Patents

Literature

35results about How to "Does not affect the area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

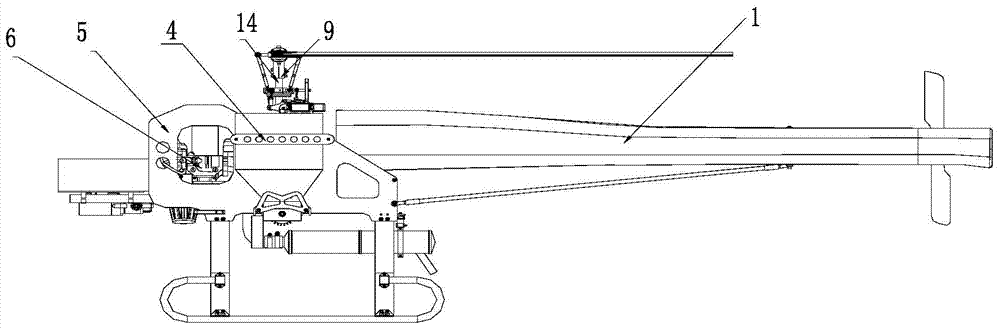

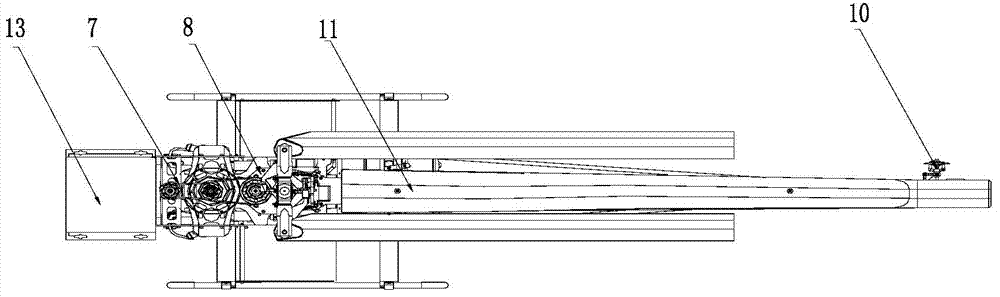

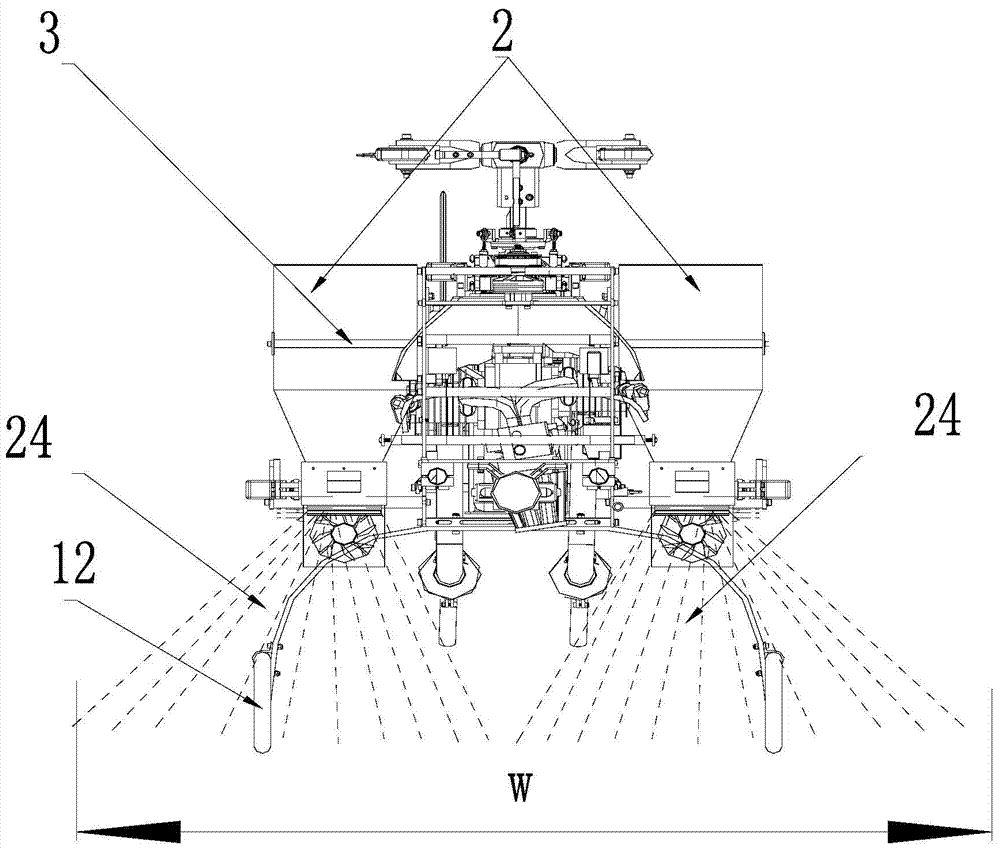

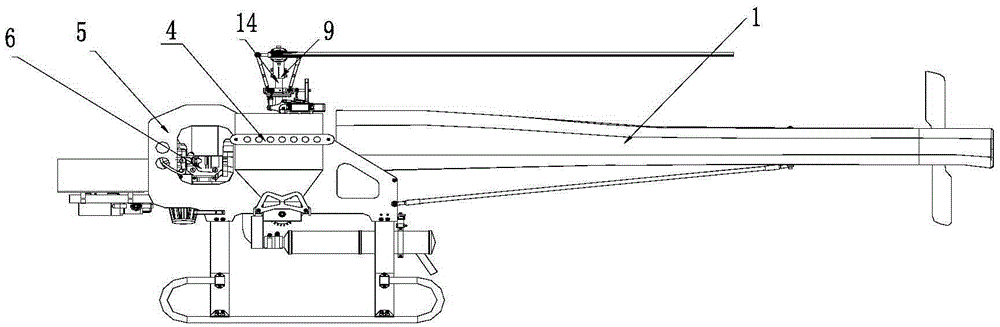

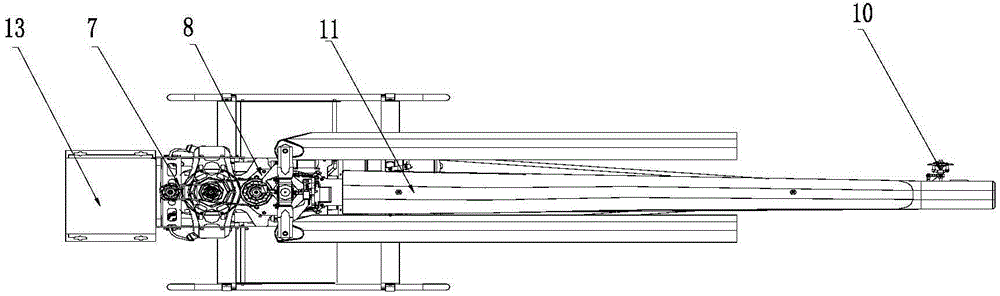

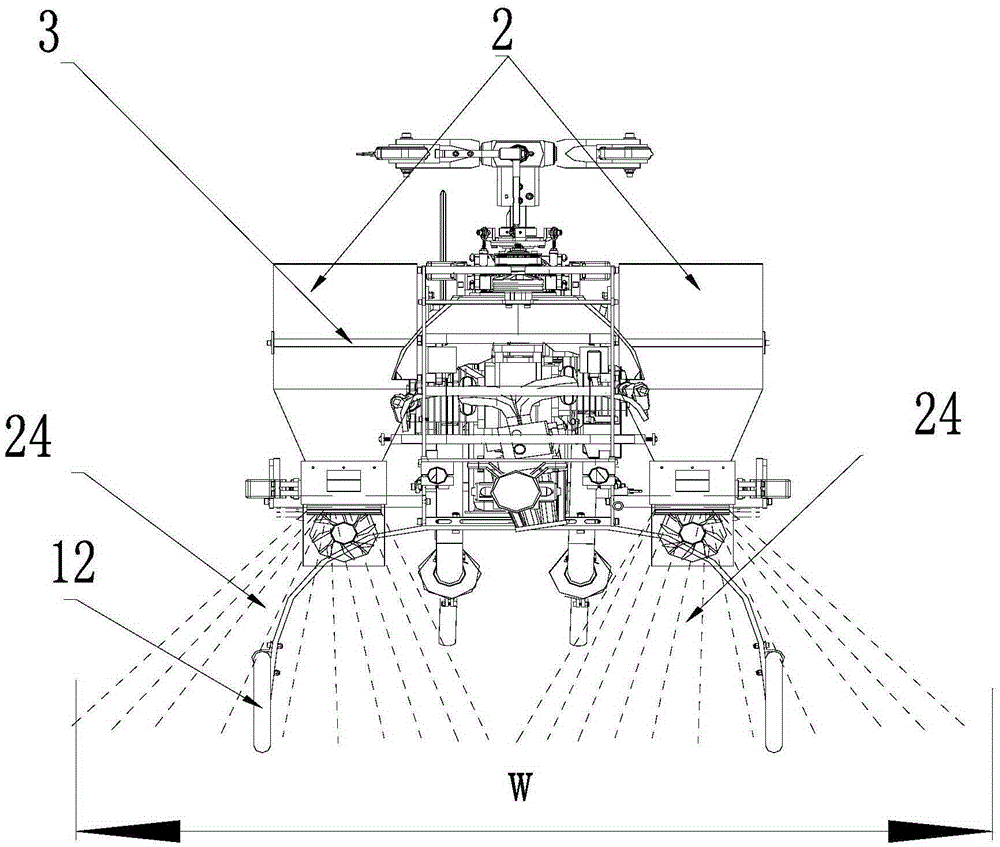

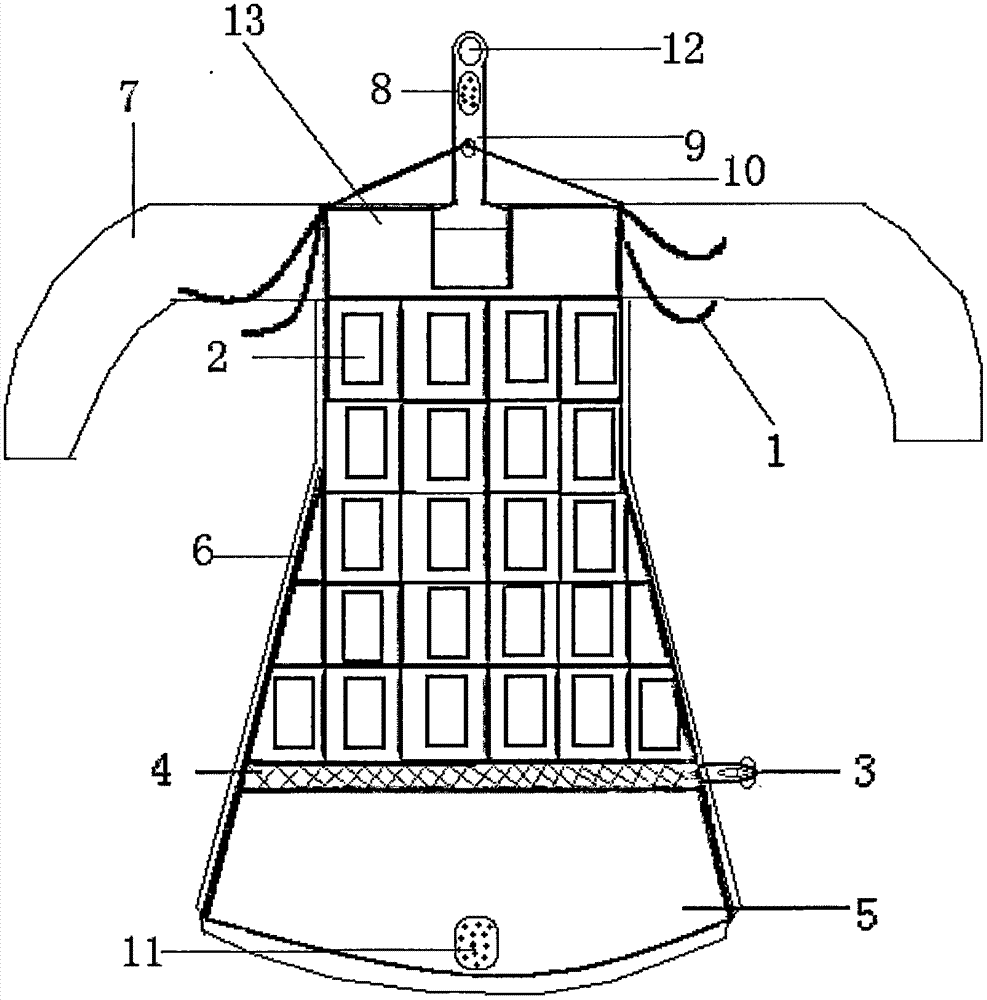

Precision seeding working system and method based on unmanned aerial vehicle platform

ActiveCN104255137AReduce labor intensityImprove work efficiencyAircraft componentsBroadcast seedersElectric machineryEngineering

The invention discloses a precision seeding working system and method based on an unmanned aerial vehicle platform. The system comprises an unmanned aerial vehicle (1) and seeding devices (2) fixed on the unmanned aerial vehicle. Each seeding device (2) comprises a seed box (15), a fixed seat (16), a wind power seed scattering device, a quantitative seeding roller (18), roller blades (19) and a servo motor (22); the servo motor is driven by a battery; the wind power seed scattering device is a fan (17) only or an air supply channel consisting of a fan and a sleeve; the seed box (15) is fixed on the top of the fixed seat (16); the servo motor (22) is mounted on the fixed seat; the quantitative seeding rollers (18) controlled by the servo motor realize precision seeding; by the adoption of the wind power seed scattering device, seeding is uniform. The precision seeding working system based on the unmanned aerial vehicle platform can realize precision seeding work and is high in seeding efficiency and easy to implement.

Owner:湖南星索尔航空科技有限公司

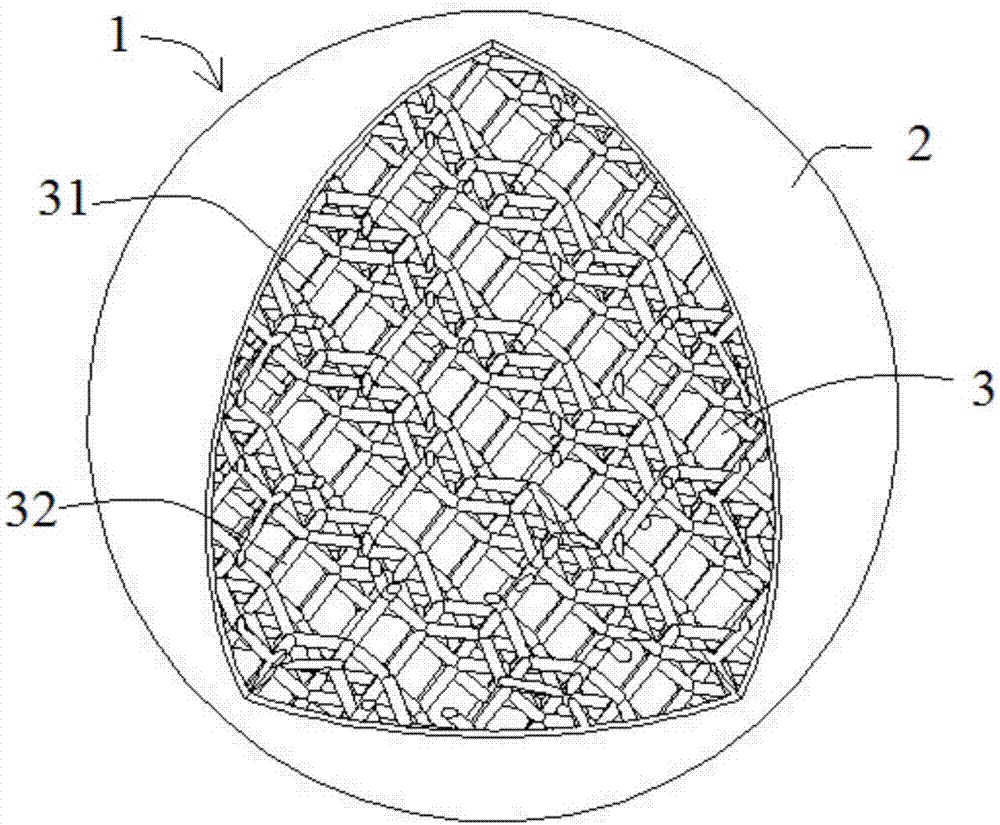

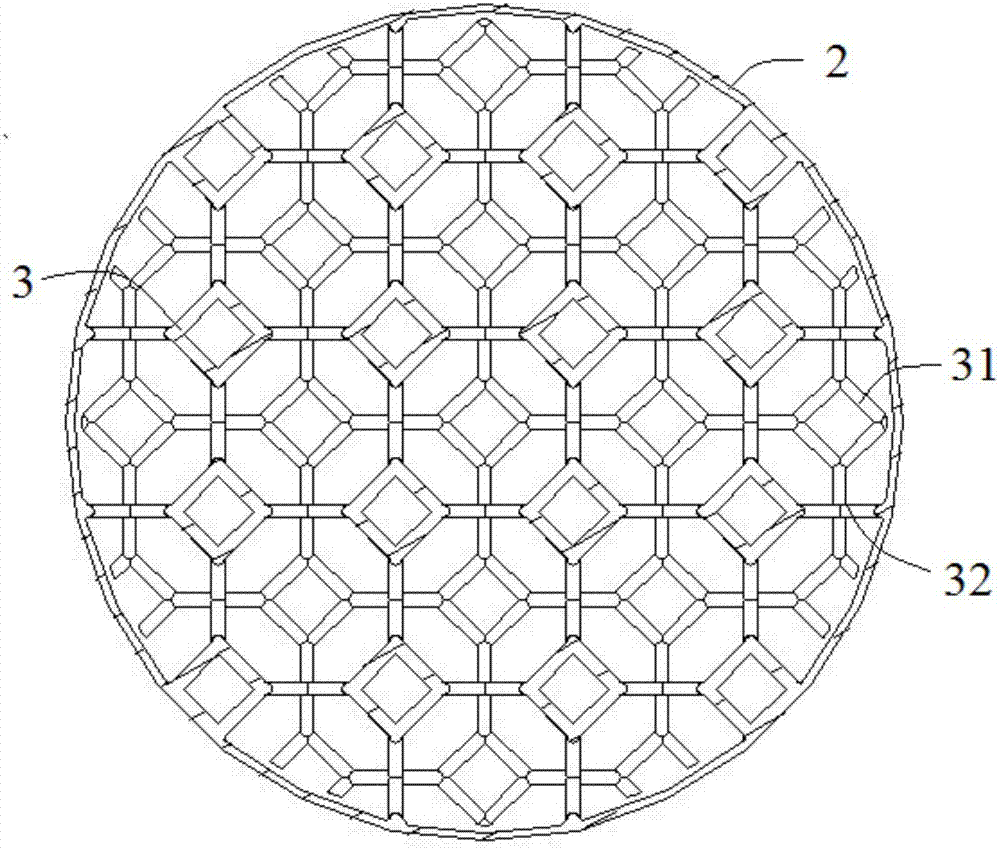

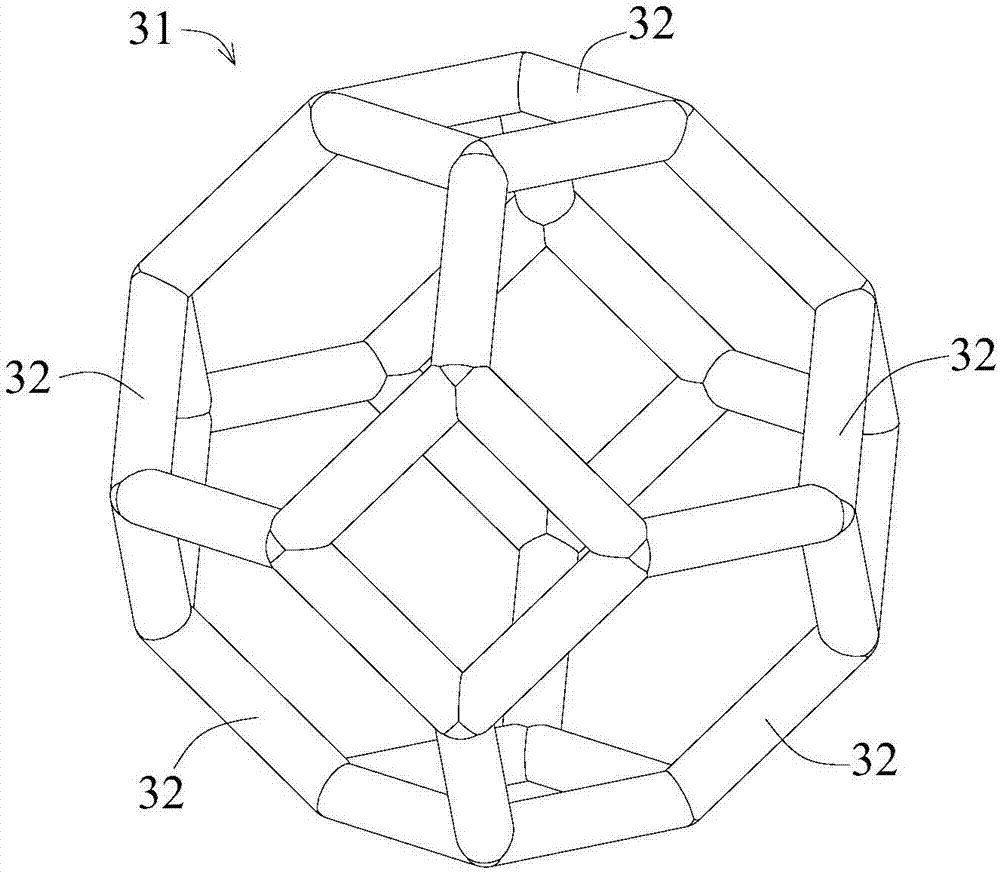

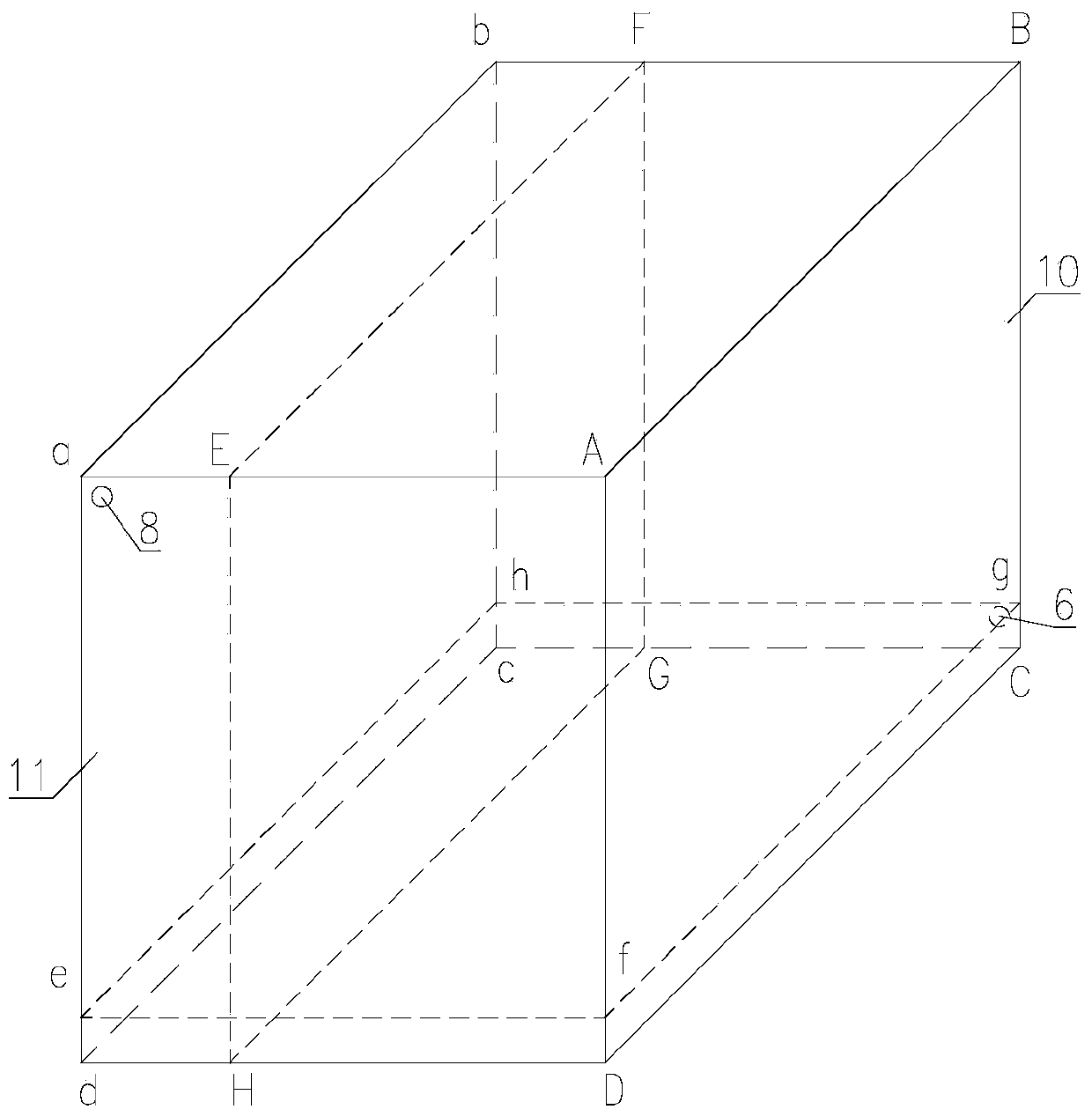

Composite light structure with high energy absorbing rate and good buffer ability and structure main body

