Patents

Literature

69results about How to "High specific area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

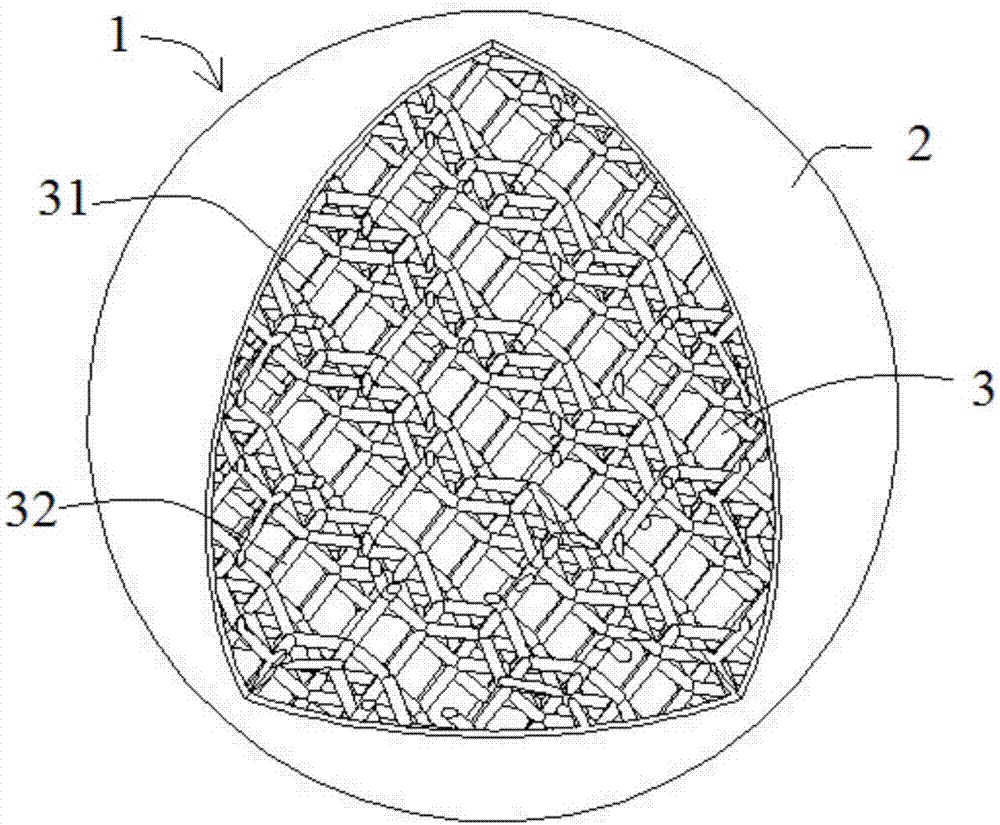

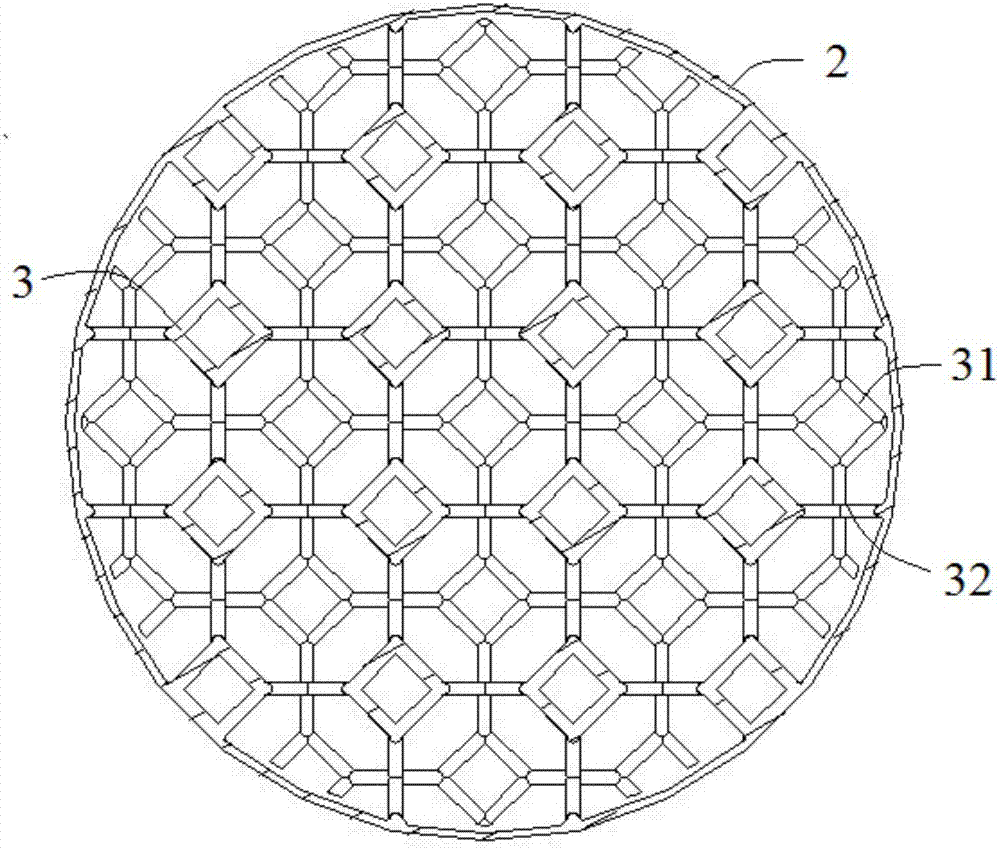

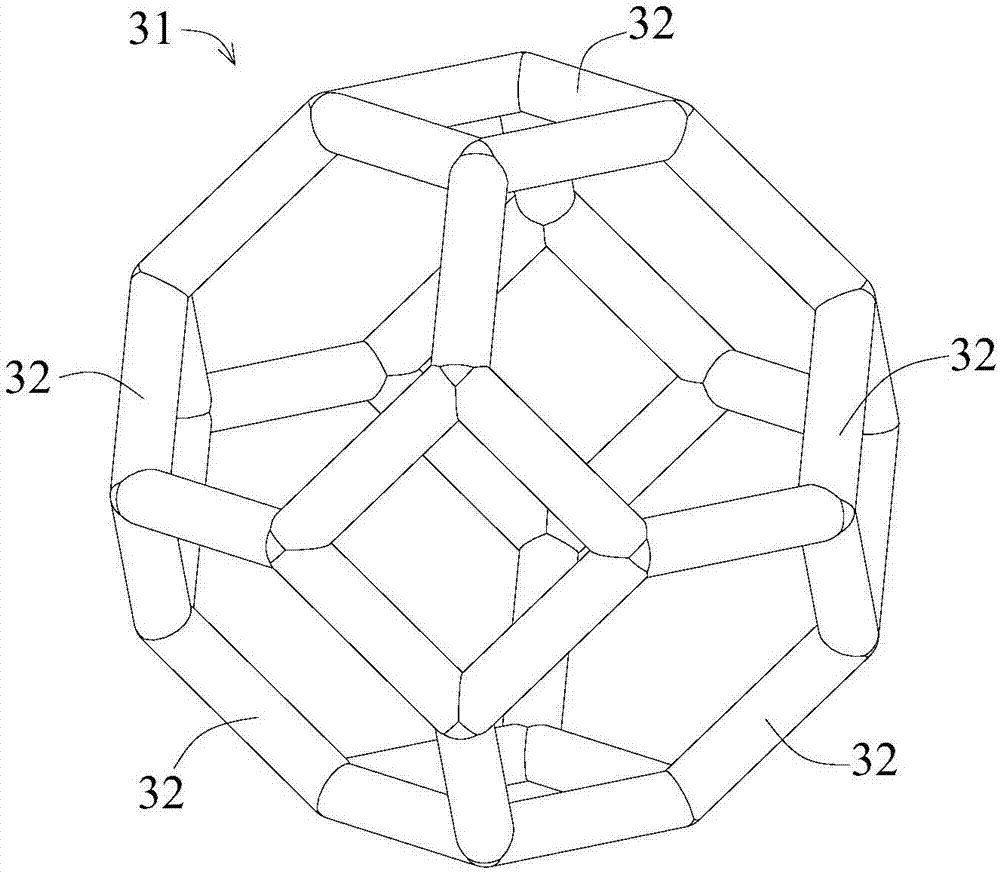

Composite light structure with high energy absorbing rate and good buffer ability and structure main body

InactiveCN107448528AHigh energy absorptionQuality improvementHigh internal friction springsLow internal friction springsDot matrixHigh energy

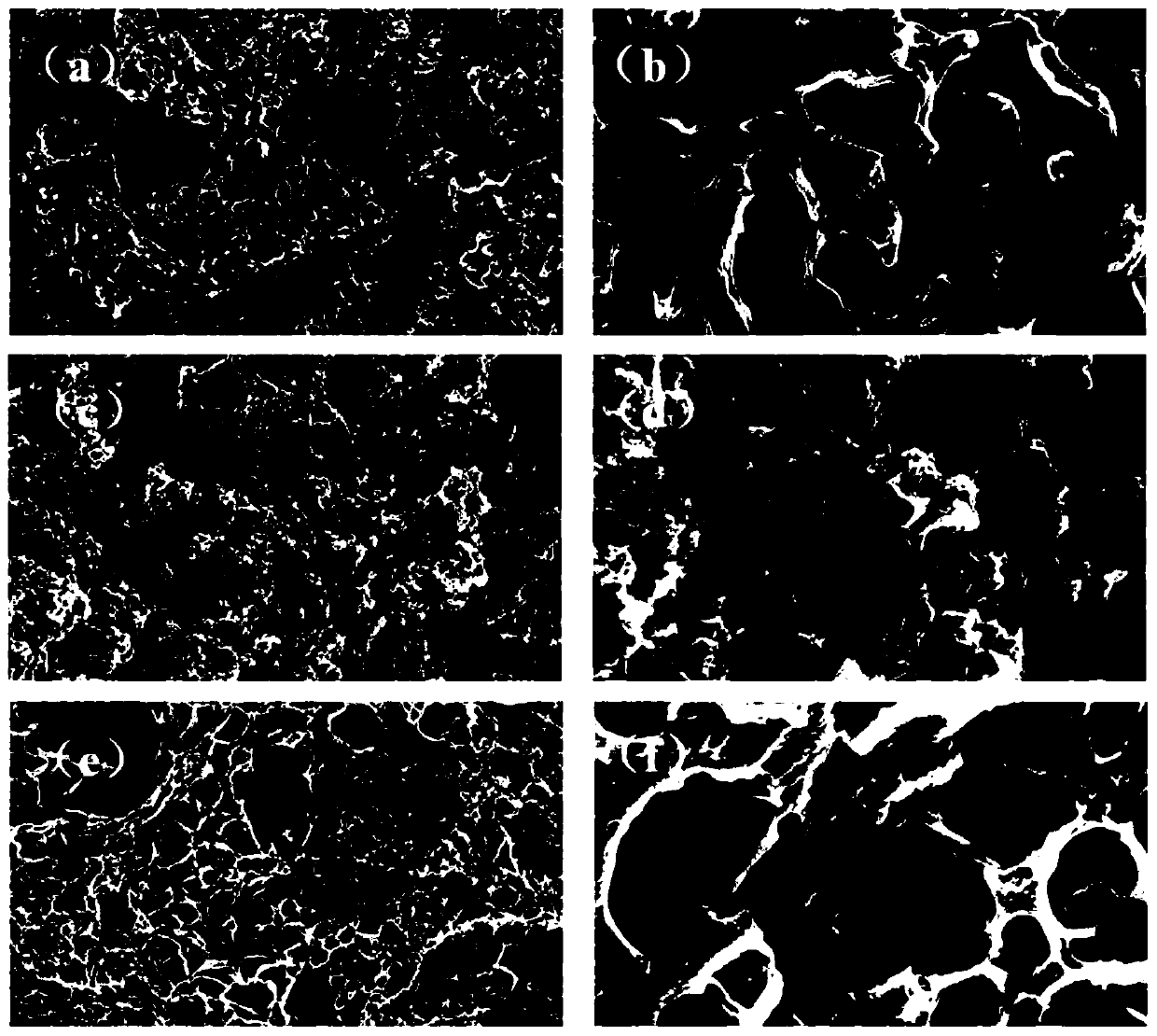

The invention discloses a composite light structure with a high energy absorbing rate and good buffer ability and a structure main body. The composite light structure with the high energy absorbing rate and good buffer ability comprises a housing and an inner support, wherein the housing is sealed and hollow; the inner support is connected in the housing; the inner support is of a dot matrix structure; the inner support comprises a plurality of unit cells which are arranged according to a preset rule; and each cell unit is in the shape of a framework comprising a plurality of supporting rods. The composite light structure with the high energy absorbing rate and good buffer ability and the structure main body disclosed by the invention have the characteristics of relatively small weight, relatively high specific areas, strong energy absorbing ability and relatively strong buffer ability.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

