Device and method for synchronous desulfurization and denitrification of flue gas

A technology for desulfurization, denitrification and flue gas, applied in separation methods, chemical instruments and methods, and air quality improvement, etc., can solve problems such as difficulty in meeting industrial emission standards, high investment and operating costs, and no improvement in NO solubility. Overcome the effects of insoluble NO, low operating cost and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

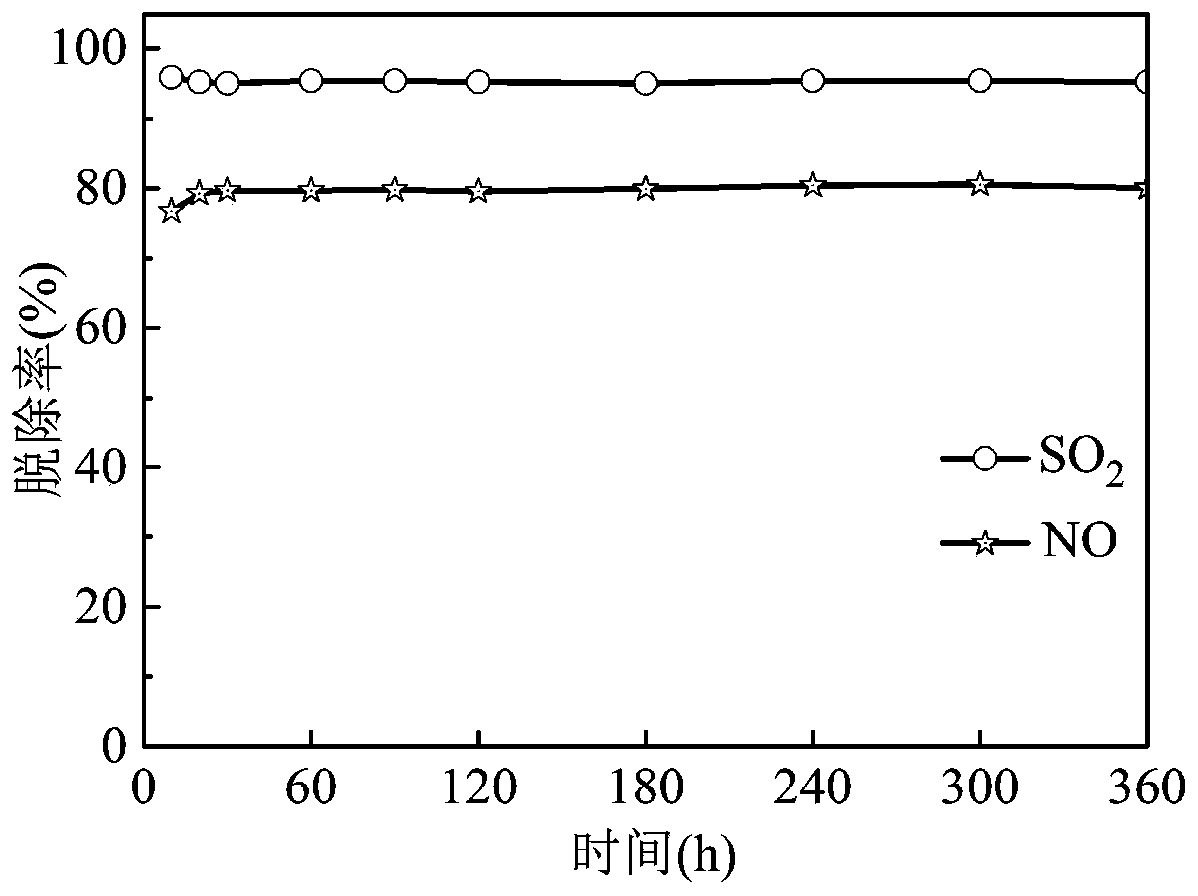

[0051] The device and method of this embodiment are used to treat the flue gas of a certain glass kiln, and the flue gas flow rate is 15000Nm 3 / h.