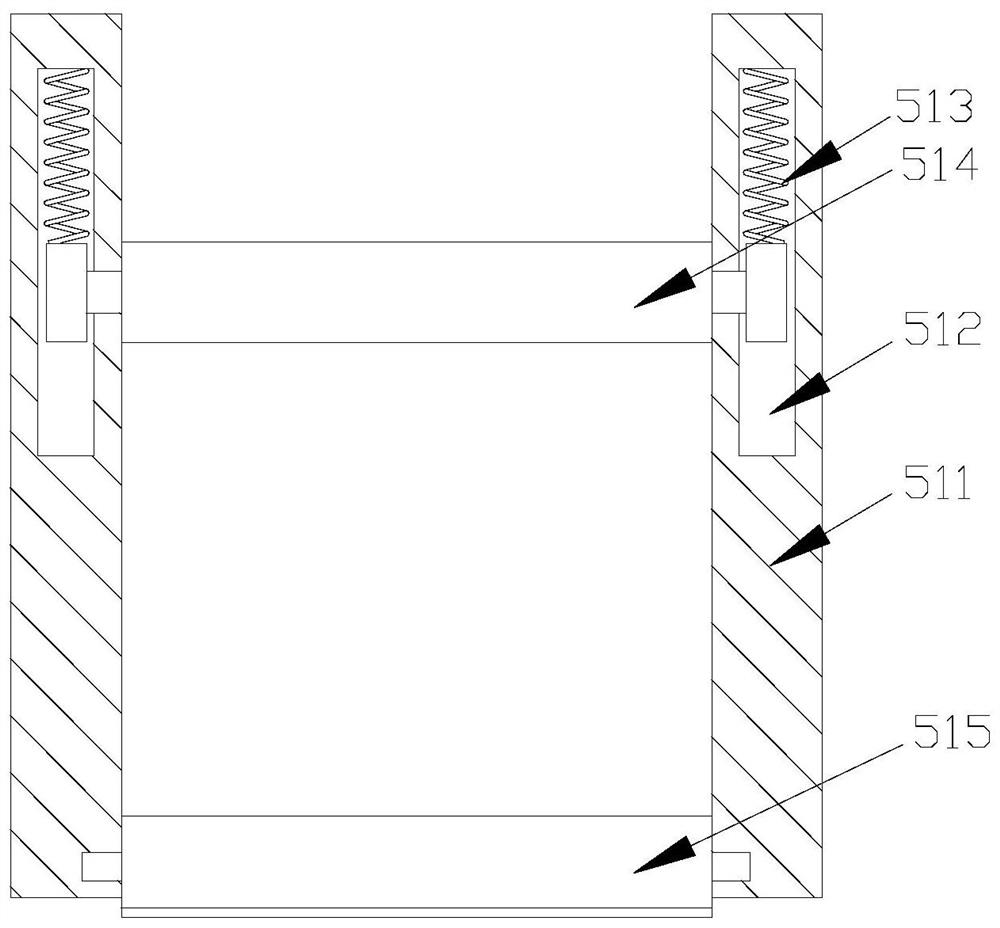

InactiveCN107448528AHigh energy absorptionQuality improvementHigh internal friction springsLow internal friction springsDot matrixHigh energy

The invention discloses a composite light structure with a high energy absorbing rate and good buffer ability and a structure main body. The composite light structure with the high energy absorbing rate and good buffer ability comprises a housing and an inner support, wherein the housing is sealed and hollow; the inner support is connected in the housing; the inner support is of a dot matrix structure; the inner support comprises a plurality of unit cells which are arranged according to a preset rule; and each cell unit is in the shape of a framework comprising a plurality of supporting rods. The composite light structure with the high energy absorbing rate and good buffer ability and the structure main body disclosed by the invention have the characteristics of relatively small weight, relatively high specific areas, strong energy absorbing ability and relatively strong buffer ability.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

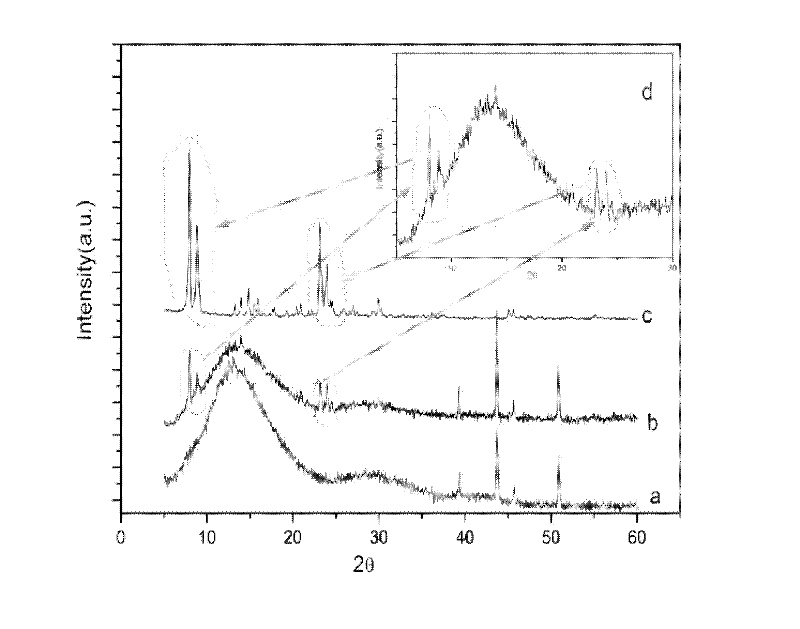

Paper sintering metal fiber load molecular sieve membrane and preparation method thereof

InactiveCN102512978AUniform structure distributionSimple preparation processSemi-permeable membranesMetal fiberMolecular sieve

The invention discloses a paper sintering metal fiber load molecular sieve membrane and a preparation method thereof. The paper sintering metal fiber load molecular sieve membrane has the thickness of 0.1-1.5mu m. The preparation method comprises the following steps of: pulping size prepared from an adhesive and a metal fiber at a mass ratio of (1-1):(1-3), drying, then sintering in a nitrogen or hydrogen atmosphere, preprocessing through an anode oxidization process, and synthesizing the molecular sieve membrane with an adjustable thickness on the surface of the metal fiber by adopting a secondary growth process. The preparation method is simple; the sintering metal fiber is of a three-dimensional net structure, and has the characteristics of high porosity, high mechanical strength, good flexibility and convenience for formation; the porosity can be regulated within a large range; and the synthesized molecular sieve membrane is thin and is good in continuity.

Owner:SOUTH CHINA UNIV OF TECH

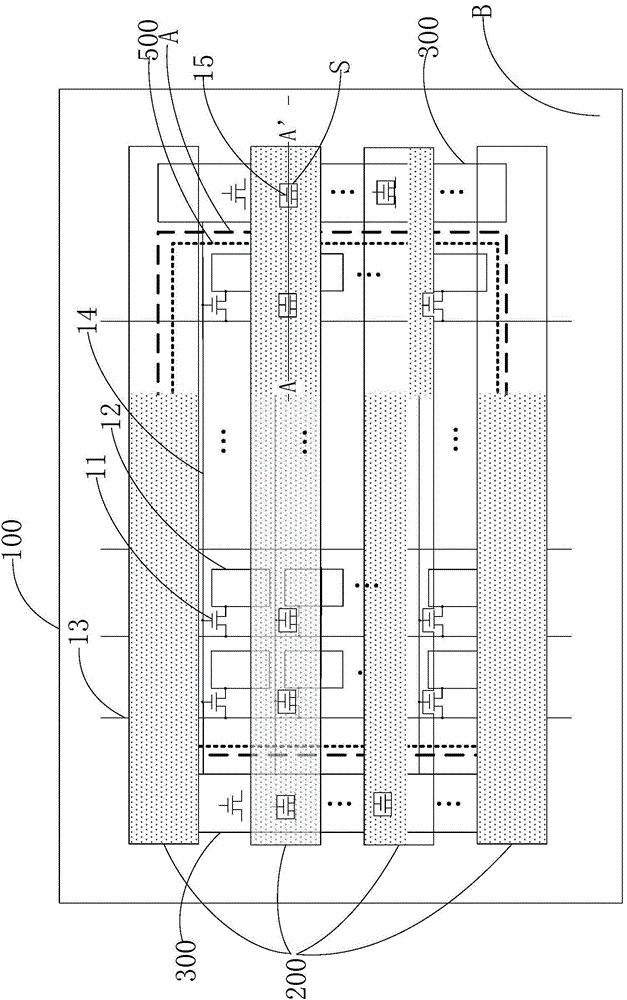

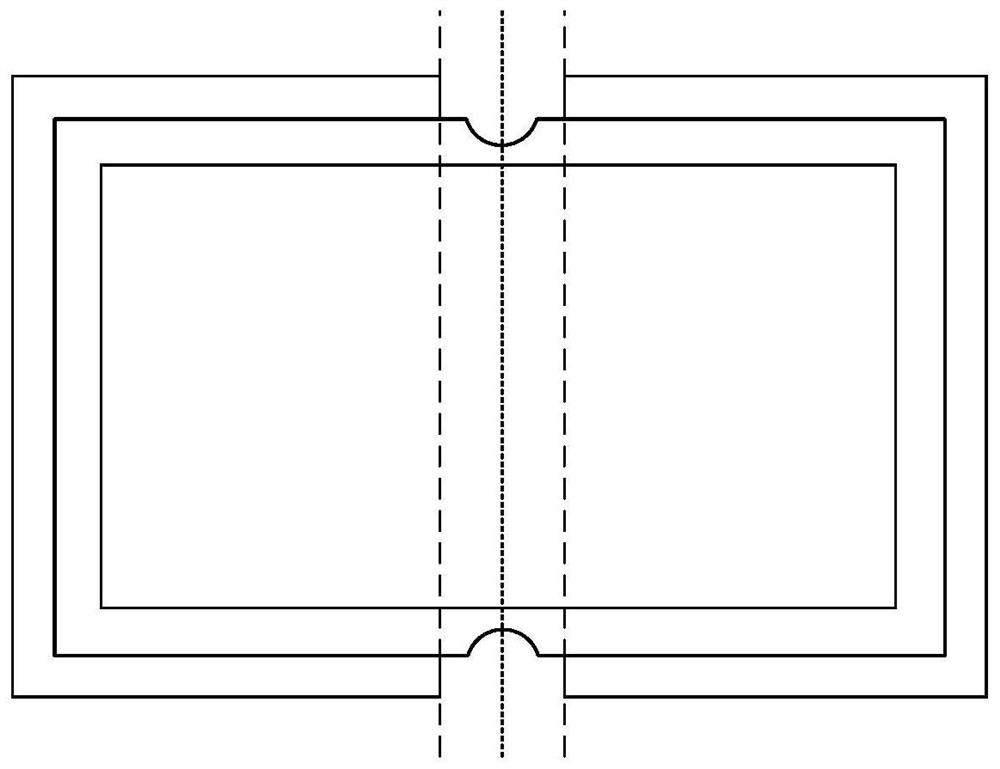

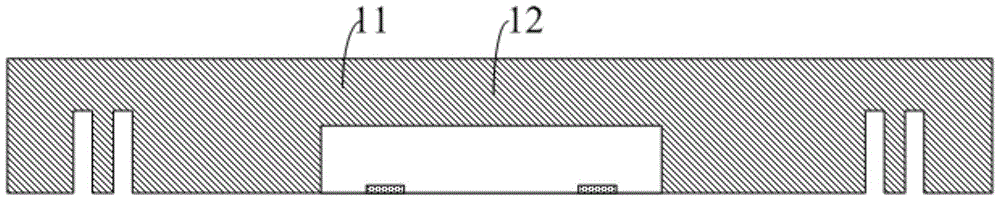

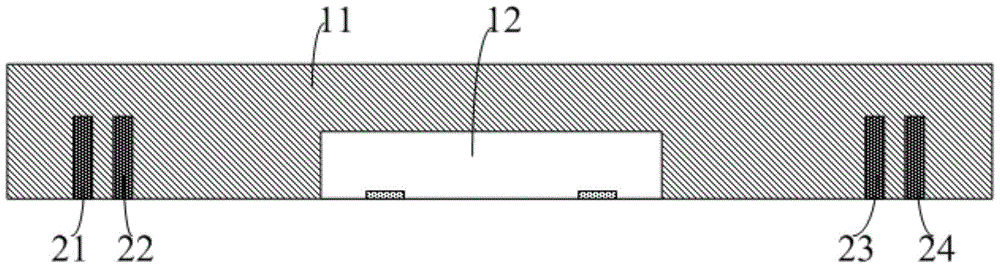

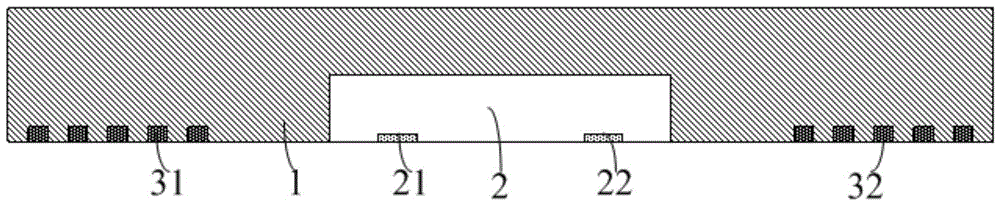

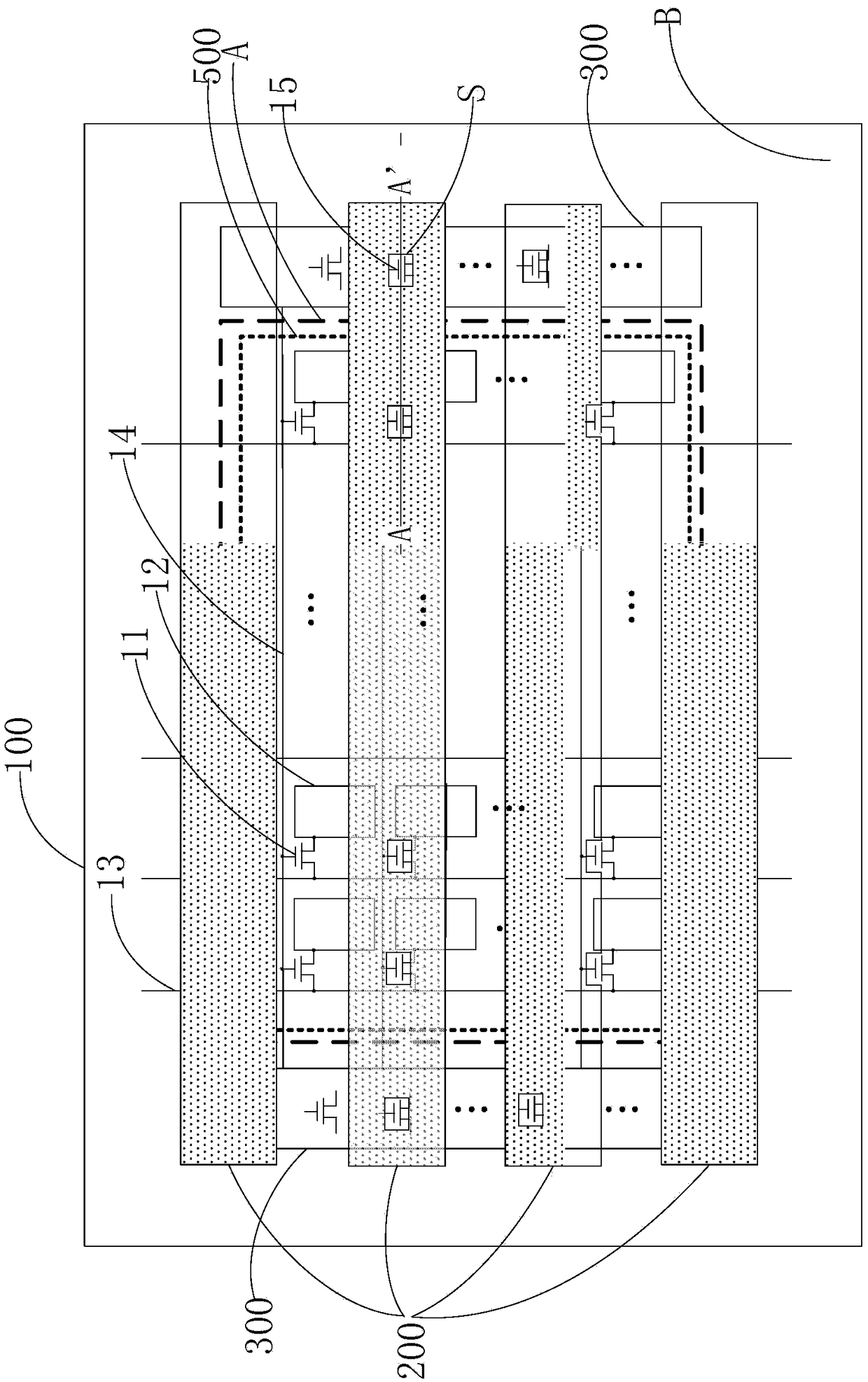

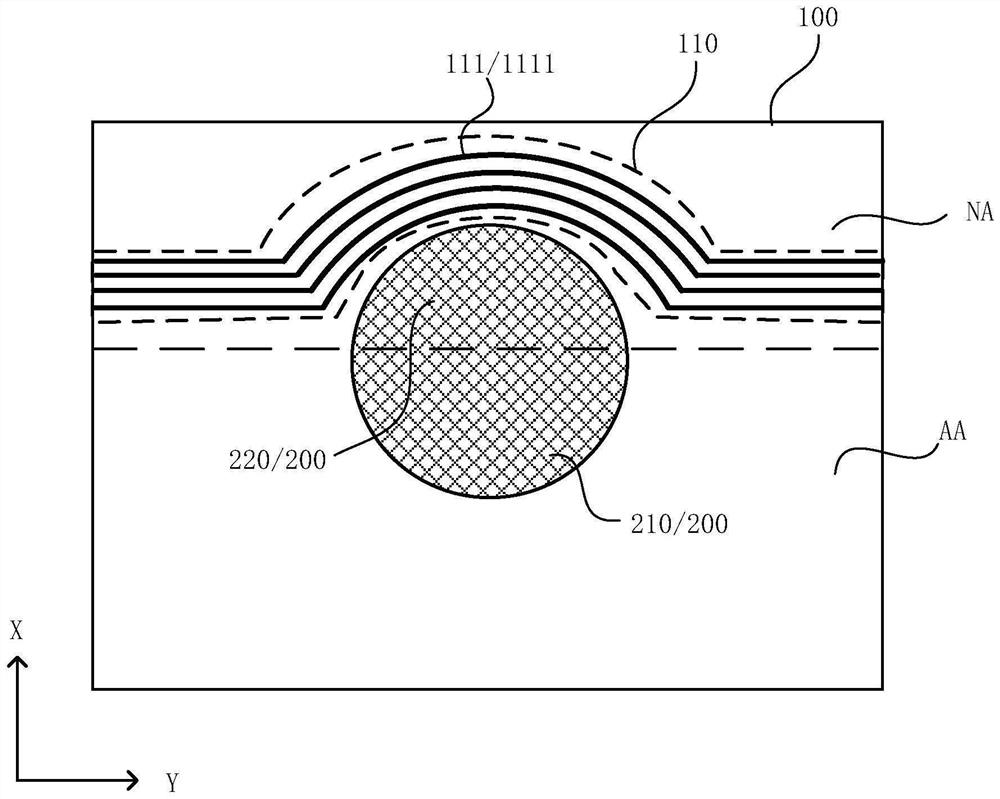

Embedded touch display screen and touch display device

ActiveCN104657016ASmall sizeDoes not affect the areaInput/output processes for data processingDisplay deviceHuman–computer interaction

