithium ion battery

A lithium-ion battery and conductive adhesive technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems that the dispersion effect affects the battery capacity, battery consistency, poor dispersion of conductive agents and binders, and easy agglomeration. To achieve the effect of improving the dispersion effect, facilitating swelling and avoiding agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

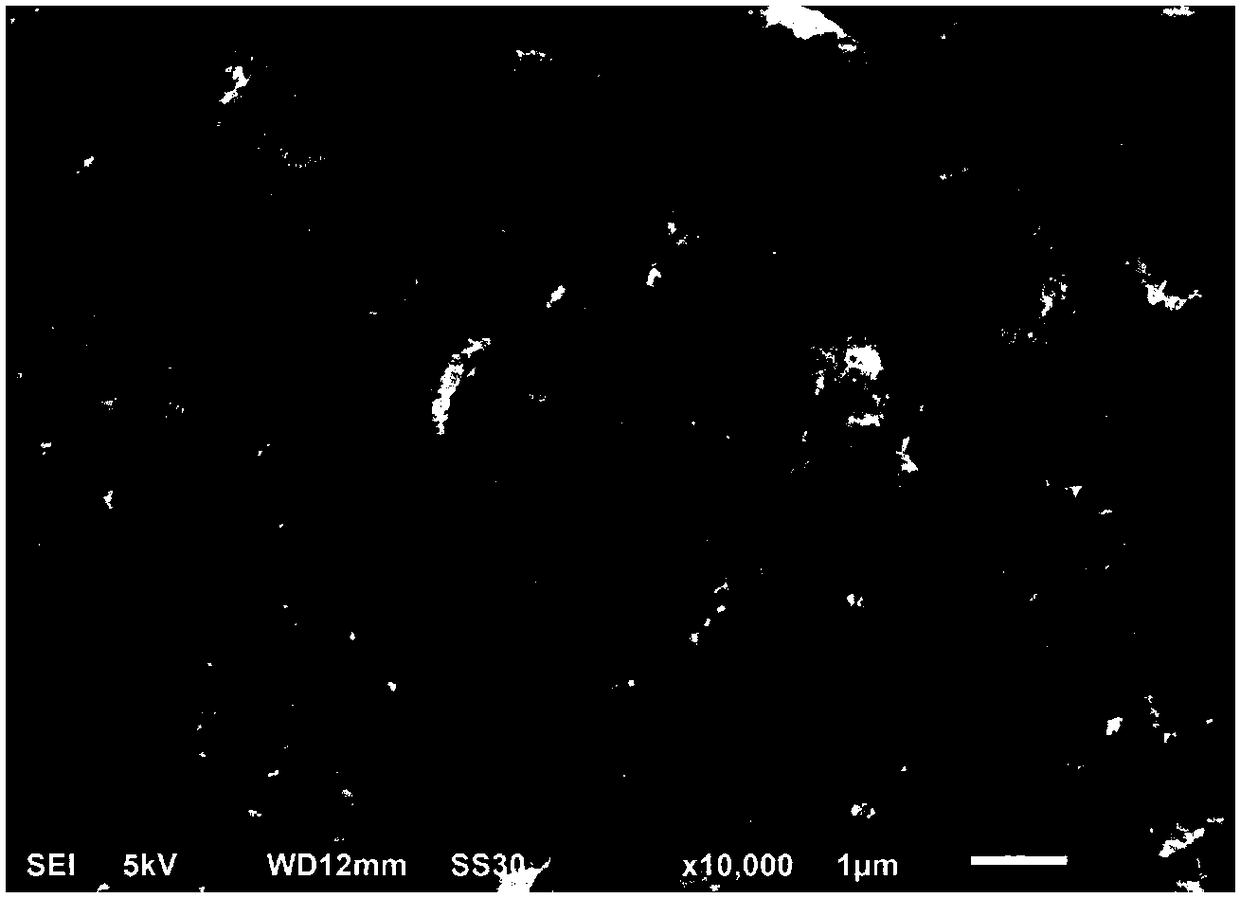

[0033] In the process of making the conductive glue, the present invention uses carbon nanotubes and SuperP as conductive agents, sodium carboxymethyl cellulose as a thickener, and N-methylpyrrolidone as a cosolvent, and the components are according to the mass ratio of carbon nanotubes: SuperP: sodium carboxymethyl cellulose: N-methylpyrrolidone: water = 1:2:6:36:405 mass ratio for mixing to obtain a solid content of the final conductive adhesive of 2%. Concrete preparation process is as follows:

[0034] (1) First add 50% sodium carboxymethyl cellulose powder into the mixer, then add conductive agent carbon nanotubes and SuperP, and finally put in the remaining sodium carboxymethyl cellulose powder, start stirring, and stir for revolution The speed is 8rpm, and the stirring time is 10min;

[0035] (2) Add N-methylpyrrolidone solution equivalent to 4 times the weight of the powder to the mixed powder, start stirring, the revolution speed of stirring is 10rpm, the dispersion ...

