Patents

Literature

89results about How to "Achieve precision seeding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

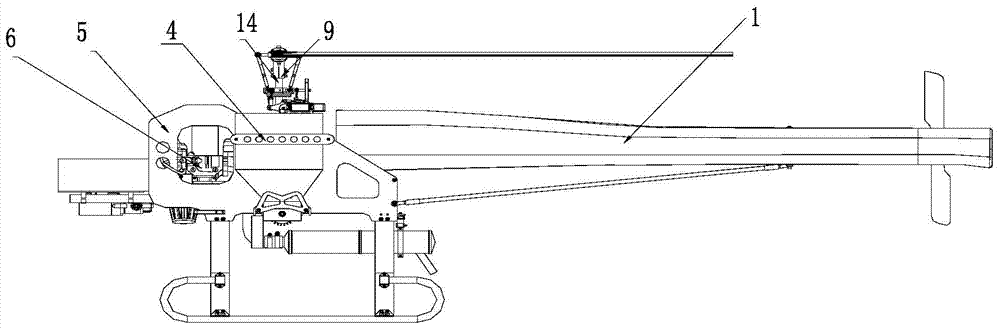

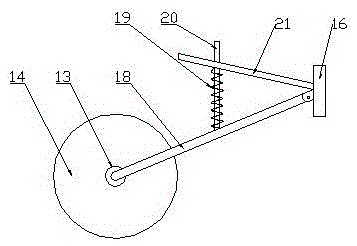

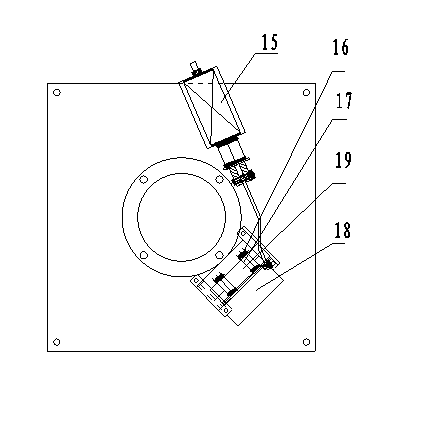

Precision seeding working system and method based on unmanned aerial vehicle platform

ActiveCN104255137AReduce labor intensityImprove work efficiencyAircraft componentsBroadcast seedersElectric machineryEngineering