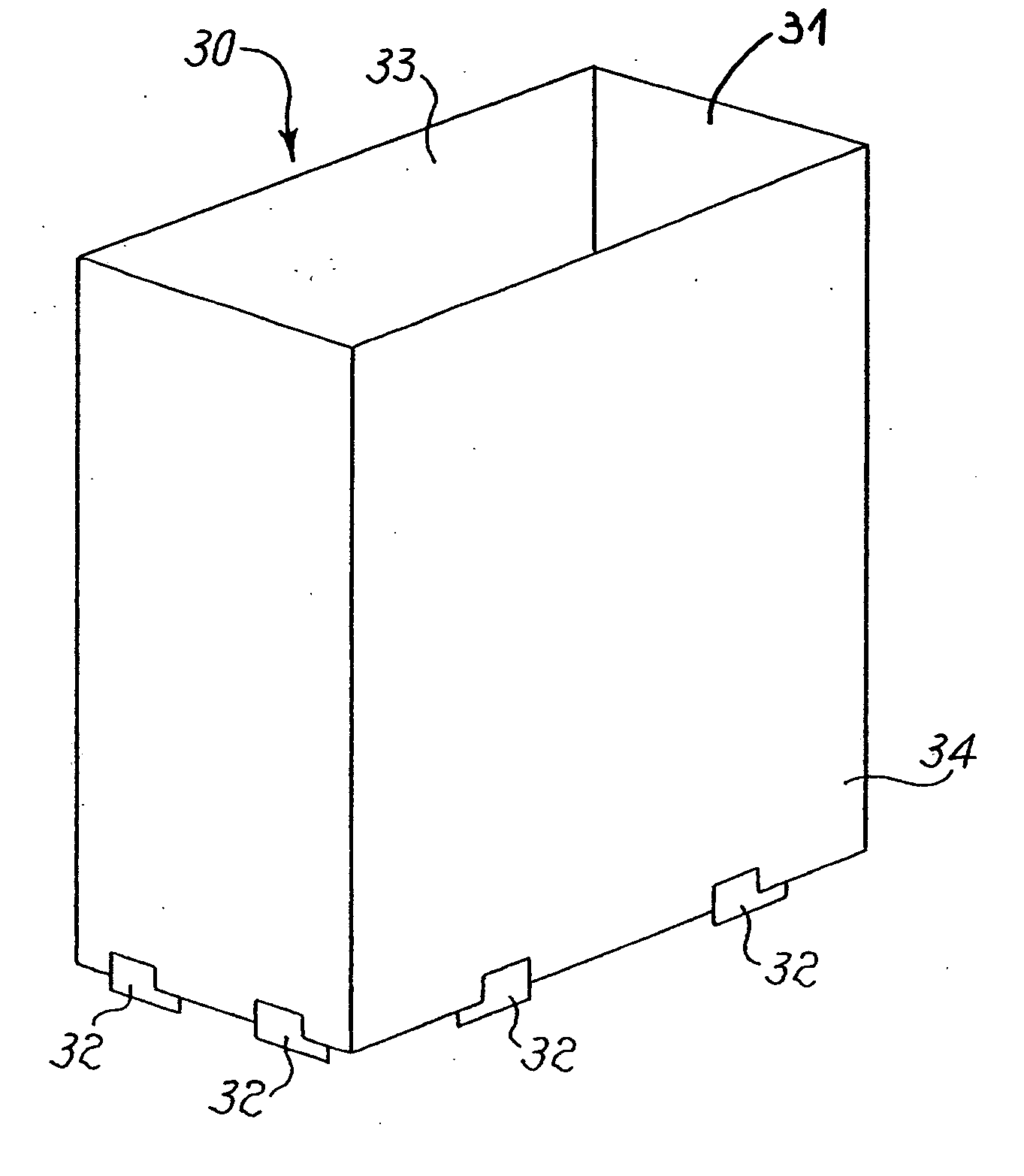

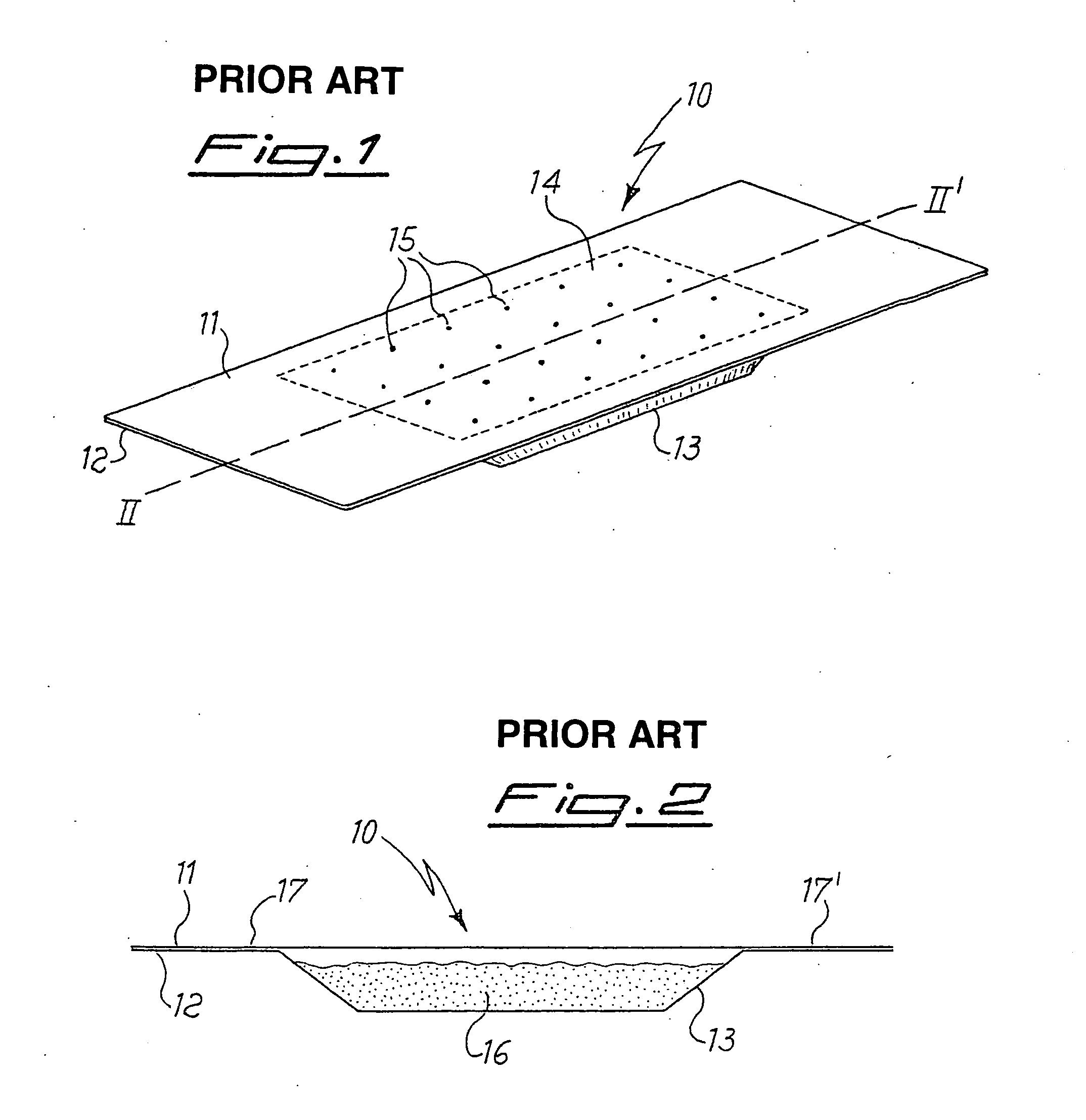

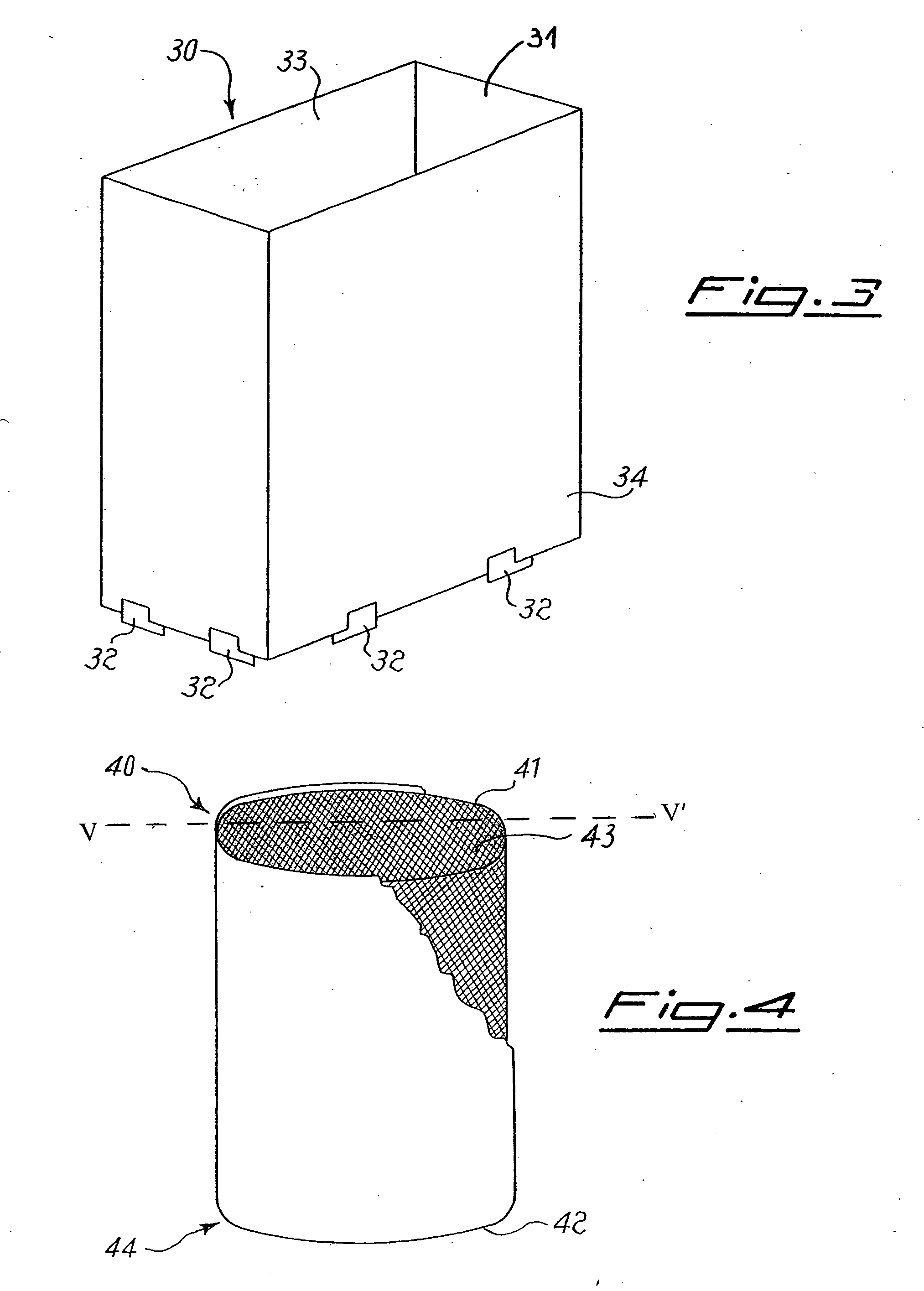

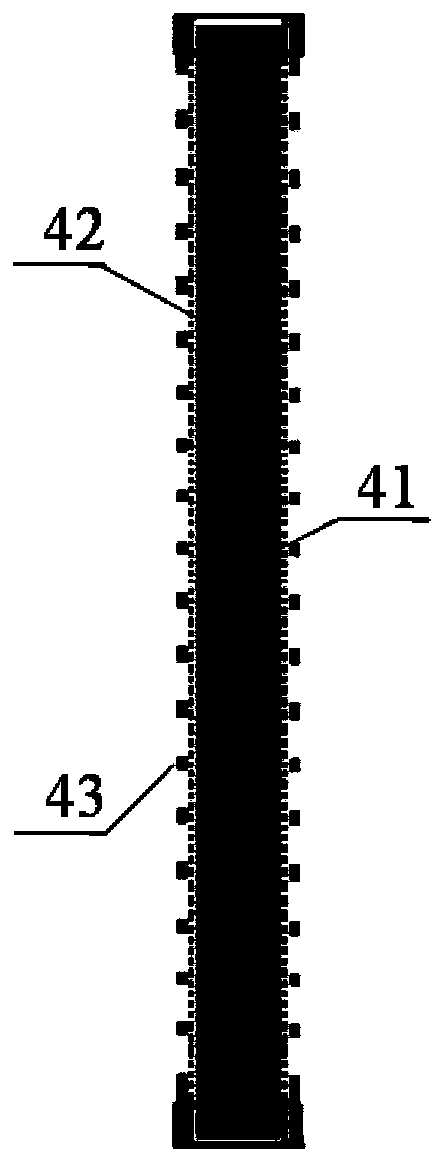

Accessory member for dispensers of alkali metals

InactiveUS20050145179A1Avoid depositionConstant and uniform deposit yieldLiquid surface applicatorsElectroluminescent light sourcesEngineeringMechanical engineering

An accessory member for alkali metals dispensers is provided in the form of a screen (30; 40; 60) of substantially tubular shape, one end (34; 44; 64) of which can be applied to an alkali metals dispenser (10). The cross-section of the one end is superposable to an entire alkali metals emission zone (14) of the dispenser (10). The contact portion between the one end (34, 44; 64) and the dispenser (10) is made with a low thermal conductivity material. The screen (30; 40; 60) is provided with an internal surface having a high specific area.

Owner:SAES GETTERS SPA

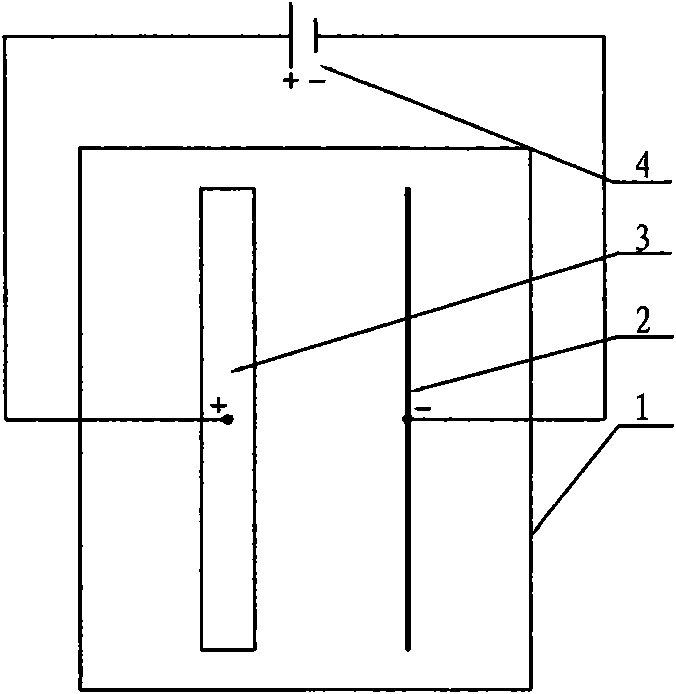

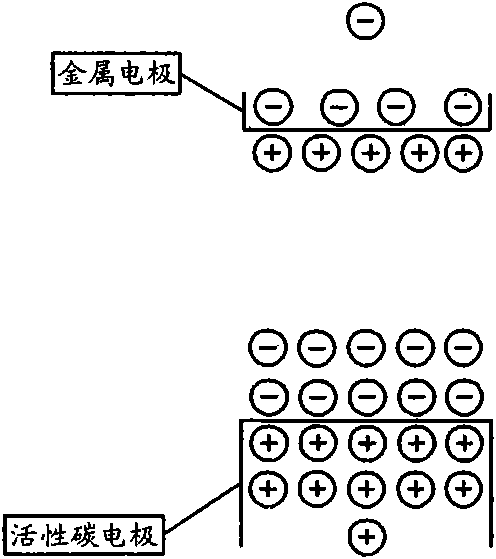

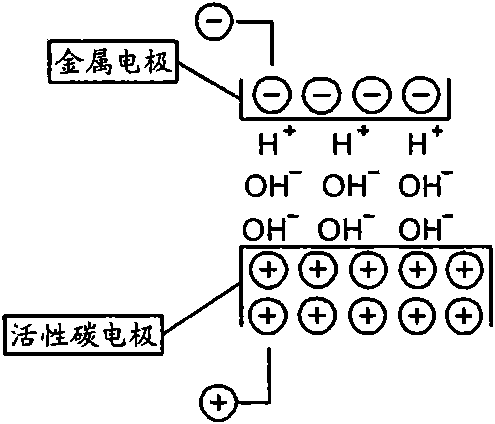

Reductive water non-diaphragm electrolysis device

InactiveCN102020341ARealize popularization of commercializationReduce consumptionWater/sewage treatmentActivated carbonStable state

The invention relates to a reductive water non-diaphragm electrolysis device belonging to the technical field of electrolysis of water and comprising an electrolyzer, a pair of negative electrode and positive electrode arranged in the electrolyzer, and a power supply electrically connected with the negative electrode and the positive electrode; one of the negative electrode and the positive electrode is an activated carbon electrode mainly made of activated carbon, and the other electrode is a metal electrode made of metal; the distance delta between the negative electrode and the positive electrode is not greater than 5m but is greater than 0. The device can adapt to various kinds of raw water and can prepare reductive water with wide pH range and a stable state without adding any substance directly by electrifying; moreover, compared with various water electrolysis devices, the reductive water non-diaphragm electrolysis device has lower power consumption and manufacturing cost, and thereby, the commercial popularization of the non-diaphragm electrolysis device can be implemented.

Owner:李国梅 +2

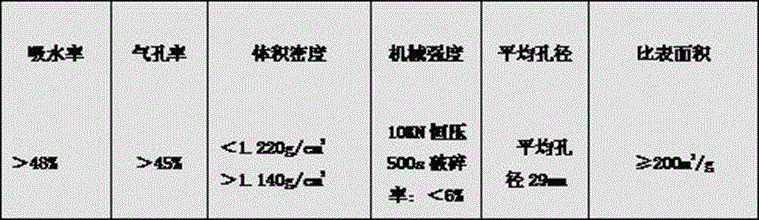

Method for preparing porous ceramic material for adsorbing heavy metals

ActiveCN106045553AHigh specific areaHigh mechanical strengthOther chemical processesAlkali metal oxides/hydroxidesCompound (substance)Chemical adsorption

The invention discloses a method for preparing a porous ceramic material for adsorbing heavy metals. The method comprises the following steps: (1) preparing pug; (2) preparing a phosphorous compound solution: dissolving 20-40 parts (by weight) of phosphorous compound in 30-60 parts (by weight) of water so as to obtain the phosphorous compound solution; (3) carrying out milling: adding the phosphorous compound solution prepared in the step (2) into the pug prepared in the step (1), and carrying out milling for 20 to 30 minutes by using a mixing mill; (4) carrying out ceramic green body forming; (5) carrying out ceramic green body drying; and (6) carrying out ceramic green body burning. The porous ceramic material for adsorbing the heavy metals, prepared by the method, has the advantages of porosity, high specific area, high mechanical strength, high physical adsorptivity, high chemical adsorptivity and wide chemical adsorption adaptability.