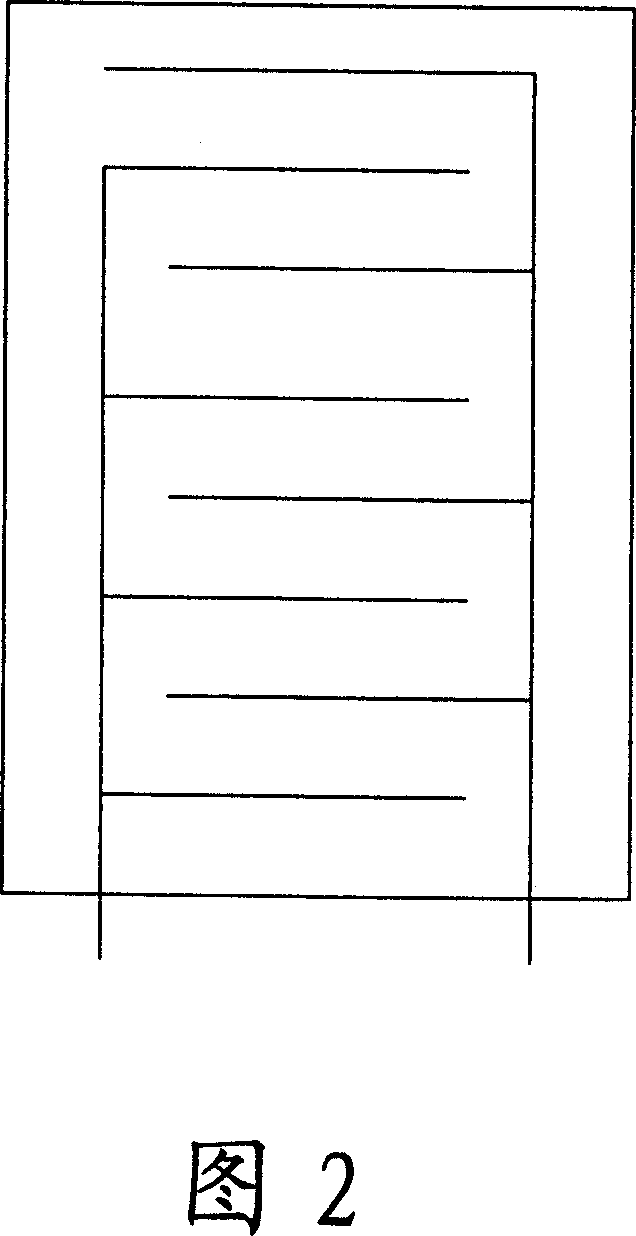

The invention discloses an embedded touch display screen and a touch display device. The embedded touch display screen comprises a display panel and a touch electrode, wherein the display panel comprises a display region and a frame region; the touch electrode covers the display region and extends to the frame region. Known from the above contents, according to the technical scheme provided by the invention, the size of the touch electrode is enlarged; except for the to-be-covered display region, the coverage region of the touch electrode extends to the frame region; by virtue of enlarging the size of the touch electrode, the touch sensitivity of edge parts of the display region is improved on the premise of not influencing the area of the display region.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD +1

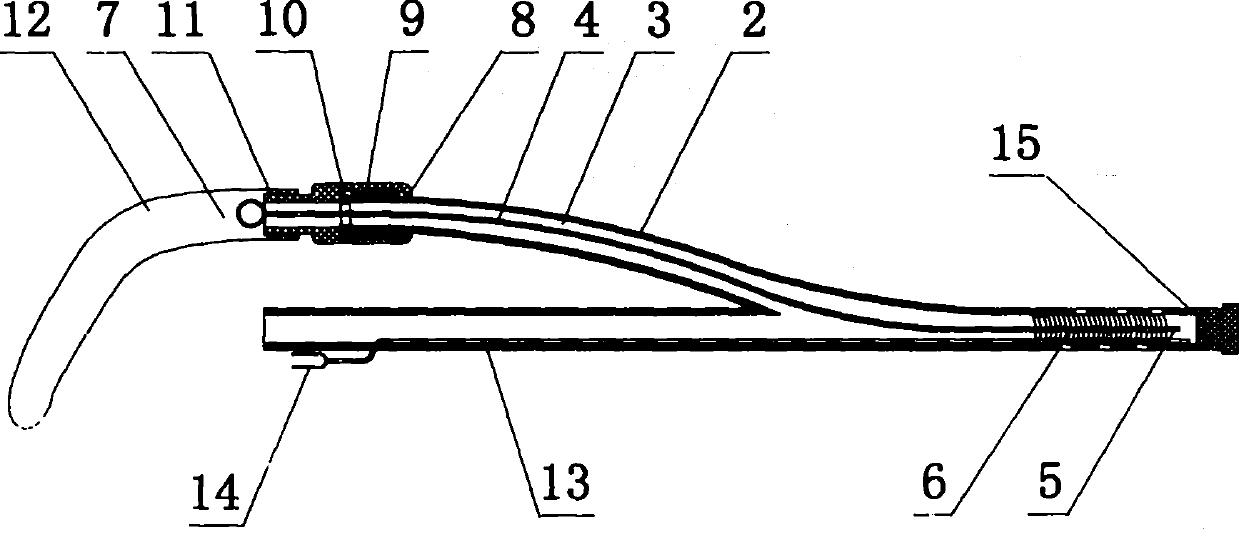

Airtight type drainage tube inner wall cleaning device

InactiveCN103861847ADoes not affect the areaDoes not affect the drainage effectHollow article cleaningDrainage tubesAir tightness

The invention discloses an airtight type drainage tube inner wall cleaning device. According to the airtight type drainage tube inner wall cleaning device, the pipe wall of the middle section of a drainage tube is provided with a cleaning channel tube which is identical to the drainage tube in diameter; a cleaning brush is mounted inside the cleaning channel tube, the tail end of the cleaning channel tube is provided with a tube joint, one end of the tube joint is provided with an internal thread port, the tail end of the cleaning channel tube is threadedly connected with the internal thread port, and an O-shaped seal ring is mounted between the connecting end surfaces of the cleaning channel tube and the internal thread port; the other end of the tube joint is provided with a retaining socket port, and a cleaning rod operating space closing sleeve made of soft airtight materials sleeves the retaining socket port. The airtight type drainage tube inner wall cleaning device has the advantages of effectively avoiding wound protecting material scrapping due to blocking of the drainage tube, prolonging the usage time of wound protecting materials, reducing waste, saving medical cost and facilitating repeated cleaning operation.

Owner:孙济宇

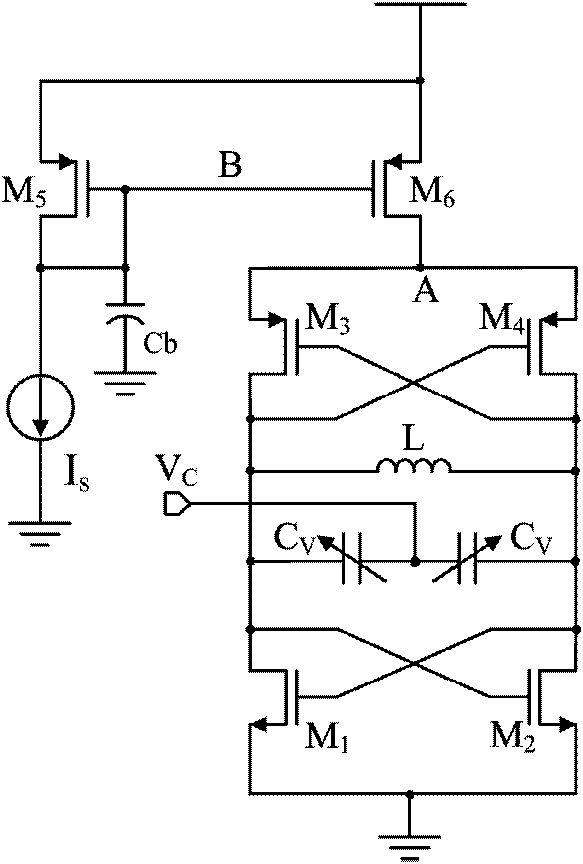

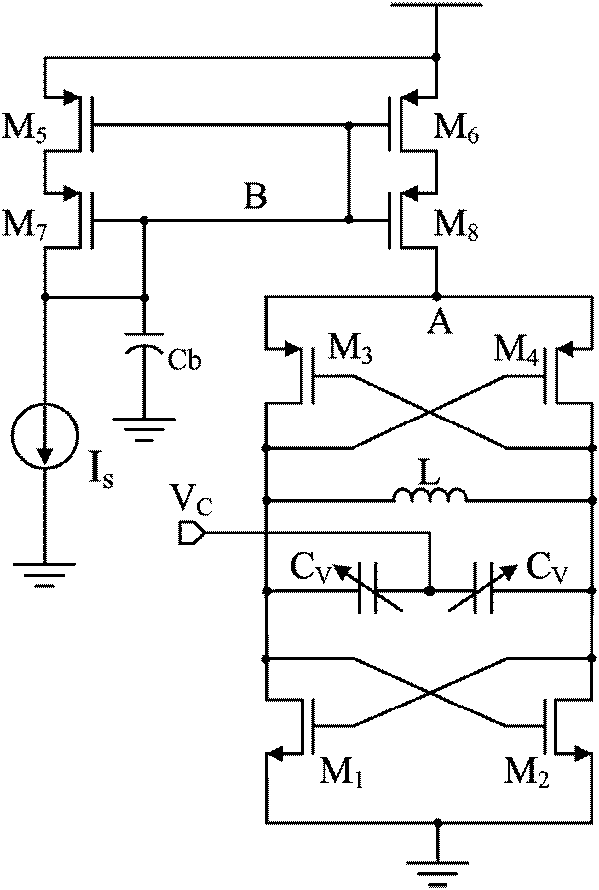

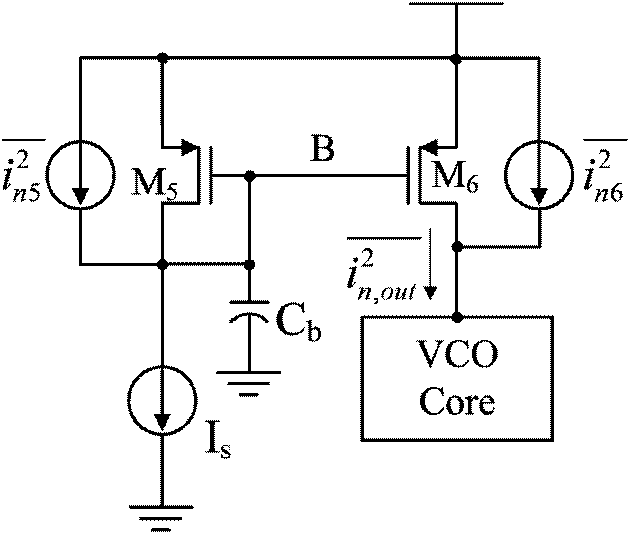

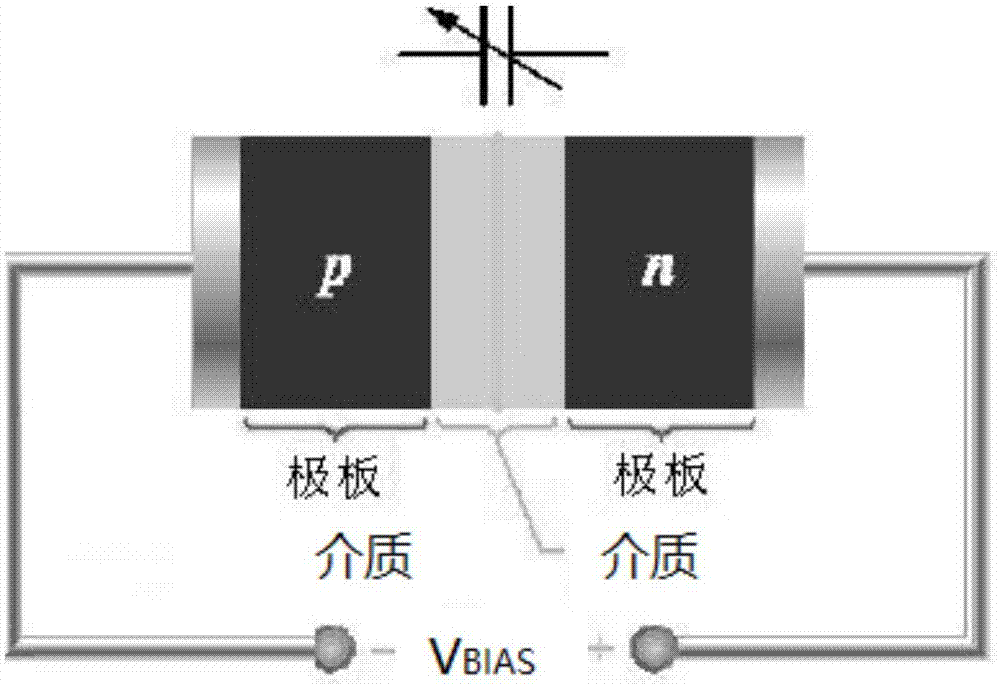

Low-phase-noise LC VCO based on improved tail current source structure

InactiveCN102088289AReduce phase noiseDoes not affect the areaPulse automatic controlOscillations generatorsMOSFETCapacitance

The present invention relates to a low-phase-noise LC VCO (a voltage controlled oscillator based on inductance-capacitance resonance) based on an improved tail current source structure, wherein the tail current source is in series with a P-MOSFET M6 working in a linearity area and a P-MOSFET M8 working in a saturation area, wherein the grids of the P-MOSFET M6 and the P-MOSFET M8 are connected with each other; a current mirror is composed of four P-MOSFETs in such a manner that two P-MOSFETs M5 and M6 which are connected in series are arranged parallelly with two P-MOSFETs M7 and M8 that are connected in series; the current is biased to the VCO through the current mirror. Because the P-MOSFET M6 working in the linearity area has a low drain-source voltage, introducing the M6 has little influence on the largest amplitude of VCO output signal. Moreover, introducing the M6 can increase the equivalent resistance looked from the drain terminal (i.e. point A) of the M8 so as to decrease theloss of a resonant cavity and make the LC VCO realize a lower phase noise.

Owner:XI AN JIAOTONG UNIV

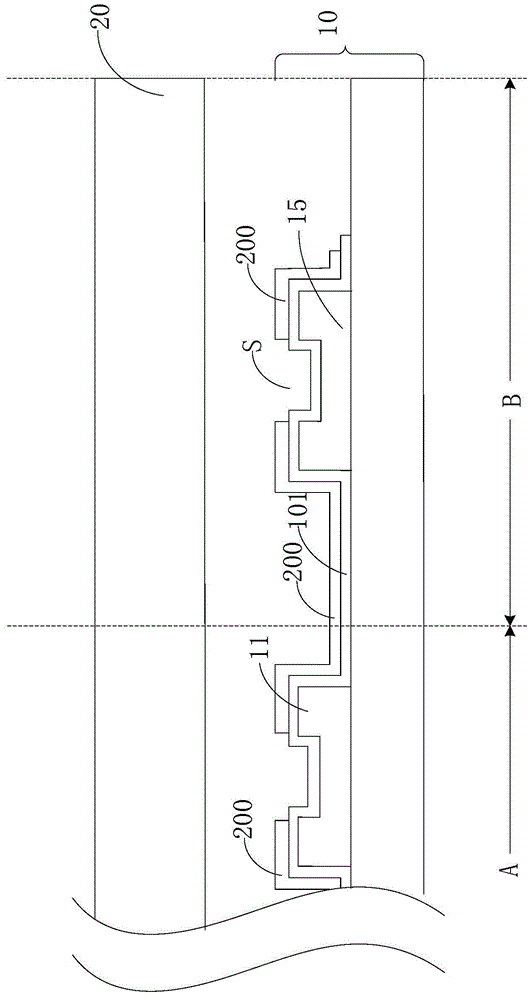

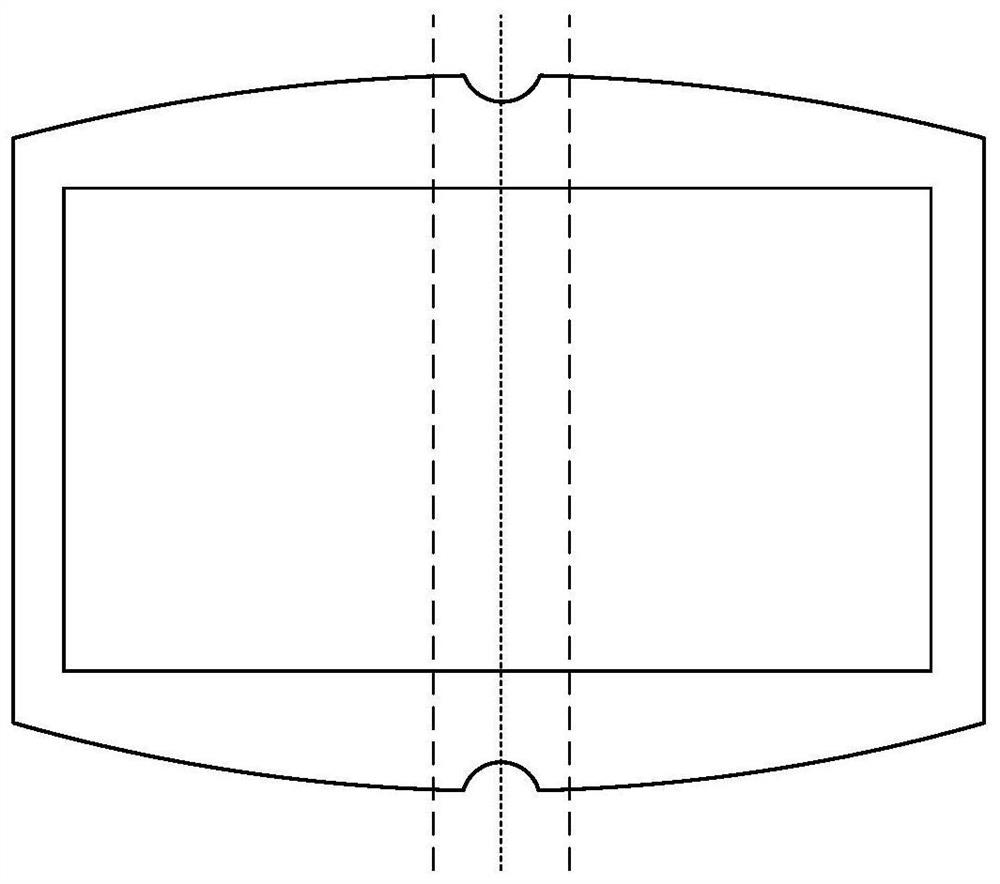

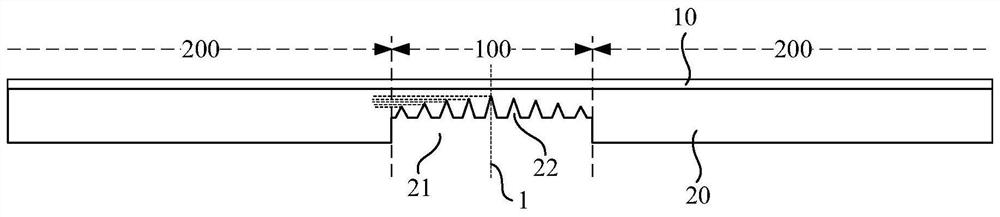

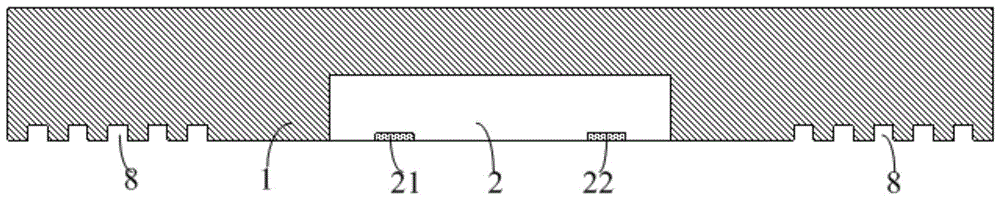

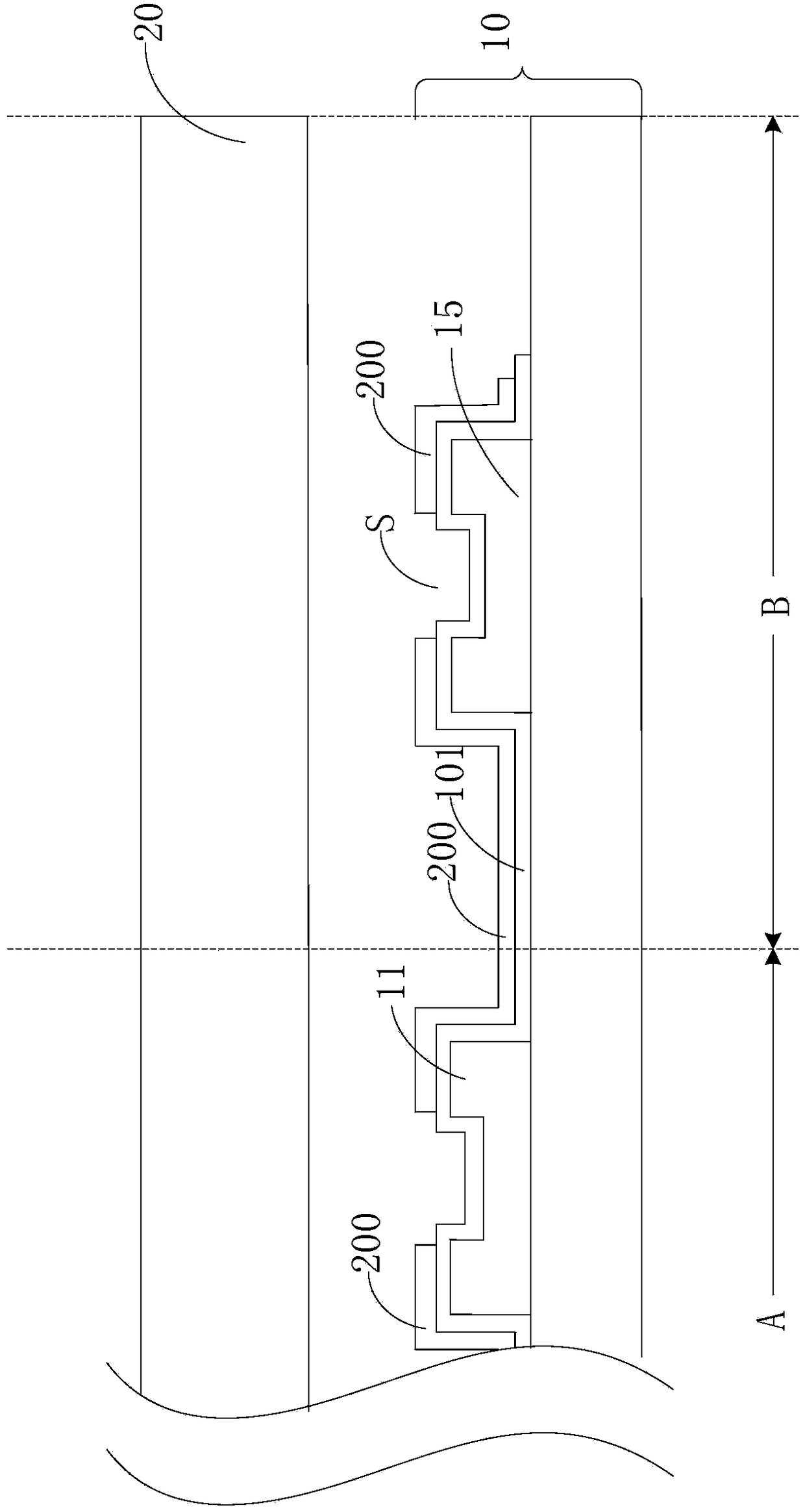

Foldable display device

ActiveCN112562519ARegular border appearanceGuaranteed separation effectPhotovoltaic energy generationIdentification meansDisplay deviceStructural engineering

The embodiment of the invention discloses a foldable display device. The foldable display device comprises a flexible display module and a supporting main body, the supporting main body of the bendingarea is flexible, a first bending notch is formed in one side, deviating from the flexible display module, of the supporting main body, a plurality of sawtooth-shaped second bending notches are further formed in the side, deviating from the flexible display module, of the first bending notch, one second bending notch extends along the folding line, and the thickness of the supporting main body atthe position of the second bending notch is gradually reduced in the direction parallel to the surface of the flexible display module and towards the folding line along the edge of the foldable display device. According to the embodiment of the invention, the problem that a film layer is easy to misplace and separate during bending due to the fact that an existing bendable display device cannot effectively control the position of the bending stress line can be solved, the bending stress line can be effectively controlled to coincide with the preset folding line, it is ensured that the supporting main body of the bending area is bent according to a preset mode, and misplacement and separation of the film layer are avoided.

