Flexible comb protective sleeve and platy comb comprising same

A sheath and comb technology, applied in hair combs, hair or scalp washing devices, clothing, etc., can solve problems such as different technical solutions, achieve simple and compact structure, delay bending deformation, and prevent breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

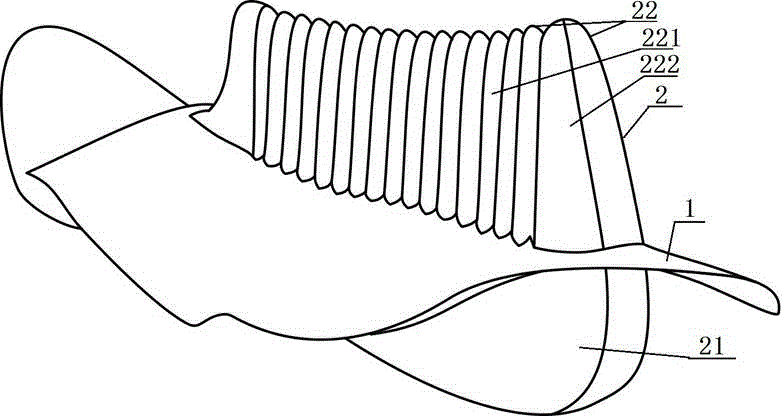

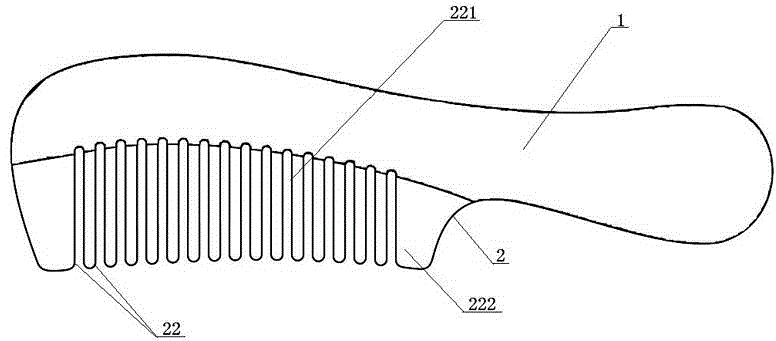

[0038] see figure 2 and image 3 : the present invention is flat (generally, the thickness of comb tooth tip place is less than comb body-that is the thickness of comb back place), thin plate-like comb 2, and it adopts natural hard material (including but not limited to bamboo wood plank, stone plank, angle bone plank) processing and forming. The comb 2 includes a comb body 21. As far as the comb body 21 is concerned, the comb body 21 is a hexahedron with: a larger front and back surface; Long side; the two end faces with the smallest area between the front and back surfaces.

[0039]A plurality of comb teeth 22 extend from one elongated side of the above-mentioned comb body 21, and these comb teeth 22 are composed of larger auxiliary teeth 222 at both ends and main teeth 221 between the auxiliary teeth 222. A plurality of comb teeth 22 are regularly and alternately arranged side by side on one elongated side of the comb body 21 . Based on this, the comb teeth 22 can be i...

Embodiment 2

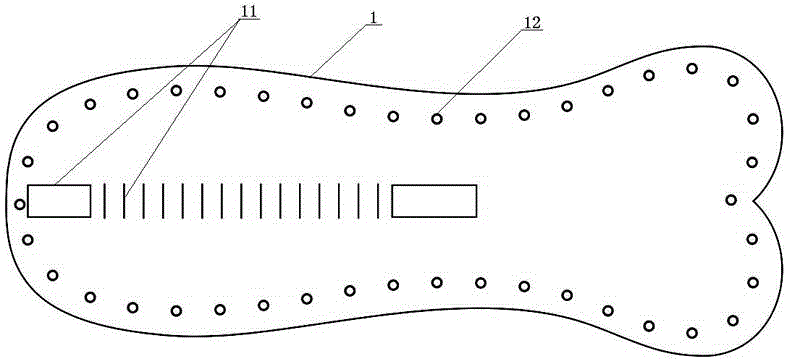

[0048] see Figure 4 and Figure 5 , the other structure of this embodiment is the same as that of Embodiment 1, the difference is: 1. the structure of the comb 2, the comb body 21 is used as the handle portion, and the handle portion is also the comb body 21; 2. the comb on the sheath body 1 The teeth wearing space 11 is only slit-shaped, so that only the main teeth 221 on the comb body 21 can pass through, and the part of the sheath body 1 corresponding to the auxiliary teeth 222 of the comb 2 in space is a completely open gap structure ; 3. The height of the sheath body 1 is less than the height of the comb body 21 of the comb 2, and the insufficient part is filled by the joint portion 12 on the sheath body 1.

Embodiment 3

[0050] see Image 6 and Figure 7 : other structures of the present embodiment are the same as embodiment 1, and the difference is: 1. the structure of the comb 2, the comb body 21 is used as the handle portion, and the handle portion is also the comb body 21; 2. the width of the sheath body 1 is only The main teeth 221 of the comb teeth 22 correspond to the combing space, and the comb teeth wearing space 11 on the sheath body 1 is only slot-shaped, so that only the main teeth 221 on the comb body 21 can pass through.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com