Preparation method of SiOC ceramic aerogel

An aerogel and ceramic technology, applied in the field of preparation of SiOC ceramic aerogel, can solve the problem of difficult control of the pore size of SiOC ceramic aerogel, and achieve stable temperature resistance and oxidation resistance, high specific surface area, and stable structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0026] Specific embodiment one: the preparation method of a kind of SiOC ceramic airgel of the present embodiment is carried out according to the following steps:

[0027] 1. Weigh 1 to 10 parts of hydrogen-containing polymethylsiloxane, 1 to 10 parts of 2,4,6,8-tetramethyl-2,4,6,8-tetravinylcyclotetra Siloxane, 0.1-1 part of chloroplatinic acid and 20-98 parts of acetone, set aside;

[0028] 2. 1-10 parts of hydrogen-containing polymethylsiloxane, 1-10 parts of 2,4,6,8-tetramethyl-2,4,6,8-tetravinylcyclotetra Siloxane, 0.1-1 part of chloroplatinic acid and 20-98 parts of acetone are evenly mixed and placed in a hydrothermal reaction kettle, and then the hydrothermal reaction kettle is put into an oven preheated to a temperature of 120-160°C. Keep the temperature at 120-160°C for 240min-350min, then cool naturally to room temperature to obtain a gel;

[0029] 3. Soak the gel obtained in step 2 for 2 to 5 times with acetone, each time for 24 hours, then soak the gel with etha...

specific Embodiment approach 2

[0032] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is: in step 2, put the hydrothermal reactor into an oven preheated to a temperature of 140°C, and keep it warm for 240min to 350min at a temperature of 140°C , and then cooled naturally to room temperature. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0033] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: in step two, put the hydrothermal reaction kettle into an oven that is preheated to a temperature of 120-160°C. Keep warm for 260min under the condition, then cool down to room temperature naturally. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