Owner:HUBEI YANGTZE IND INNOVAION CENT OF ADVANCED DISPLAY CO LTD

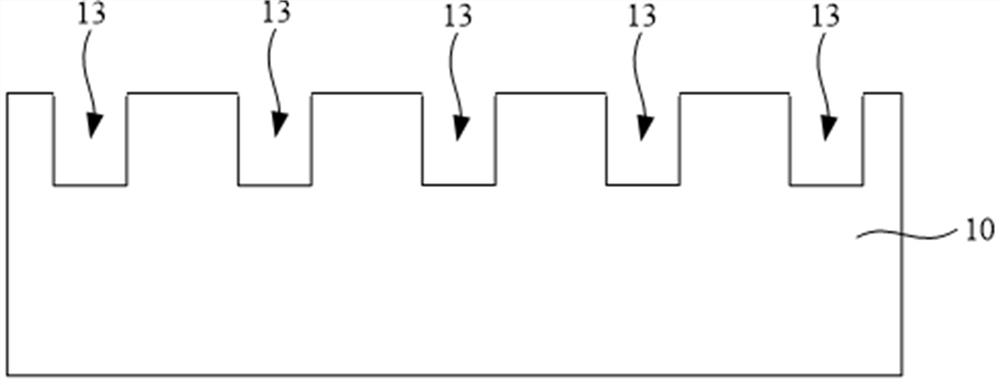

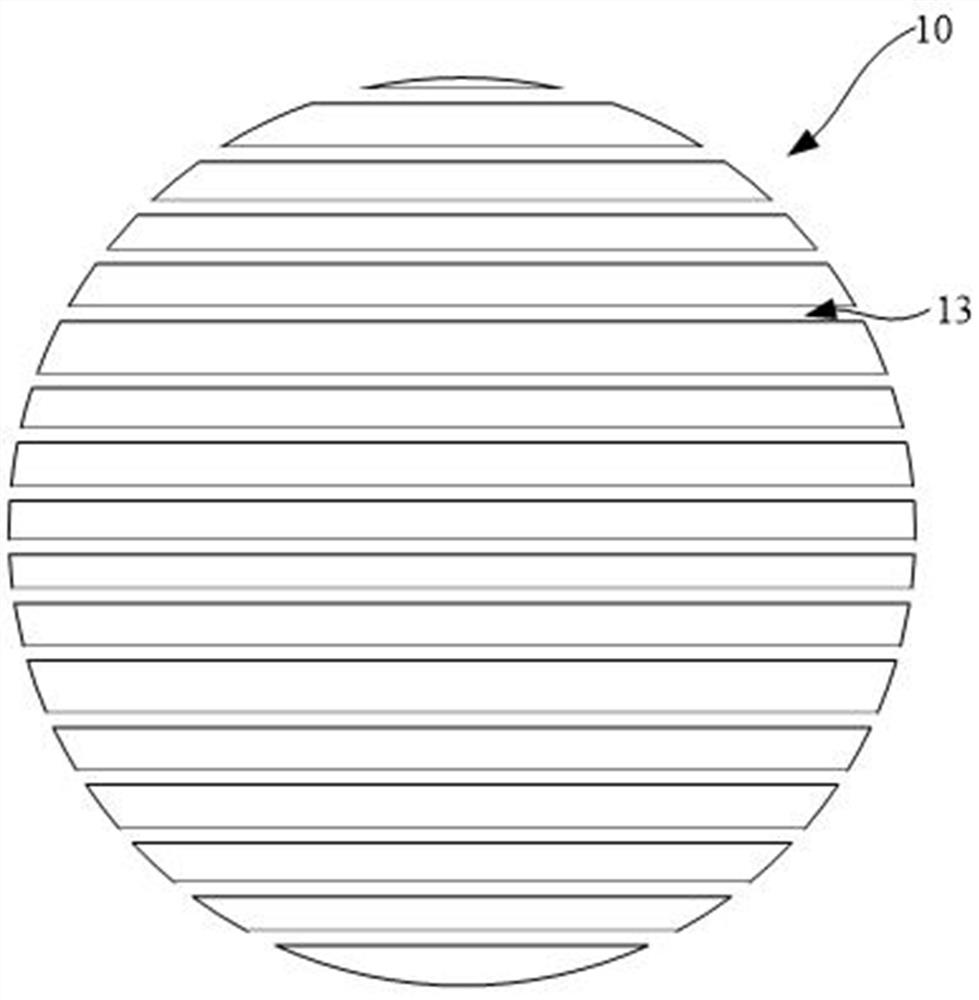

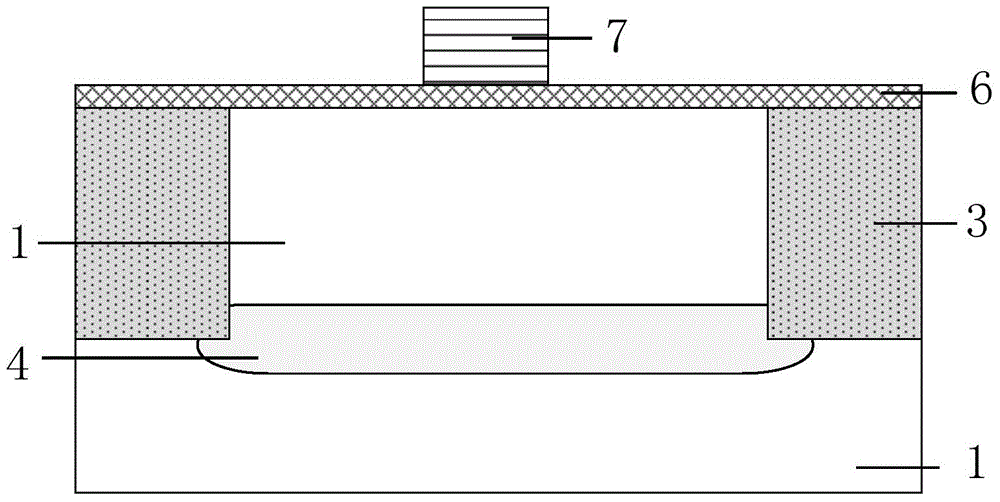

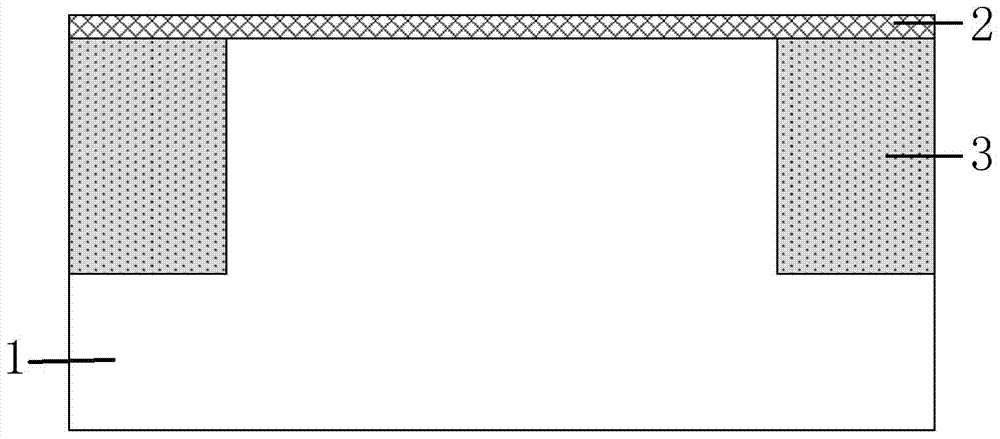

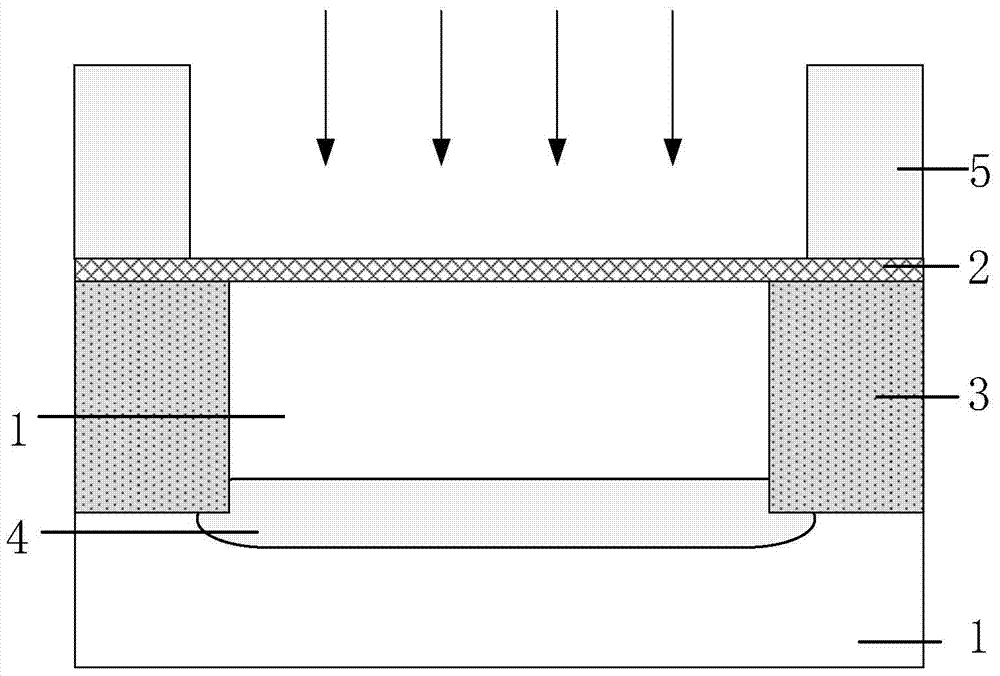

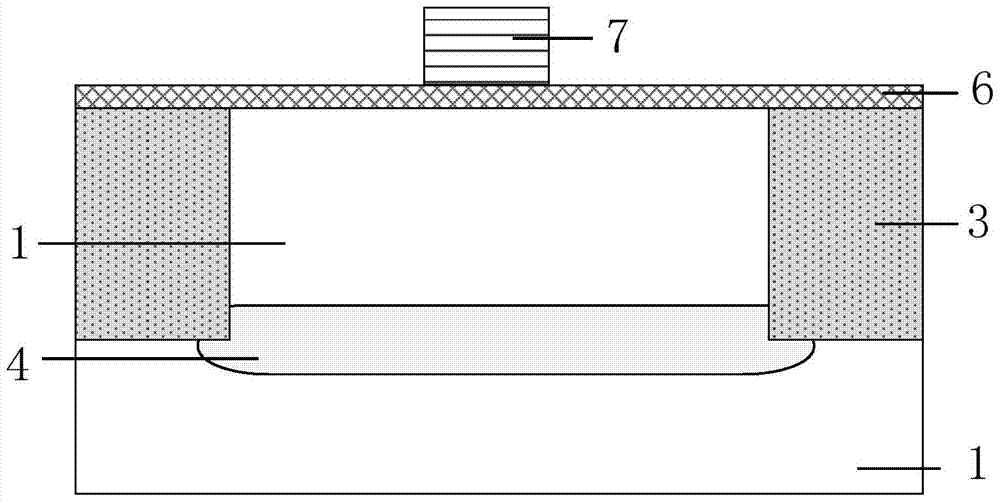

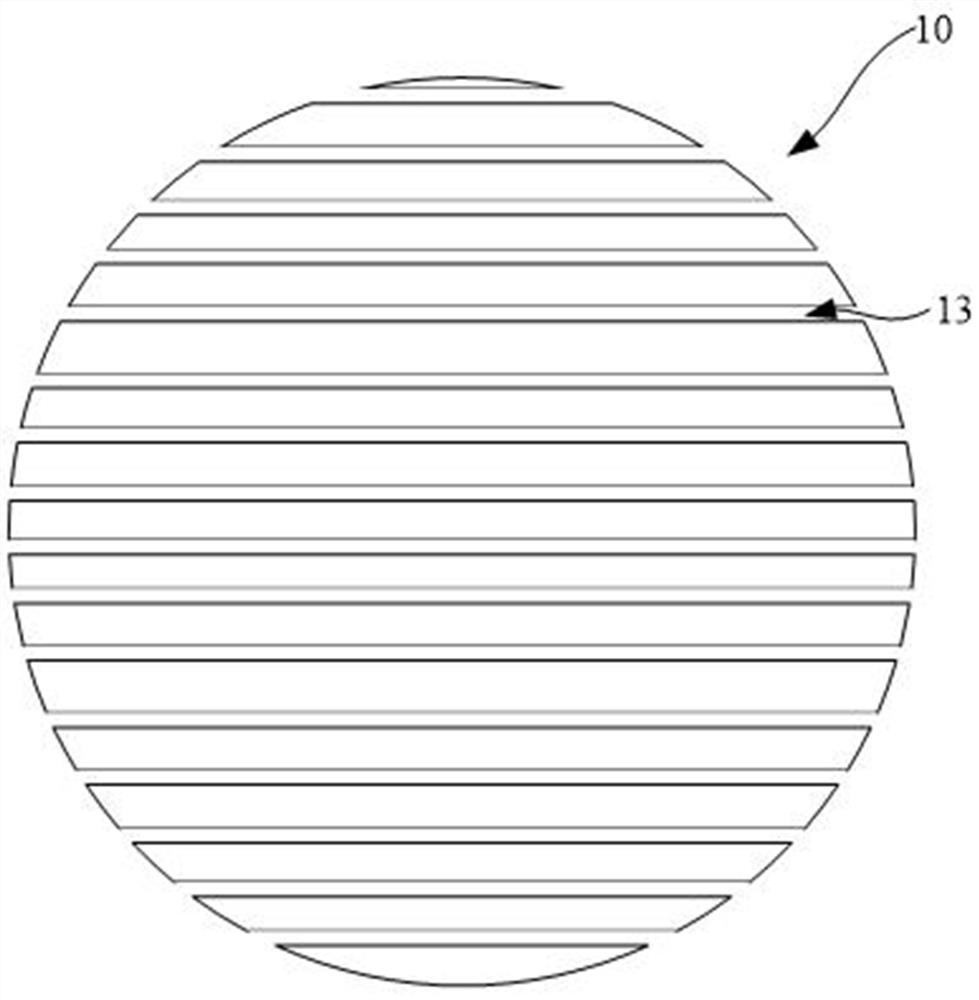

SOI wafer with high heat dissipation performance and preparation method of SOI wafer

ActiveCN113764366AImprove cooling effectSmall sizeSemiconductor/solid-state device detailsSolid-state devicesWaferCarbon nanotube

The invention provides an SOI wafer with high heat dissipation performance and a preparation method of the SOI wafer. The SOI wafer sequentially comprises a bulk silicon wafer, a buried oxide layer and a silicon device layer, a groove with a preset depth is formed in one side, close to the buried oxide layer, of the bulk silicon wafer, the groove is filled with a high-thermal-conductivity material, the high-thermal-conductivity material is fixed by adopting heat dissipation glue, and the high-thermal-conductivity material is a carbon nano tube or molybdenum disulfide. According to the invention, the grooves are formed in the bulk silicon wafer, and the grooves are filled with the high-thermal-conductivity material made of the carbon nanotubes or the molybdenum disulfide, so that the heat dissipation performance of an SOI circuit can be effectively improved based on the high thermal conductivity of the carbon nanotubes and the molybdenum disulfide, and the size of the SOI wafer is made to be larger; in addition, the high-thermal-conductivity material is arranged in the bulk silicon wafer, the area of the silicon device layer is not affected, the utilization rate of the active region is improved, the cost is reduced, and the integration level is improved.

Owner:MICROTERA SEMICON (GUANGZHOU) CO LTD

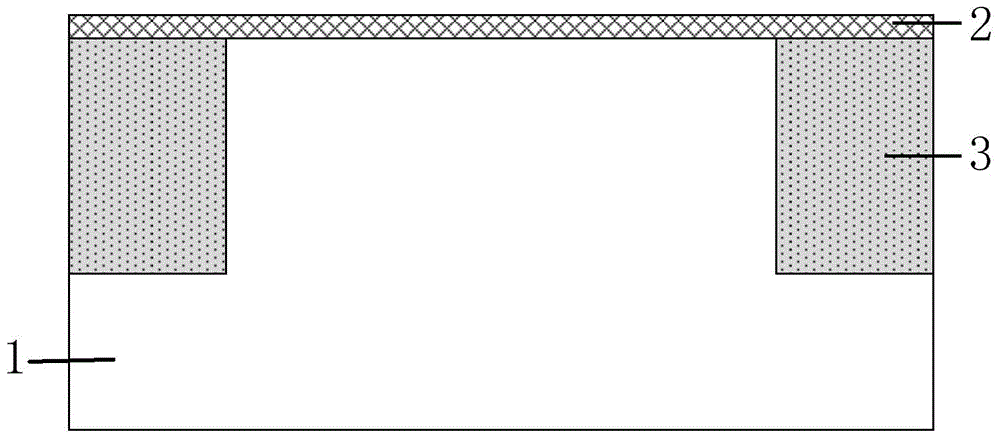

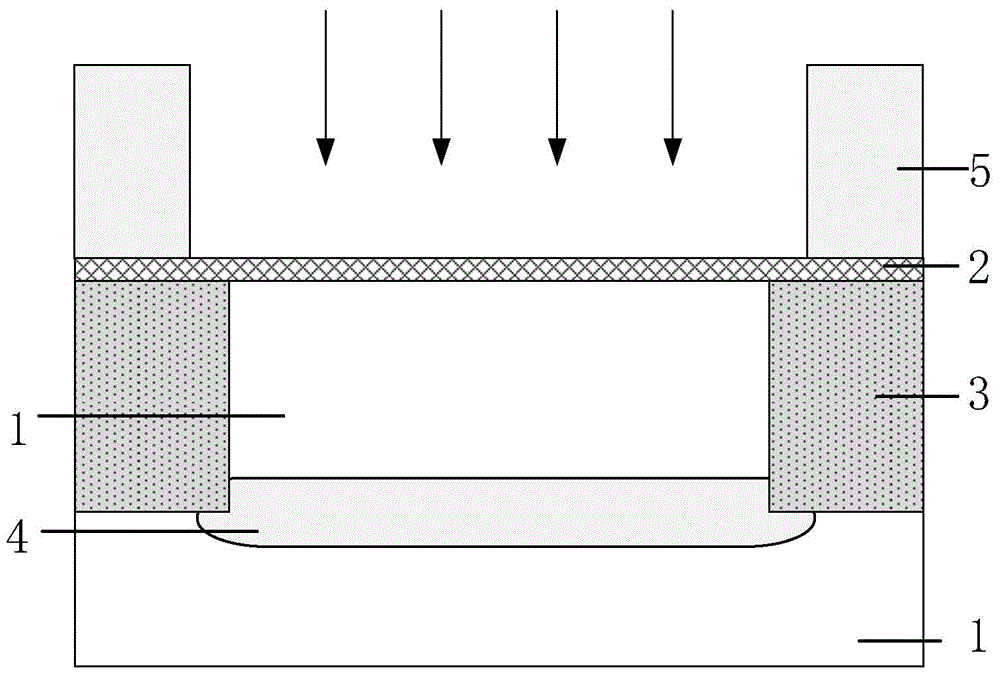

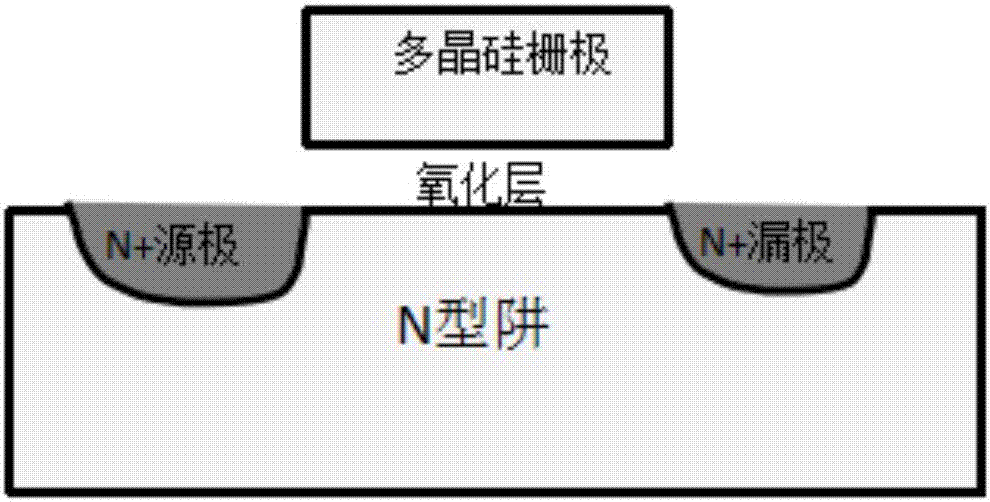

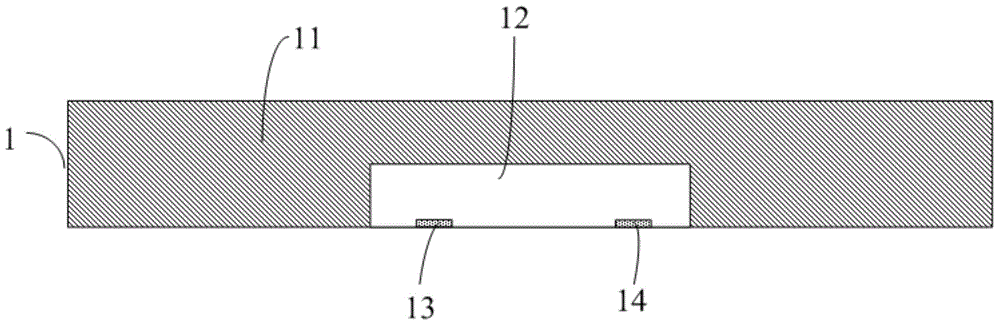

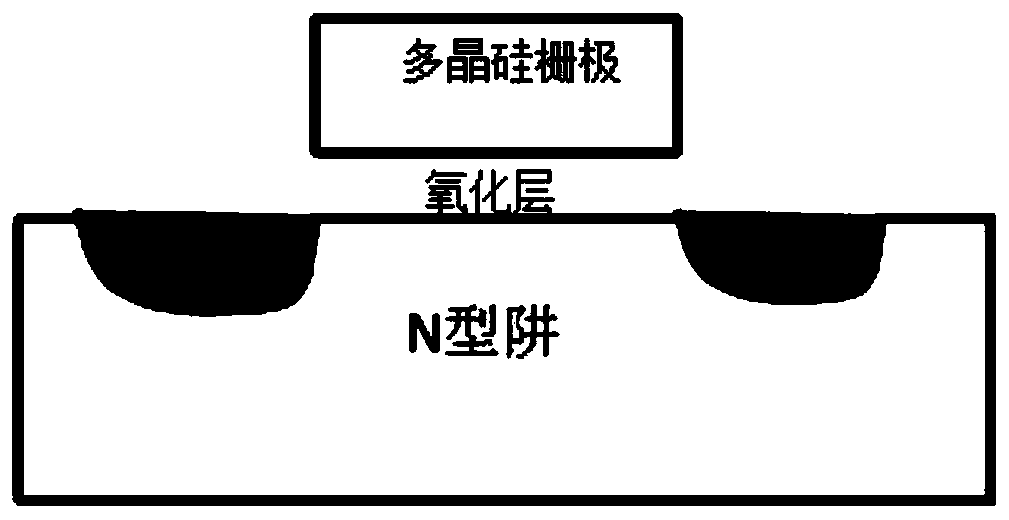

Production method of tunneling field-effect transistor

ActiveCN104362095APerformance is not affectedDoes not affect the areaSemiconductor/solid-state device manufacturingSemiconductor devicesCMOSP type silicon

The invention discloses a production method of a tunneling field-effect transistor and belongs to the field of CMOS (complementary metal-oxide-semiconductor transistor) ULSI (ultra-large scale integrated circuits) and their field-effect transistor logic devices. According to the production method, a p-type silicon wafer of relative high impedance is used as a trench region and a body region of a TFET (tunneling field-effect transistor) device, a mask for injection of an N<-> region is added on basis of the standard CMOS-IC process, the N<-> region injected deep in a trench, device isolation is achieved for the TFET in circuit application, and device performances and device area are unaffected.

