A plate heat exchange muffler

A kind of muffler, chip technology, applied in the direction of heat exchanger type, indirect heat exchanger, noise suppression, etc., can solve the problems of increasing flow resistance, affecting the area of airflow passage, increasing heat exchange loss, etc., to reduce heat dissipation. Loss, enhance heat transfer effect, good noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Compared with the prior art, the present invention has specifically realized compared with the prior art:

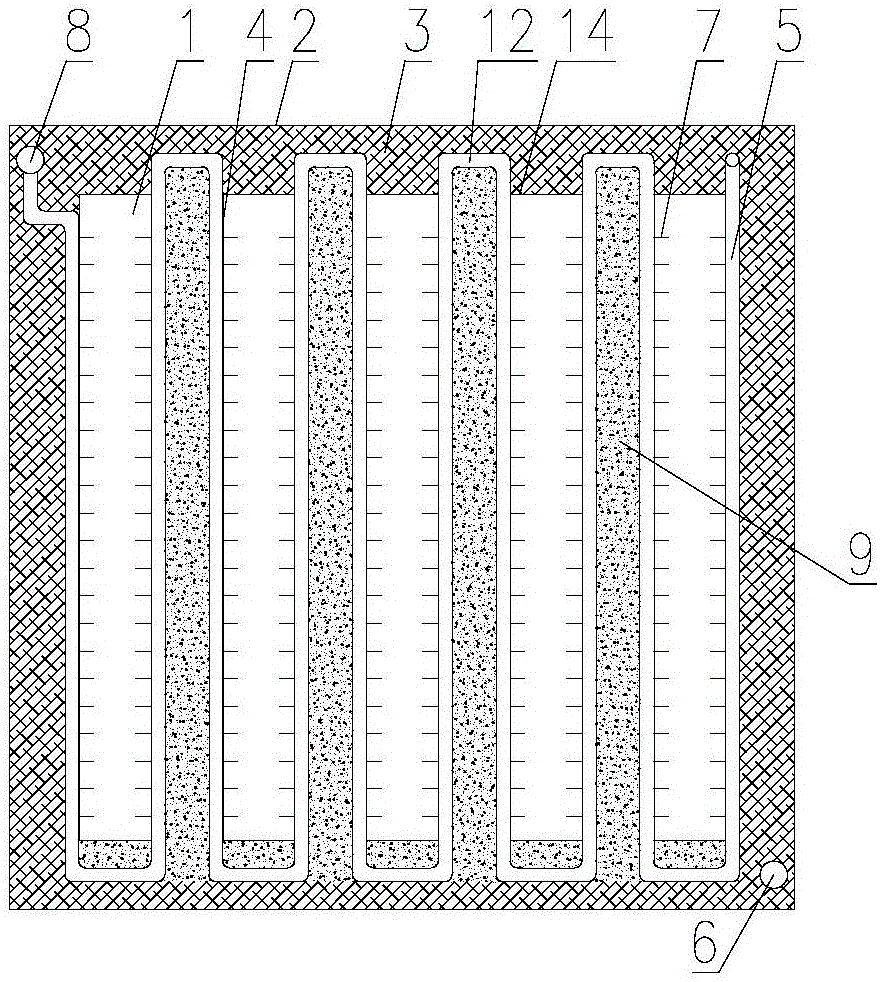

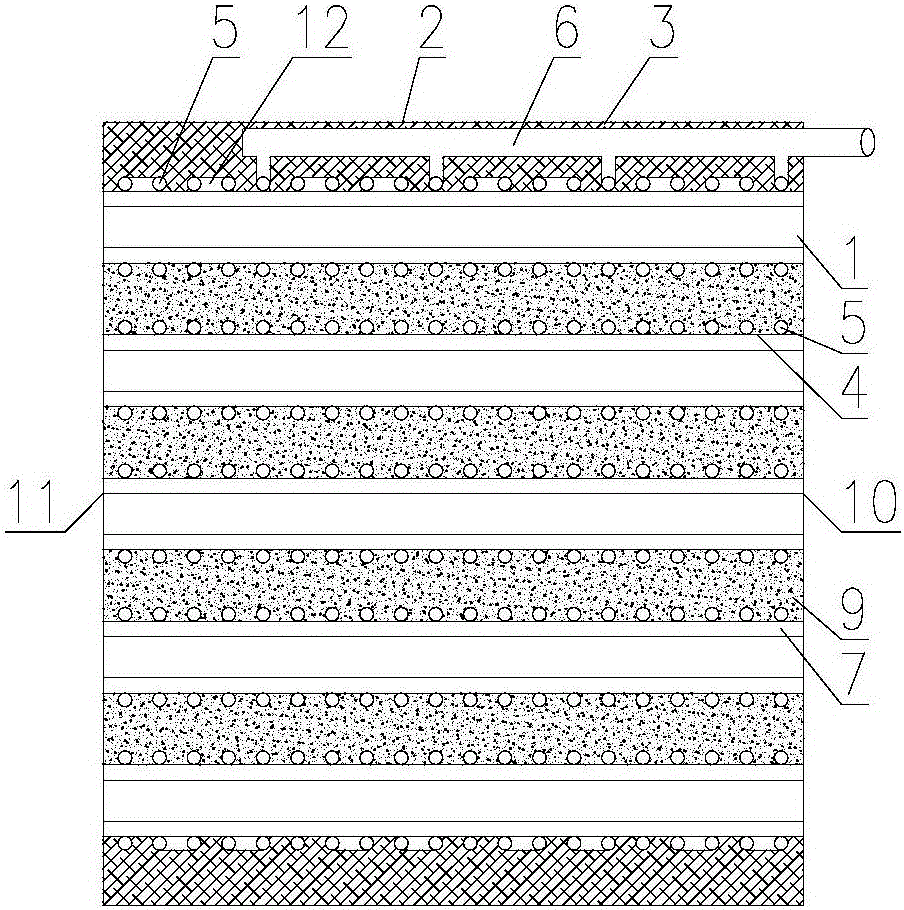

[0029] ①In order to increase the heat exchange area, one side of the heat exchange tube bundle is next to the air flow channel, and fins are installed on it; ②In order not to affect