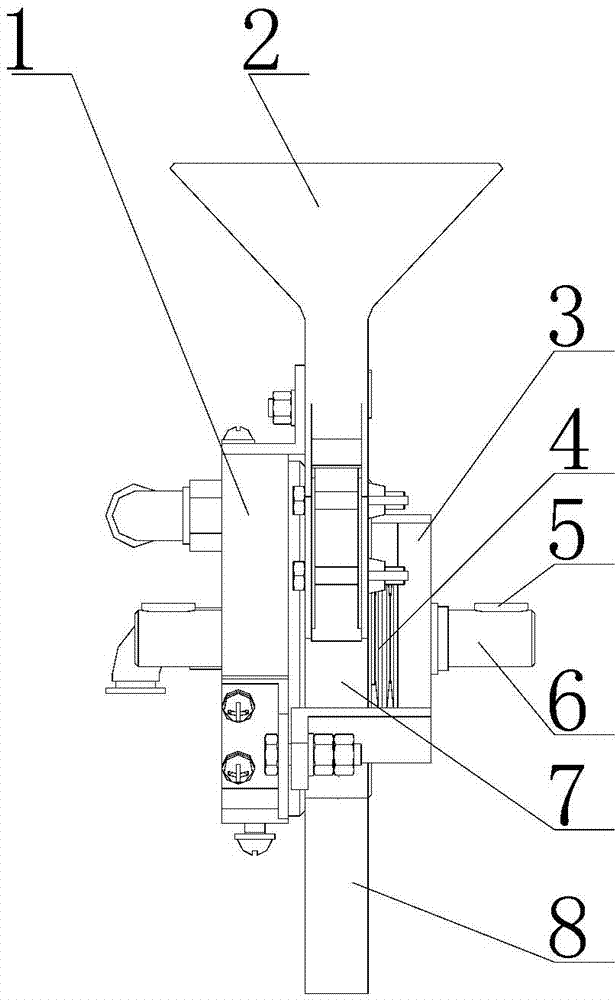

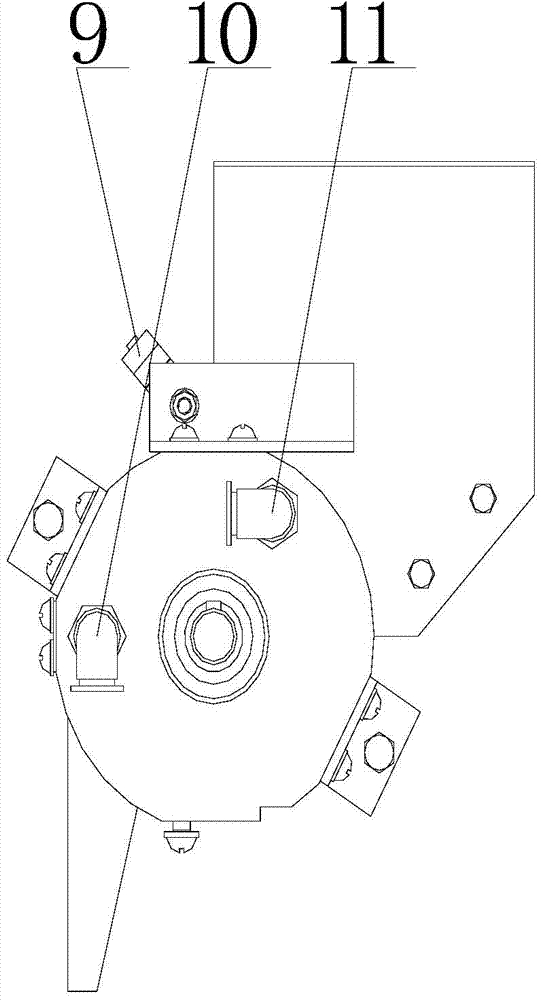

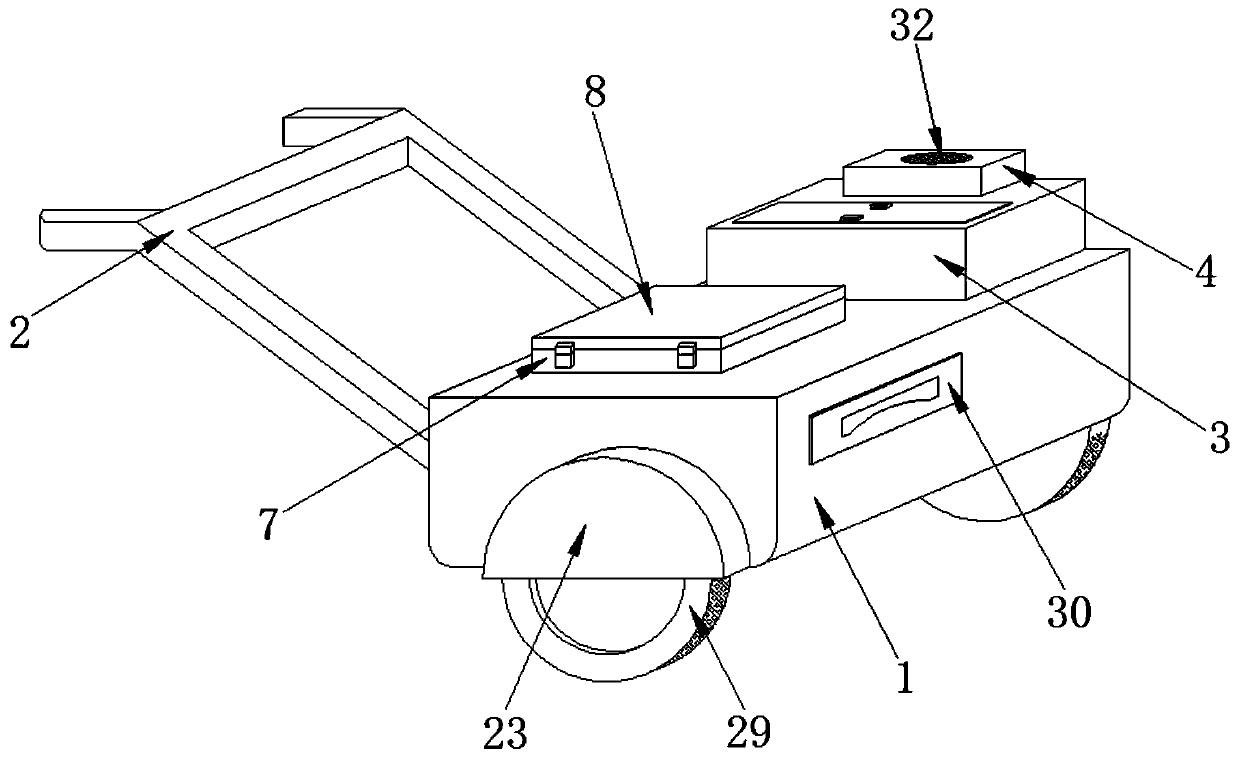

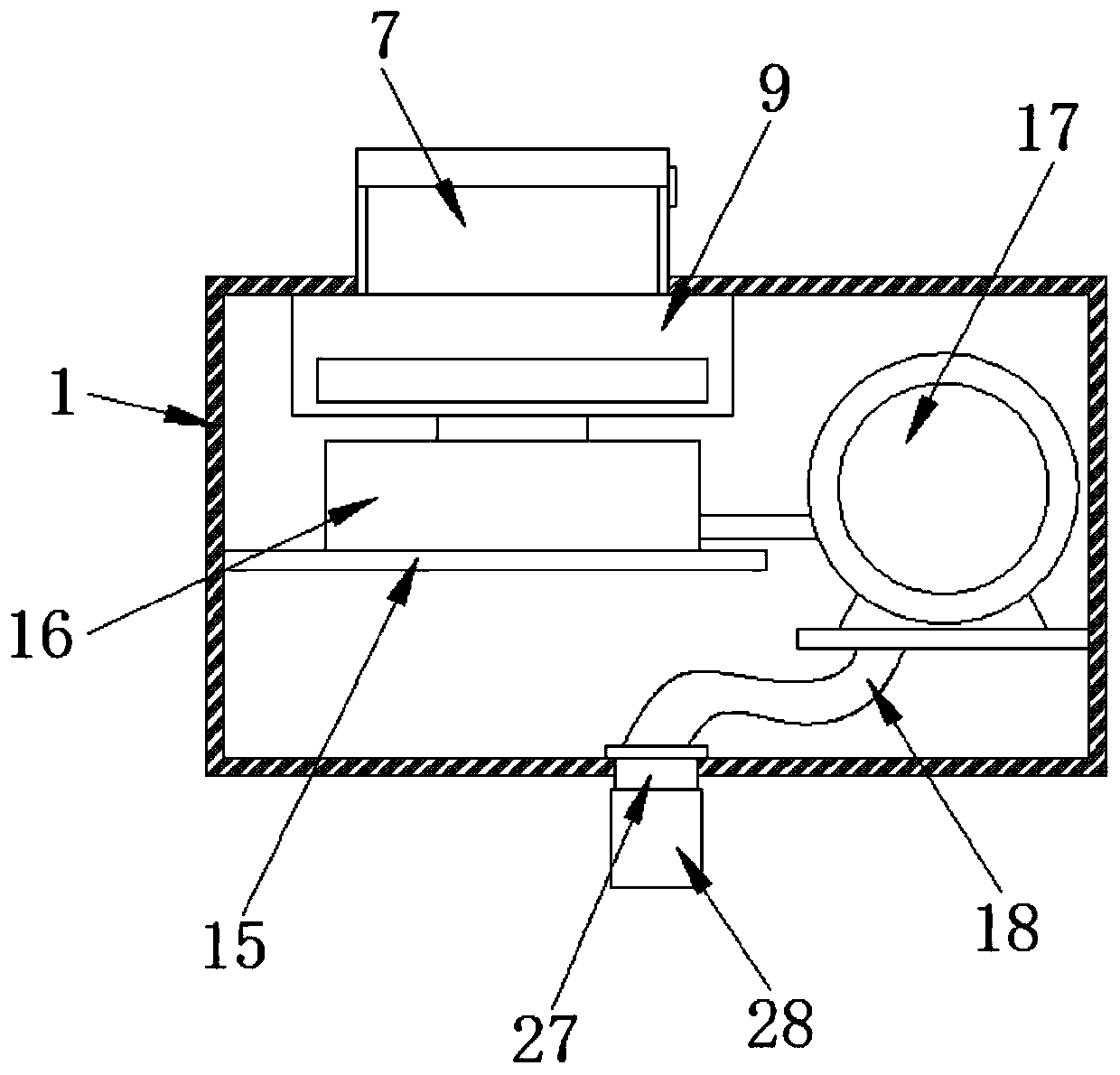

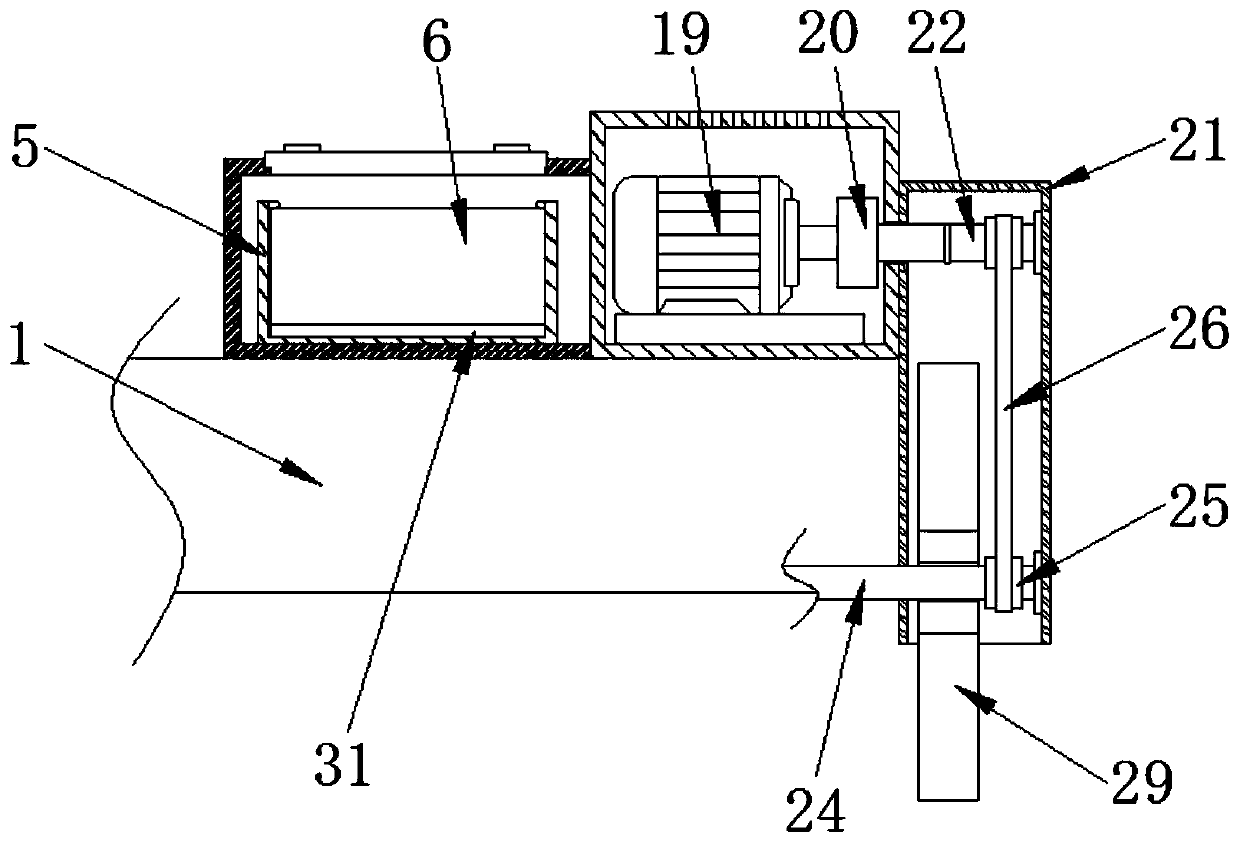

The invention discloses a precision seeding working system and method based on an unmanned aerial vehicle platform. The system comprises an unmanned aerial vehicle (1) and seeding devices (2) fixed on the unmanned aerial vehicle. Each seeding device (2) comprises a seed box (15), a fixed seat (16), a wind power seed scattering device, a quantitative seeding roller (18), roller blades (19) and a servo motor (22); the servo motor is driven by a battery; the wind power seed scattering device is a fan (17) only or an air supply channel consisting of a fan and a sleeve; the seed box (15) is fixed on the top of the fixed seat (16); the servo motor (22) is mounted on the fixed seat; the quantitative seeding rollers (18) controlled by the servo motor realize precision seeding; by the adoption of the wind power seed scattering device, seeding is uniform. The precision seeding working system based on the unmanned aerial vehicle platform can realize precision seeding work and is high in seeding efficiency and easy to implement.