Owner:PEKING UNIV

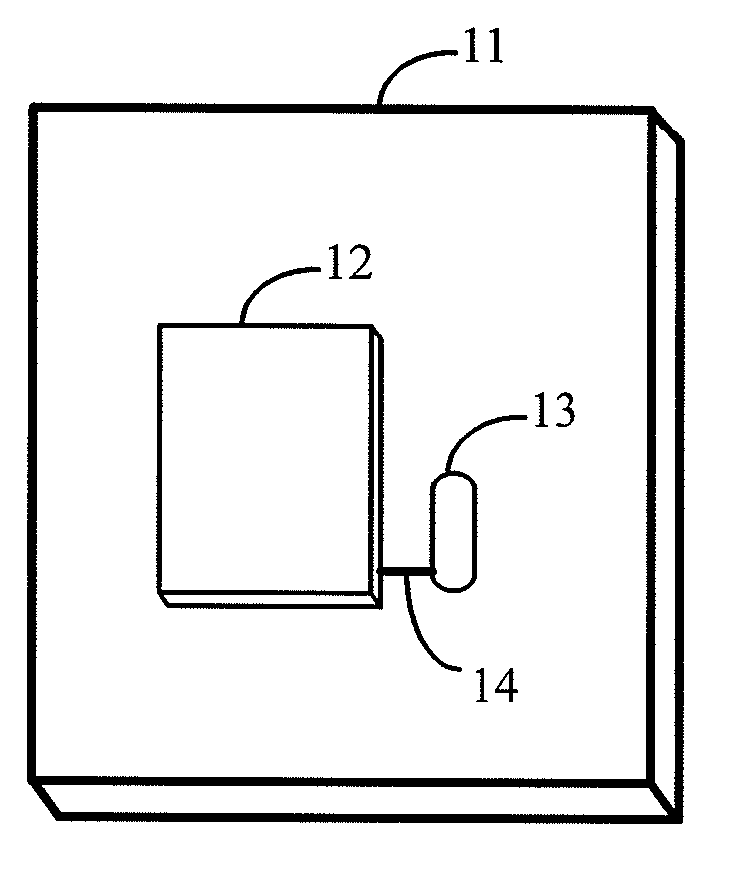

Radio-frequency filter piece packaging structure

InactiveCN102983832ADoes not affect the areaLow costImpedence networksSolid-state devicesEngineeringRadio frequency

The invention provides a radio-frequency filter piece packaging structure. An inductance machine of the structure is low in cost and small in occupied space, and inductance is easy to adjust. The radio-frequency filter piece packaging structure comprises a packaging base plate and one or a plurality of pipe cores, and further comprises a pipe core bonding zone which is arranged on the pipe core, a plurality of base plate bonding zones which are arranged on the packaging base plate, and a bonding line which connects the plurality of base plate bonding zones, and connects one or a plurality of the base plate bonding zones and each pipe core bonding zone on the one or the plurality of pipe cores.

Owner:TIANJIN UNIV

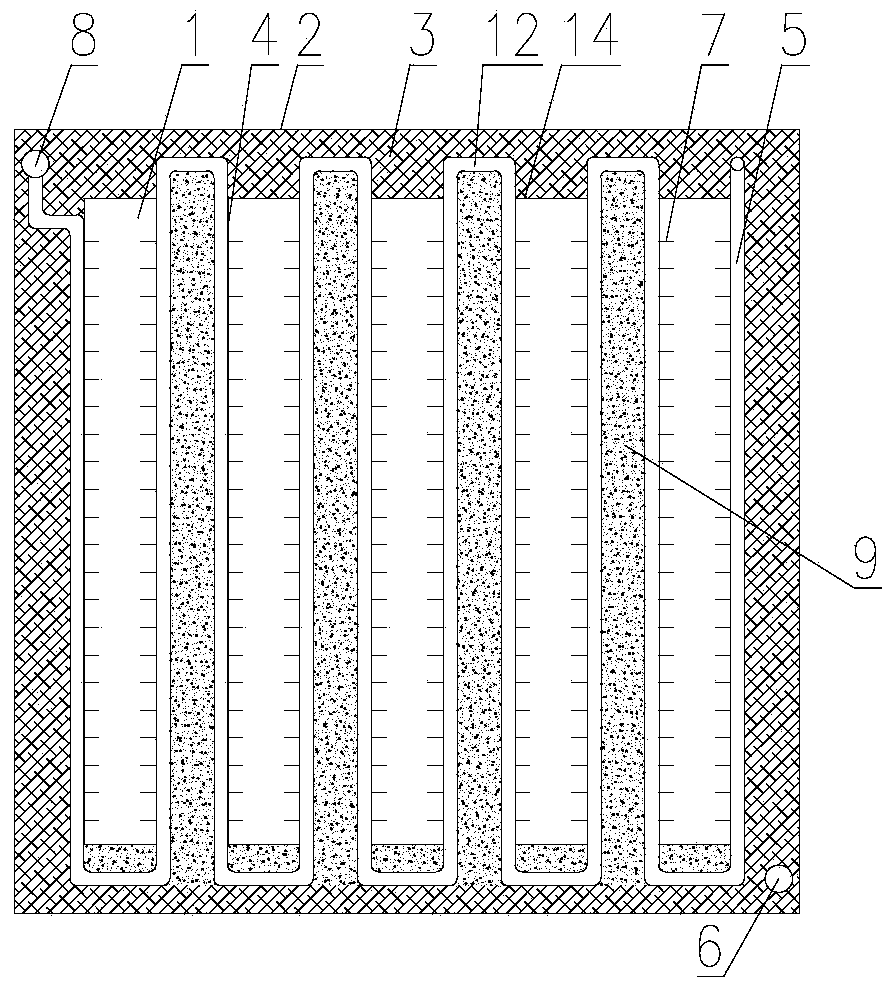

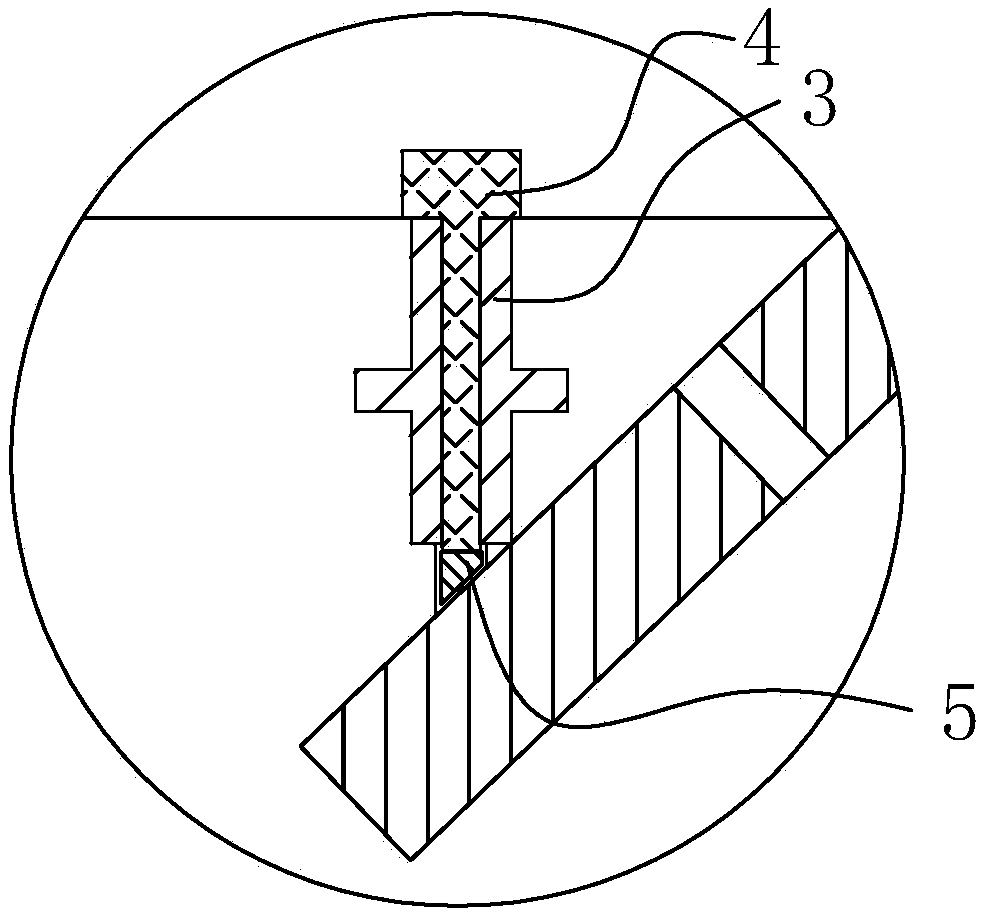

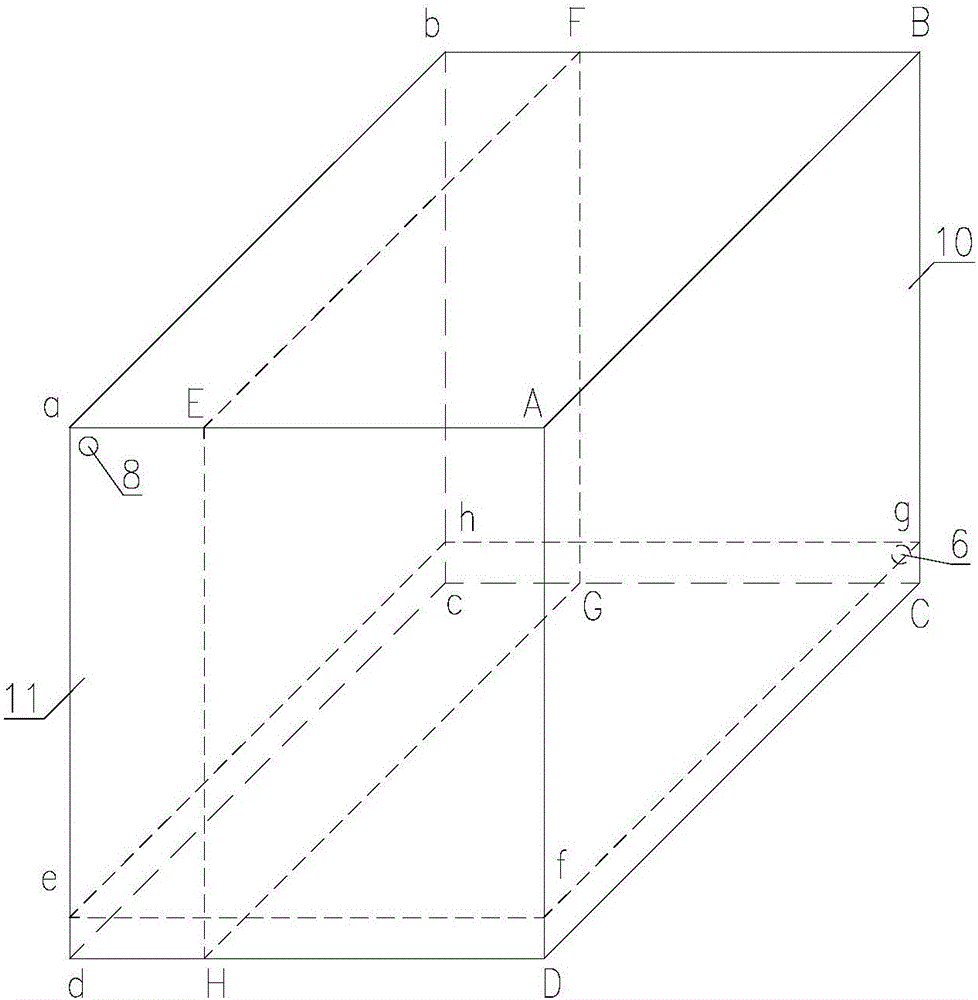

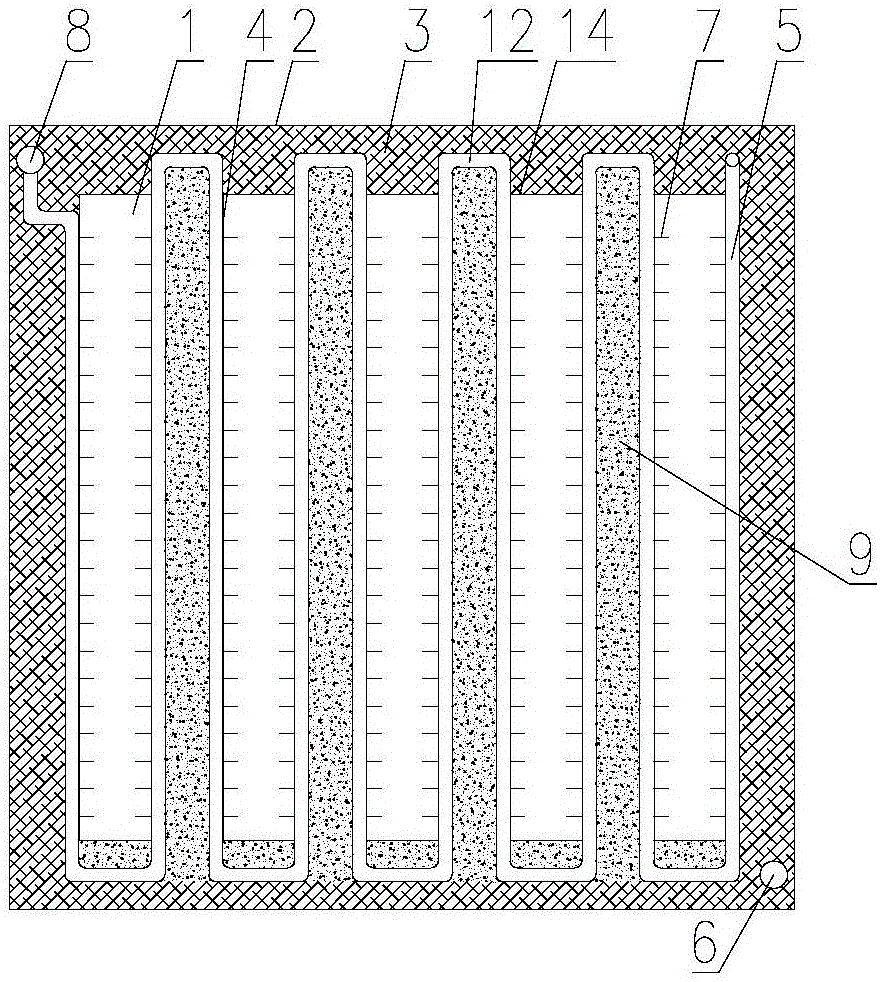

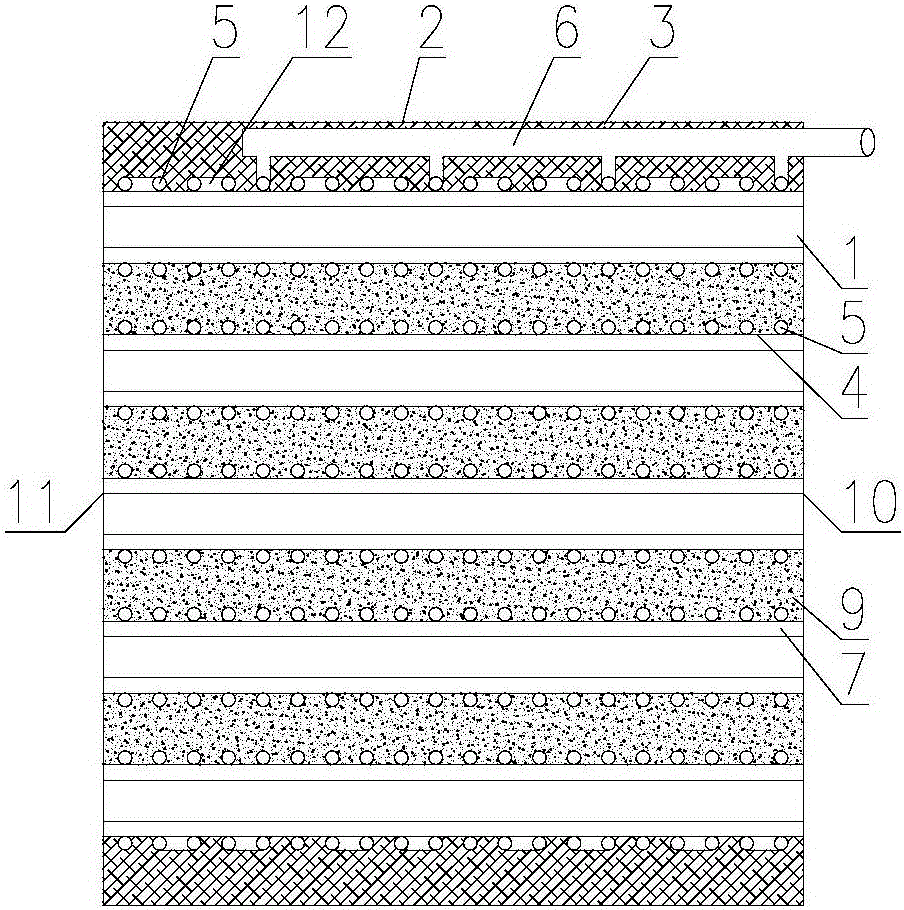

Piece type heat exchange silencer

ActiveCN103471226AReduce resistanceDoes not affect the areaNoise suppressionStationary tubular conduit assembliesWaste heat recovery unitThermal insulation

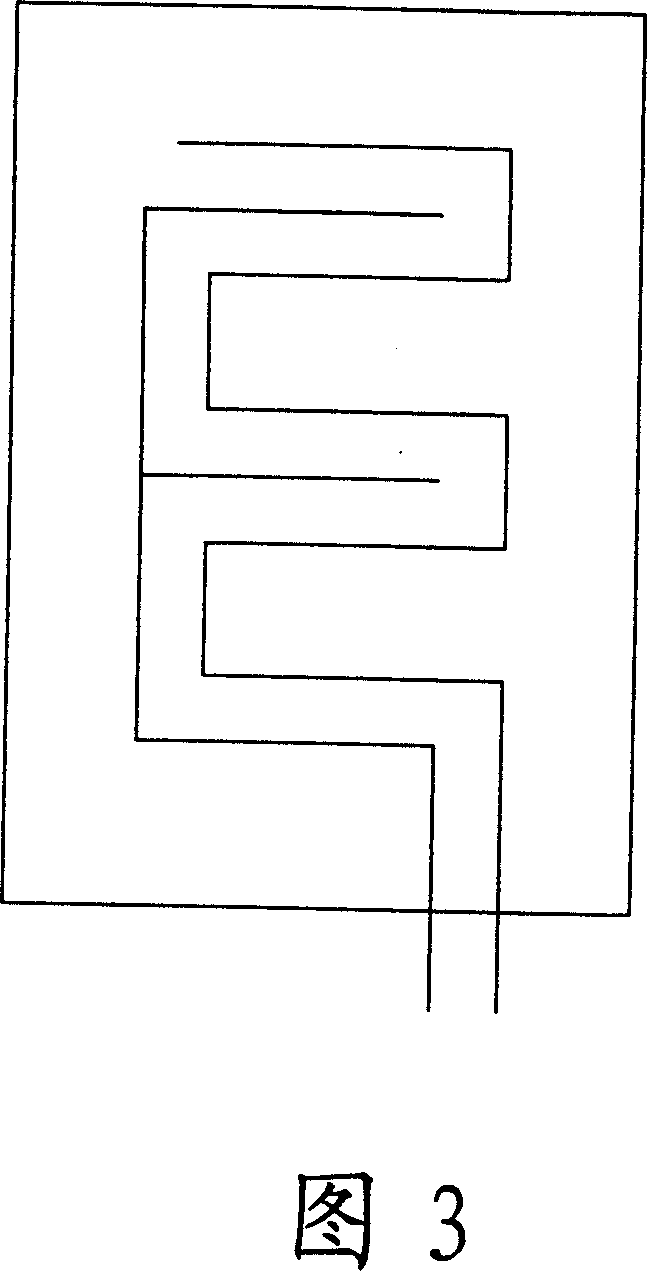

The invention discloses a piece type heat exchange silencer which satisfies a plurality of technical indexes such as a noise eliminating coefficient, the heat exchange efficiency, regenerative noise, resistance loss and the like. According to the piece type heat exchange silencer, space wasting is reduced on the condition that all indexes are satisfied; the noise eliminating coefficient is maintained, the regenerative noise, and the flow resistance are increased due to the fact that a heat exchange pipe bundle is arranged inside noise eliminating materials; purposes of waste heat recovery or air conditioning treatment are achieved and extra space is not occupied during the heat exchange process; heat dissipation loss is reduced due to the fact that peripheral noise eliminating materials are made of thermal insulation type materials; the heat exchange effect is increased due to the fact that the middle noise eliminating materials are made of ordinary noise eliminating materials.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

