High-wear-resistance barrier moisture-permeable material as well as preparation method and application thereof

A highly wear-resistant and moisture-permeable technology, used in applications, other household appliances, chemical instruments and methods, etc., can solve problems such as being unsuitable for exposure to the working environment, poor wear resistance of PE film, and inability to use protective clothing, etc. Good abrasiveness and moisture permeability, excellent film-forming properties, and the effect of improving moisture permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~13

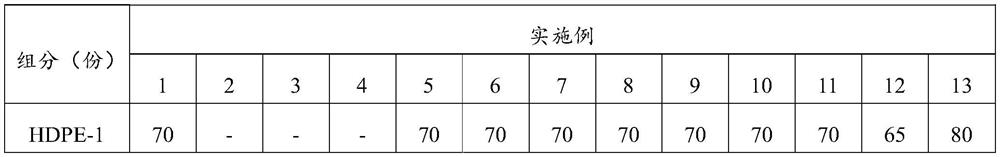

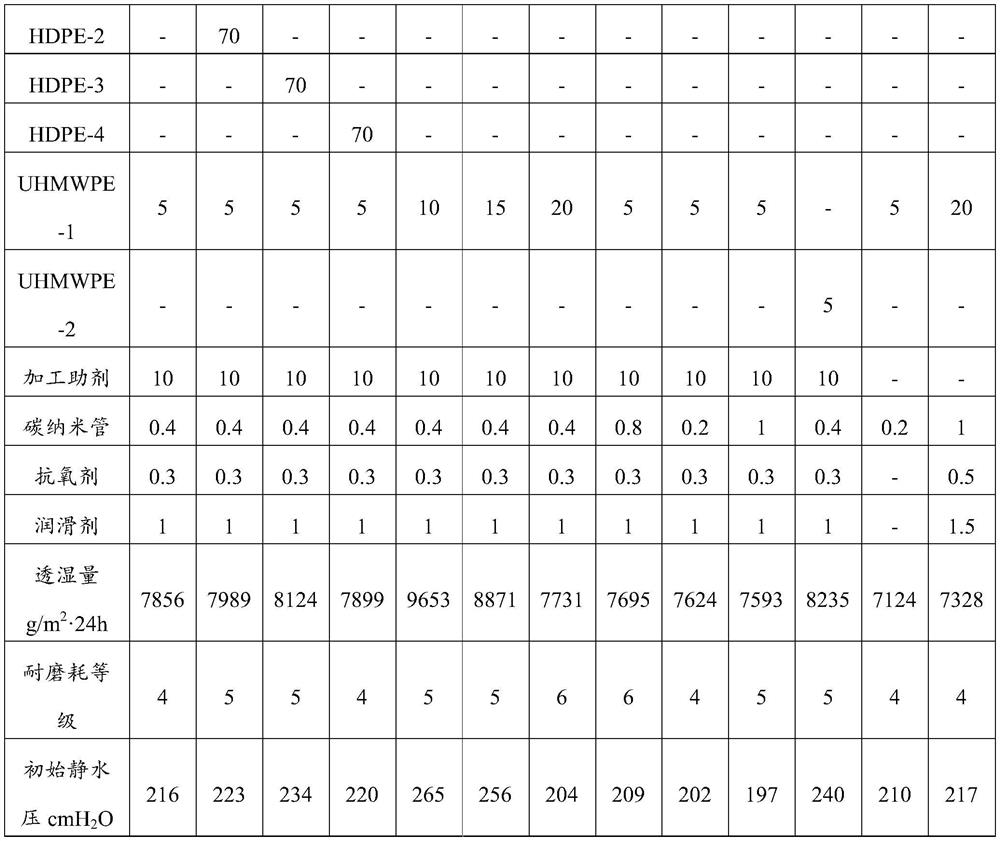

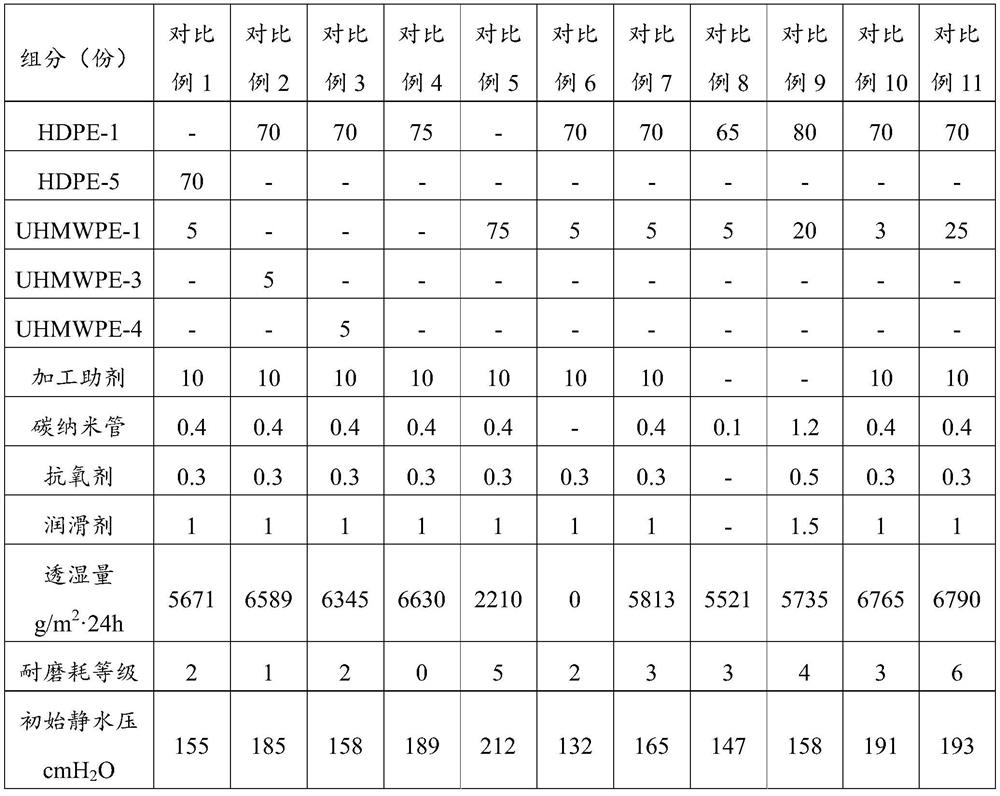

[0052] Examples 1-13 provide a high wear-resistant barrier and moisture-permeable material, the formula of which is shown in Table 1 in parts by weight, and the preparation method is as follows:

[0053] (1) carbon nanotubes, ethanol and lauric acid are mixed according to the weight ratio of carbon nanotubes: ethanol: lauric acid=20:1:80, and stirred at 40°C to obtain an oily carbon nanotube mixture;

[0054] (2) Add HDPE, UHMWPE, processing aids, antioxidants and lubricants into the high mixer, and mix at 1000-2000rpm for 1-3 minutes to obtain a uniform premix;

[0055] (3) Put the premixed material into the twin-screw extruder for melt extrusion, inject the carbon nanotube mixture prepared in step (1) into the melting section, the temperature of each zone of the screw is 190-230°C, and vacuum out small molecular substances in two sections , the vacuum pressure is controlled below -0.06MPa, and vacuum granulation is used to produce a highly wear-resistant barrier moisture-per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com