Compressed wood and preparation method thereof

A technology for compressing wood and wood, applied in wood processing, manufacturing tools, wood processing appliances, etc., can solve the problems of easy springback of compressed wood, uneven heat of wood, rise, etc., short time to achieve, low water absorption recovery rate, Overcome the effect of serious environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

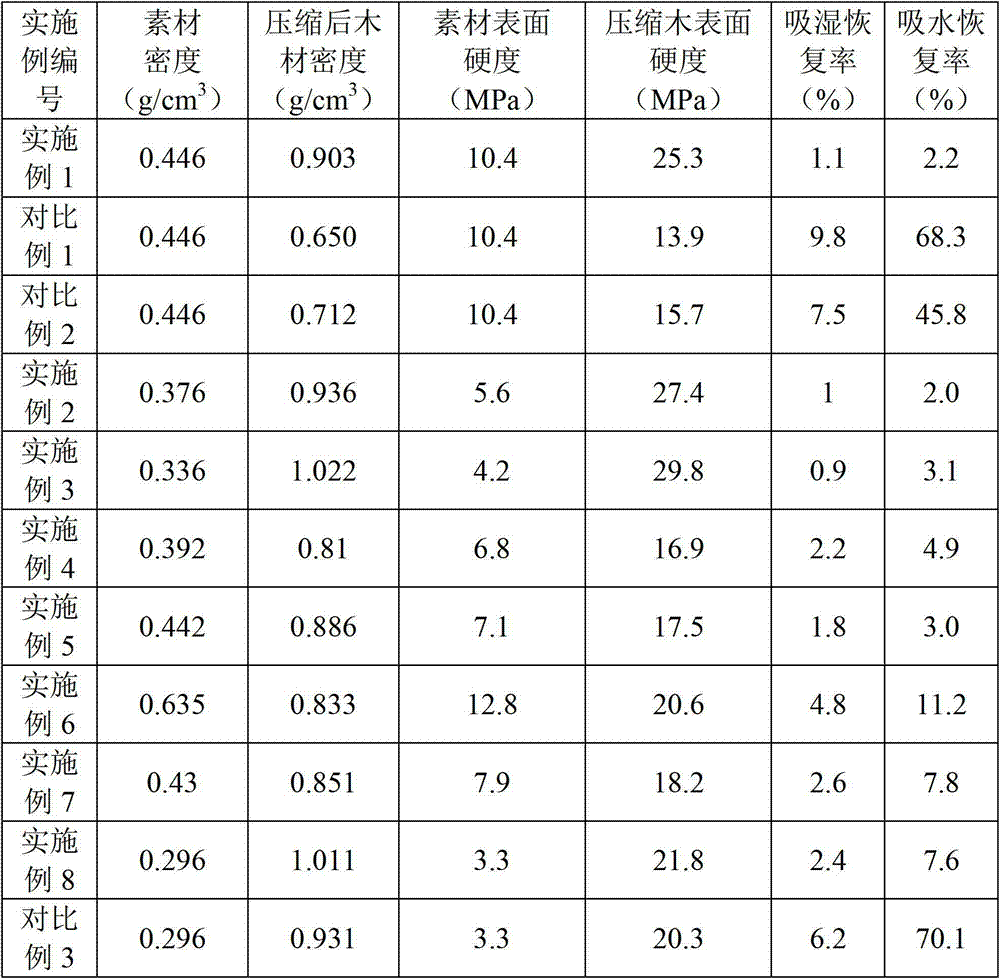

Examples

preparation example Construction

[0018] The invention provides a kind of preparation method of compressed wood, wherein, the method comprises the following steps:

[0019] (1) Carrying out the first high-frequency heating to the wood with a moisture content of 12-30% by weight, so that the core temperature of the wood reaches 80-120°C;

[0020] (2) hot pressing the wood obtained in step (1);

[0021] (3) Carrying out the second high-frequency heating to the wood obtained in step (2), so that the core temperature of the wood reaches 180-220°C.

[0022] In the present invention, hot pressing refers to compressing wood under a certain pressure under the heating condition of a hot pressing plate.

[0023] According to the present invention, the first high-frequency heating, the second high-frequency heating and hot pressing can be implemented on the same equipment, or can be implemented separately on different equipment, as long as the purpose of the present invention can be achieved. Preferably, the first high...

Embodiment 1

[0048] This embodiment is used to illustrate the preparation method of the compressed wood provided by the present invention and the compressed wood prepared by the method.

[0049] (1) The artificial forest poplar is made into a chord-oriented board with a size of 500mm (length) × 150mm (width) × 60mm (thickness) and a moisture content of 18% by weight, and placed on a high-frequency hot press (Shijiazhuang Development Zone Era Electric Co., Ltd., the model is GJW-PI-336-JY, the same below) Preheating, the preheating temperature is 180 ° C, and the preheating time is 2 seconds;

[0050] (2) Carry out the first high-frequency heating on the preheated plate, the frequency of the high-frequency electromagnetic wave is 6.78MHz, and the heating time is 4min, so that the core temperature of the plate reaches 100°C, and then maintain the core temperature at 100°C , hold time is 1min;

[0051] (3) Then press the plate on both sides in the radial direction for hot pressing, the compr...

Embodiment 2

[0059] (1) Make chordal plates with dimensions of 500mm (length)×150mm (width)×75mm (thickness) and a moisture content of 16% by weight from Chinese fir, and preheat them on a high-frequency hot press at a temperature of 200 ℃, the preheating time is 5 seconds;

[0060] (2) Carry out the first high-frequency heating on the preheated plate, the high-frequency electromagnetic wave frequency is 6.78MHz, and the heating time is 5min, so that the core temperature of the plate reaches 105°C, and then maintain the core temperature at 105°C , the holding time is 1.5min;

[0061] (3) Then press the plate on both sides in the radial direction for hot pressing, the compression rate of hot pressing is 45%, the hot pressing temperature is 200°C, the hot pressing pressure is 20MPa, and the closing speed is 0.5mm / s;

[0062] (4) Carry out the second high-frequency heating on the compressed plate, the high-frequency electromagnetic wave frequency is 6.78MHz, and the heating time is 1min, so ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com