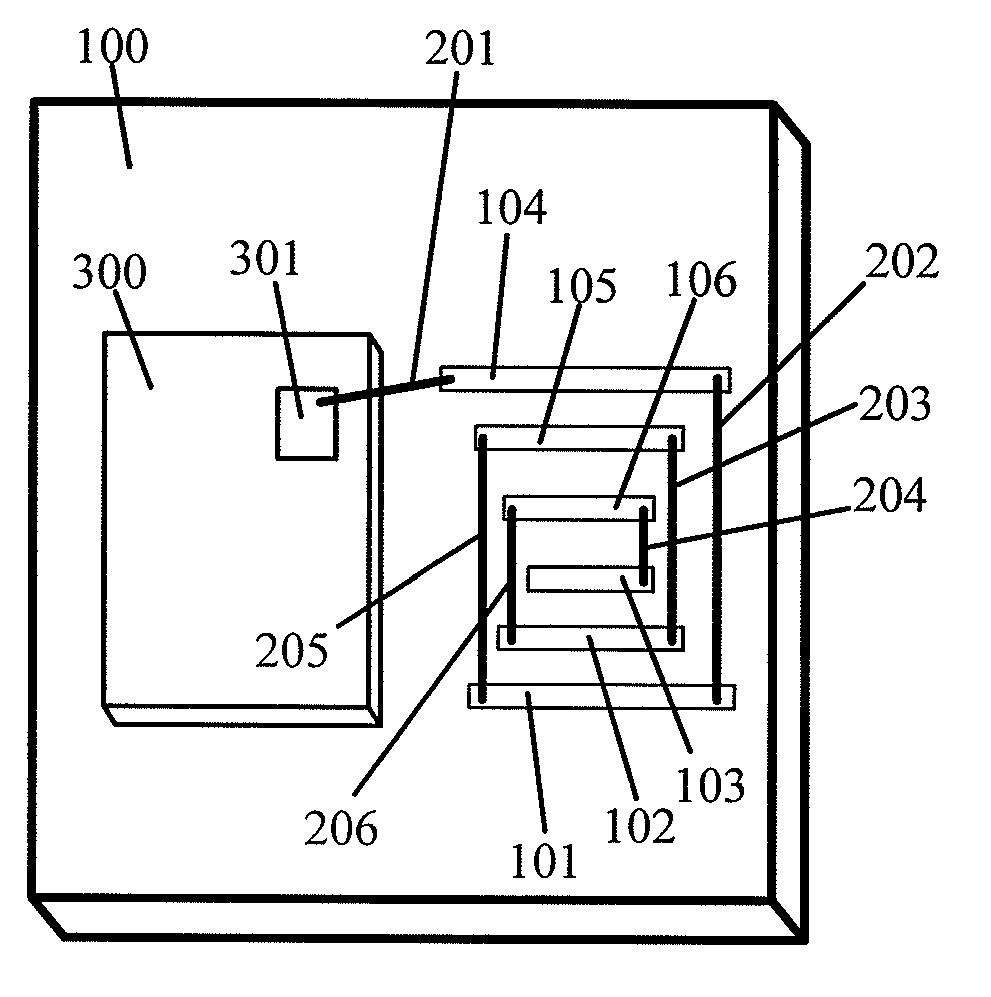

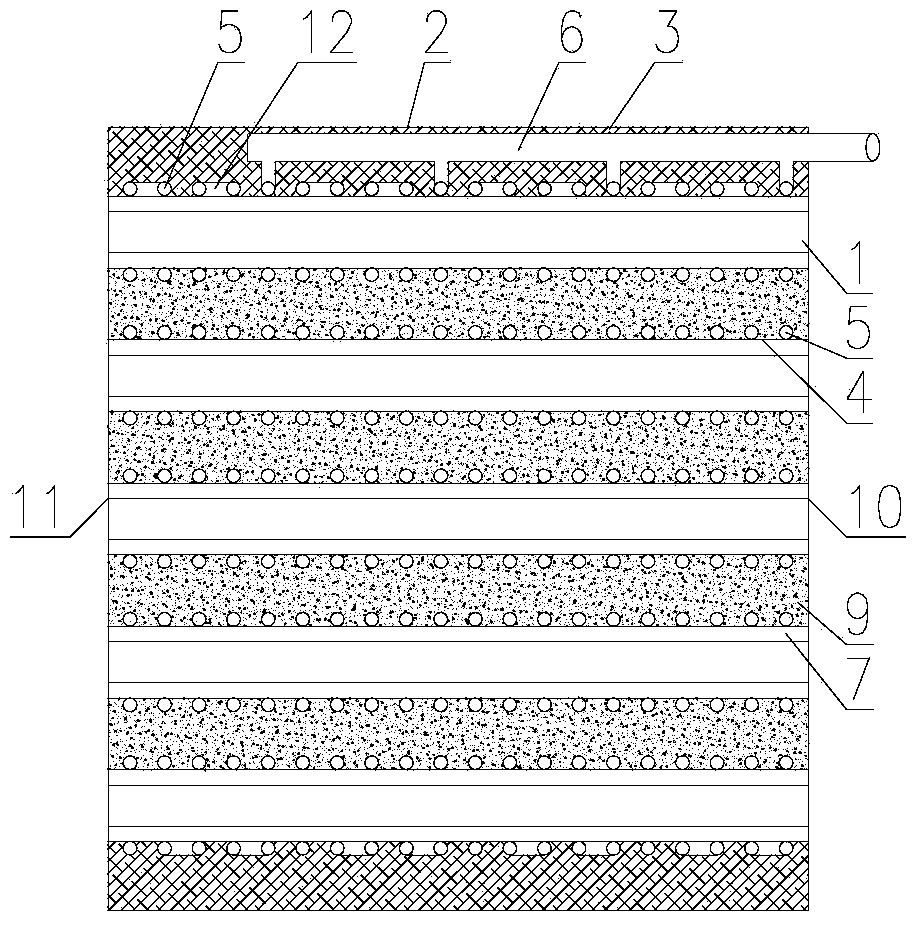

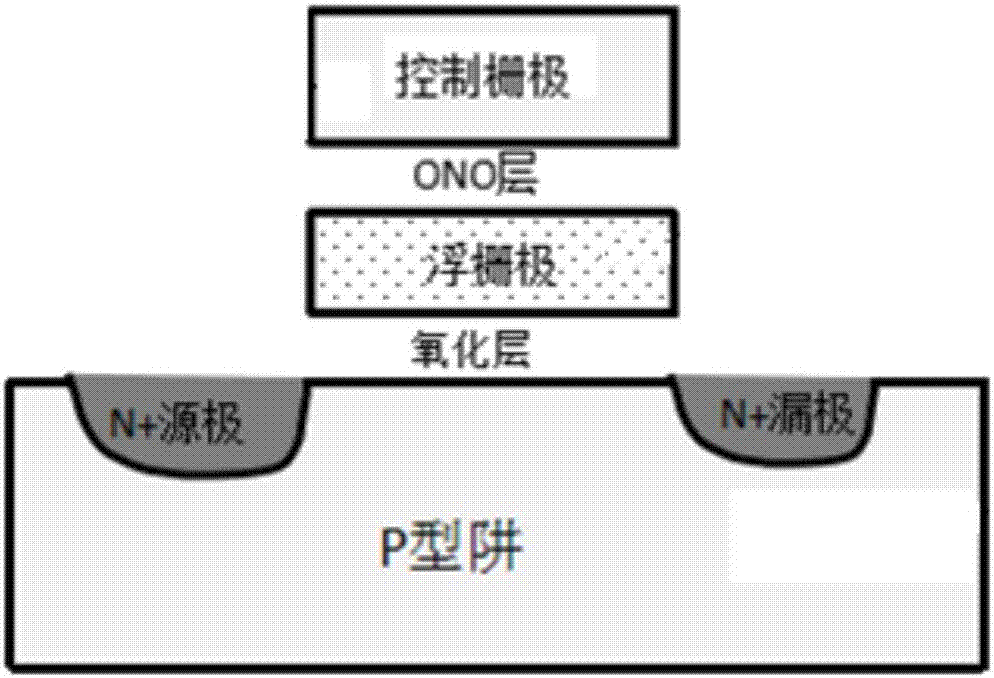

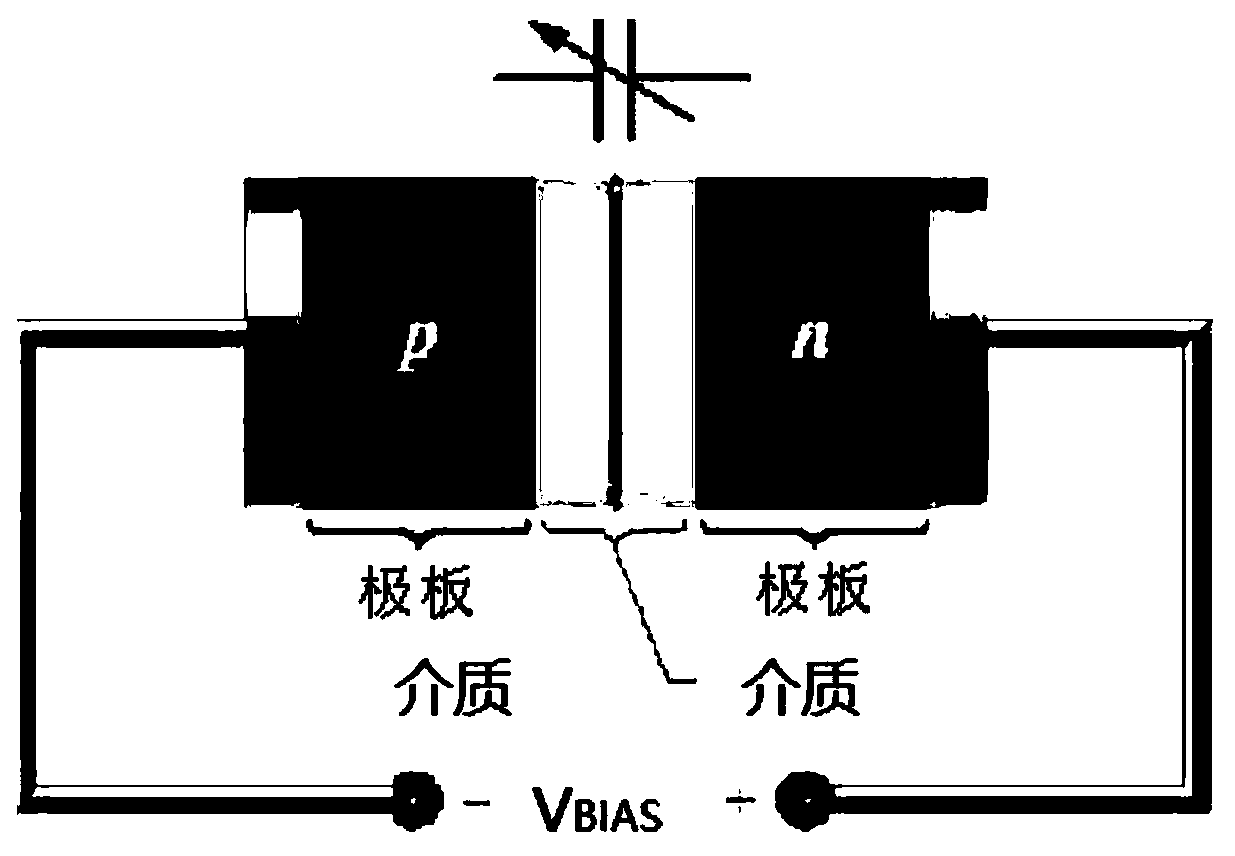

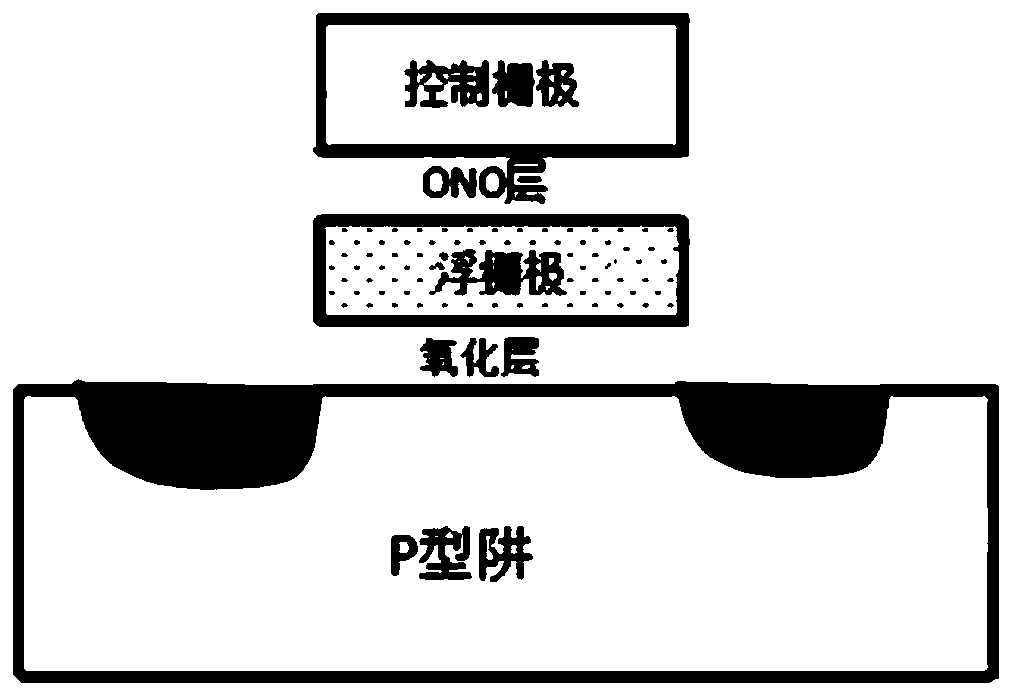

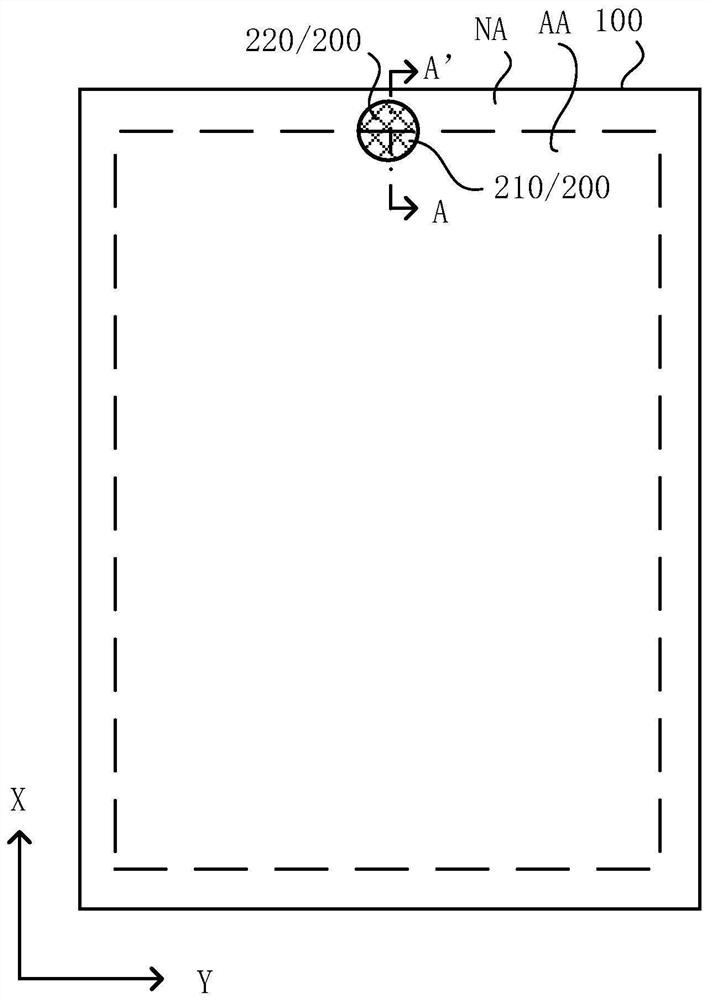

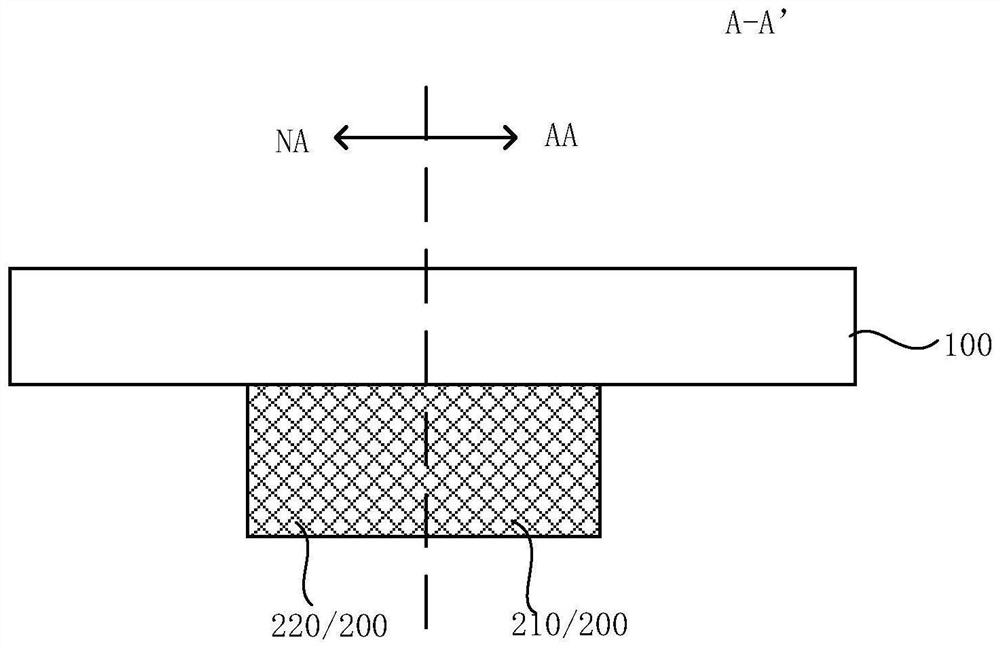

Varactor structure used in flash memory circuit and manufacture method thereof

ActiveCN107346792AIncrease capacitanceLarge capacitySemiconductor/solid-state device manufacturingSemiconductor devicesVaricapEngineering

The invention provides a varactor structure used in a flash memory circuit and a manufacture method thereof. The varactor structure comprises a substrate, a first insulating layer formed on the substrate, a floating gate formed on the first insulating layer, a control gate arranged opposite to the floating gate, and a second insulating layer formed between the floating gate and the control gate. A source and a drain are formed on the substrate. A first connection wire separately led out from the floating gate and is used as a polar plate of the capacitor of the varactor. The source lead out wire, the drain lead out wire and the lead out wire of the control gate are electrically connected together to form a second connection wire, and the second connection wire is used as the other polar plate of the capacitor of the varactor. The first insulating layer and the second insulating layer are used as the dielectric layer of the capacitor of the varactor. The varactor used in the flash memory circuit can meet the demand of a large-capacity capacitor, and can take the trend of chip miniaturization into account.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

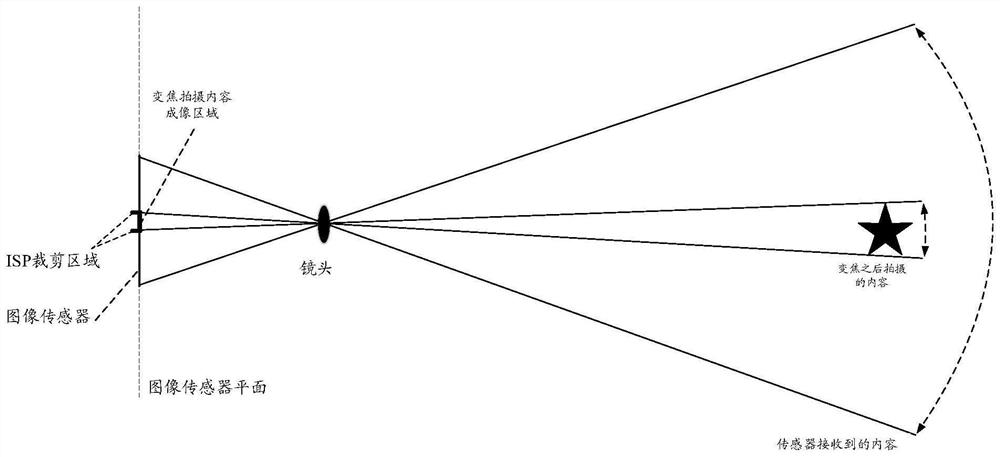

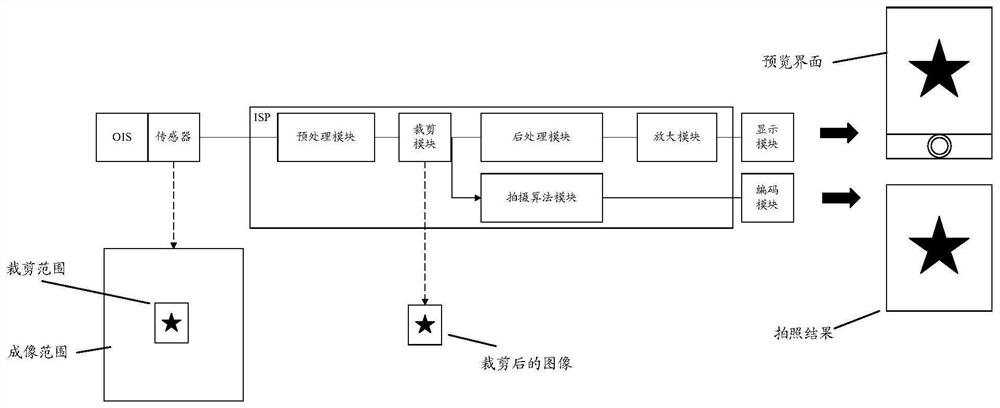

Shooting method and equipment

ActiveCN112825543AImprove experienceDoes not affect the areaTelevision system detailsColor television detailsComputer graphics (images)Engineering

The embodiment of the invention provides a shooting method and electronic equipment, and the method is applied to the electronic equipment, and comprises: receiving a digital zooming instruction, and carrying out the amplification of an original image in response to the digital zooming instruction; receiving first user operation, and determining a user concerned area from the amplified original image in response to the first user operation; and cutting the original image before amplification according to the user concerned area, and filling the interactive interface of the electronic equipment with the cut original image. According to the technical scheme provided by the invention, when the electronic equipment carries out shooting, digital zooming is carried out, especially under high-magnification digital zooming, the original image is cut according to the user concerned area determined by the user, so that the influence of shaking of the electronic equipment on final imaging is relatively small, and the user experience is improved.