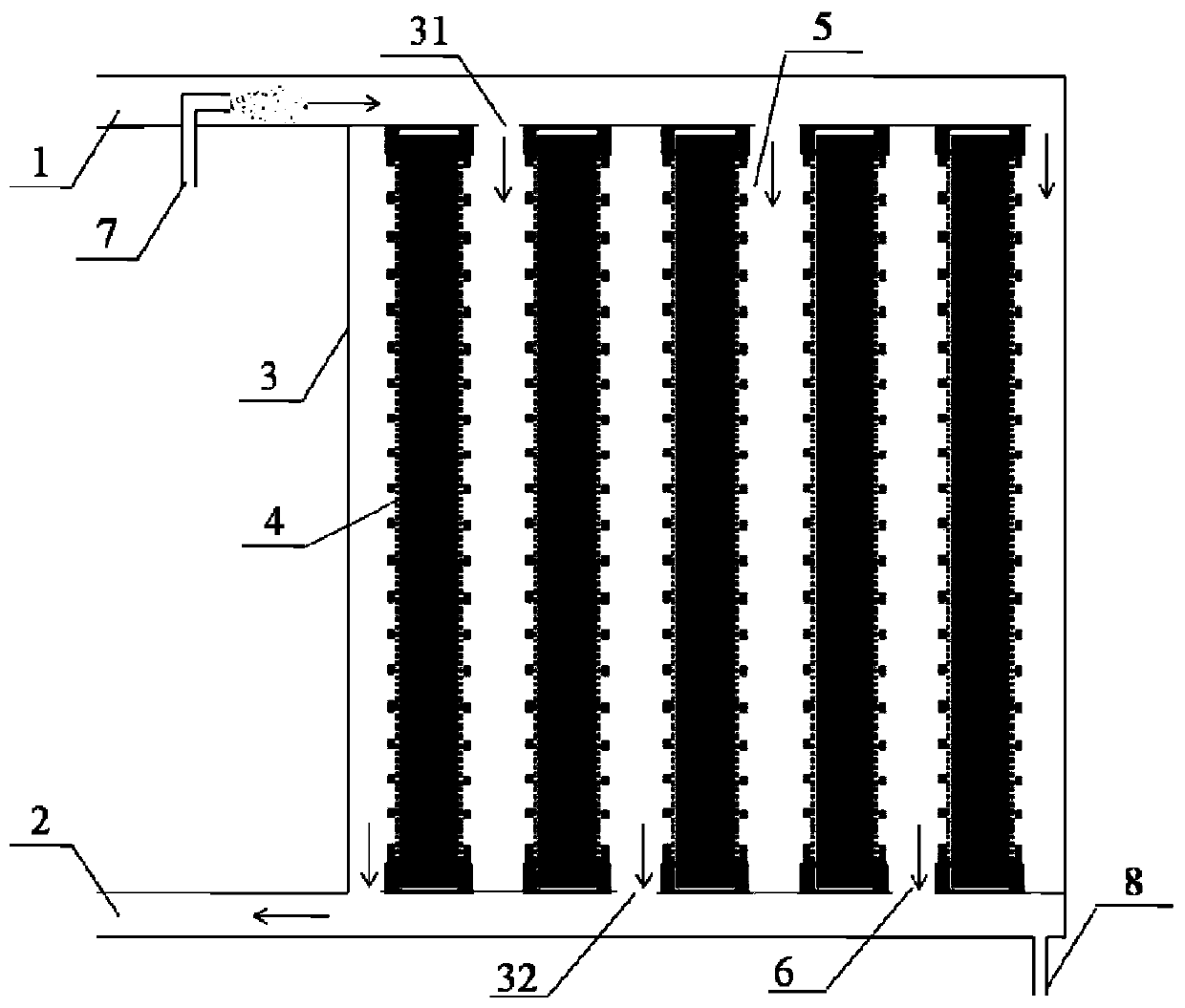

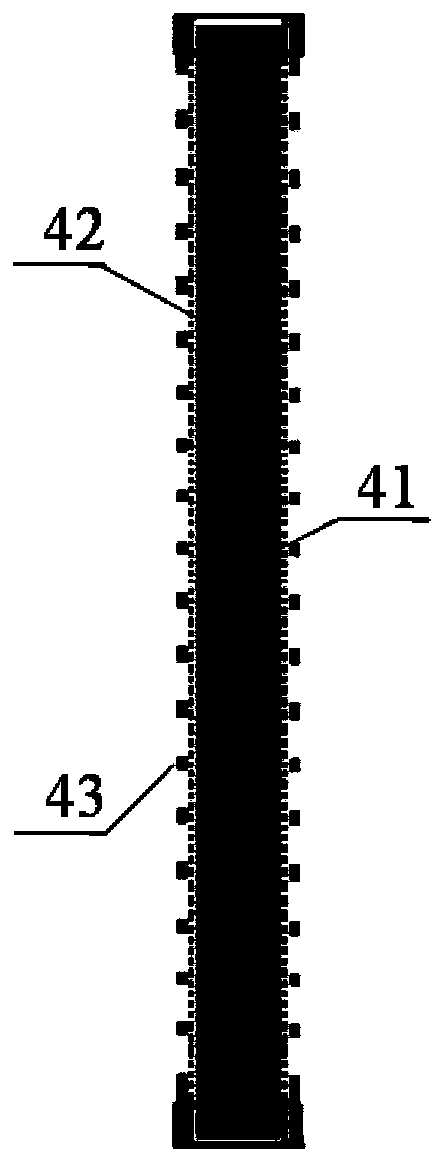

[0052] Such as figure 1 with figure 2 As shown, in the flue gas synchronous desulfurization and denitrification device of this embodiment, the box-shaped plate frame is 25 cm thick, 1 m high, and 1 m wide. According to the calculation of the flow rate and the design flow rate, 5 box-shaped frames are required, and the box-shaped frames are placed in the sealed shell in parallel, and the gap between the box-shaped frame and the side wall of the sealed shell and the gap between adjacent box-shaped frames 2cm wide, used as an air inlet or outlet slit. The box-shaped plate frame is made of 1.5mm thick galvanized sheet to form a box-shaped shell. The two sides of the shell are grooved, which is used for welding the grid-shaped fine screen with a diameter of 1mm and the grid-shaped coarse screen with an aperture of 20mm. A circula...

Embodiment 2

[0059] Such as figure 1 with figure 2 As shown, in the flue gas synchronous desulfurization and denitrification device of this embodiment, the box-shaped plate frame is 25 cm thick, 1 m high, and 1 m wide. According to the calculation of the flow rate and the design flow rate, 5 box-shaped frames are required, and the box-shaped frames are placed in the sealed shell in parallel, and the gap between the box-shaped frame and the side wall of the sealed shell and the gap between adjacent box-shaped frames 2cm wide, used as an air inlet or outlet slit. The box-shaped plate frame is made of 1.5mm thick iron plate covered with plastic film to form a box-shaped shell. The two sides of the shell are grooved, which is used for welding the grid-shaped fine screen with a diameter of 1mm and the grid-shaped coarse screen with an aperture of 20mm. After the two screens on one side are welded, the high specific area, high porosity, and corrosion-resistant Y-shaped metal mesh filler (such...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com