Method for rapidly preparing green MOFs (Metal-organic frameworks) porous microspheres

A porous microsphere, green technology, applied in the field of nanomaterials, can solve the problems of complex preparation process, single function, long time consumption, etc., and achieve the effect of less energy consumption, improved electrical conductivity, and excellent electrical conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

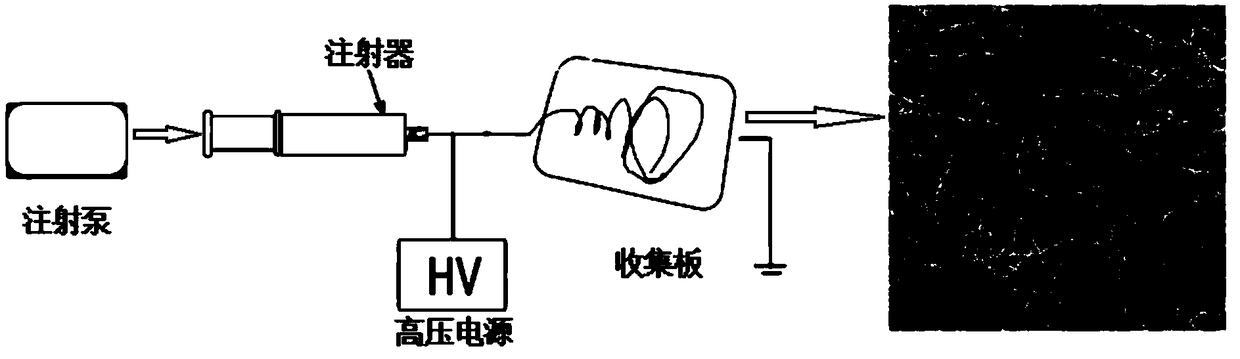

[0046] This example shows a method for the rapid preparation of green MOFs porous microspheres according to the following steps:

[0047] 1.6g PAN was added to 18.2g dimethylformamide solvent, and then 0.1g ZIF-67 was added, and the mixed solution was stirred at room temperature for 24h. Take 10ml of the homogeneous mixed solution, add 0.5g of polyaniline, stir at room temperature for 6 hours, and ultrasonically shake the mixed solution for 30 minutes before electrospinning. The electrospinning voltage was 20 kV, the flow rate was 1.5 ml / h, and the distance between the needle and the collection plate was 10 cm.

Embodiment 2

[0049] This case study demonstrates a method for quickly preparing green MOFs porous microspheres as follows:

[0050] 1.6g PAN was added to 18.2g dimethylformamide solvent, then 0.2g ZIF-67 was added, and the mixed solution was stirred at room temperature for 24 hours. Take 10ml of uniform mixed solution, add 0.5g of polyaniline, stir at room temperature for 6h, before electrospinning, the mixed solution is ultrasonically shaken for 30min. The electrospinning voltage is 20kV, the flow rate is 1.5ml / h, and the distance between the needle and the collecting plate is 10cm.

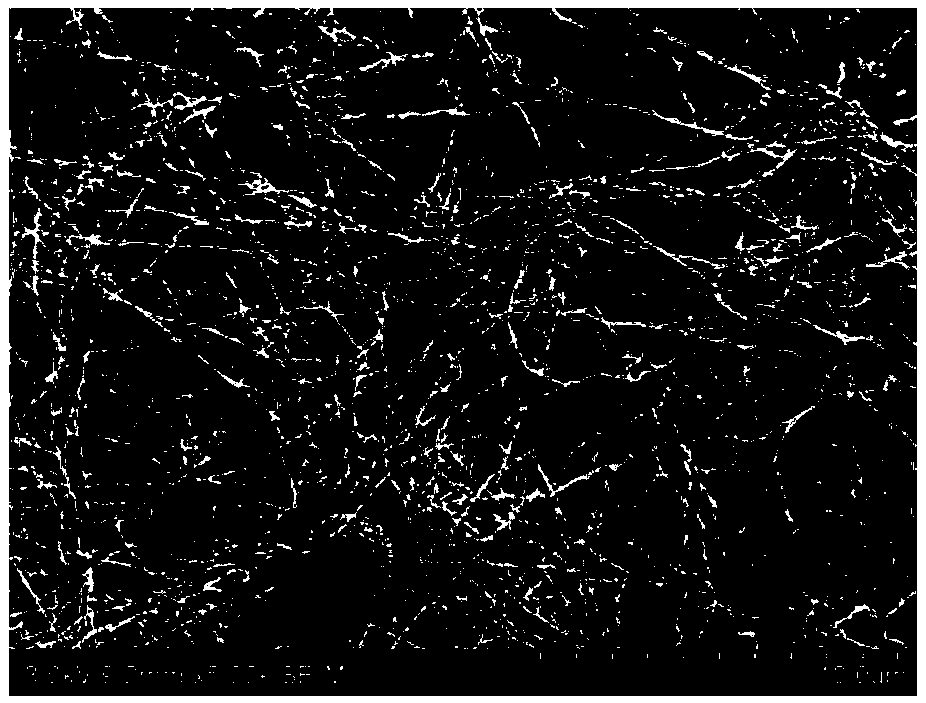

[0051] Please refer to the performance of the green MOFs porous microspheres obtained in this example Figure 2 to Figure 3 ,Such as figure 2 As shown, the porous microspheres formed by ZIF-67 nanoparticles with cubic crystal form are uniformly distributed on polyacrylonitrile and polyaniline fibers. Such as image 3 As shown, the diameter of the formed porous microspheres is between 1-3 μm.

Embodiment 3

[0053] This case study demonstrates a method for quickly preparing green MOFs porous microspheres as follows:

[0054] 1.6g PAN was added to 18.2g dimethylformamide solvent, and then 0.3g ZIF-67 was added, and the mixed solution was stirred at room temperature for 24h. Take 10 ml of the homogeneous mixed solution, add 0.5 g of polyaniline, stir at room temperature for 6 hours, and ultrasonically shake the mixed solution for 30 minutes before electrospinning. The electrospinning voltage is 20kV, the flow rate is 1.5ml / h, and the distance between the needle and the collecting plate is 10cm.

[0055] Please refer to the performance of the green MOFs porous microspheres obtained in this example Figure 4 to Figure 5 ,Such as Figure 4 As shown, ZIF-67 porous microspheres are evenly distributed on polyacrylonitrile and polyaniline fibers. Such as Figure 5 As shown, the diameter of the formed porous microspheres can reach 3-5 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com