Owner:HUAWEI TECH CO LTD

A precision seeding operation system and method based on an unmanned aerial vehicle platform

ActiveCN104255137BReduce labor intensityImprove work efficiencyAircraft componentsBroadcast seedersElectric machineEngineering

Owner:湖南星索尔航空科技有限公司

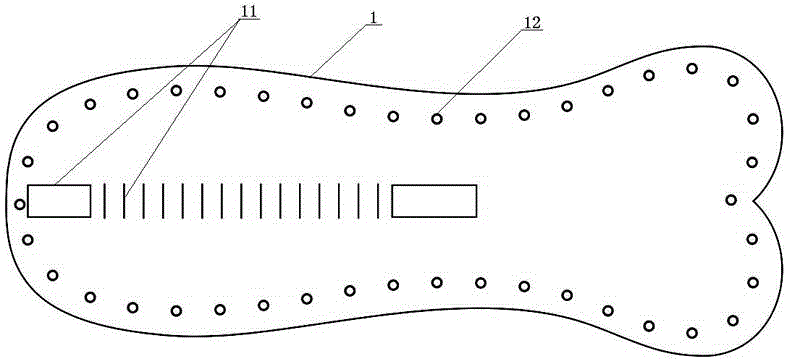

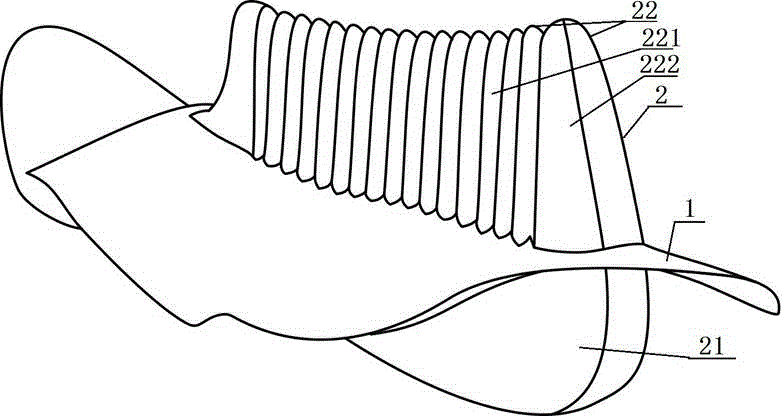

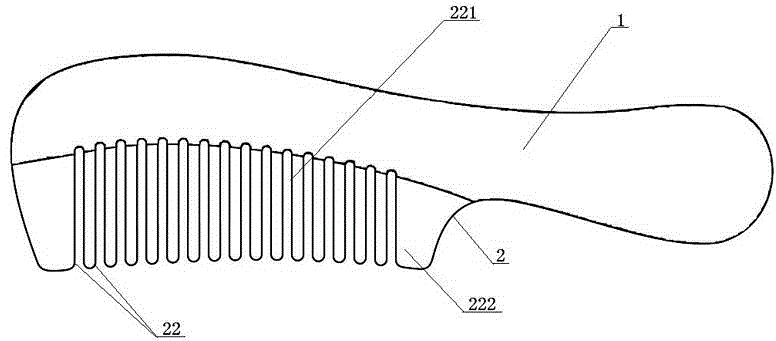

Flexible comb protective sleeve and platy comb comprising same

InactiveCN104665202ASimple and compact structureDelayed bending deformationHair combsEngineeringMechanical engineering

The invention discloses a flexible comb protective sleeve and a platy comb comprising the same. The flexible comb protective sleeve comprises a protective sleeve body, wherein the protective sleeve body is formed by cutting a flexible material, and the protective sleeve body can be fixedly arranged and coated on a comb body of a corresponding comb; multiple comb teeth which are arranged at intervals are arranged on the side surface of the comb body of the platy comb in a stretching way, the comb body of the platy comb is fixedly provided with the protective sleeve body which is formed by cutting the flexible material, and the comb body of the platy comb which is made of natural materials such as bamboo, wood and horn bones can be covered by the protective sleeve body. According to the flexible comb protective sleeve disclosed by the invention, the area that the surface of the comb body is directly in contact with natural air can be effectively reduced on the premise that a normal combing function of the comb is not affected, the easy-to-deform comb body on the platy comb which is made of the bamboo, the wood or the horn bones is enabled to adapt to the change of the natural air, bending deformation of the comb due to damping can be effectively delayed, the platy comb can be prevented from being broken to a certain degree, the service life of the platy comb is effectively prolonged, the cost is low, and the practicability is high.

Owner:刘燕西

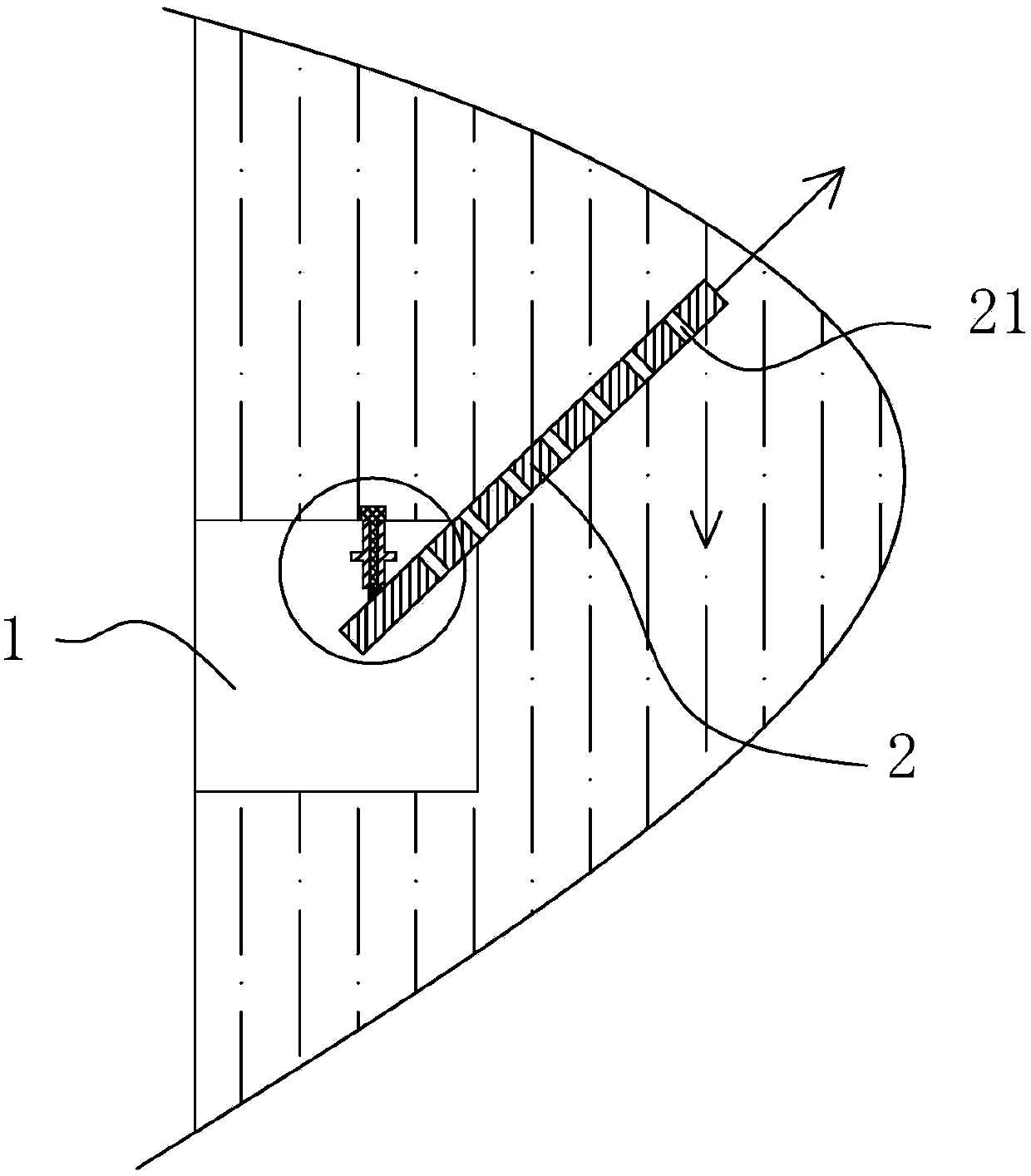

River garbage interception structure for municipal engineering

PendingCN107829415AEasy to cleanDoes not affect the areaWater cleaningRiver routingAgricultural engineering

The invention discloses a river garbage interception structure for municipal engineering. The river garbage interception structure for the municipal engineering comprises an intercepting pier arrangedin a river channel, and an intercepting plate extending towards the river channel is arranged on the intercepting pier; and an included angle between the extending direction of the intercepting plateand the direction of water flow is an obtuse angle, and a plurality of through-flow holes are formed in the intercepting plate. Because the through holes are formed, except for being able to intercept garbage, the through-flow area cannot be affected. Moreover, the obtuse angle is formed between the intercepting plate and the river flow direction, so that the garbage is intercepted between the intercepting plate and the river channel wall, and cleaning of the garbage by people is convenient. The river garbage interception structure for the municipal engineering is used for municipal bridges.

Owner:FOSHAN UNIVERSITY

A plate heat exchange muffler

ActiveCN103471226BReduce resistanceDoes not affect the areaNoise suppressionStationary tubular conduit assembliesWaste heat recovery unitFriction loss

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

A kind of preparation method of tunneling field effect transistor

ActiveCN104362095BPerformance is not affectedDoes not affect the areaSemiconductor/solid-state device manufacturingSemiconductor devicesCMOSP type silicon

Owner:PEKING UNIV

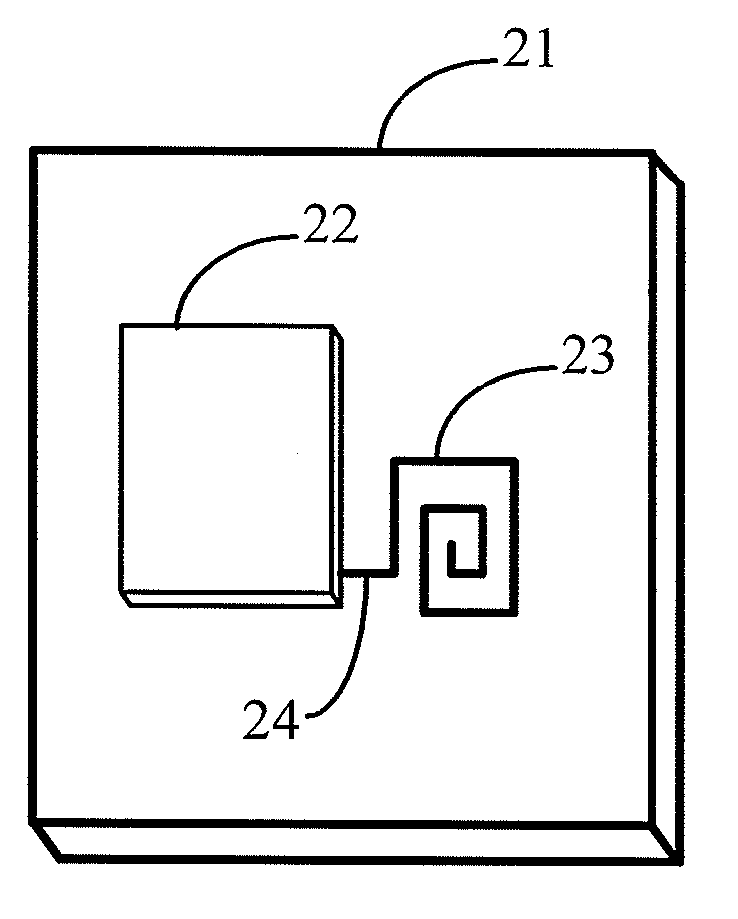

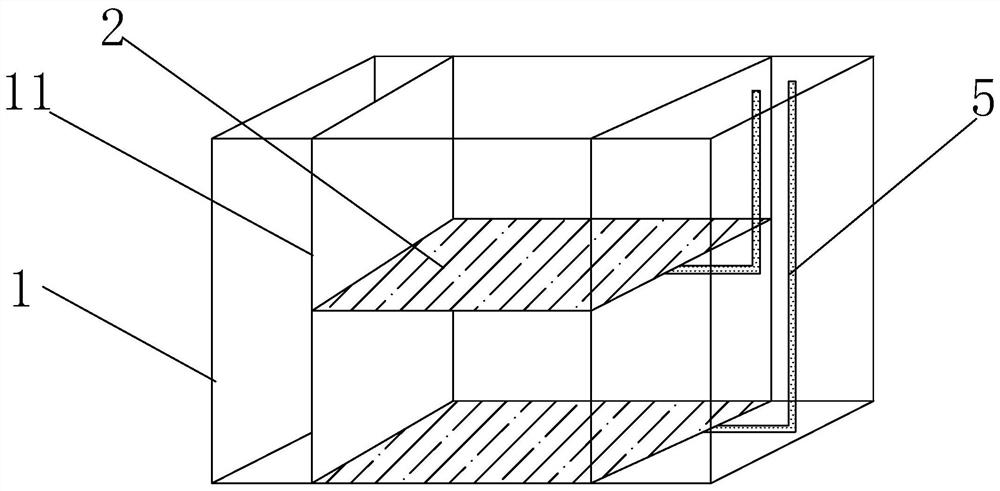

Integrated passive capacitor fan-out wafer-level packaging structure and manufacturing method

ActiveCN103972217BDoes not affect the areaShorten the electrical connection lengthSemiconductor/solid-state device detailsSolid-state devicesCapacitanceSolder ball

The invention relates to an integrated passive capacitance fan-out wafer-level packaging structure and a manufacturing method, including a plastic package and a chip; the feature is that a first metal post, a second metal post, a third The first metal post and the second metal post are located on one side of the chip, and the third metal post and the fourth metal post are located on the other side of the chip; The first metal layer, the second metal layer, the third metal layer and the fourth metal layer are arranged in the layer, the first metal layer is connected with the first metal column, the second metal layer is connected with the second metal column and the first electrode, and the second metal layer is connected with the first metal column and the first electrode. The third metal layer is connected to the third metal column and the second electrode, and the fourth metal layer is connected to the fourth metal column; the metal layer under the bump is respectively arranged on the four metal layers, and the solder is respectively arranged on the outer surface of the metal layer under the point. ball. The invention realizes the integration of fan-out chip packaging and thin-film integrated passive passive devices, and improves the electrical quality.

Owner:NAT CENT FOR ADVANCED PACKAGING CO LTD

Integrated passive device fan-out wafer level packaging structure and manufacturing method

ActiveCN103972218BDoes not affect the areaShorten the electrical connection lengthSemiconductor/solid-state device detailsSolid-state devicesEngineeringElectrical and Electronics engineering

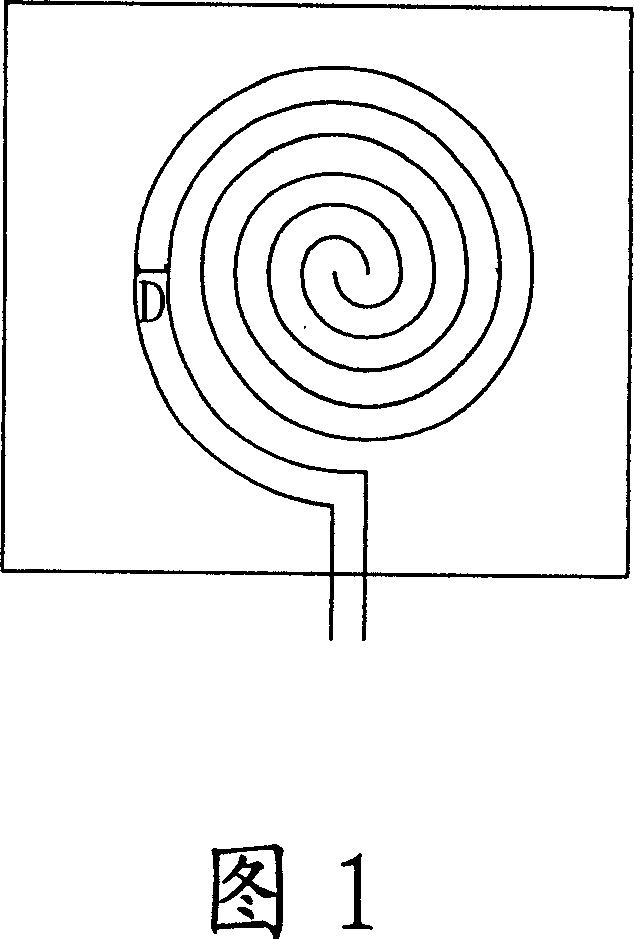

The invention relates to an integrated passive device fan-out-type wafer-level packaging structure and a manufacturing method of the integrated passive device fan-out-type wafer-level packaging structure. The integrated passive device fan-out-type wafer-level packaging structure comprises a modeling plastic body and a chip, and is characterized in that a spiral metal wire distribution layer is arranged in the modeling plastic body, an insulating layer is arranged on the front surface of the modeling plastic body, a metal wire leading layer is distributed in the insulating layer and is connected with an electrode of the chip and the metal wire distribution layer, and a welding ball is arranged on the metal wire leading layer. The manufacturing method of the packaging structure comprises the following steps that (1) the chip is packaged in the modeling plastic body in a plastic mode; (2) a spiral groove body is formed in the front surface of the modeling plastic body, and the metal wire distribution layer is manufactured in the groove body; (3) the insulating layer is manufactured on the front surface of the modeling plastic body, a window is formed in the insulating layer, a metal layer is manufactured on the surface of the insulating layer, a needed graph is etched on the metal layer, and the metal wire leading layer is obtained; (4) an insulating layer is manufactured on the metal wire leading layer, a window is formed in the insulating layer, and the welding ball is manufactured in the window. By means of the integrated passive device fan-out-type wafer-level packaging structure and the manufacturing method of the integrated passive device fan-out-type wafer-level packaging structure, the electric connection length of the chip and a passive device is shortened, and the electric quality is improved.

Owner:江苏中科智芯集成科技有限公司

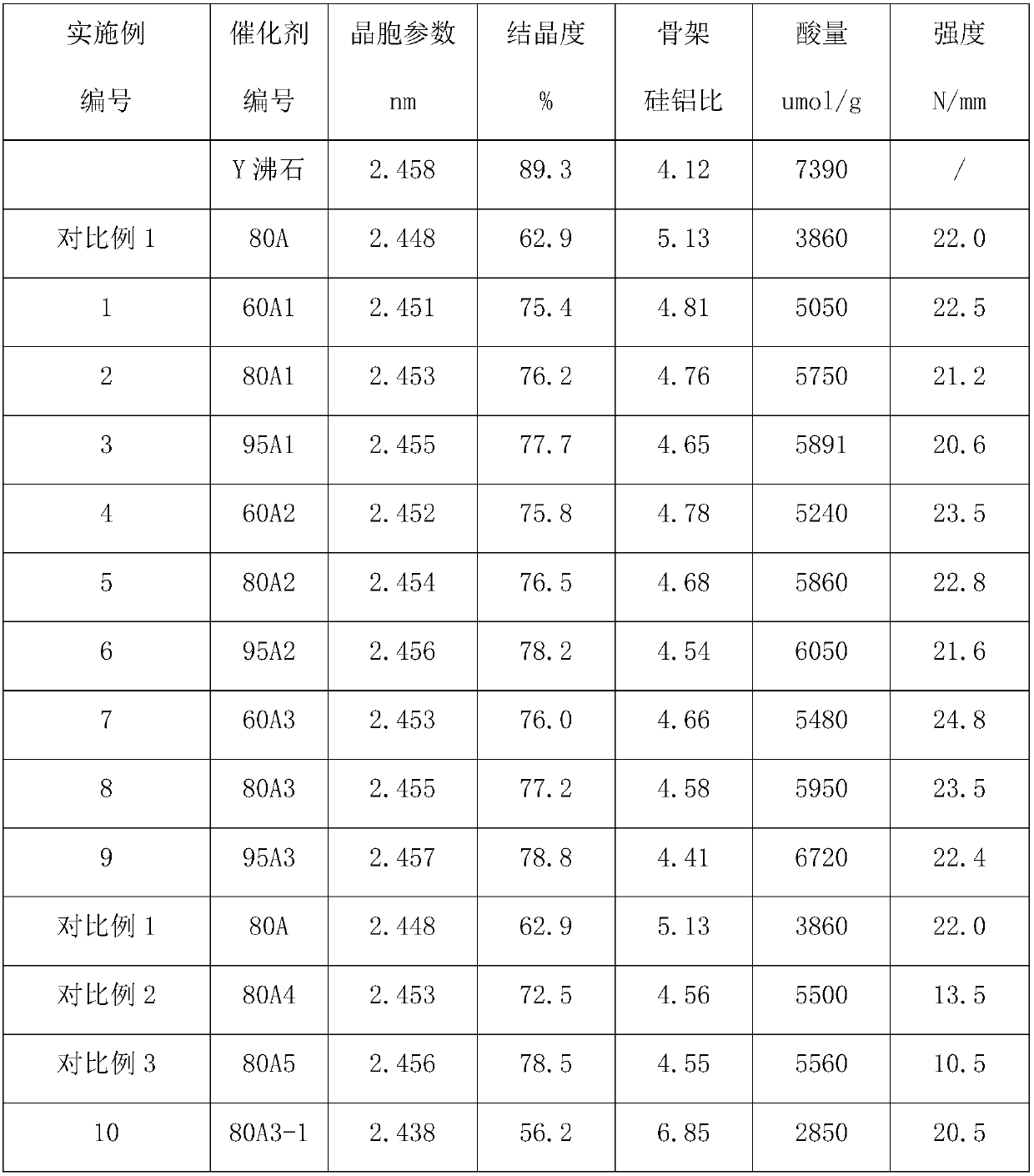

Preparation method of solid acid alkylation catalyst

ActiveCN111482196ADoes not affect the areaDoes not affect the channelMolecular sieve catalystsLiquid hydrocarbon mixtures productionMolecular sieveButene

A forming method of a solid acid alkylation catalyst is characterized by comprising the following steps: mixing a molecular sieve and acidic aluminum sol with the pH value of less than 5, the particlesize of 20-300nm and the alumina concentration of 5-20%, grinding the mixture and carrying out extrusion molding. The method is simple and easy to implement, the specific surface area and pore channels of the molecular sieve are not influenced, the acidity of the molecular sieve is not damaged, and the obtained forming agent has high strength and shows high activity and stability in alkylation reaction, especially isobutane / butene alkylation reaction.

Owner:CHINA PETROLEUM & CHEM CORP +2

Multi-functional storage cloth

InactiveCN107125816AReduce lossShorten the timeGarment special featuresOvergarmentsAmnesiaHome environment

The invention provides a multi-functional storage cloth. A rectangular pocket is fixed in the front of the cloth; the lower part of the cloth is provided with a zipper; a zipper head is installed on the zipper; the zipper is connected with a big bag; a lower Velcro is fixedly arranged at the back of the bottom of the big bag; an external raincoat is arranged outside the cloth; cloth sleeves are arranged at both sides of the upper part of the cloth; a hook and a cloth-hanging rope are fixed at both sides of the shoulders of the cloth; a cloth-hanging belt is arranged at the back of the neck of the cloth; an upper Velcro is fixed at the upper part of the cloth-hanging belt; a cloth-hanging hole is arranged at the top end of the cloth-hanging belt. The multi-functional storage cloth is an essential item for the amnesia and the busy person; the minimum space on the cloth can be made full use to accommodate more life items so as to reduce the phenomenon of item losing; people can find the needed items in a short time so as to save time and space, and avoid troubles; in addition, if the cloth is hung at home, which is a good decoration and does not affect the beauty; the cloth is small in size, easy to move and makes the home environment beautiful.