Owner:芜湖格丰环保科技研究院有限公司

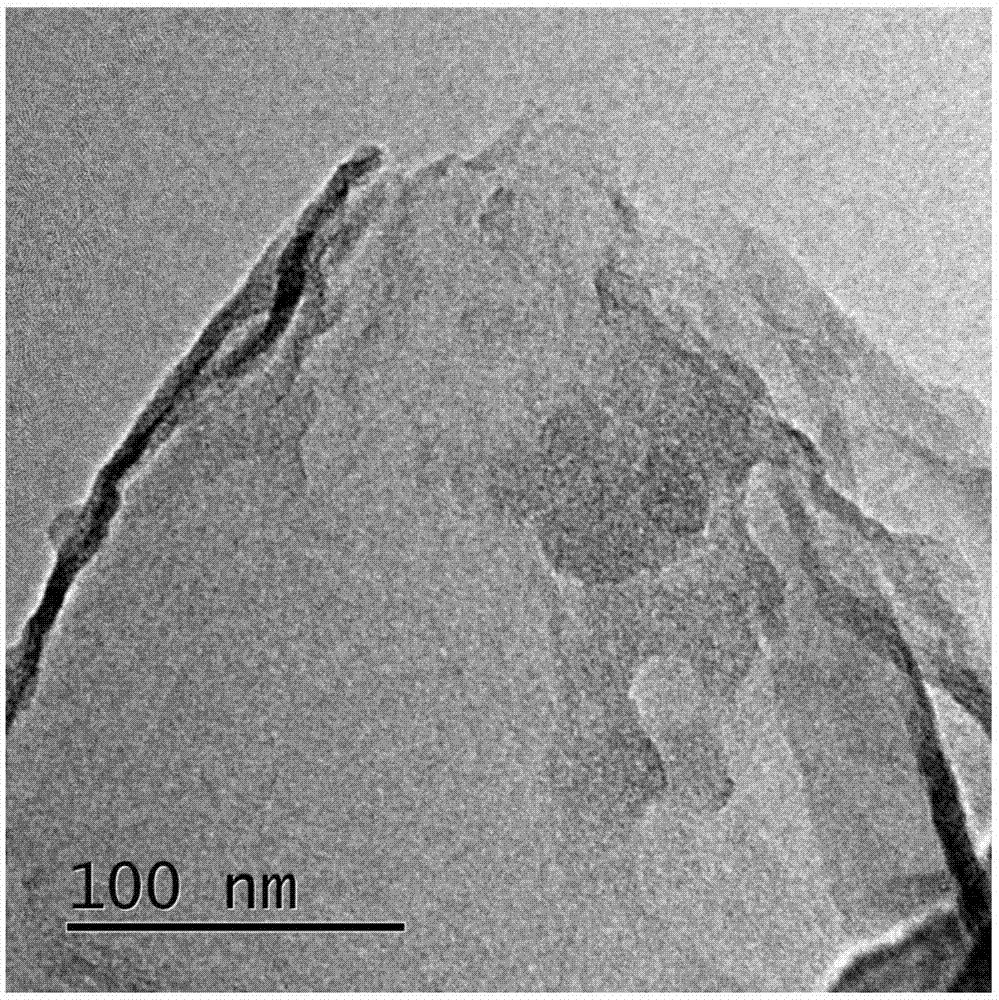

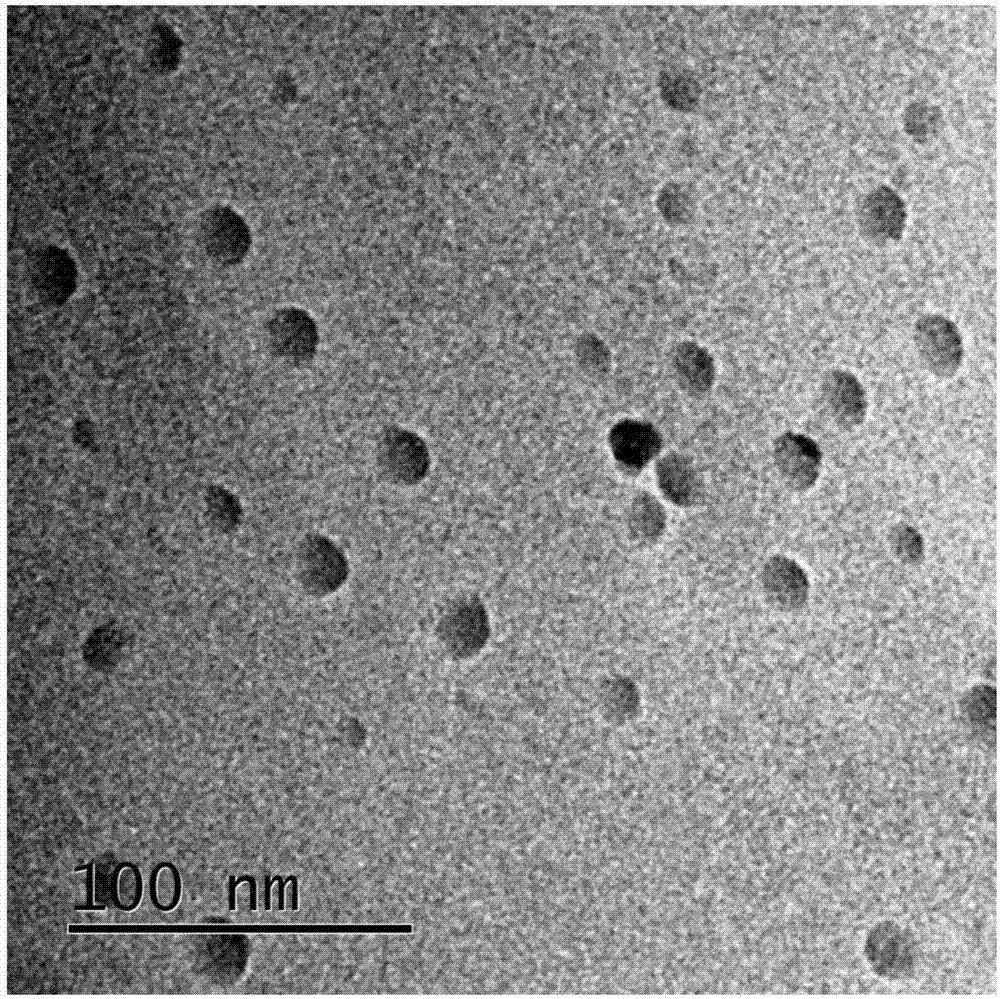

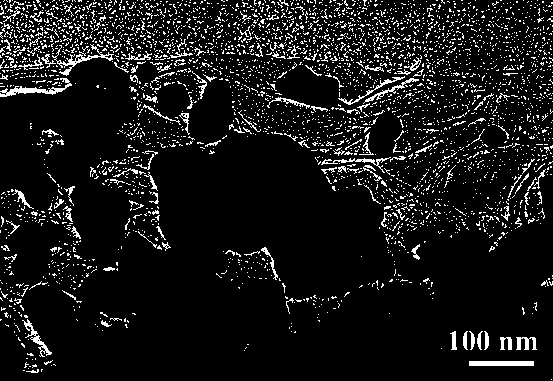

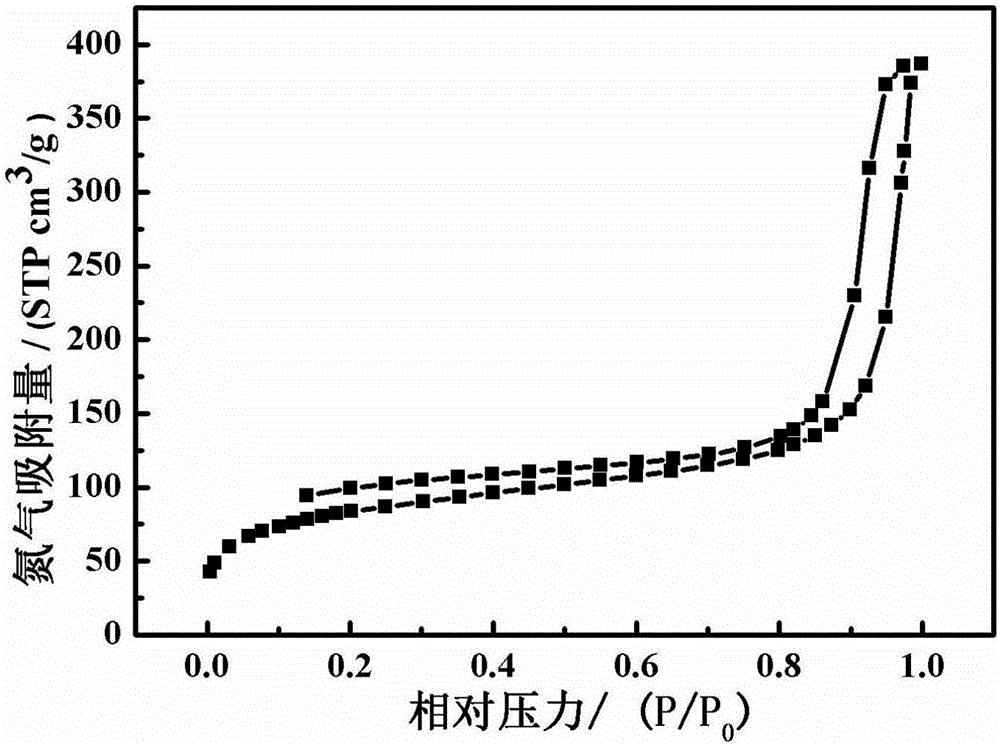

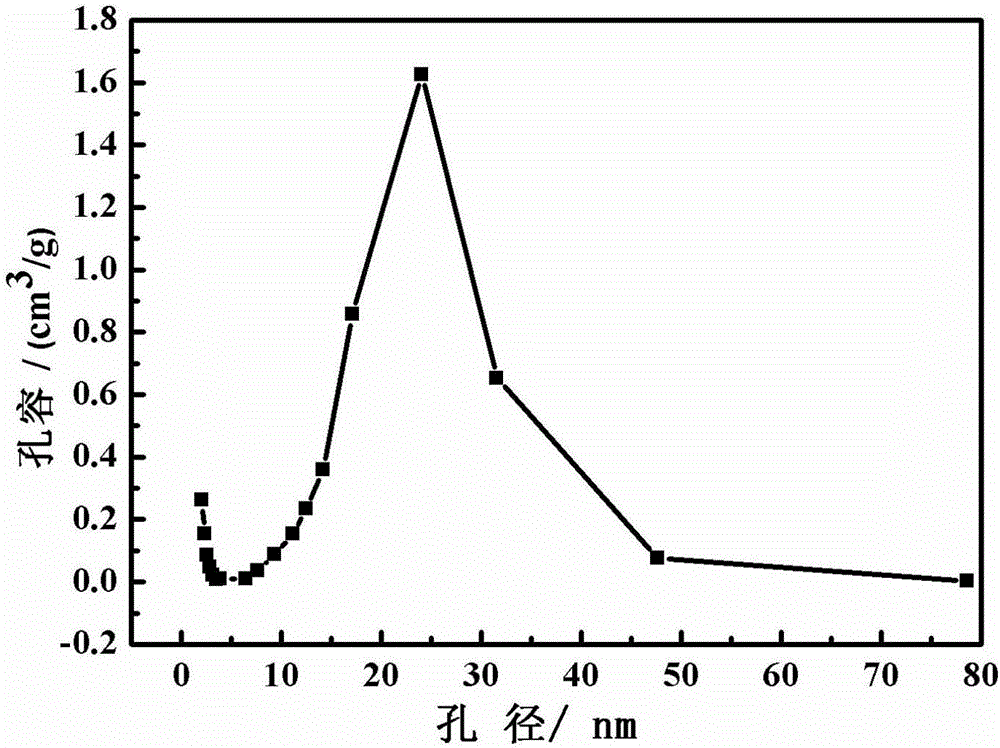

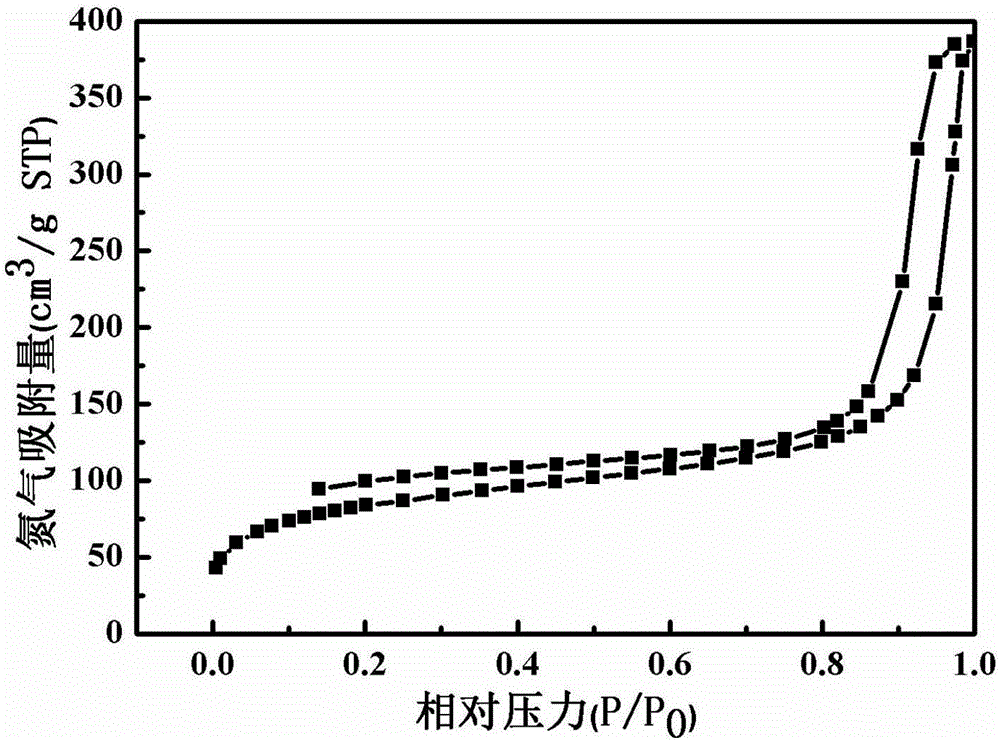

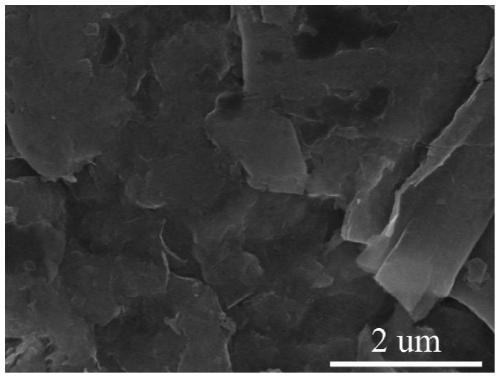

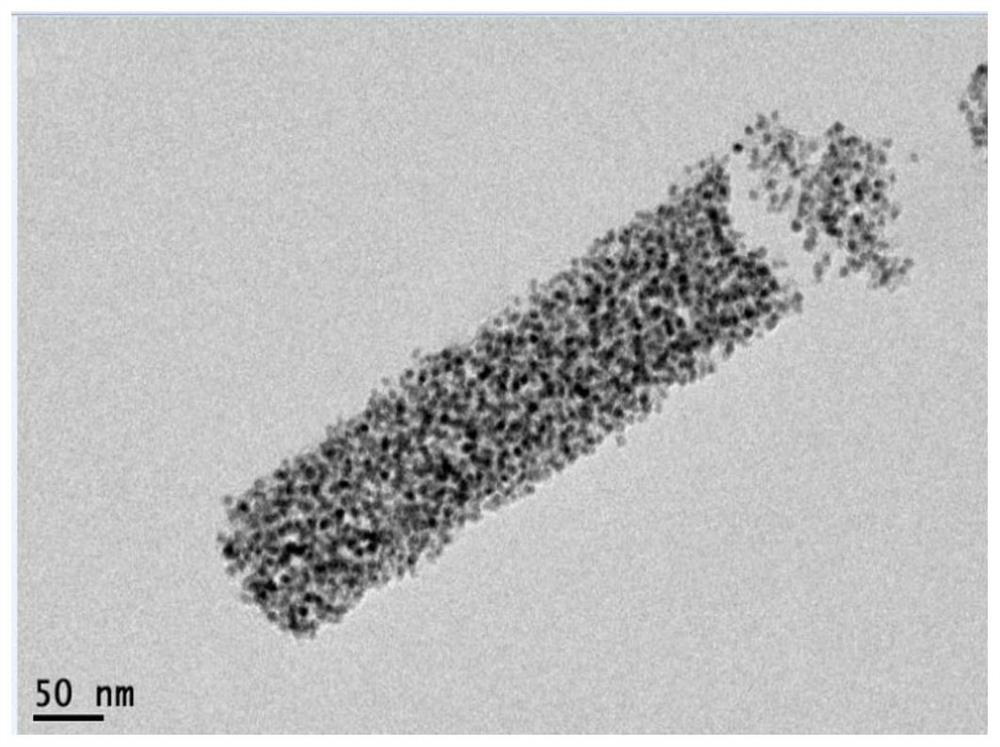

Method for preparing nano mesoporous carbon microsphere-graphene sandwich composite material

InactiveCN106910894ASimple equipmentShort cycleHybrid capacitor electrodesCell electrodesSolventCarbon source

The invention discloses a method for preparing a nano mesoporous carbon microsphere-graphene sandwich composite material, graphene oxide is dissolved in a solvent A to obtain a graphene oxide dispersion; a structure directing agent is dissolved in a solution B, then a carbon source is added for full reaction to obtain a mesoporous carbon precursor mixed liquid; the graphene oxide dispersion is added into the mesoporous carbon precursor mixed liquid for reaction to obtain a complex; and the complex is successively aged and carbonized. The nano mesoporous carbon microsphere-graphene sandwich composite material with a high specific surface area, uniform morphology and a controllable pore structure can be prepared by the method at low temperature, according to actual needs, the amount of the structure directing agent and the carbon source can be adjusted for control of the pore structure. Equipment needed in the method is simple, and the method is short in cycle, simple in process and low in cost.

Owner:XIAN UNIV OF TECH

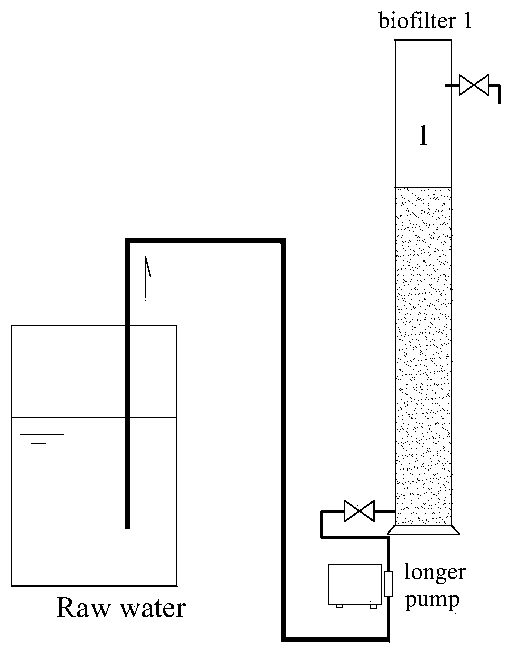

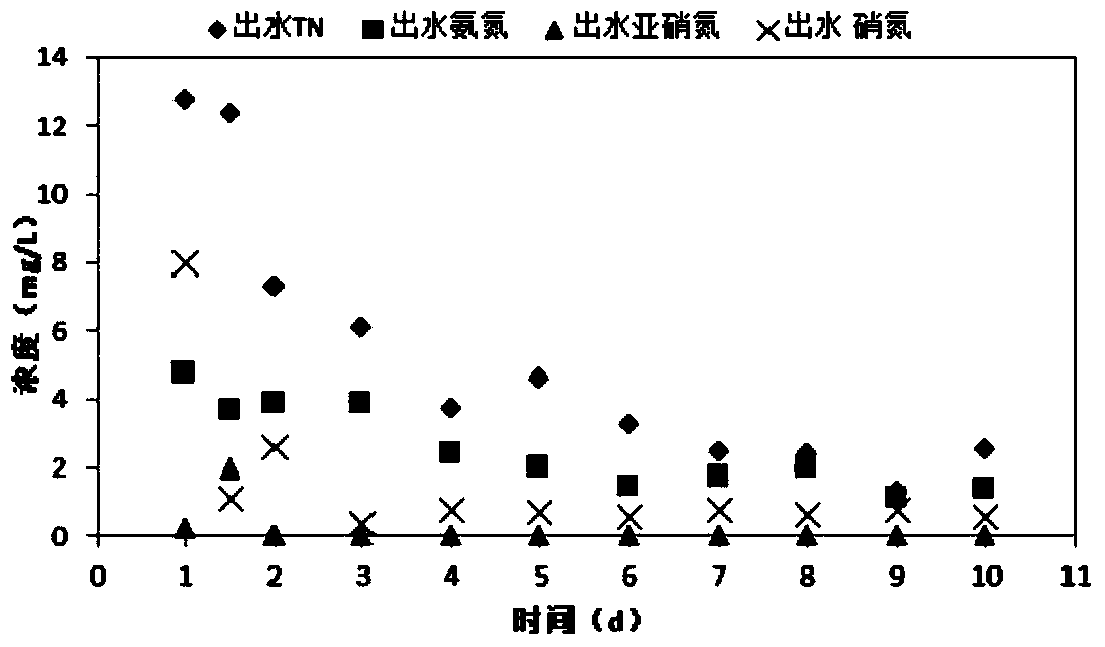

Foaming polyvinyl formal microbial carrier and preparation method thereof

InactiveCN103524648AImprove processing performancePromote nitrification and denitrification effectBiological water/sewage treatmentBinding forceAqueous solution

The invention provides a foaming polyvinyl formal microbial carrier and a preparation method thereof. The preparation method comprises the following steps of placing starch and a PVA (Polyvinyl Alcohol) water solution into a water bath at 90 DEG C, mechanically stirring till dissolution, and then adding glycol and 4-5 mol / L of sulfuric acid; step 20, uniformly stirring the solution at 60-80 DEG C, slowly adding formaldehyde, adding a carrier elasticity reinforcing agent, fast increasing the stirring speed to 450-700 rpm, and controlling reaction time to 20 minutes to form a foam solution; pouring the foam solution into a mould, and reacting under the condition of 60-80 DEG C for 18-22 hours to obtain the foaming polyvinyl formal microbial carrier. The foaming polyvinyl formal microbial carrier provided by the invention has the advantages of good elasticity, good hydrophilicity, large specific area, high porosity, high biological binding force and the like.

Owner:HUAQIAO UNIVERSITY

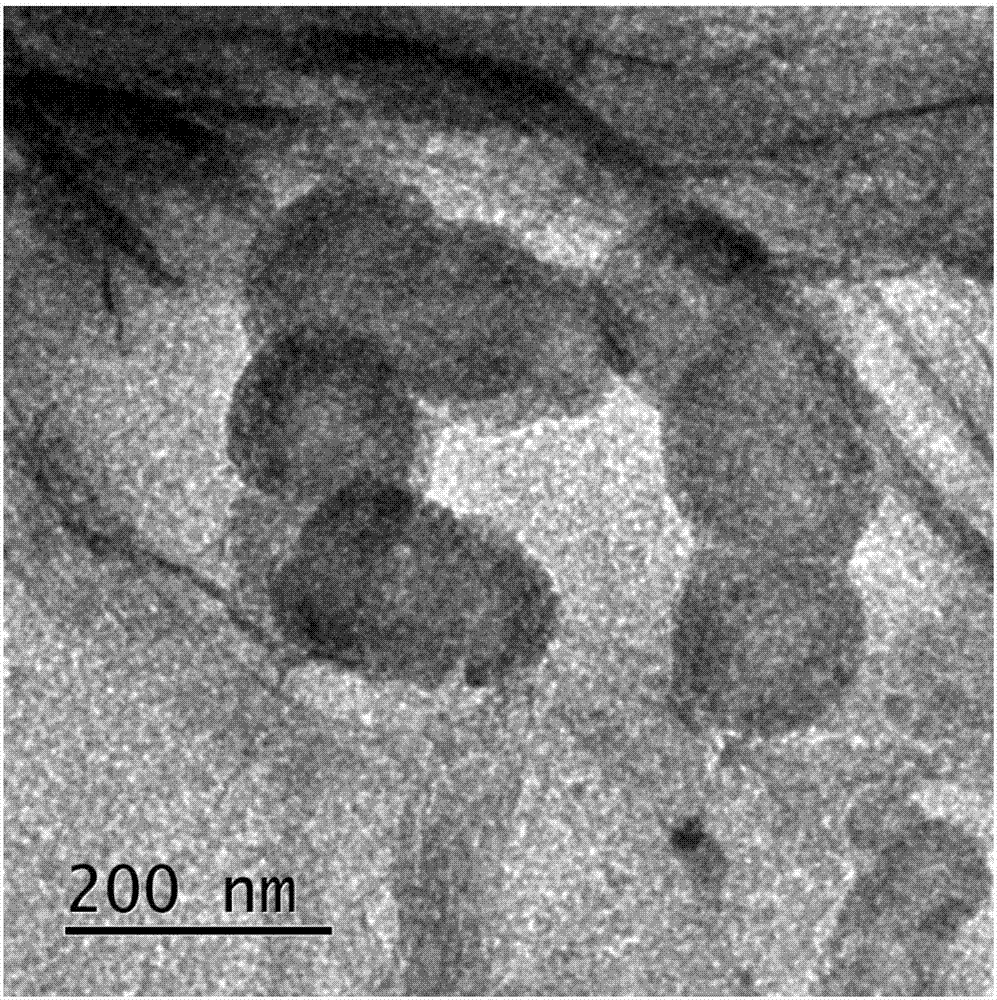

Preparation method, product and application of ferroferric oxide/nitrogen doped graphene composite material

ActiveCN107808958AHigh specific areaSave raw materialsMaterial nanotechnologySecondary cellsNitrogenNitrogen doped graphene

The invention discloses a preparation method, a product and application of a ferroferric oxide / nitrogen doped graphene composite material. The preparation method includes: preparing nitrogen doped graphene oxide dispersion liquid, preparing a FeOOH / GO intermediate-state composite material, and preparing ferroferric oxide / nitrogen doped graphene. Soluble iron salt is used as a raw material, and hydrolysis and calcining of the iron salt are utilized for self-assembly to form the ferroferric oxide / nitrogen doped graphene composite material. The composite material has certain 3D structural configuration and has high specific surface area and good three-dimensional pore structure passages, and unique structure can optimize wetting condition of electrolyte to enable the composite material to present high operation stability.

Owner:上海禾澜纳米科技有限公司

Preparation method of SiOC ceramic aerogel

InactiveCN106242610AHigh specific areaNarrow pore size distributionCeramicwareSupercritical dryingArgon atmosphere

Provided is a preparation method of SiOC ceramic aerogel. The invention relates to an aerogel material preparation technology, in particular to a preparation method of the SiOC ceramic aerogel. The problem that for an existing method for preparing the SiOC ceramic aerogel, the aperture is difficult to control is solved. The method comprises the steps that hydrogen-containing polymethylsiloxane, 2,4,6,8-tetramethyl-2,4,6,8-tetravinylcyclotetrasiloxane, chloroplatinic acid and acetone are mixed to be uniform and then put into a hydrothermal reaction kettle for reacting, and gel is obtained; the gel is soaked with acetone and ethyl alcohol in sequence, supercritical drying treatment is conducted, the temperature is increased to 700 DEG C to 1,300 DEG C under a nitrogen or argon atmosphere, heat preservation is conducted for 1 h to 3 h, natural cooling is conducted to room temperature, and the SiOC ceramic aerogel is obtained. The SiOC ceramic aerogel has the advantages of being high in specific surface area, narrow in pore diameter distribution, stable in structure and stable in temperature resistance and oxidation resistance and can be applied to the fields of thermal insulation, energy storage and the like.