Embodiment 2

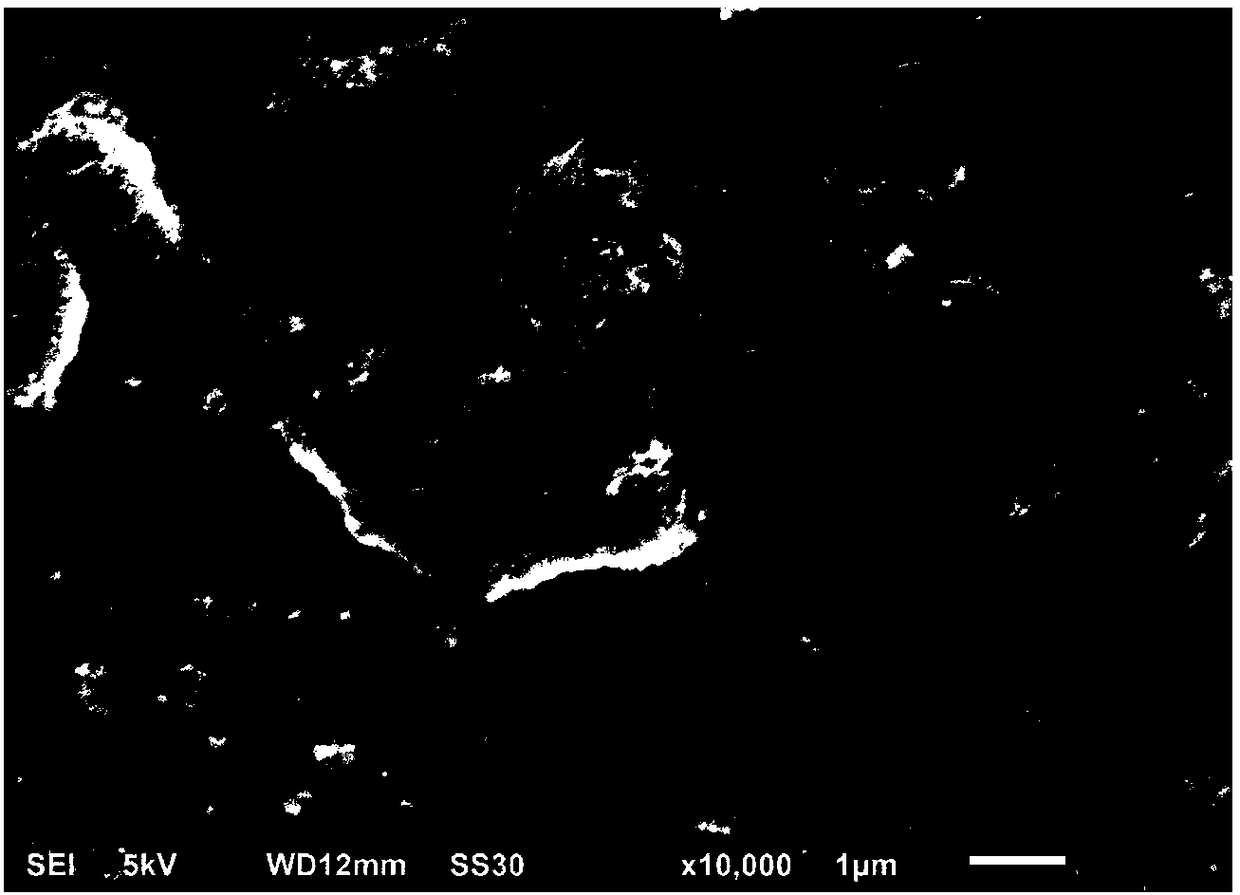

[0041] In the process of making the conductive glue in the present invention, KS-6 and SuperP are used as conductive agents, sodium carboxymethyl cellulose is used as a thickener, and N-methylpyrrolidone is used as a cosolvent, and the mass ratio of each component is KS-6: SuperP: sodium carboxymethyl cellulose: N-methylpyrrolidone: water = 1:2:6:54:297 mass ratio for mixing to obtain a solid content of 2.5% of the final conductive adhesive. Concrete preparation process is as follows:

[0042] (1) First add 50% sodium carboxymethyl cellulose powder into the mixer, then add conductive agent KS-6 and SuperP, and finally put in the remaining sodium carboxymethyl cellulose powder, start stirring, and stir for revolution The speed is 5rpm, and the stirring time is 15min;

[0043] (2) Add N-methylpyrrolidone solution equivalent to 6 times the weight of the powder to the mixed powder, start stirring, the revolution speed of stirring is 12rpm, the dispersion speed is 300rpm, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com