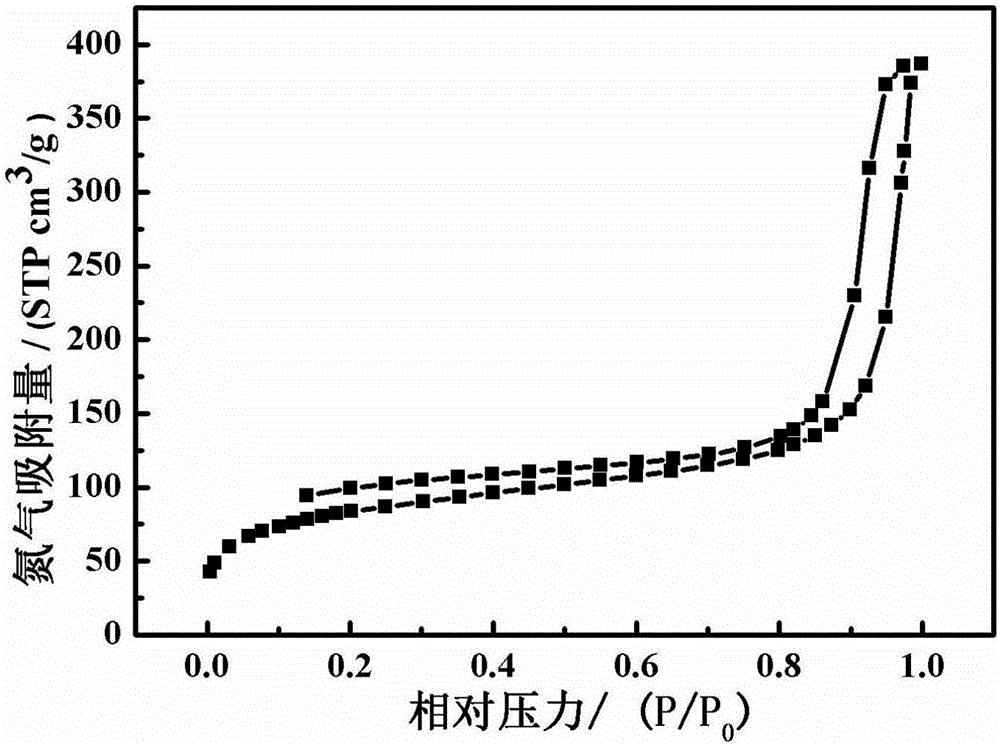

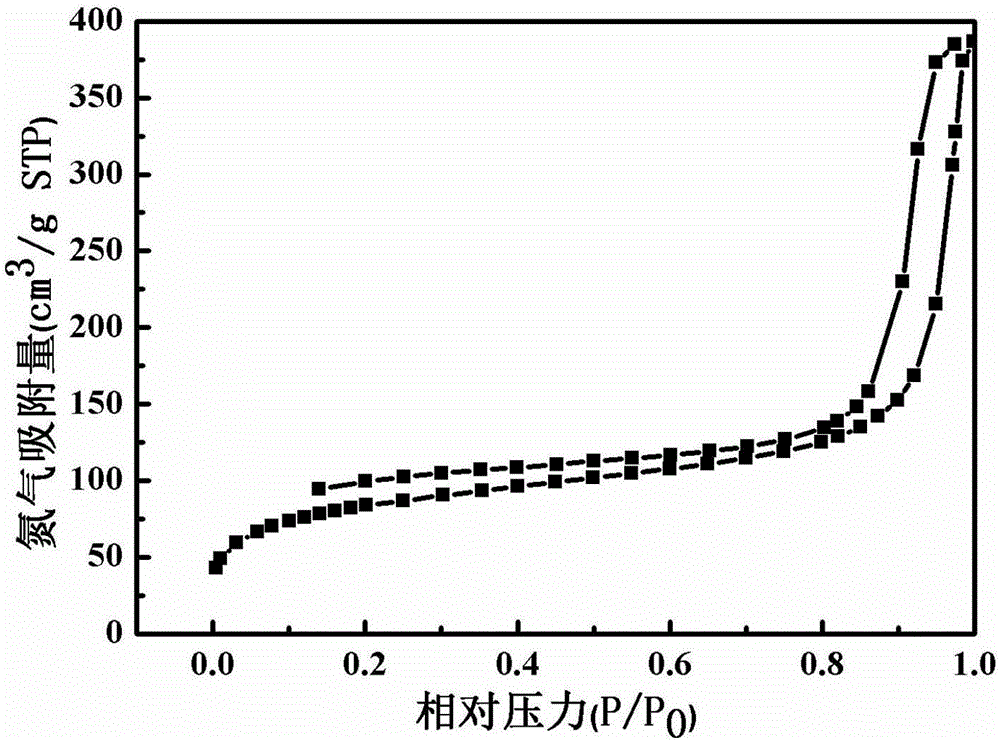

| specific surface area | aaaaa | aaaaa |

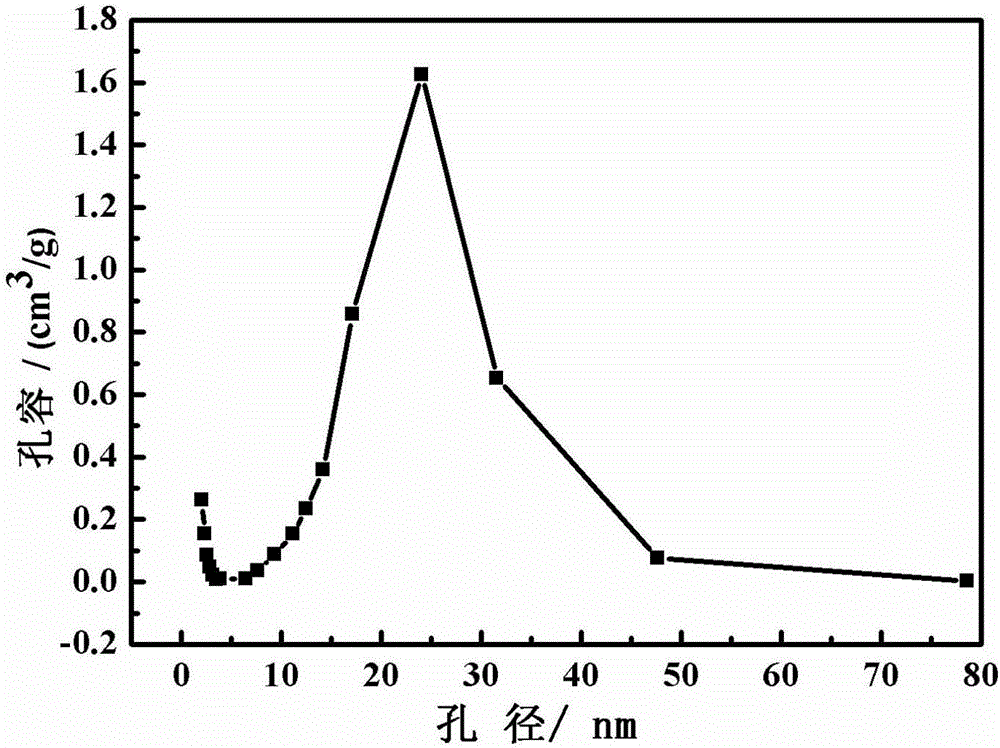

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com