Owner:湖南星索尔航空科技有限公司

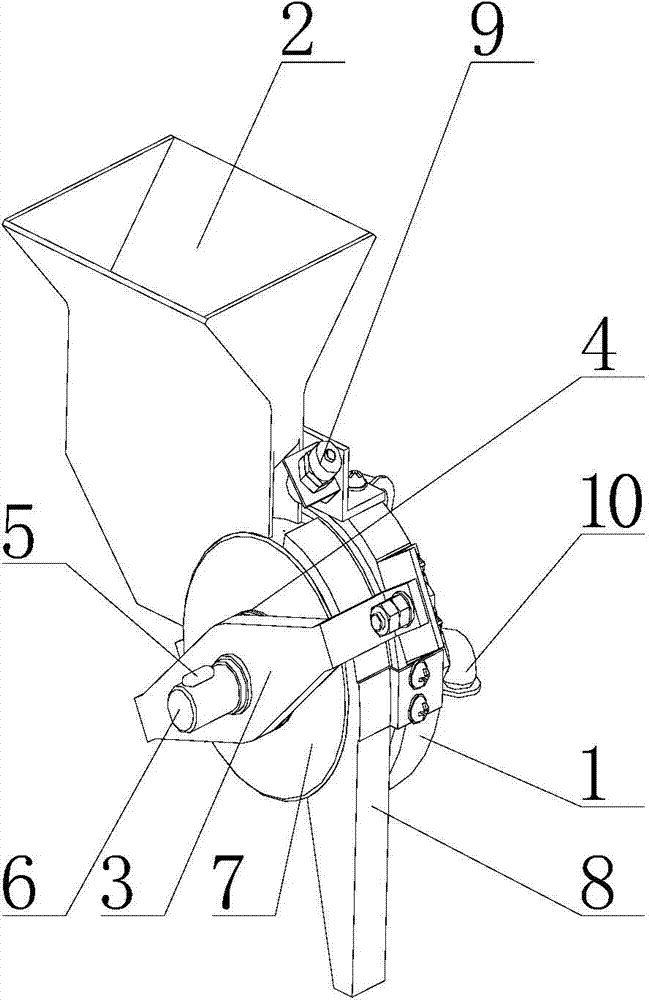

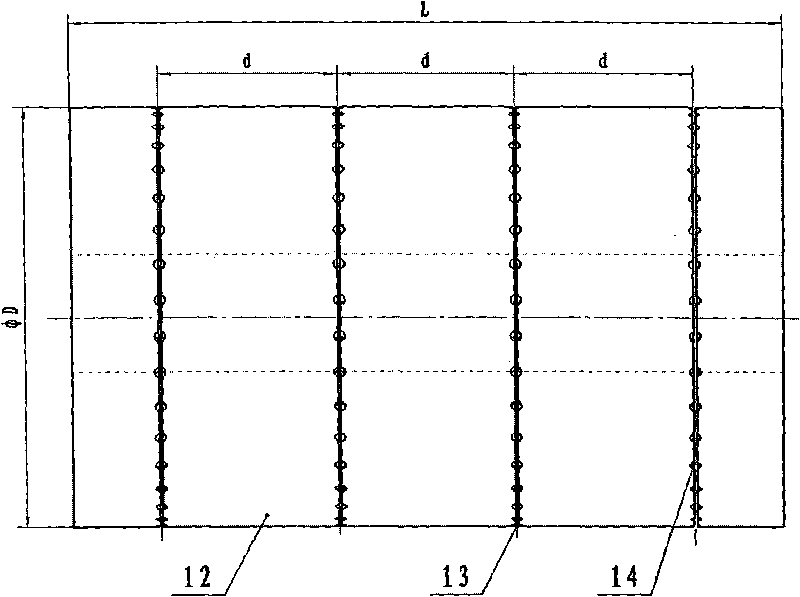

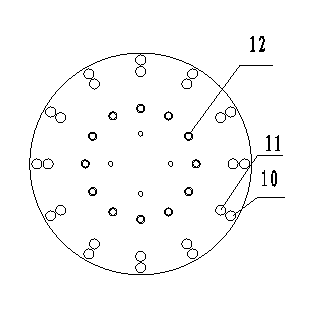

Precision seed-metering device and precision seed-metering device group for direct sowing of small-granular seeds