Owner:任佳穆

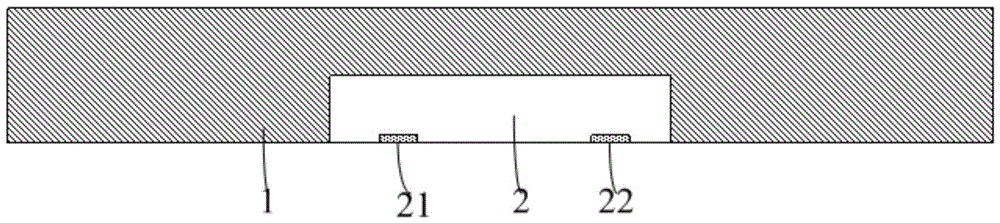

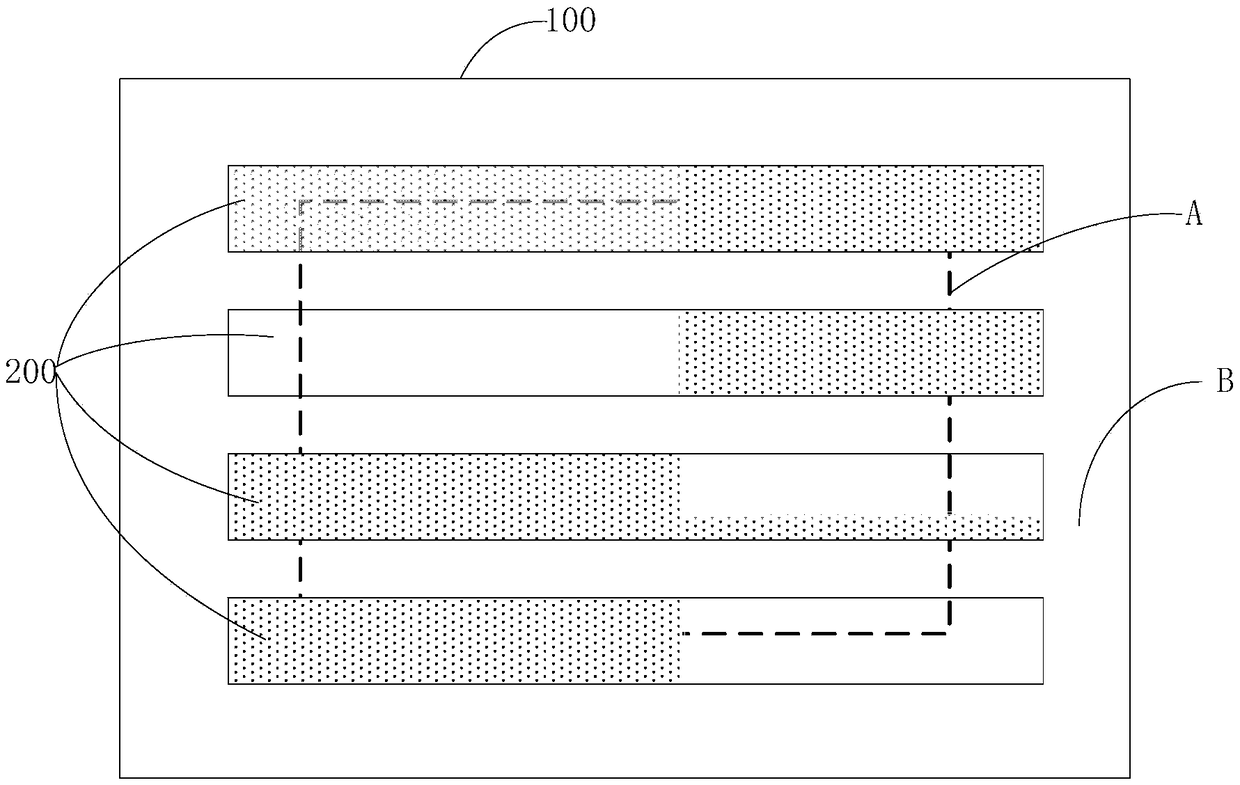

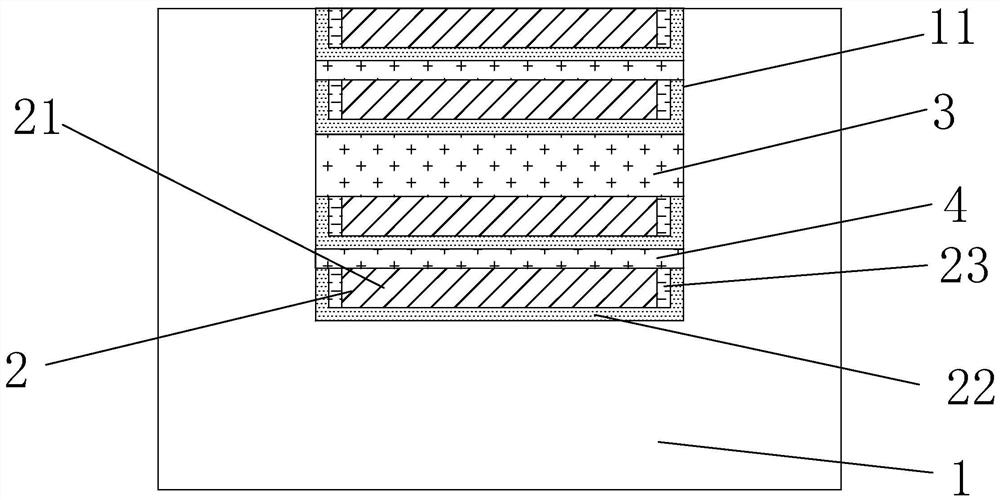

Capacitance induction system

InactiveCN100342649CDoes not affect the areaElectronic switchingInput/output processes for data processingInduction systemCapacitance

The capacitance induction system includes an insulated baseplate and several modules of capacitance induction. The modules of capacitance induction with interval between each other are formed on the insulated baseplate in matrix mode. Each capacitance induction module includes first electrode and second electrode. Second electrode encircle periphery of first electrode with equal interval between them. An equivalent capacitance is formed between first electrode and second electrode. When outer edge of the second electrode is fixed, adjusting distance between inner edge and first electrode changes equivalent capacitance of the capacitance induction module. Thus, when the capacitance induction module is charged, even elctrical level can be generated.

Owner:HOLTEK SEMICON

In-cell touch display and touch display device

ActiveCN104657016BSmall sizeDoes not affect the areaInput/output processes for data processingDisplay deviceHuman–computer interaction

The invention discloses an embedded touch display screen and a touch display device. The embedded touch display screen comprises a display panel and a touch electrode, wherein the display panel comprises a display region and a frame region; the touch electrode covers the display region and extends to the frame region. Known from the above contents, according to the technical scheme provided by the invention, the size of the touch electrode is enlarged; except for the to-be-covered display region, the coverage region of the touch electrode extends to the frame region; by virtue of enlarging the size of the touch electrode, the touch sensitivity of edge parts of the display region is improved on the premise of not influencing the area of the display region.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD +1

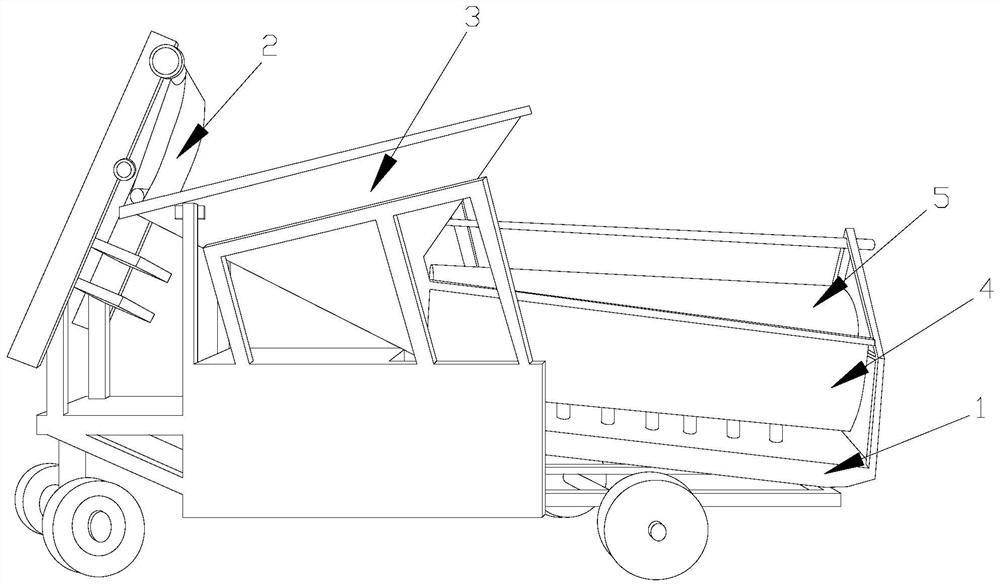

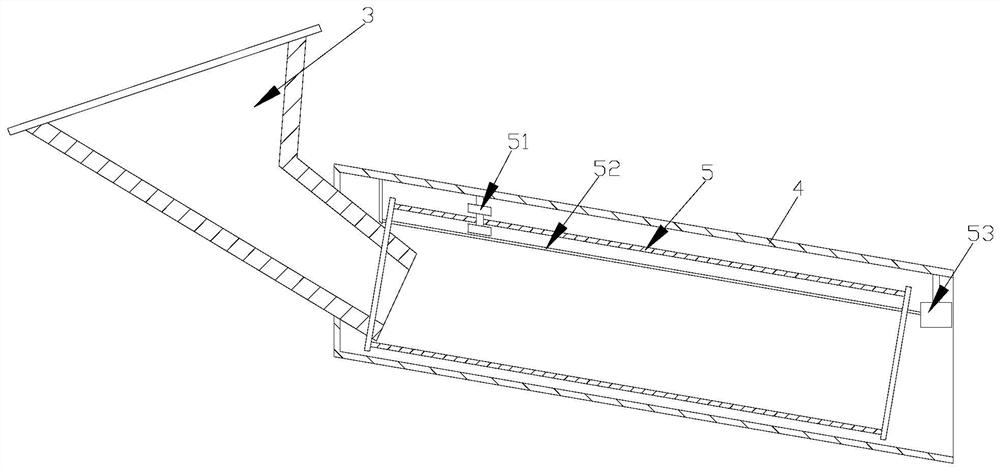

sand screening machine for construction machinery

The invention discloses a sand screening machine for construction machinery, the structure of which comprises a base, a conveyor belt, a sand feeding bucket, a sand loading bucket, and a sand screening bucket; The loose mud roller is composed of a roller body, a bump, and a rotating shaft; the bump is composed of a slot, a top mud block, and a second spring; the present invention can make The roller body is in close contact with the sand sieve hopper. After the bumps are arranged around the outer surface of the roller body, they can be inserted into the sand sieve hopper through the bumps, so as to clean up the sea mud attached to the sand sieve hopper and avoid sea mud Attached to the sand sieve bucket, causing the sieve hole of the screening drum to be blocked, will not affect the sand screening area of the sieve bucket.

Owner:兰陵县德隆机械有限公司

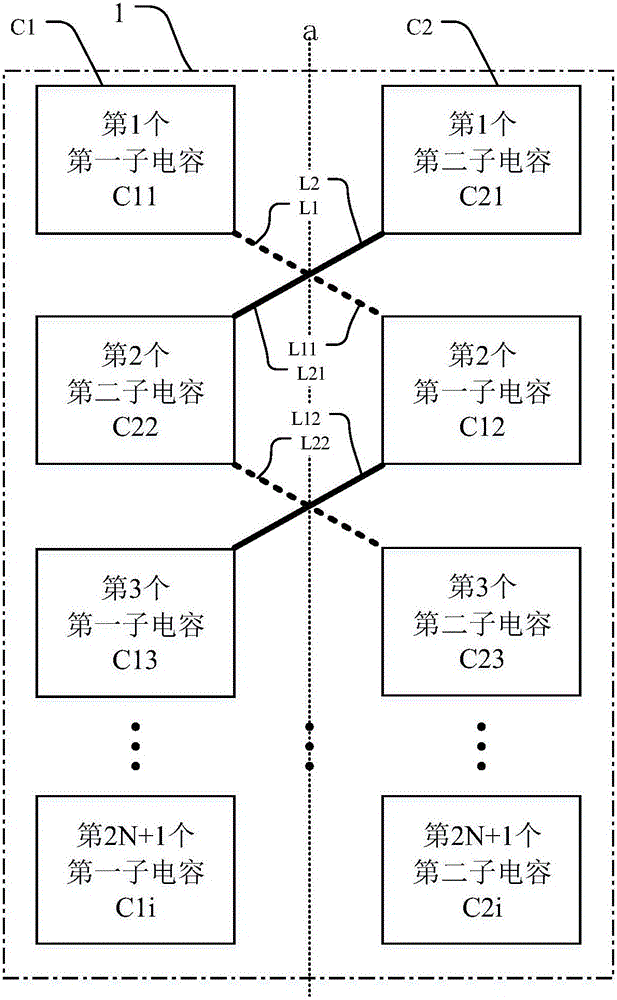

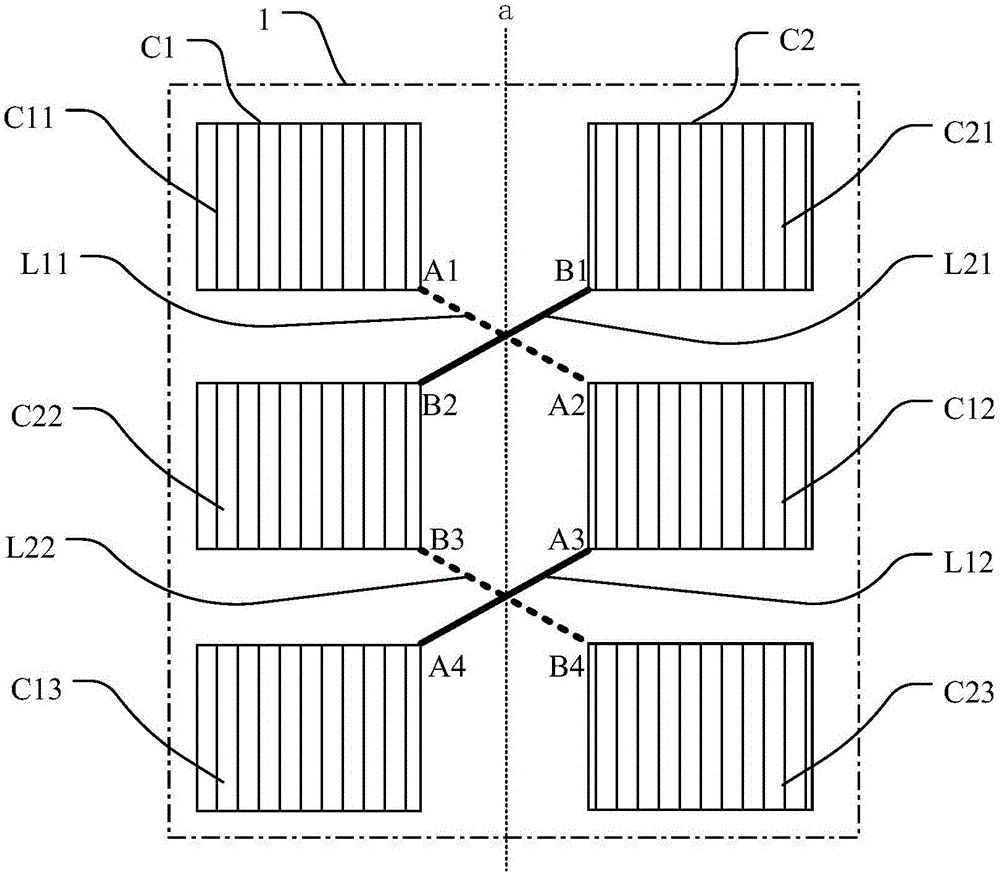

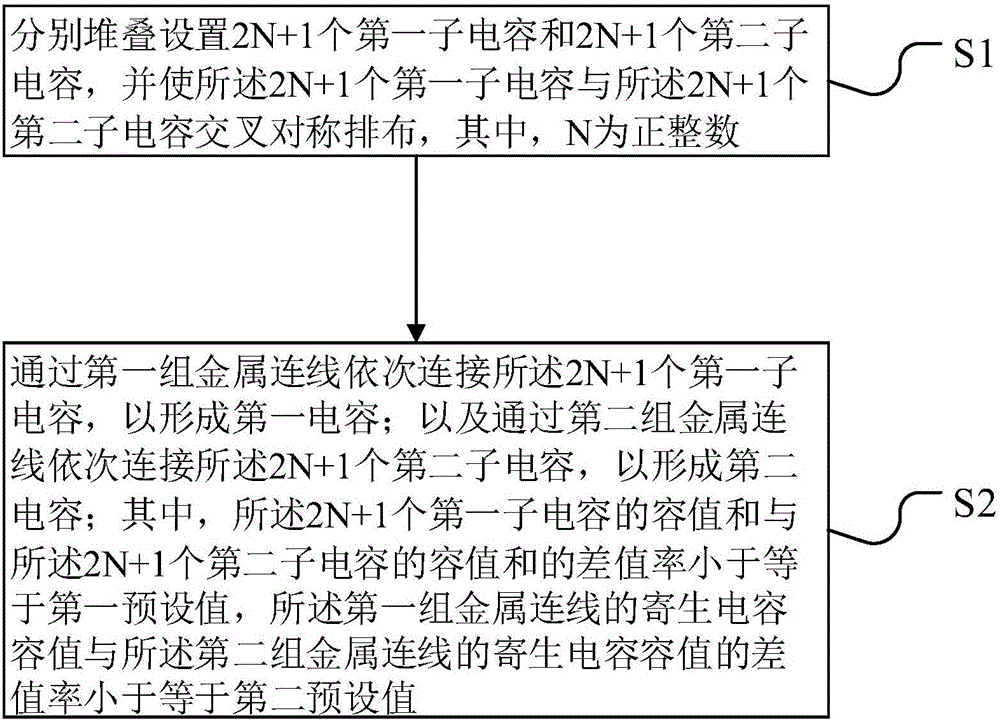

Capacitor and layout method thereof

InactiveCN105932015AImprove matching accuracyWill not change the capacitanceSemiconductor/solid-state device detailsSolid-state devicesParasitic capacitanceCapacitor

The invention discloses a capacitor and a layout method thereof, and aims at solving the problem that the integrated circuit design is limited by an existing method of reducing the difference ratio of a lead capacitance by changing the sizes of single capacitors to improve the capacitance matching precision. The capacitor comprises a first capacitor (C1) and a second capacitor (C2), which are in cross symmetric arrangement along an axis (a), wherein the first capacitor (C1) comprises 2N+1 first sub-capacitors (C11-C1i) which are sequentially connected through a first group of metal lines (L1); the second capacitor (C2) comprises 2N+1 second sub-capacitors (C21-C2i) which are sequentially connected through a second group of metal lines (L2); N is a positive integer; i is 2N+1; the difference ratio of the capacitance sum of the sub-capacitors (C11-C1i) and the sub-capacitors (C21-C2i) is not greater than a first preset value; and the difference ratio of the parasitic capacitances of the first group of metal lines (L1) and the second group of metal lines (L2) is not greater than a second preset value. The effect of improving the capacitance matching precision under the premise of not changing the sizes of the single capacitors is achieved.

Owner:WUHAN SYNTEK CO LTD

Soi wafer with high heat dissipation performance and preparation method thereof

ActiveCN113764366BImprove cooling effectSmall sizeSemiconductor/solid-state device detailsSolid-state devicesWaferCarbon nanotube

The invention provides an SOI wafer with high heat dissipation performance and a preparation method thereof. The SOI wafer sequentially comprises: a bulk silicon wafer, a buried oxide layer, and a silicon device layer; A groove with a preset depth is filled with a material with high thermal conductivity, the material with high thermal conductivity is fixed with heat dissipation glue, and the material with high thermal conductivity is carbon nanotube or molybdenum disulfide. By setting grooves in the bulk silicon wafer and filling the grooves with high thermal conductivity materials such as carbon nanotubes or molybdenum disulfide, based on the high thermal conductivity of carbon nanotubes and molybdenum disulfide, it can effectively improve The heat dissipation performance of the SOI circuit makes the size of the SOI wafer larger; in addition, the high thermal conductivity material is set in the bulk silicon wafer, which does not affect the area of the silicon device layer, improves the utilization of the active area, reduces the cost, and improves the integration. Spend.

Owner:MICROTERA SEMICON (GUANGZHOU) CO LTD

A varactor diode structure used in a flash memory circuit and a manufacturing method thereof

ActiveCN107346792BDoes not affect the areaReduce areaSemiconductor/solid-state device manufacturingSemiconductor devicesHemt circuitsMiniaturization

The invention provides a varactor structure used in a flash memory circuit and a manufacture method thereof. The varactor structure comprises a substrate, a first insulating layer formed on the substrate, a floating gate formed on the first insulating layer, a control gate arranged opposite to the floating gate, and a second insulating layer formed between the floating gate and the control gate. A source and a drain are formed on the substrate. A first connection wire separately led out from the floating gate and is used as a polar plate of the capacitor of the varactor. The source lead out wire, the drain lead out wire and the lead out wire of the control gate are electrically connected together to form a second connection wire, and the second connection wire is used as the other polar plate of the capacitor of the varactor. The first insulating layer and the second insulating layer are used as the dielectric layer of the capacitor of the varactor. The varactor used in the flash memory circuit can meet the demand of a large-capacity capacitor, and can take the trend of chip miniaturization into account.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

Display module and display device

PendingCN114120835AAvoid settingDoes not affect the areaTelevision system detailsColor television detailsComputer hardwareVertical projection

The invention discloses a display module and a display device, and relates to the technical field of display, the display module comprises a display panel, and the display panel comprises a display area and a non-display area surrounding the display area; the light sensing element comprises a first branch part and a second branch part, the vertical projection of the first branch part on the display panel is located in the display area, and the vertical projection of the second branch part on the display panel is located in the non-display area. According to the invention, the narrow bezel can be realized, and the influence on the display effect in the display state can be reduced.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

Embedded capacitor structure and manufacturing method thereof

PendingCN114094012ADoes not affect the areaReduce areaSolid-state devicesCapacitorsCapacitancePower efficient

The invention discloses an embedded capacitor structure and a manufacturing method thereof, the capacitor structure comprises a substrate with a trench with a certain depth, the bottom of the trench is sequentially provided with multiple layers of electrode structures which are arranged at intervals along the depth direction of the trench, and each electrode structure comprises an electrode layer, and a bonding layer and a first dielectric layer which are arranged around the electrode layer; the first dielectric layer and the bonding layer sequentially wrap the side wall of each electrode layer, the electrode structures are attached to the side wall of the trench through the bonding layers, each bonding layer further wraps the bottom faces of the electrode layer and the first dielectric layer, and a second dielectric layer is arranged between every two adjacent spaced electrode structures. And two adjacent and spaced electrode structures and the second dielectric layer between the two adjacent and spaced electrode structures form a group of capacitor structures. The DRIE and depth end point detection technology is adopted to form the trench with the vertical side wall, the thickness, the area and the shape of the capacitor structure can be adjusted according to requirements, variable control over the capacitance value is achieved, and finally the purpose of optimizing the efficiency is achieved.

Owner:泉州市三安集成电路有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com