Owner:HARBIN INST OF TECH

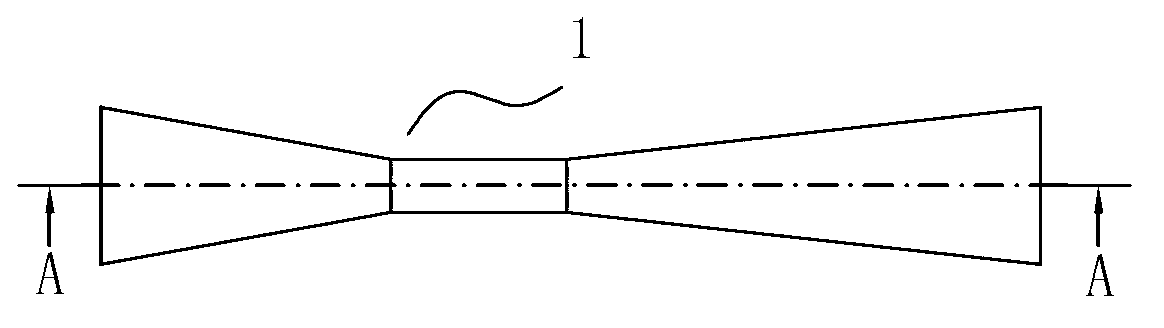

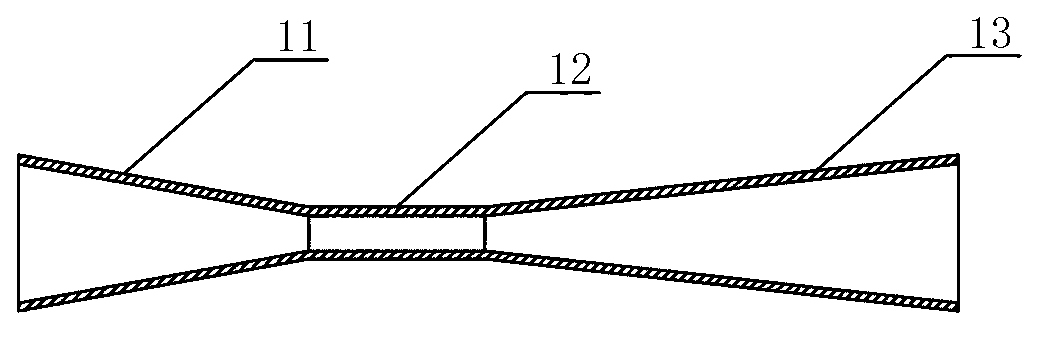

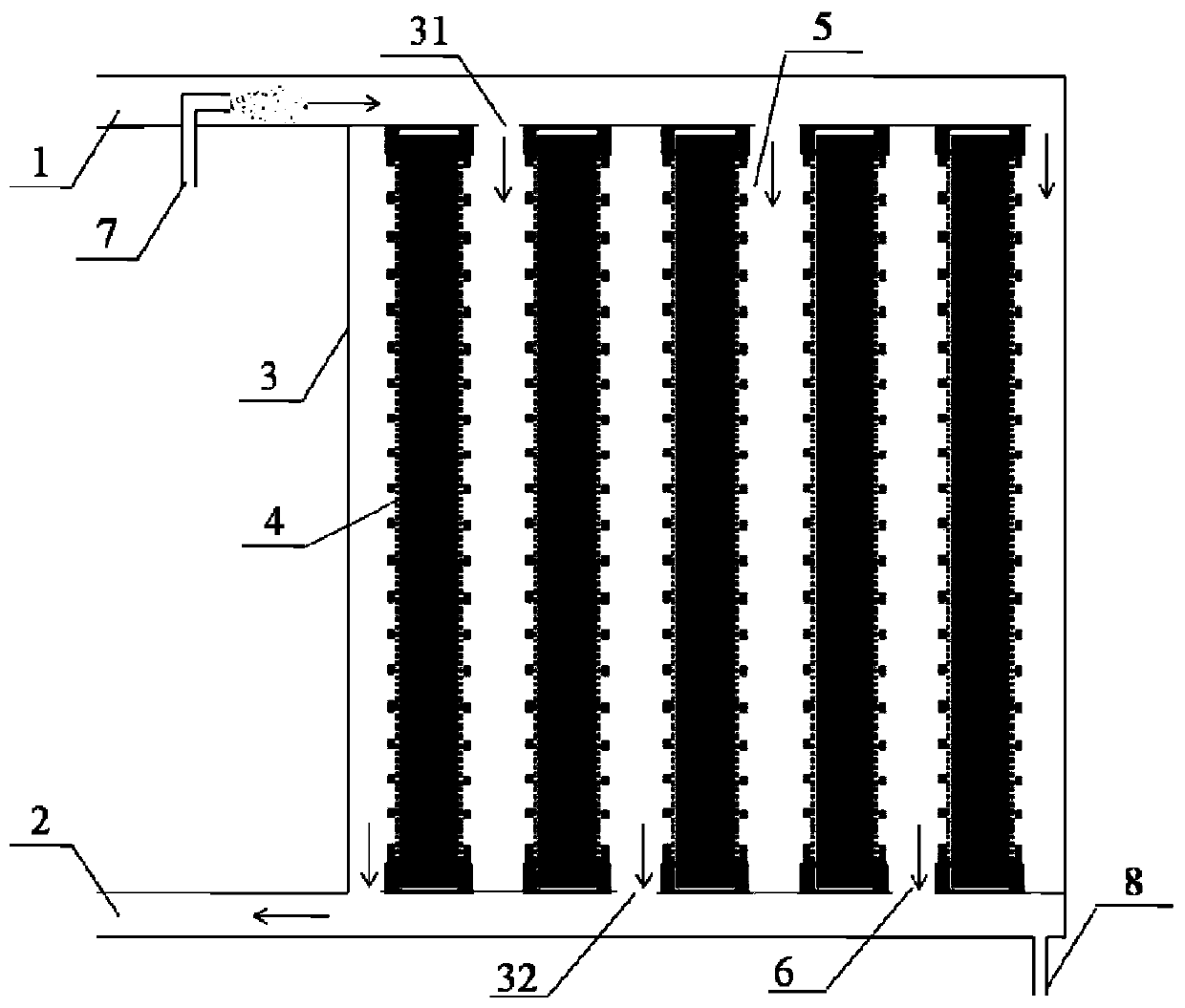

Method and device for reinforcing cane juice neutralization reaction by hydraulic micro-oscillation

InactiveCN103122397AGood clarificationResidue reductionPurification using alkaline earth metal compoundsLiquid glucoseEngineering

The invention relates to a method for reinforcing cane juice neutralization reaction by hydraulic micro-oscillation, which is applicable to a clarification technique of cane juice or liquid glucose by a sulfurous process. The method comprises the steps of preliming, primary heating, stoving neutralization, hydraulic micro-oscillation reinforced cane juice neutralization reaction, secondary heating and settling. The hydraulic micro-oscillation reinforced cane juice neutralization reaction is implemented in a way that: the cane juice or neutralized juice subjected to stoving neutralization reaction is pumped into a hydraulic micro-oscillation reinforced cane juice neutralization reaction device to subjected to hydraulic micro-oscillation reinforced cane juice neutralization reaction, and enters the steps of secondary heating and settling. The hydraulic micro-oscillation reinforced cane juice neutralization reaction device for implementing the method can change the size of the flow section of the cane juice or liquid glucose in the flowing process: the device is a cylindrical container or tubular container with inconsistent cross-sectional area. The method and device provided by the invention can reinforce the cane juice neutralization reaction, and enhance the purity of the clear juice by more than 1%; and the consumption of lime and sulfur is reduced by more than 20%.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY +1

Block boron carbide-silicon carbide composite aerogel preparation method

ActiveCN108147817AUniform porosityLarge specific surface areaShieldingCeramicwareSupercritical dryingBoron carbide

The invention relates to a block boron carbide-silicon carbide composite aerogel preparation method. The method includes: stirring nano boron carbide powder, resorcinol, formaldehyde, 3-aminopropyl triethyl silicane, absolute ethyl alcohol and deionized water according to a mole ratio to obtain faint yellow composite sol solution, and standing to obtain wet gel; subjecting the wet gel to solvent replacement, drying the wet gel according to a CO2 supercritical drying technique to obtain a boron carbide-silicon carbide precursor, and adopting a carbon thermal reduction technique in an inert atmosphere to obtain block boron carbide-silicon carbide composite aerogel. The block boron carbide-silicon carbide composite aerogel prepared according to the method has advantages of high specific surface, low density, high porosity, high temperature resistance and the like, a technical process is simple and easy in operation, and preparation of the block boron carbide-silicon carbide composite aerogel hopefully has a promising application prospect in fields of chemical equipment, high-temperature kilns and the like.

Owner:NANJING UNIV OF TECH

Preparation method of high temperature-resistant boron carbide-silicon carbide compound aerogel

The invention relates to a preparation method of a high temperature-resistant boron carbide-silicon carbide compound aerogel. The method comprises taking absolute ethyl alcohol and deionized water assolvent, mixing a preferable boron source with m-dihydroxybenzene, formaldehyde and 3-aminopropyl triethyl silane at a certain molar ratio to obtain a solution, namely, light yellow compound gel; performing aging and solvent replacement on the wet gel and then drying the wet gel through the supercritical drying technology to obtain a boron carbide-silicon carbide precursor, and under protection ofinert gas and through carbon thermal reduction, obtaining the high temperature-resistant boron carbide-silicon carbide compound aerogel. The preparation method of the high temperature-resistant boroncarbide-silicon carbide compound aerogel is simple and reliable in preparation process and rich and simple in raw materials; the prepared high temperature-resistant boron carbide-silicon carbide compound aerogel can be widely applied to the fields such as chemical equipment and high-temperature kiln.

Owner:NANJING TECH UNIV

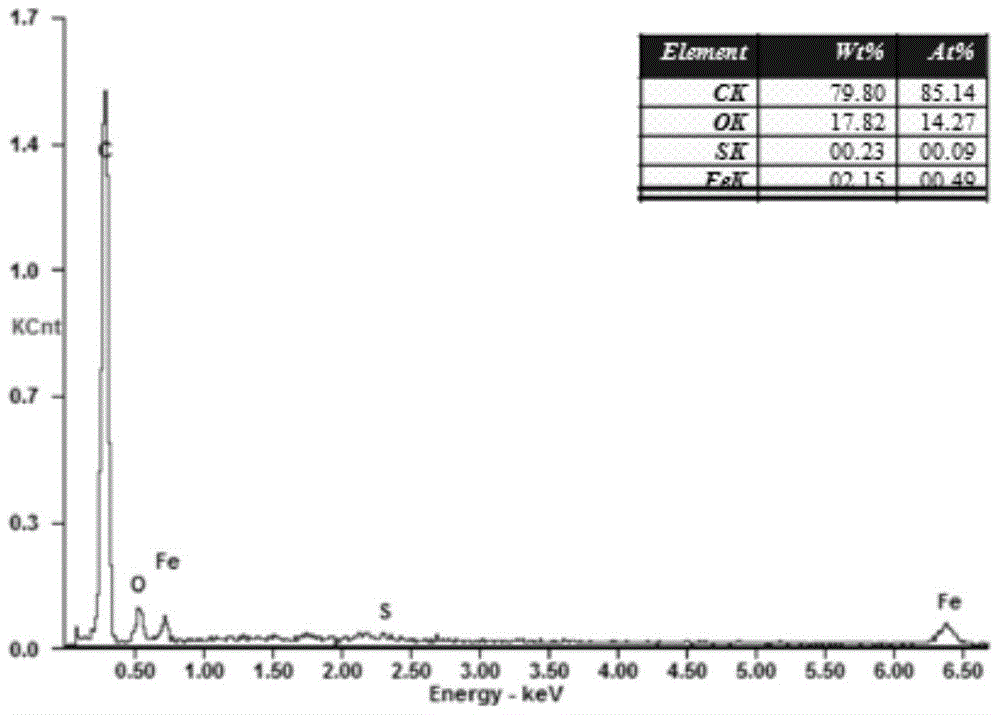

Fe-doped walnut shell activated carbon for treating dye wastewater as well as preparation method and application of activated carbon

ActiveCN105664896AFast adsorption rateImprove adsorption capacityOther chemical processesWater contaminantsMalachite greenMalachite green stain

The invention discloses Fe-doped walnut shell activated carbon for treating dye wastewater as well as a preparation method and an application of the activated carbon. The Fe-doped walnut shell activated carbon takes walnut shells as a raw material and is prepared through acid solution treatment, inorganic salt treatment, pyrolysis treatment, activating treatment and high-temperature heat treatment. The Fe-doped walnut shell activated carbon has the Fe content of 2.15%(wt%), the specific surface area of 1779.31 m<2> / g, the maximum adsorption of 531.08 mg / g for methylene blue as well as the adsorption exceeding 500 mg / g for other dyes including methyl orange, malachite green and methyl red. The Fe-doped walnut shell activated carbon is high in adsorption capacity, high in adsorption speed, easy to recycle and reusable, and the treatment cost is greatly saved. Meanwhile, according to the method, the waste walnut shells are taken as the raw material, operation is convenient, the cost is low, secondary pollution cannot be caused, and agricultural waste is recycled.

Owner:NORTHWEST UNIV(CN)

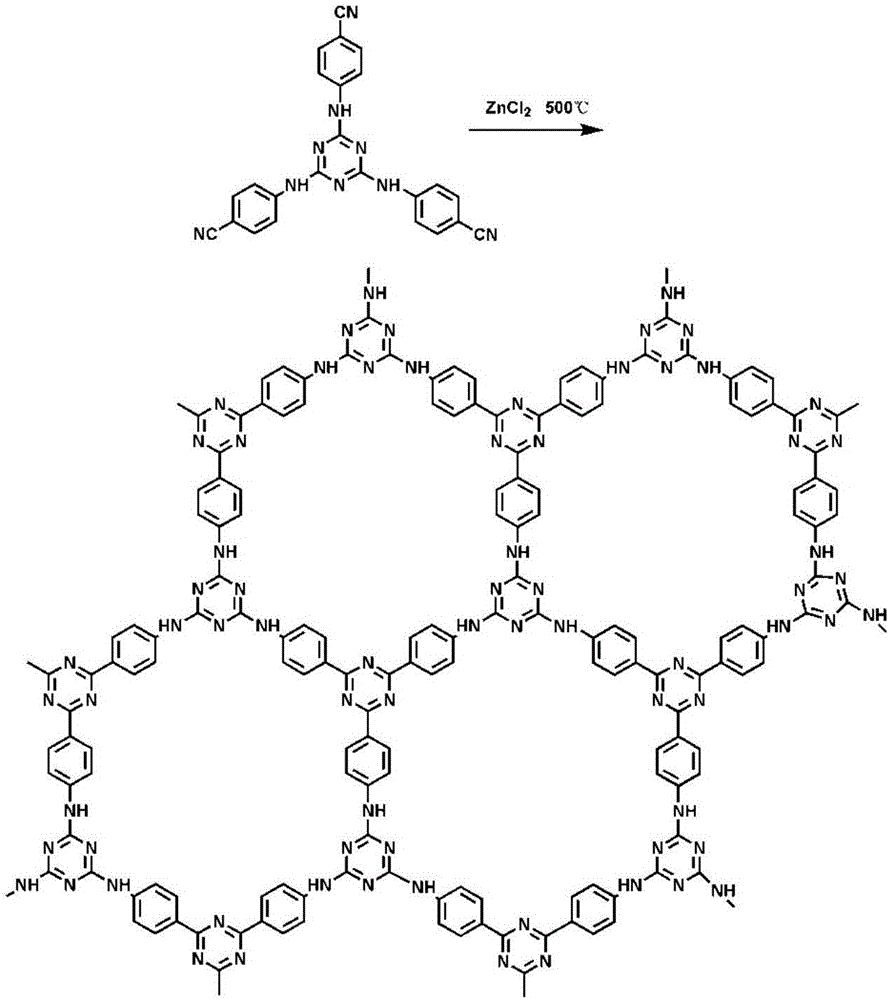

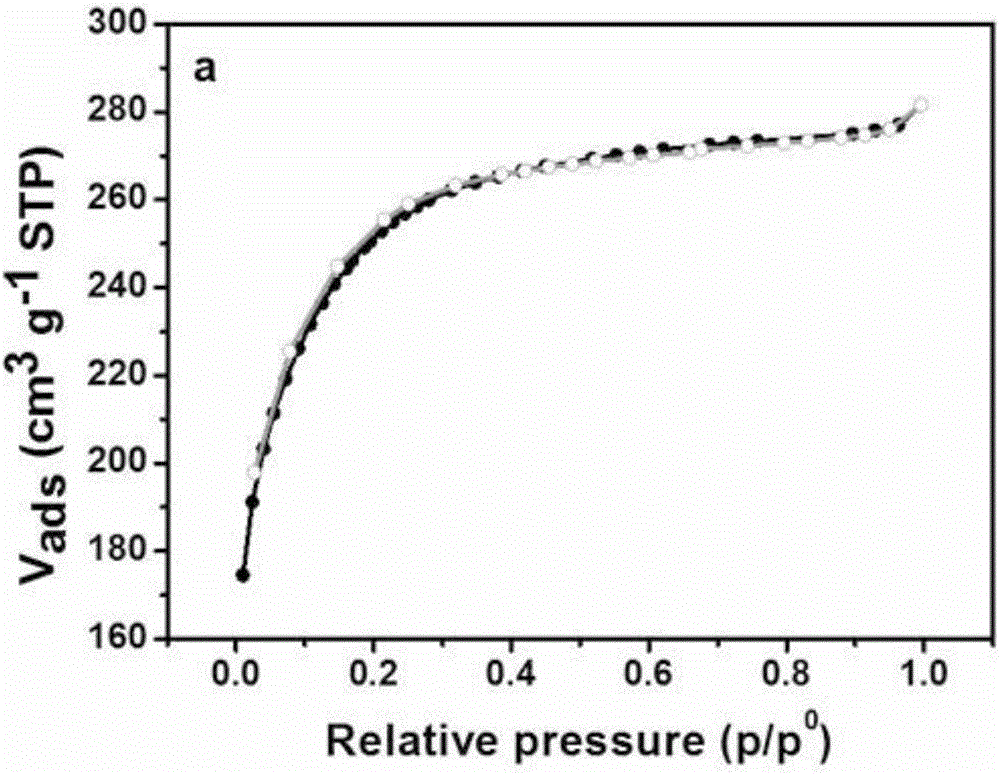

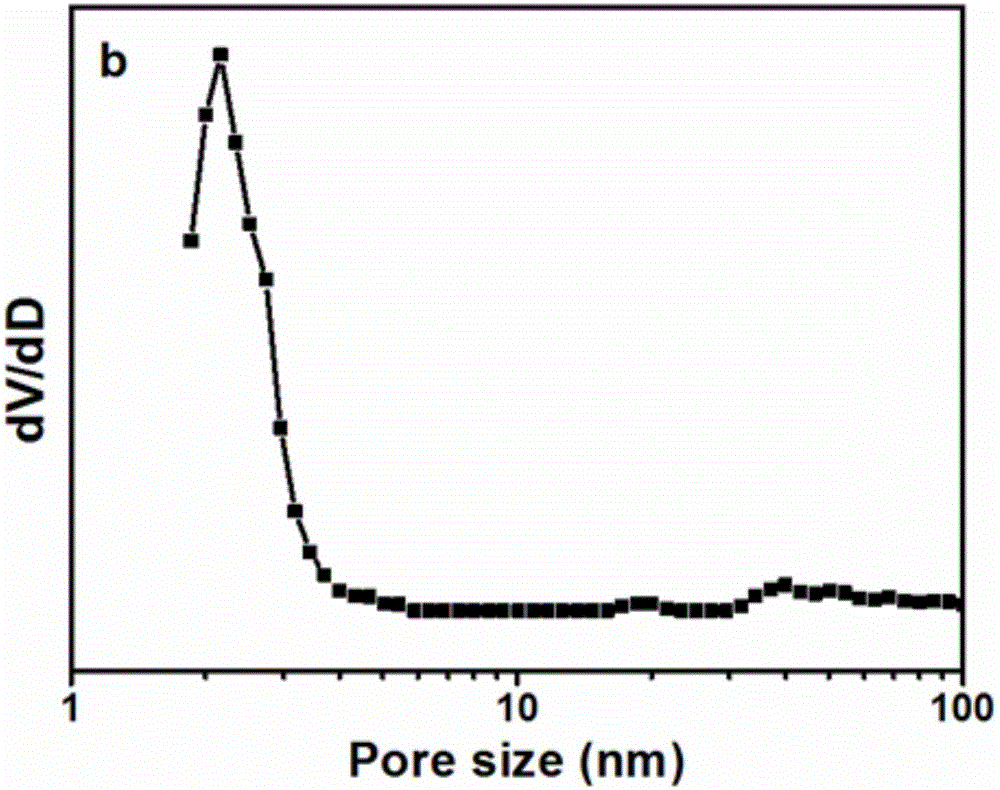

Catalyst prepared by using aryl-containing s-triazine cyclic polymer as precursor as well as preparation method and application thereof

The invention discloses a catalyst prepared by using an aryl-containing s-triazine cyclic polymer as a precursor. The catalyst is prepared according to the following steps of 1), adding an aryl-containing s-triazine monomer into a polymerization catalyst, uniformly dispersing the aryl-containing s-triazine monomer, sealing a tube, making an obtained mixture react at a heating temperature, completing a reaction, and washing and drying a reaction product, so as to obtain the aryl-containing s-triazine cyclic polymer; 2), carrying out heat treatment on the aryl-containing s-triazine cyclic polymer in an inert atmosphere, so as to obtain the catalyst prepared by using the aryl-containing s-triazine cyclic polymer as the precursor. The invention also provides a preparation method and application of the catalyst. The catalyst provided by the invention is higher in catalytic activity, low in cost and simple in preparation process, and further, has high activity and high stability.