the noise reduction effect, the heat exchange tube bundle is evenly placed in the pores of the perforated shell; ③In order to reduce the surrounding heat loss, the surrounding noise-absorbing material in contact with the outside world is selected as a thermal insulation type noise-absorbing material with a small thermal conductivity; ④In order to increase the heat transfer effect, the middle noise-absorbing material is selected as a noise-absorbing material with a large thermal conductivity Material.

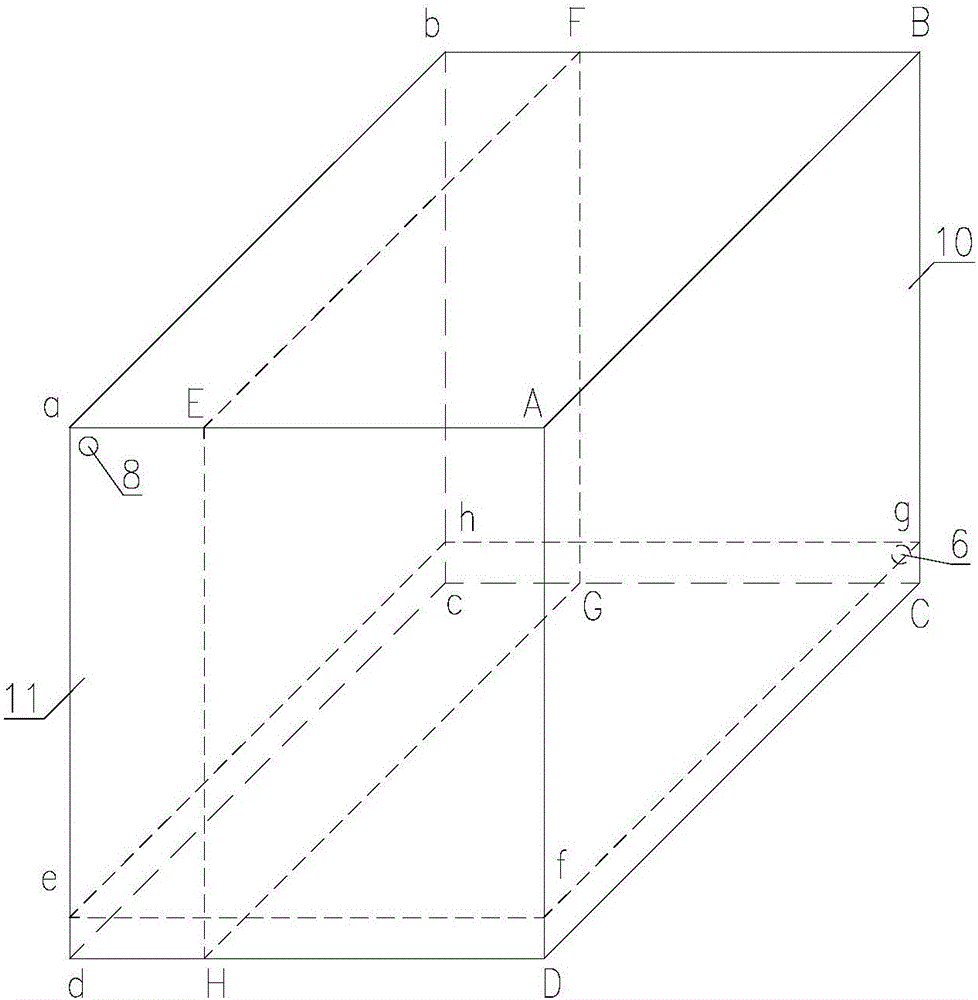

[0030] combined with Figure 1-Figure 4 , detailing the structure of the present invention. The present invention is a plate muffler with heat exchange function, which specifically inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com