Owner:XIANGTAN UNIV

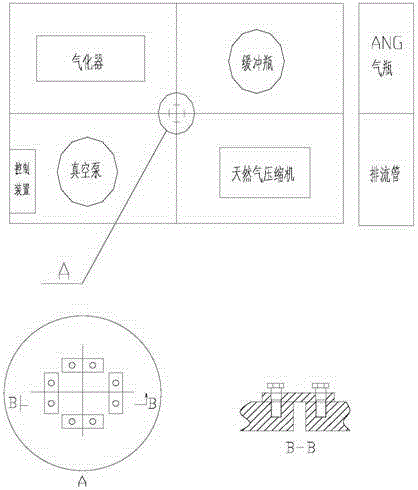

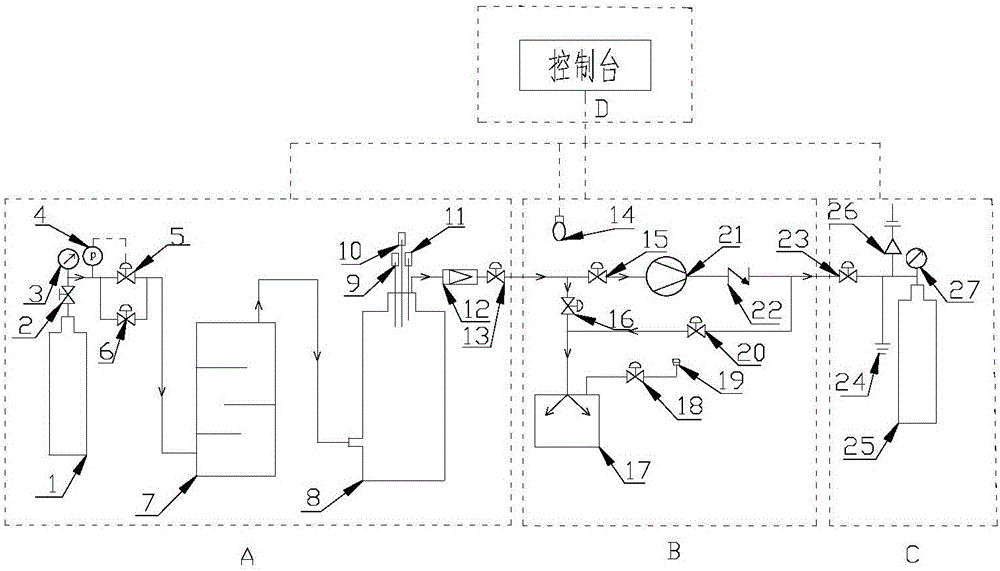

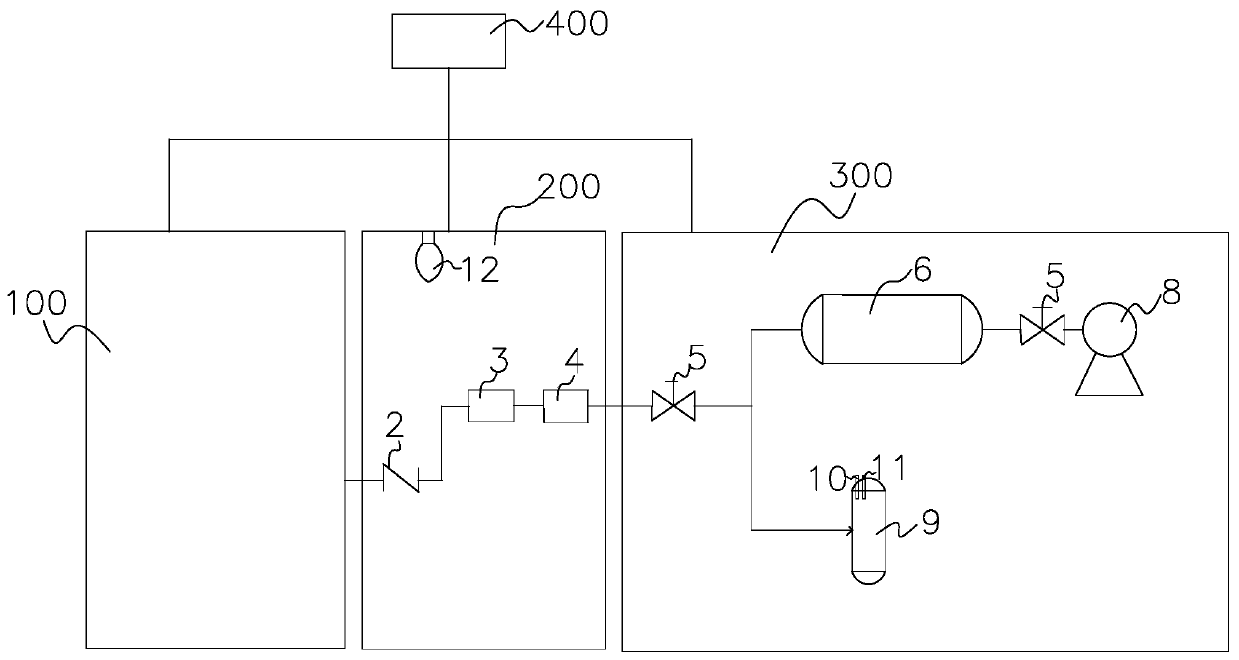

Portable adsorption type natural gas recovery device and method

InactiveCN106085529ASmall pressure fluctuationsStable jobGas treatmentDispersed particle separationBuffer tankDesorption

The invention relates to a portable adsorption type natural gas recovery device and method. The device consists of a gas collecting module, a machine pump module, an adsorption module and a control module, wherein each of the modules comprises a natural gas bottle or an LNG bottle, a gasifier, a buffer tank, a vacuum pump, a natural gas compressor, an ANG bottle, a control cabinet, a pressure, temperature and oxygen detecting probe and various valves; main body equipment of the device is mounted on a gasifier prying block, a buffer tank prying block, a vacuum pump prying block and a compressor prying block; the prying blocks are in bolt connection, so that in-site assembled prying can be convenient to perform, and a vehicle-mounted natural gas recovery device can be made, so that the movement and the operation are convenient. The ANG bottles can be demounted, and replaced, and system operation is not influenced. The device is provided with a vacuum system for vacuumizing the system. According to the portable adsorption type natural gas recovery device and the method disclosed by the invention, natural gas exhausted from the natural gas bottles or the LNG bottles is collected to the gasifier and the buffer tank; a compressor is used for compressing the natural gas through medium pressure into the ANG bottles to be stored, so that recovery is realized. When being required by outside, gas in the bottles can realize desorption for use of energy resources.

Owner:CHANGZHOU UNIV +2

Special compound fertilizer for tobaccos and preparation method of special compound fertilizer

InactiveCN105753570AIncrease dosageNutritional balanceMagnesium fertilisersAlkali orthophosphate fertiliserPotassium nitratePhosphate

The invention discloses a special compound fertilizer for tobaccos. The special compound fertilizer is prepared from the following components in parts by weight: 50 to 63 parts of potassium chloride, 200 to 450 parts of potassium sulfate, 70 to 100 parts of potassium nitrate, 100 to 200 parts of monoammonium phosphate, 100 to 210 parts of ammonium nitrate-phosphorus, 4 to 40 parts of a boron fertilizer, 55 to 81 parts of magnesium sulfate, 21 to 26 parts of ZnSO4.7H2O and 10 to 20 parts of a release controlling agent. A preparation method comprises the following steps: mixing, pre-heating, granulating, drying, sieving, cooling and sieving again. The special compound fertilizer for the tobaccos is specially designed by aiming at fertilizer demanding characteristics of the tobaccos, and has the effects of enhancing the adsorption efficiency on the fertilizer by soil and improving the absorption rate of nitrogen and a phosphorus fertilizer.

Owner:广西壮族自治区烟草公司百色市公司

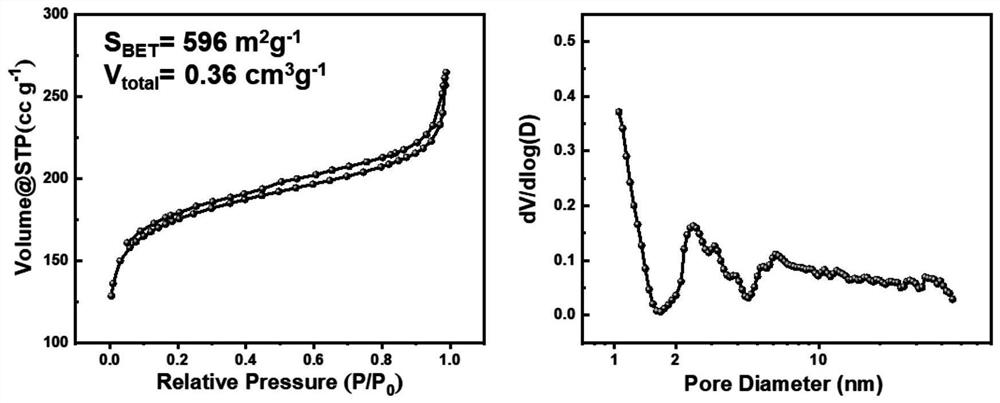

Method for preparing mesoporous carbon material by catalytically activating sodium lignin sulfonate with organic sylvite

The invention discloses a method for preparing a mesoporous carbon material by catalytically activating sodium lignin sulfonate with organic sylvite. An organic sylvite activator and sodium lignin sulfonate are uniformly mixed at an impregnation ratio of 1: (2-4) by a stirrer, and the pH value of the solution is controlled to be 6.0 to 8.0; the solution is dried at 150-170 DEG C to remove moistureto form a sodium lignin sulfonate / activator dry powder raw material; the dry powder raw material is put into a tubular furnace, the furnace is heated from 30 DEG C to 700-900 DEG C at a heating rateof 10-20 DEG C / min in a nitrogen atmosphere, constant-temperature activation is performed on the material at the temperature for 1-2h, and the furnace is cooled to room temperature after activation; and a sample obtained after activation is taken out and washed with deionized water to remove impurities, the sample is repeatedly washed with deionized water until the pH value is 7, and finally, thesample is dried at 55-65 DEG C to remove water, thereby obtaining the mesoporous carbon material. The lignin-based mesoporous carbon material is prepared from organic sylvite as an activator and sodium lignin sulfonate. The mesoporous carbon material is convenient to produce and process, and the prepared mesoporous carbon material has the characteristics of a large number of mesopores and large specific surface area.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

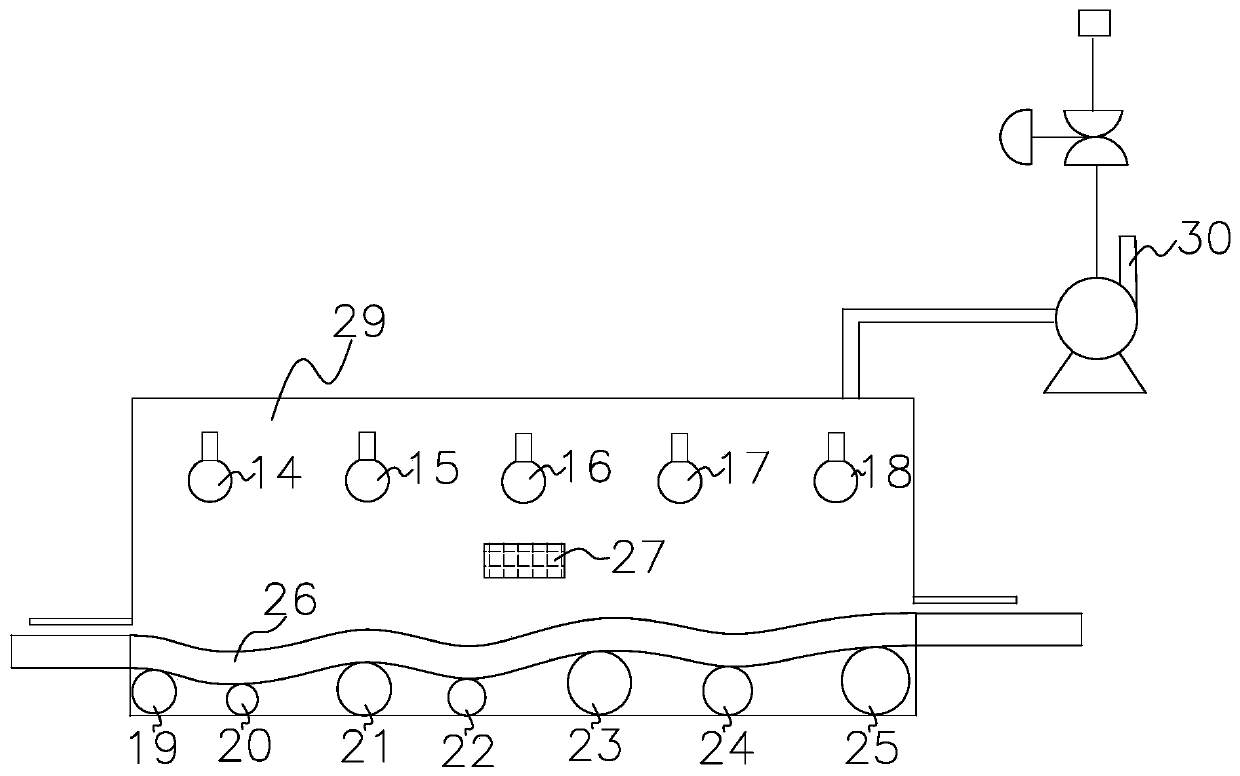

Movable skid-mounted combined adsorbent local desorption regeneration device

InactiveCN109926036AConvenient group skid installationEasy to disassembleCombustible gas purificationFilter regenerationMicrowaveSorbent

The invention relates to a movable skid-mounted combined adsorbent local desorption regeneration device. The device comprises a "microwave and vacuum" desorption module, a condensation module, a recovery module and a control module; and the "microwave and vacuum" desorption module is suitable for integrally desorbing an adsorbent transported by an adsorbent conveying device to generate an oil-gasmixture and the adsorbent; the condensing module is suitable for collecting the oil-gas mixture and condensing the oil-gas mixture to generate oil and gas; the recovery module is suitable for collecting and respectively recovering the oil and gas; and the control module is suitable for controlling "microwave and vacuum" desorption, the condensation module and the recovery module. The device realizes the desorption of the adsorbent to prevent environmental pollution; and the four modules are placed in a corresponding skid, so the device can be locally mounted, and is easy to transport.

Owner:CHANGZHOU UNIV

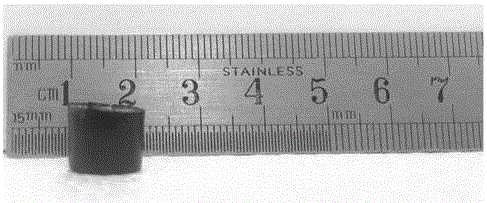

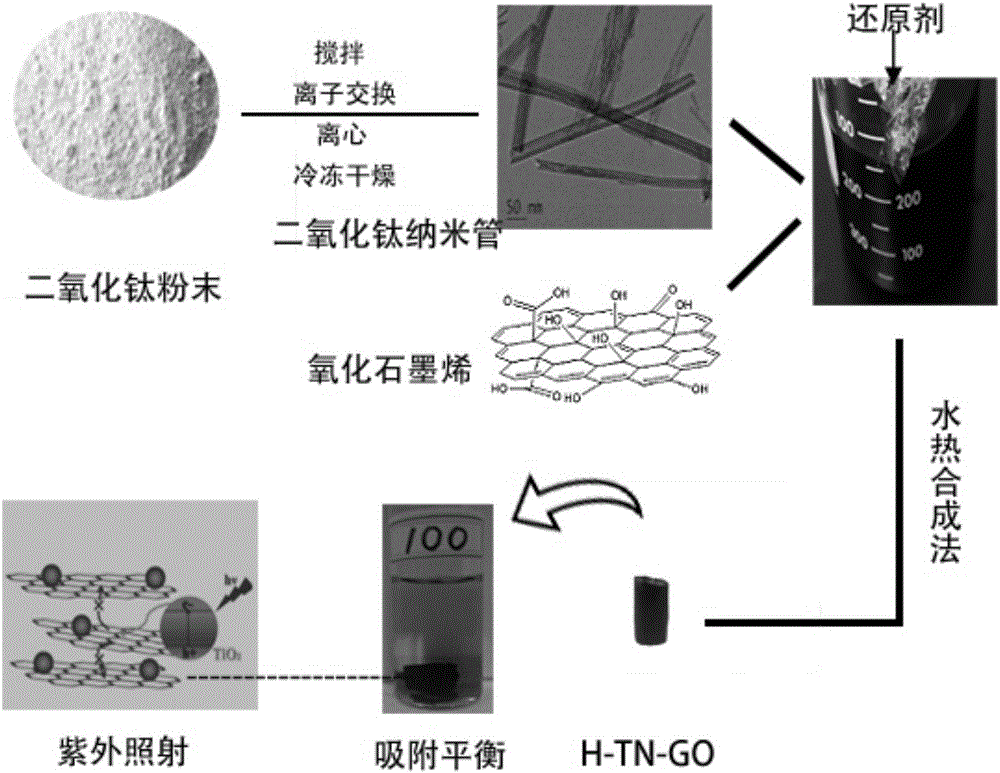

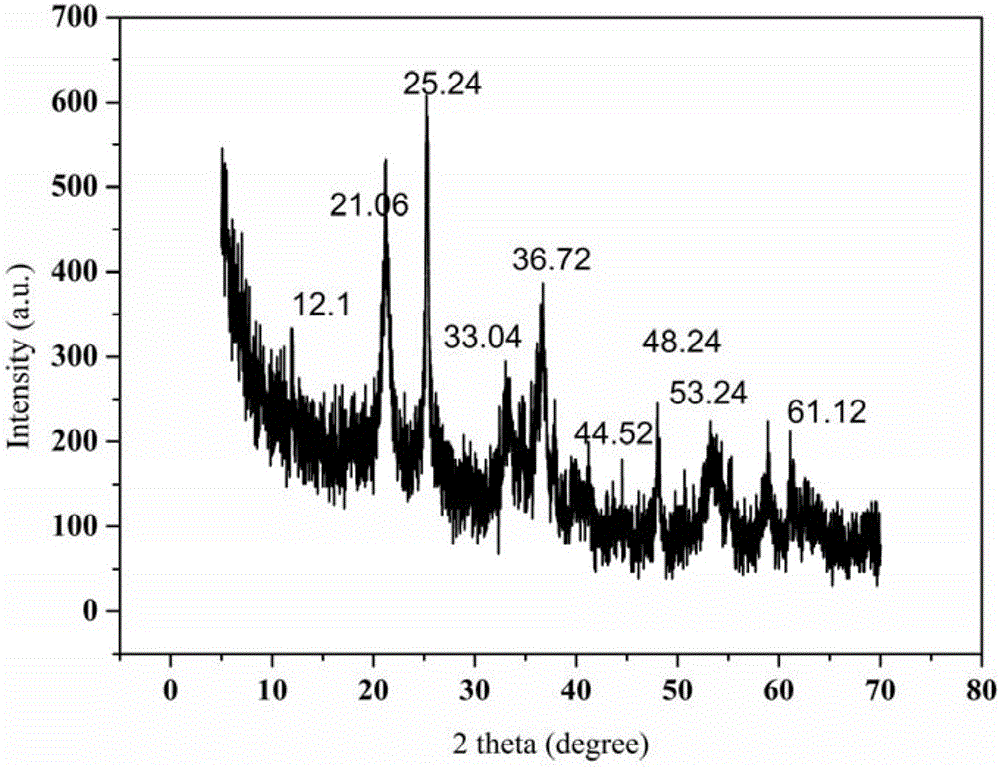

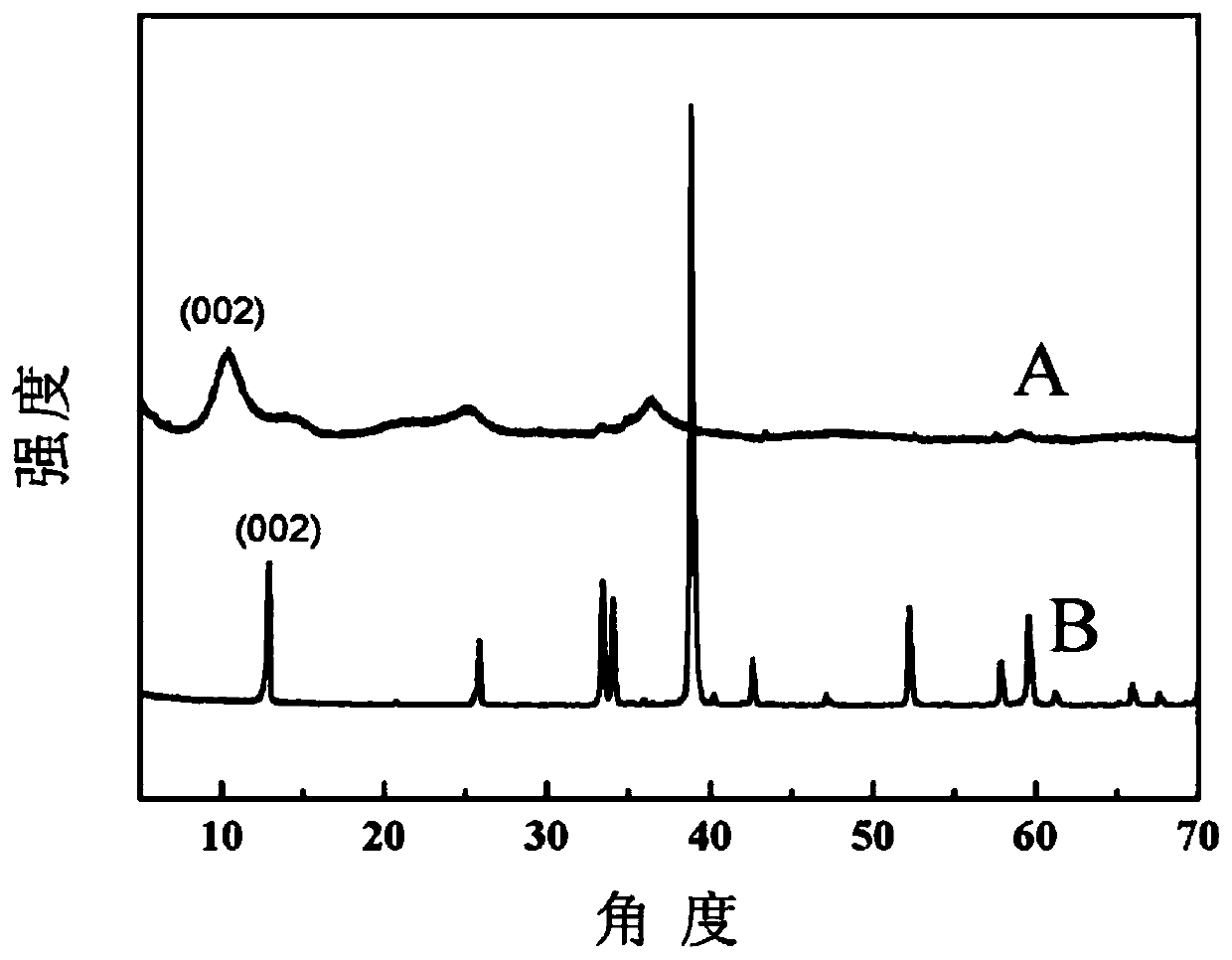

Graphene-TiO2 nanotube hydrogel, preparation method, and application thereof

InactiveCN106582518AHigh specific areaImprove hydrophilicityPhysical/chemical process catalystsWater/sewage treatment by irradiationWater bathsTio2 nanotube

The invention discloses a graphene-TiO2 nanotube hydrogel, a preparation method, and an application thereof. The preparation method includes the steps of: (1) adding water to graphene oxide to fully dissolve the graphene oxide to obtain a graphene oxide water solution; (2) adding the TiO2 nanotube to the graphene oxide water solution with full stirring to prepare a graphene-TiO2 nanotube solution; (3) preparing a FeSO4 water solution; (4) adding the FeSO4 water solution to the graphene-TiO2 nanotube solution with uniform mixing to obtain a mixed liquid; (5) performing self-assembly to the mixed liquid in the step (4) under a water bath environment to obtain the graphene-TiO2 nanotube hydrogel. The preparation method is simple and employs easy-to-obtain raw materials. During synthesis, the method abides by the principle of green chemistry and is free of catalysts and toxic solvents, so that the hydrogel is toxic-free. The hydrogel can be industrially produced and can effectively remove antibiotics from waste water.

Owner:NANJING UNIV

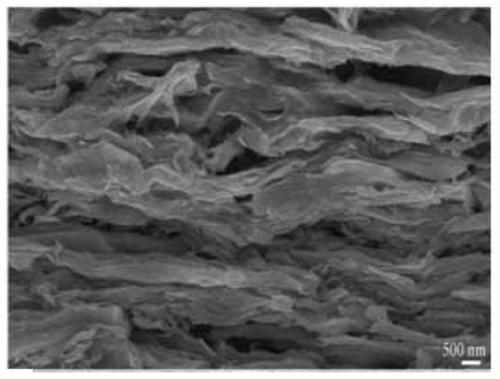

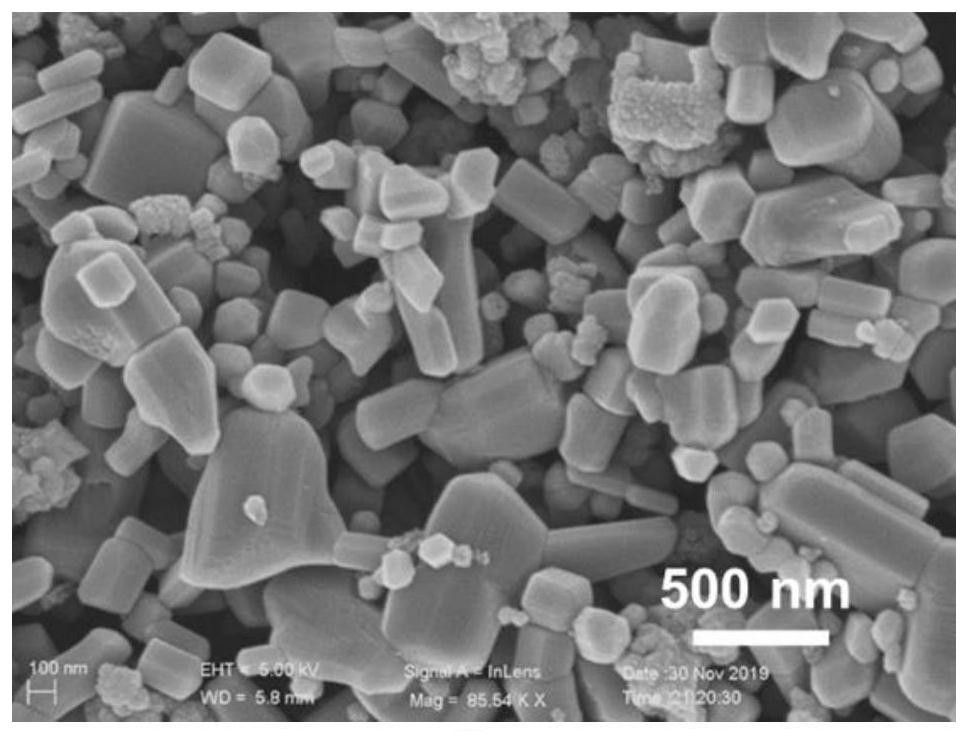

One-step method for synthesizing few-layer Nb2C material and application of few-layer Nb2C material

PendingCN109911897AIncrease dosageEasily damagedCarbon compoundsCell electrodesWater bathsSynthesis methods

The invention relates to a one-step method for synthesizing a few-layer Nb2C material and an application of the few-layer Nb2C material and aims to solve the problems that existing few-layer Nb2C preparation methods require an intercalation agent and synthesis methods are relatively complex. The synthesis method comprises the following steps: 1, placing Nb2AlC powder in an HF aqueous solution withmass concentration being 30%-50%, and performing stirring in a water bath at 55-65 DEG C for 90-130 h to obtain a reacted solution; 2, performing centrifugation cleaning on the reacted solution by acentrifuge at 8000-10000 r / min, and when the pH of the system is 5-6, reducing the rotating speed of the centrifuge to 4000-6000 r / min to continue centrifugation cleaning to obtain a suspension; 3, filtering the suspension. Synthesis steps are simplified and no intercalation agent is needed. Few-layer Nb2C shows advantages of high specific surface area, high specific capacity, long cycle life andthe like when serving as anode of a lithium-ion battery.

Owner:HARBIN NORMAL UNIVERSITY

Method for batch preparation of pure phase AlON transparent ceramic powder body

The invention relates to a method for batch preparation of a pure phase AlON transparent ceramic powder body, belonging to the technical field of preparation of the transparent ceramic powder body. The method comprises the steps as follows: taking nanometer Al2O3 and active carbon as raw materials; mixing the raw materials on a planetary ball mill at a low rotation speed; quickly drying slurry on an electric heating plate; loading powder by a region distribution and preset air hole technology; and preparing the pure phase AlON transparent ceramic powder body in combination with a low-temperature quick carbon removal process. Different region phases of the obtained AlON powder body are stable in composition and good in uniformity, so that the AlON powder body is suitable for batch production; and an AlON transparent ceramic with high transmittance rate can be obtained by taking the AlON powder body as a raw material and sintering the AlON powder body in a shorter time at a lower temperature, which shows that the AlON powder body prepared by the method is good in sintering activity and is suitable for preparing the AlON transparent ceramic.

Owner:DALIAN MARITIME UNIVERSITY

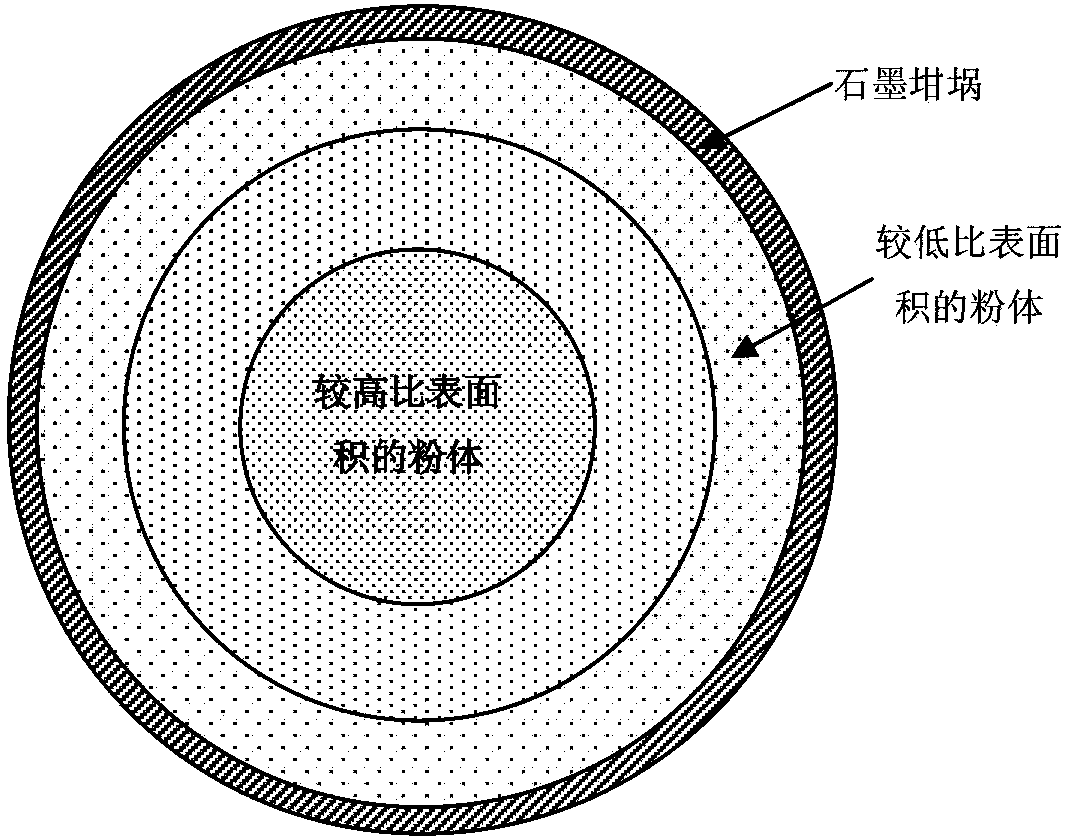

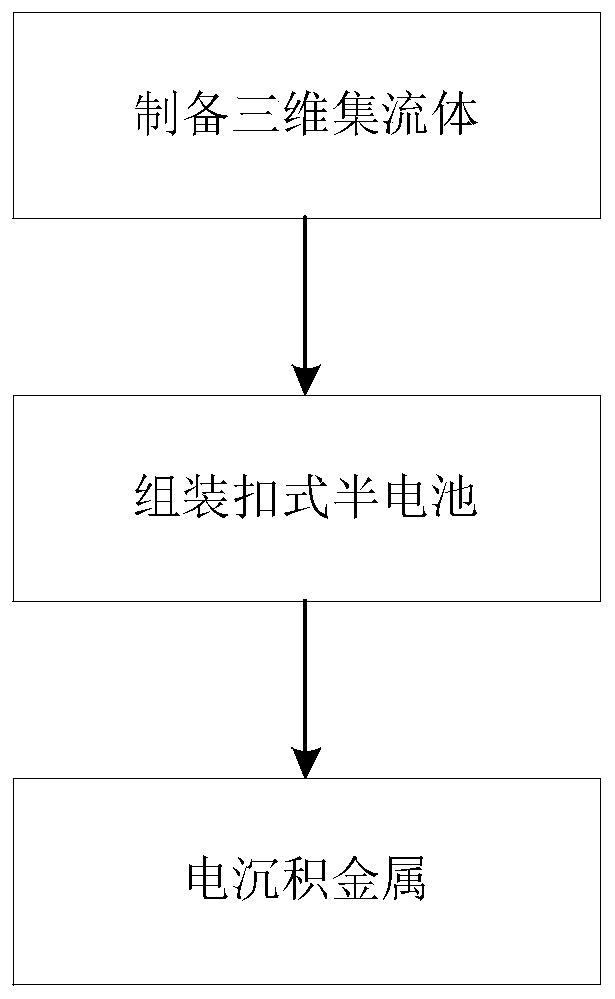

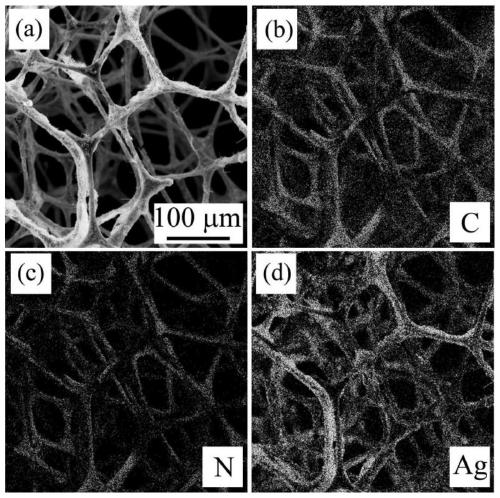

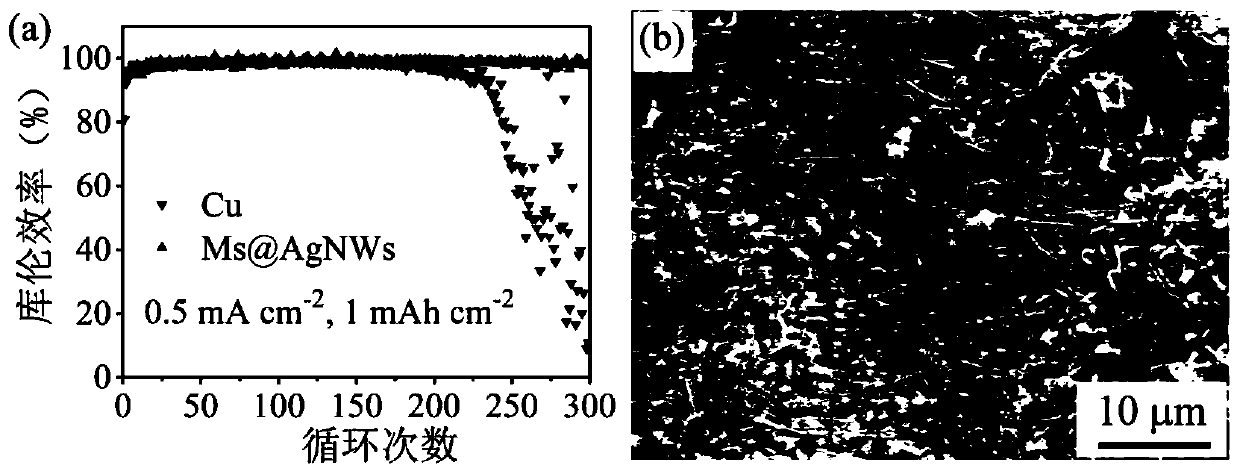

Three-dimensional flexible metal negative electrode and preparation method thereof

ActiveCN111403678AHigh affinityLower overpotentialElectrode carriers/collectorsElectrode collector coatingMetal nanowiresOverpotential

The invention belongs to the field of metal secondary batteries, and discloses a three-dimensional flexible metal negative electrode and a preparation method thereof. The method comprises the following steps: (a) preparing metal nanowire ink, selecting sponge, soaking the sponge in the metal nanowire ink until the sponge is saturated, taking out the sponge, and performing drying to obtain a three-dimensional flexible current collector; (b) selecting a metal negative electrode, taking the three-dimensional flexible current collector as a positive electrode, and assembling the button half-cell by utilizing the positive electrode and the metal negative electrode; (c) carrying out electro-deposition on the button half-cell to enable the metal negative electrode to be deposited on the three-dimensional flexible current collector, and disassembling the button half-cell to obtain the three-dimensional flexible current collector with the metal negative electrode deposited on the surface, namely the required three-dimensional flexible metal negative electrode. The invention also discloses a product prepared by the method. According to the invention, the metal nucleation overpotential is reduced, and the stress generated in the electrodeposition process is absorbed and released, so the problem of dendritic crystal growth in the metal negative electrode is solved.

Owner:HUAZHONG UNIV OF SCI & TECH

Method for preparing porous carbon material by using non-nano zinc oxide or zinc hydroxide and porous carbon material

The invention provides a method for preparing a porous carbon material by using non-nano zinc oxide or zinc hydroxide and the porous carbon material. The method comprises the following steps: a carbon precursor and a non-nano pore forming agent are fully mixed, and a mixture is obtained; the non-nano pore forming agent is selected from non-nano zinc oxide or non-nano zinc hydroxide; in an inert atmosphere, the mixture is carbonized at a temperature higher than 800 DEG C to obtain the porous carbon material; or the mixture is carbonized at the temperature lower than 800 DEG C, pickled and dried to obtain the porous carbon material. According to the method provided by the invention, a prefabricated nano-sized template agent is not needed, common non-nano zinc oxide or zinc hydroxide is directly adopted, in the heating process, nano-particles generated in situ by the non-nano pore-forming agent are used as the template agent for pore-forming, the nano-particles and the carbon base are subjected to carbon thermal reduction reaction at high temperature to generate metal simple substance evaporation for further pore forming, subsequent etching is avoided, and the obtained porous carbon is large in specific area, high in porosity and wide in pore size distribution.

Owner:UNIV OF SCI & TECH OF CHINA

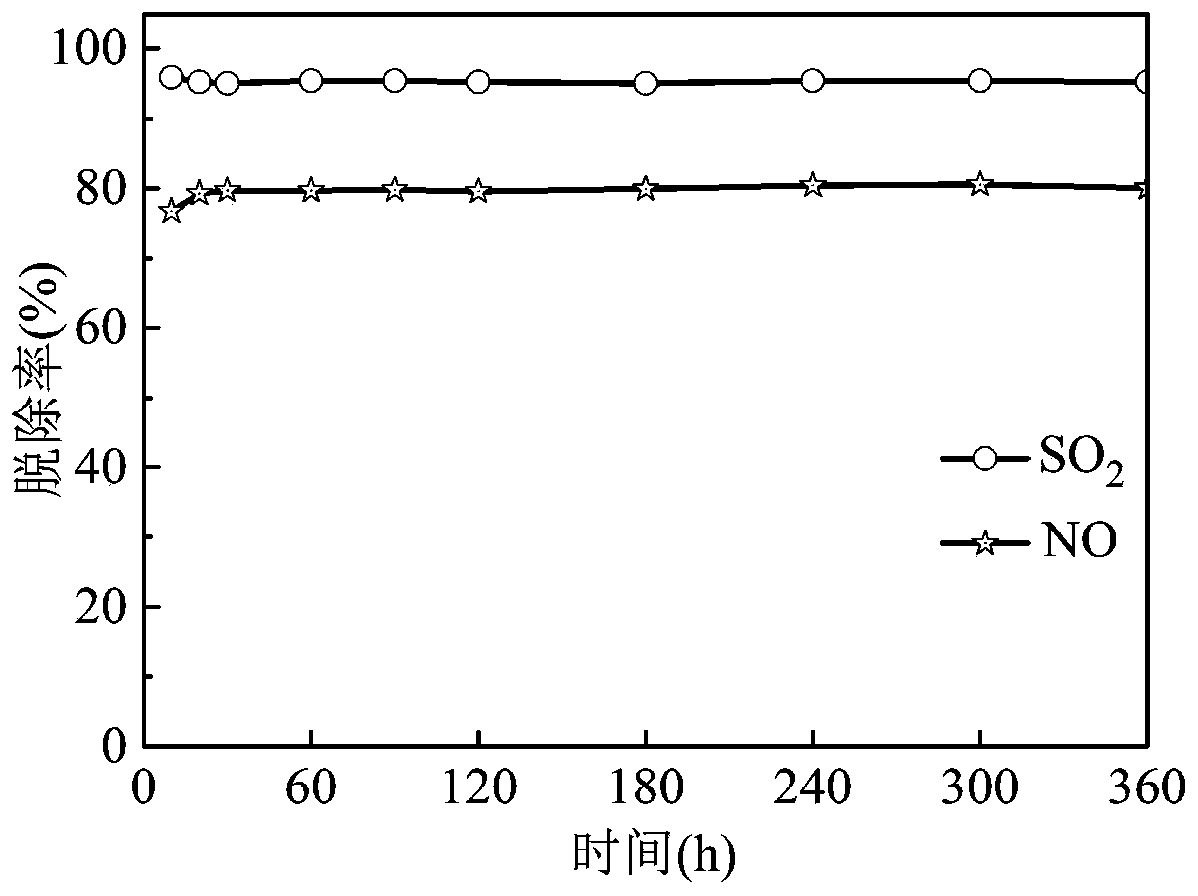

Device and method for synchronous desulfurization and denitrification of flue gas

ActiveCN110152476ALow running costIncrease absorption rateDispersed particle separationAir quality improvementNitrateSulfate

The invention discloses a device and method for synchronous desulfurization and denitrification of flue gas. The method comprises the following steps: a porous filler is put in a box-shaped plate frame to be used as a gas-permeable absorption and reaction medium, a washing absorption liquid containing polyethylene glycol and manganese oxide is added into a flue gas pipeline by using a spraying mode, the washing absorption liquid forms a liquid film on the surface of the filler, and the manganese oxide in the washing absorption liquid converts NO and SO2 in the flue gas into a nitrate and a sulfate, respectively. After the flue gas is treated by the device and method for synchronous desulfurization and denitration provided by the invention, the SO2 removal rate is maintained at 95% or more,the NO removal rate is maintained at 80% or more, and the reaction product can be separated and utilized; and the equipment is simple, the operation costs are low, and the device and the method havevery good prospects.

Owner:HEFEI UNIV OF TECH

Method for producing 2-ethylhexyl alcohol sulfate salt

InactiveCN105541669ARemove in timeHigh specific areaSulfuric acid esters preparationMicroreactorFluid phase

The present invention discloses a method for producing 2-ethylhexyl alcohol sulfate salt. The method is as below: injecting different inlet 2-ethylhexyl alcohol and a liquid sulfonating agent into a micro-reactor from different inlets of the micro-reactor, mixing and conducting a sulfonation reaction; controlling the reaction temperature at 5-50 DEG C, staying the reaction products in the micro-reactor for 0.5 milliseconds to 5 seconds, and then sending the reaction products into a micro-mixer connected with the micro-reactor to neutralize with a neutralizing agent, and aging for 0-30 min after neutralization, so as to obtain a transparent light yellow 2-ethylhexyl alcohol sulfate salt liquid. The method uses liquid-liquid phase reaction for synthesis of 2-ethylhexyl alcohol sulfate salt, not only obtains a high yield of 100%, but also does not produce any waste gas and waste requiring subsequent treatment. The method simplifies the production process, and improves the production effectiveness.

Owner:GUANGZHOU LONKEY INDAL +1

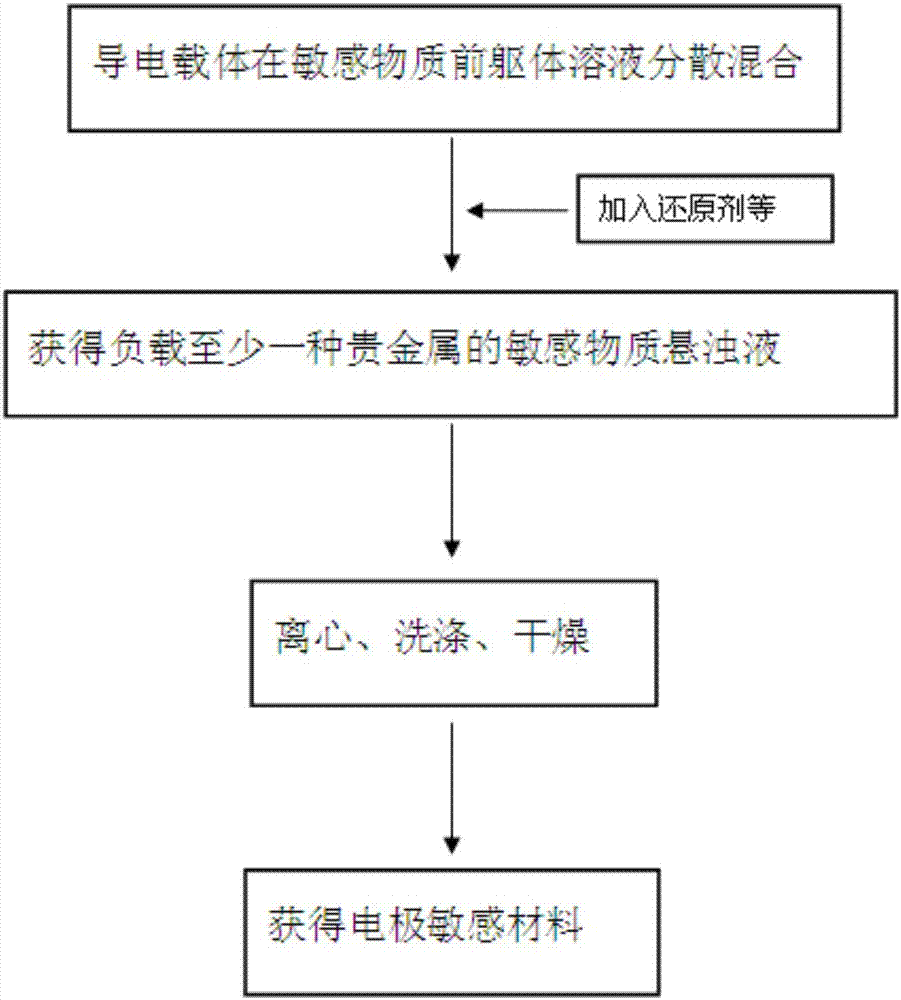

Application of electrochemical oxygen sensor sensitive material

InactiveCN107290408AHigh specific areaImprove conductivityMaterial electrochemical variablesOxygen sensorElectrode Contact

The invention discloses an application of an electrochemical oxygen sensor sensitive material and belongs to the technical field of electrochemistry. The sensitive material comprises one or more precious metal sensitive materials supported on conductive carbon, an inorganic additive and one or more metal oxide additive adding parts, wherein an oxygen sensor comprises two or more electrodes contacted with an acidic electrolyte. The novel sensitive material combined in oxygen diffusion electrodes has higher activity and stability under the condition of the acidic electrolyte and can provide detection and alarm signals.

Owner:STATE GRID CORP OF CHINA +2

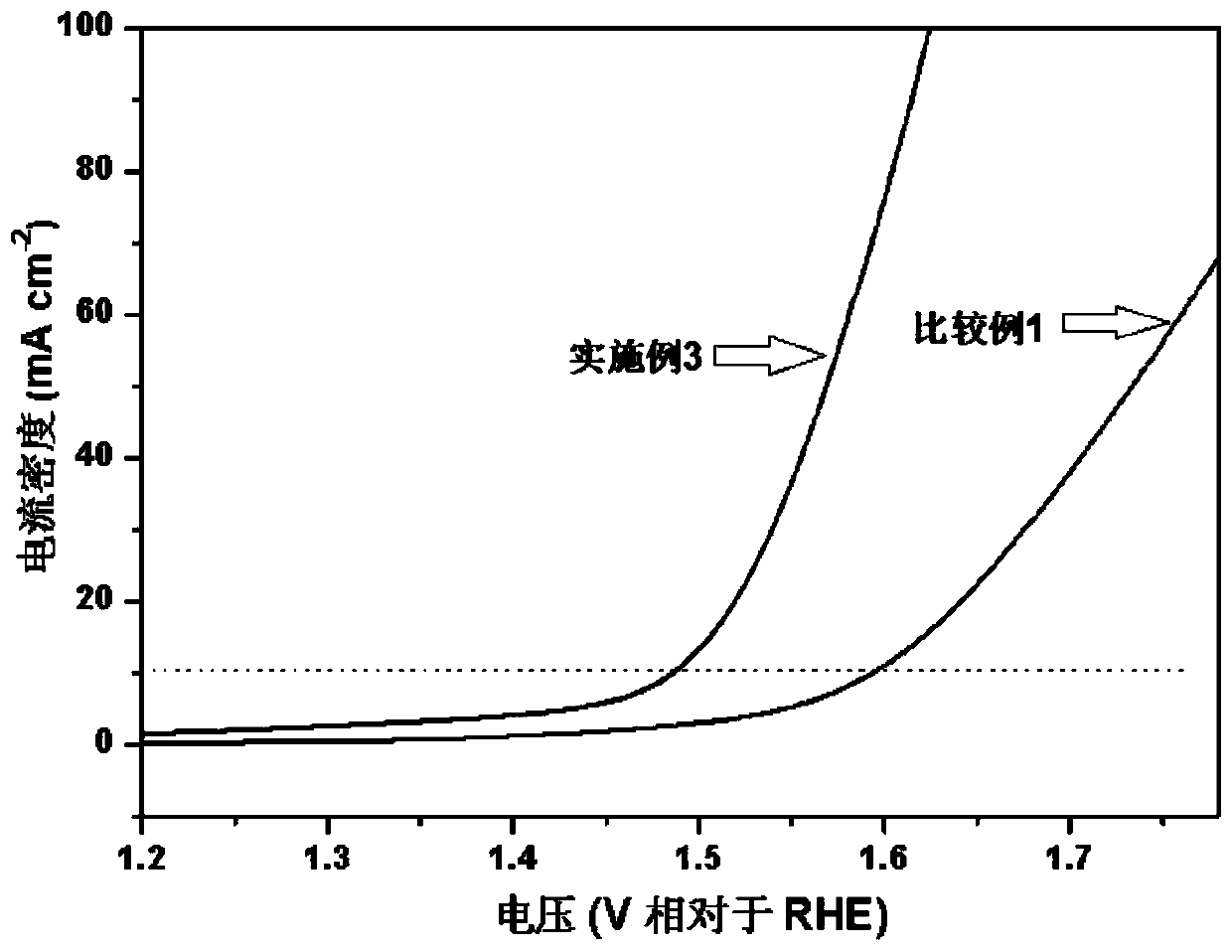

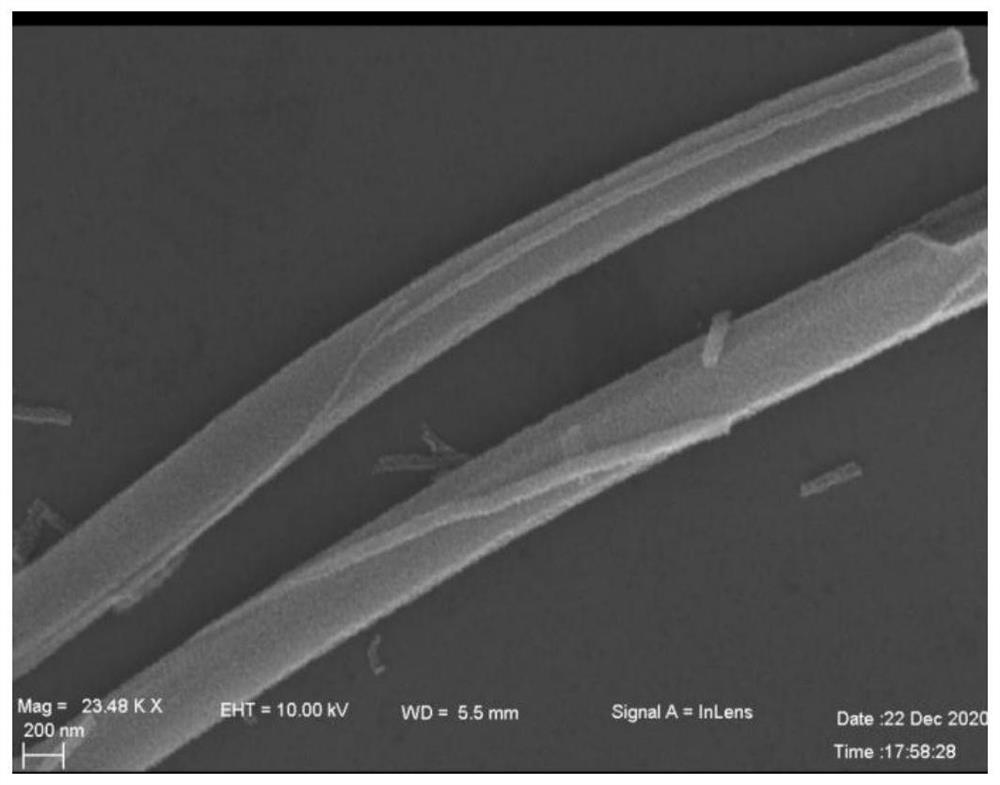

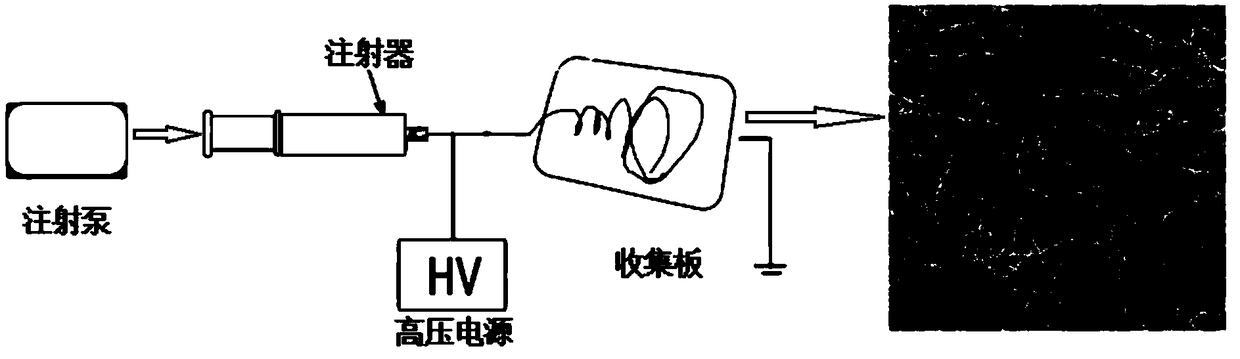

Preparation method of low-overpotential cobalt-based composite electrolyzed water oxygen evolution catalyst

InactiveCN109939681AHigh activityImprove catalytic performanceMetal/metal-oxides/metal-hydroxide catalystsElectrodesFiberArgon atmosphere

The invention discloses a preparation method of a low-overpotential cobalt-based composite electrolyzed water oxygen evolution catalyst. The method comprises the following steps: (1) adding a polymerinto a solvent to form a mixed solution, adding a cobalt-based metal organic framework (MOF) to prepare a solution, and preparing a fiber film I from the solution by taking carbon paper as a substratethrough electrostatic spinning; (2) calcining the fiber film I in a nitrogen or argon atmosphere, so as to obtain a precursor II; and (3) calcining the precursor II, so as to obtain the low-overpotential cobalt-based composite electrolyzed water oxygen evolution catalyst. The overpotential of the catalyst is only 260mV when the alternating current density is 10mA / cm<-2>, and the catalyst is an electric catalyst with relatively low overpotential in cobalt-based electric catalysts. Meanwhile, the preparation method of the low-overpotential cobalt-based composite electrolyzed water oxygen evolution catalyst has the beneficial effects that the process is simple, safe and controllable, and the consumed time and energy are little.

Owner:SUZHOU UNIV

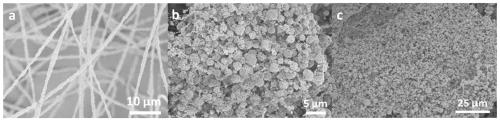

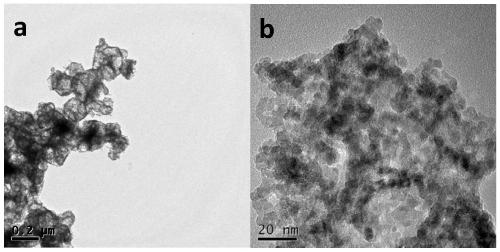

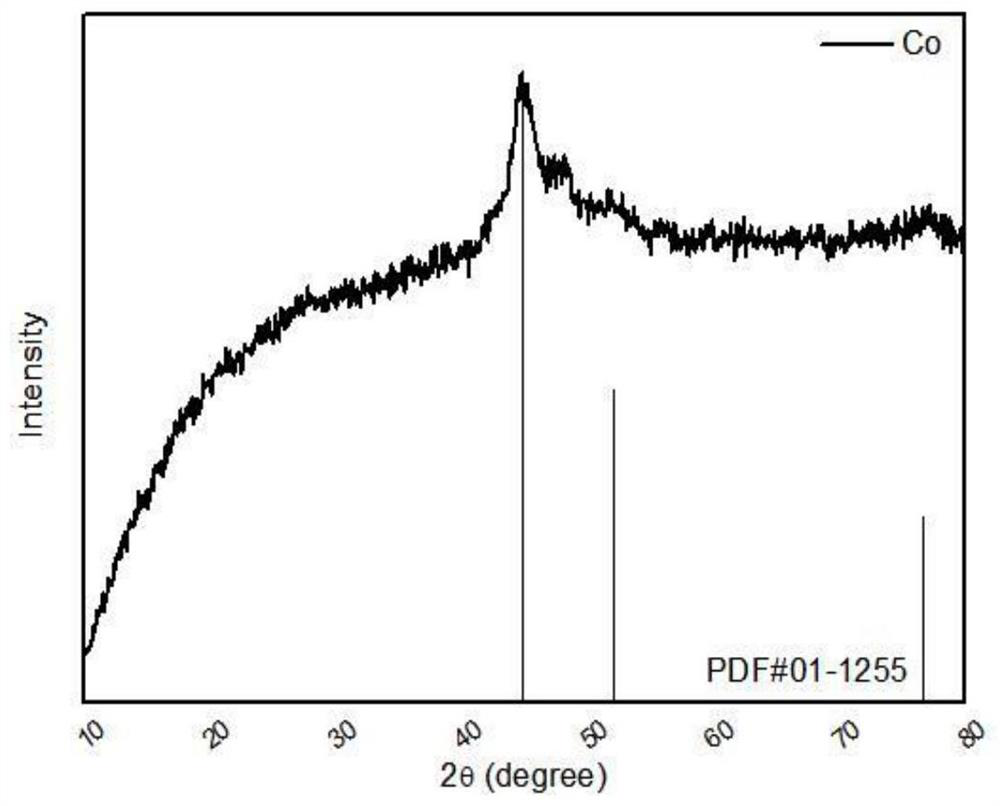

Preparation method of porous rod-like Co/C nanorod composite material

The invention relates to the technical field of catalysts, provides a preparation method of a porous rod-like Co / C nanorod composite material, aims at the problem of high cost of a noble metal doped modified electrocatalyst, the preparation method comprises the following steps: preparing a precursor by utilizing NTA and Co (NO3) 2.6 H2O hydrothermal method, calcining the precursor, calcining in inert gas at 450-500 DEG C for 2-2.5 hours, and after calcining, cooling to obtain the rod-like porous Co / C nanorod composite electrocatalyst. The rod-like porous Co / C nanorod composite electrocatalyst is prepared from NTA and metal salt Co (NO3) 2.6 H2O through hydrothermal treatment and then tubular furnace sintering, the condition is mild, the purity is good, and the prepared rod-like porous Co / C nanorod composite electrocatalyst has high electrocatalytic activity.

Owner:HANGZHOU NORMAL UNIVERSITY

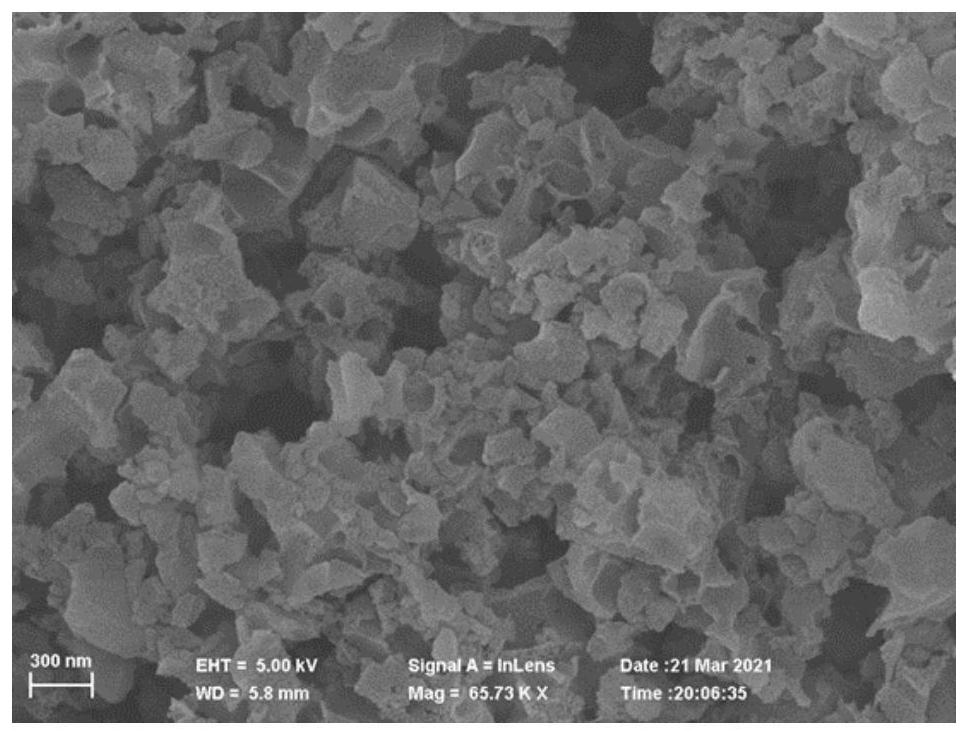

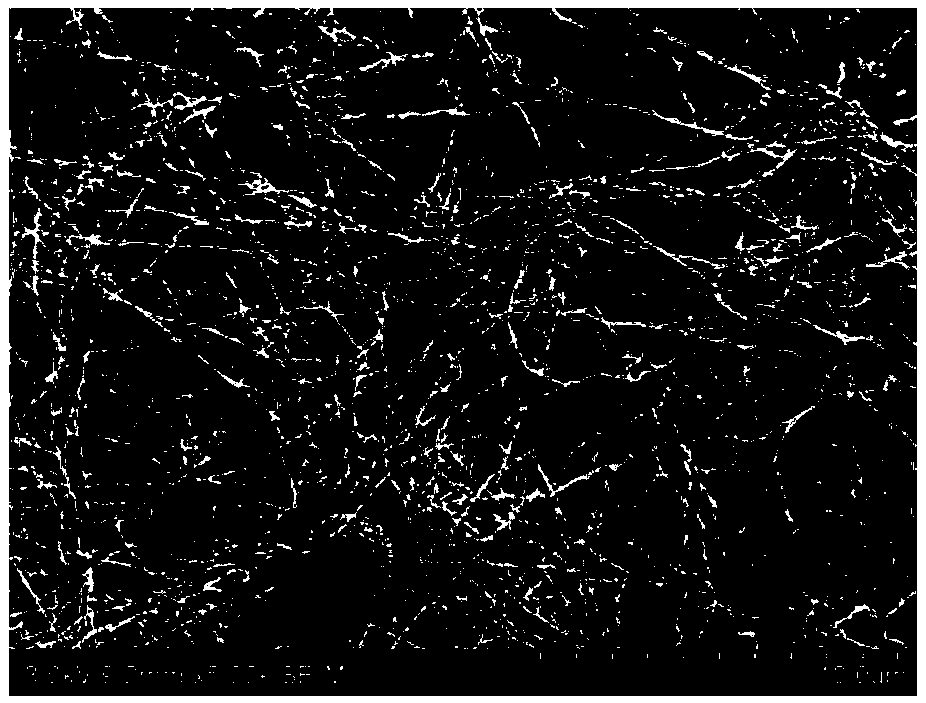

Method for rapidly preparing green MOFs (Metal-organic frameworks) porous microspheres

InactiveCN108854877AImprove spinnabilityImprove conductivityMicroballoon preparationMicrocapsule preparationMetal-organic frameworkRoom temperature

The invention discloses a method for rapidly preparing green MOFs (Metal-organic frameworks) porous microspheres. The method comprises the steps: adding a first polymer to a solvent, and stirring andmixing at room temperature to obtain a mixed solution I; adding MOFs to the mixed solution I, and then stirring and mixing at room temperature to obtain a mixed solution II; ultrasonically oscillatingthe mixed solution II uniformly, and then obtaining the green MOFs porous microspheres by electrospinning treatment. The method disclosed by the invention has the advantages that the preparation process is simple, safe and controllable, less time and energy are consumed, and the cubic crystal type MOFs are converted into the MOFs porous microspheres by electrospinning. Most importantly, in the process of preparing the MOFs porous microspheres, no contaminating heavy metals or toxic substances are used, and no pollution is caused.

Owner:SUZHOU UNIV

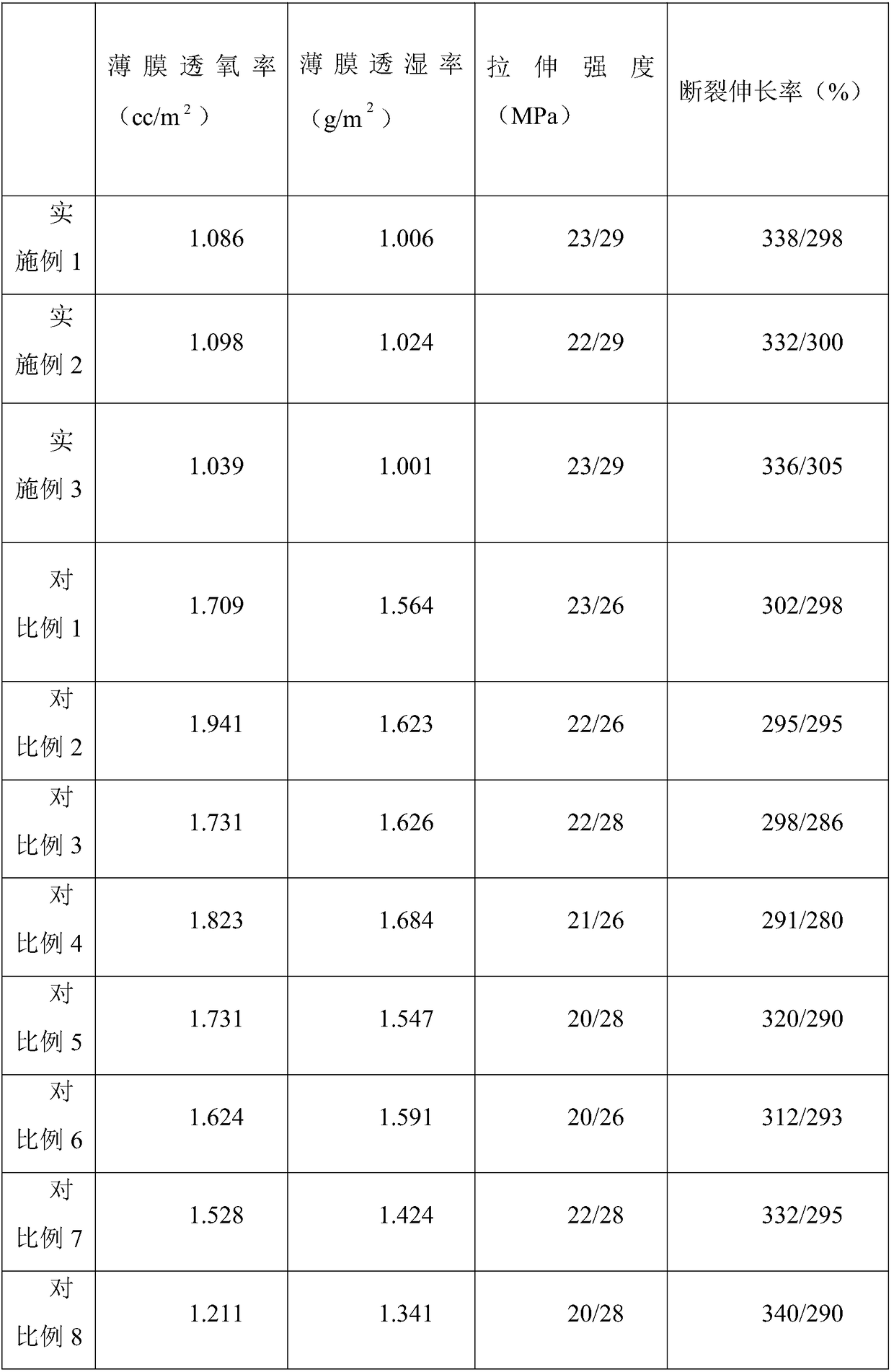

High-performance and high-barrier-property food packaging film and preparation method thereof

InactiveCN108395559AImprove barrier propertiesHigh specific areaFlexible coversWrappersFood packagingRosin

The invention discloses a high-performance and high-barrier-property food packaging film. The high-performance and high-barrier-property food packaging film is prepared from the following raw materials in parts by weight: 38 to 44 parts of modified polymethylethylene carbonate, 22 to 24 parts of nano silicon dioxide, 12 to 16 parts of ethylene-vinyl acetate copolymer, 3 to 5 parts of emulsifier, 2to 4 parts of processing auxiliary agent and 14 to 20 parts of water. According to the high-performance and high-barrier-property food packaging film disclosed by the invention, rosin is a renewableforest resource and resin acid in the rosin contains a large phenanthrene ring structure so that the tensile strength of the material can be improved. Although polymethylethylene carbonate has excellent air blocking and water blocking functions and is degradable, the polymethylethylene carbonate modified through the rosin enables a matrix material to have a high barrier property and also have a mechanical property.

Owner:CHANGDE JINRUN NEW MATERIAL TECH CO LTD

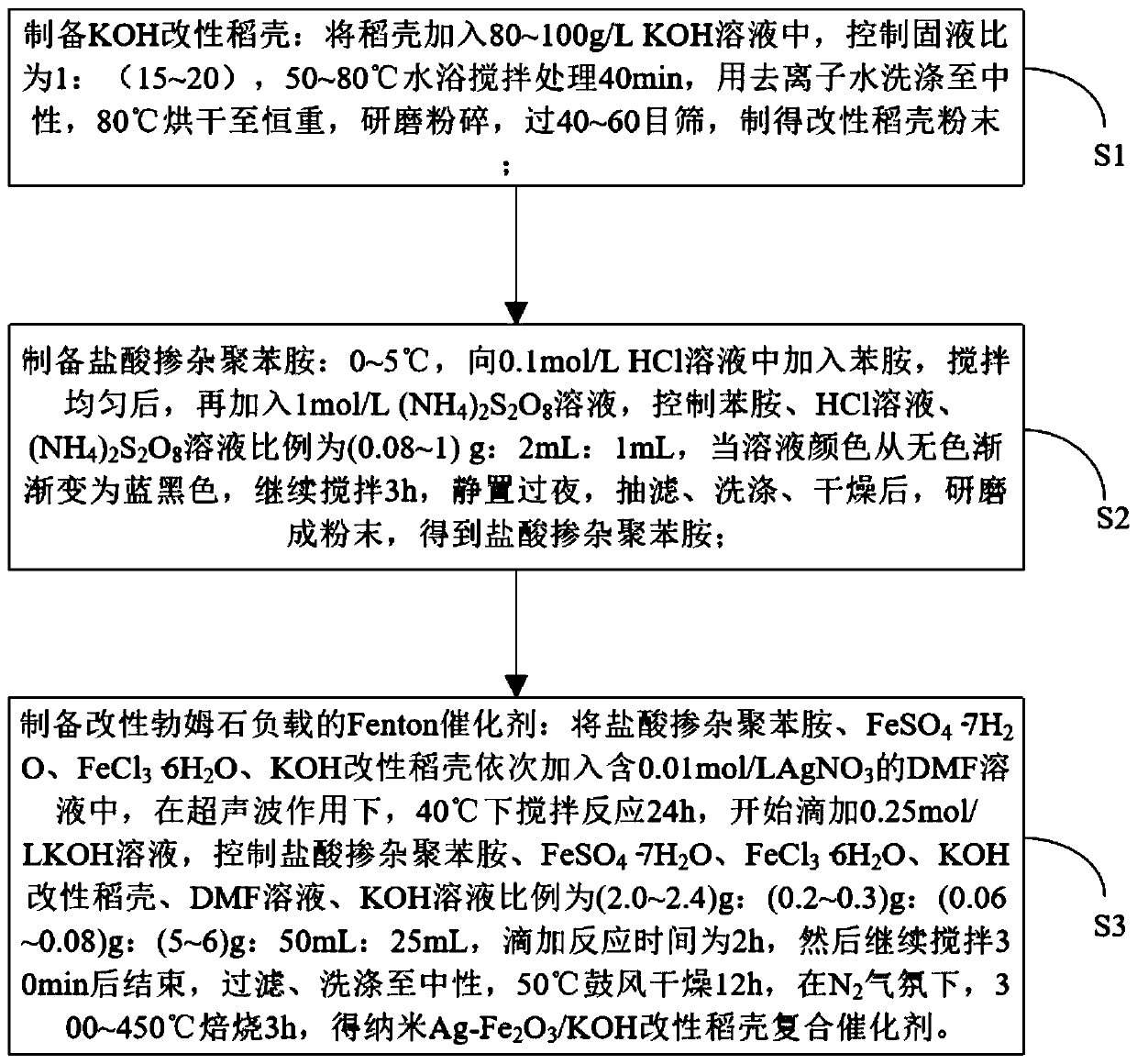

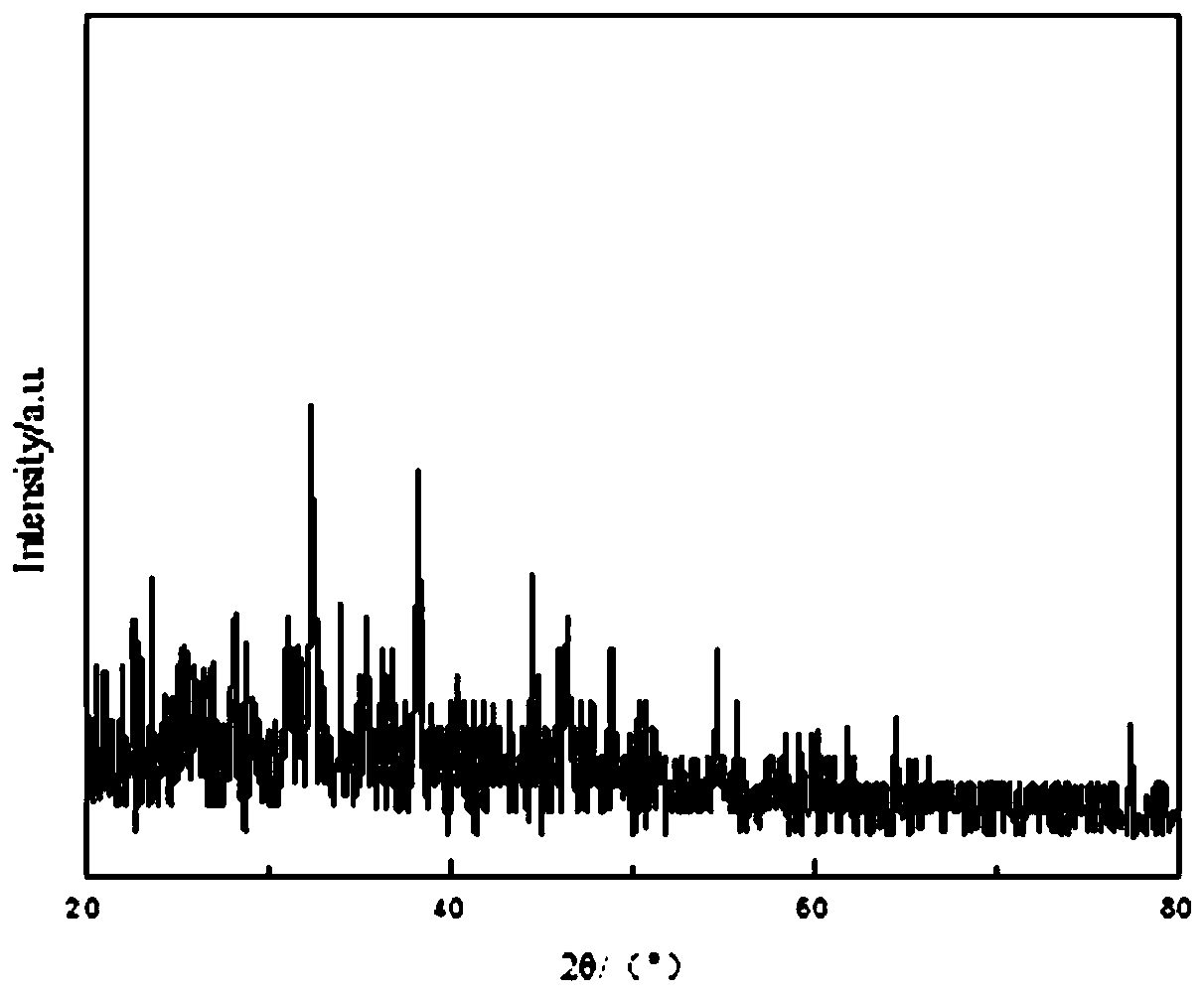

Process for preparing Fenton catalyst by using KOH modified rice husks, and applications of Fenton catalyst in degradation of printing and dyeing wastewater

InactiveCN110721751AReduce manufacturing costEasy to operateOrganic-compounds/hydrides/coordination-complexes catalystsWater contaminantsPtru catalystUltrasound - action

The invention discloses a process for preparing a Fenton catalyst by using KOH modified rice husks, and applications of the Fenton catalyst in degradation of printing and dyeing wastewater. The process comprises: S1, preparing KOH modified rice husks: adding rice husks into an 80-100 g / L KOH solution, carrying out water bath stirring treatment at 50-80 DEG C for 40 min, washing, drying, and crushing; S2, preparing hydrochloric acid doped polyaniline; and S3, preparing a KOH modified rice husk loaded Fenton catalyst: sequentially adding the hydrochloric acid doped polyaniline, FeSO4.7H2O, FeCl3.6H2O and the KOH modified rice husks into a DMF solution containing 0.01 mol / L AgNO3, carrying out a stirring reaction for 24 h at 40 DEGC under the action of ultrasonic waves, adding a 0.25 mol / L KOH solution in a dropwise manner for 2 h, continuously stirring for 30 min, ending, filtering, washing, drying, and roasting for 3 h at 150-200 DEG C in an N2 atmosphere. According to the invention, the nanometer Ag-Fe2O3 / KOH modified rice husk composite Fenton catalyst is synthesized by firstly using the KOH modified rice husk as the carrier through the in-situ one-step method at a low temperature, so that the operation is simple, the preparation cost is low, the catalytic activity is high, the selectivity is strong, and the catalyst can be recycled.

Owner:BENGBU COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com