ActiveCN104756651AFlexible line spacing adjustmentEnable direct seedingAgriculture gas emission reductionSeed depositing seeder partsPositive pressureEngineering

The invention relates to a precision seed-metering device and a precision seed-metering device group for direct sowing of small-granular seeds. The precision seed-metering device includes: a fixed gas distribution plate fixed on a rack and a seed plate fixedly sleeving a shaft. The fixed gas distribution plate separately sleeves the shaft. The seed plate is arranged closely to the fixed gas distribution plate. The fixed gas distribution plate is provided with a negative pressure chamber and a positive pressure chamber. An end surface, which faces to the fixed gas distribution plate, of the seed plate is provided with a plurality of vent holes arranged in the peripheral direction uniformly. The side surface of the periphery of the seed plate is provided with a plurality of seed-discharging suction holes which are arranged in the peripheral direction uniformly to form a circle. The number of the vent holes is equal to that of the seed-discharging suction holes and each vent hole is communicated with each corresponding seed-discharging suction hole. The vent holes are rotated with the rotation of the seed plate, wherein one vent hole is communicated with the positive pressure chamber for discharging seeds while the other partial vent holes are communicated with the negative pressure chamber for sucking the seeds. The precision seed-metering device can achieve direct sowing and precision sowing of small-granular seeds, can be used for single-row sowing and multiple-row sowing and belongs to the field of design of agricultural machinery.

Owner:SOUTH CHINA AGRI UNIV

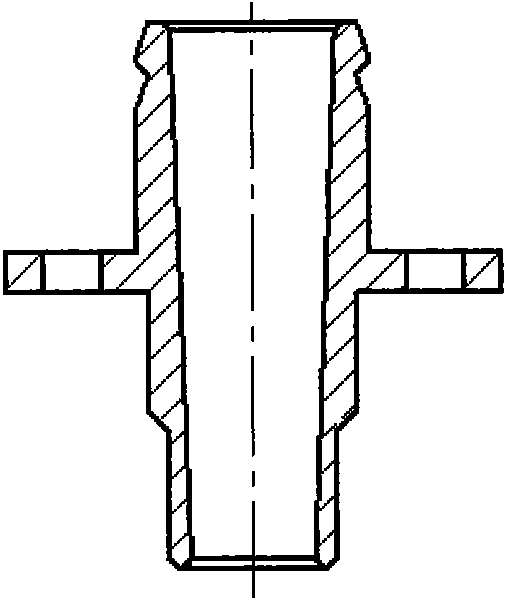

Combination hole seeder capable of adjusting seeding quantity

ActiveCN102612904ALarge adjustment rangeImprove general performanceSeed depositing seeder partsSeederDrive shaft

The invention provides a combination hole seeder capable of adjusting the seeding quantity, which comprises a casing and a seed-metering wheel device; the casing is provided with a seed feeding chamber; and the seed-metering wheel device is mounted in the casing, and comprises a transmission shaft, a combination hole wheel, an adjusting positioning mechanism and a hole wheel casing, wherein the combination hole wheel is mounted on the transmission shaft, and at least two groups of holes in different sizes are arranged on the circumference of the combination hole wheel; the adjusting positioning mechanism is mounted on the transmission shaft, and connected with the combination hole wheel; the hole wheel casing is sleeved on the periphery of the combination hole wheel, at least part of the hole wheel casing is placed in the seed feeding chamber, a plurality of external through holes are arranged on the circumference of the hole wheel casing, and are larger than one smaller group of the two groups of holes; and when the combination hole wheel rotates by adjusting the adjusting positioning mechanism, the external through holes are selectively communicated with one group of the groups of holes. The combination hole seeder has the advantages of being capable of adjusting the seeding quantity, large in adjusting range, and convenient to adjust.

Owner:SOUTH CHINA AGRI UNIV

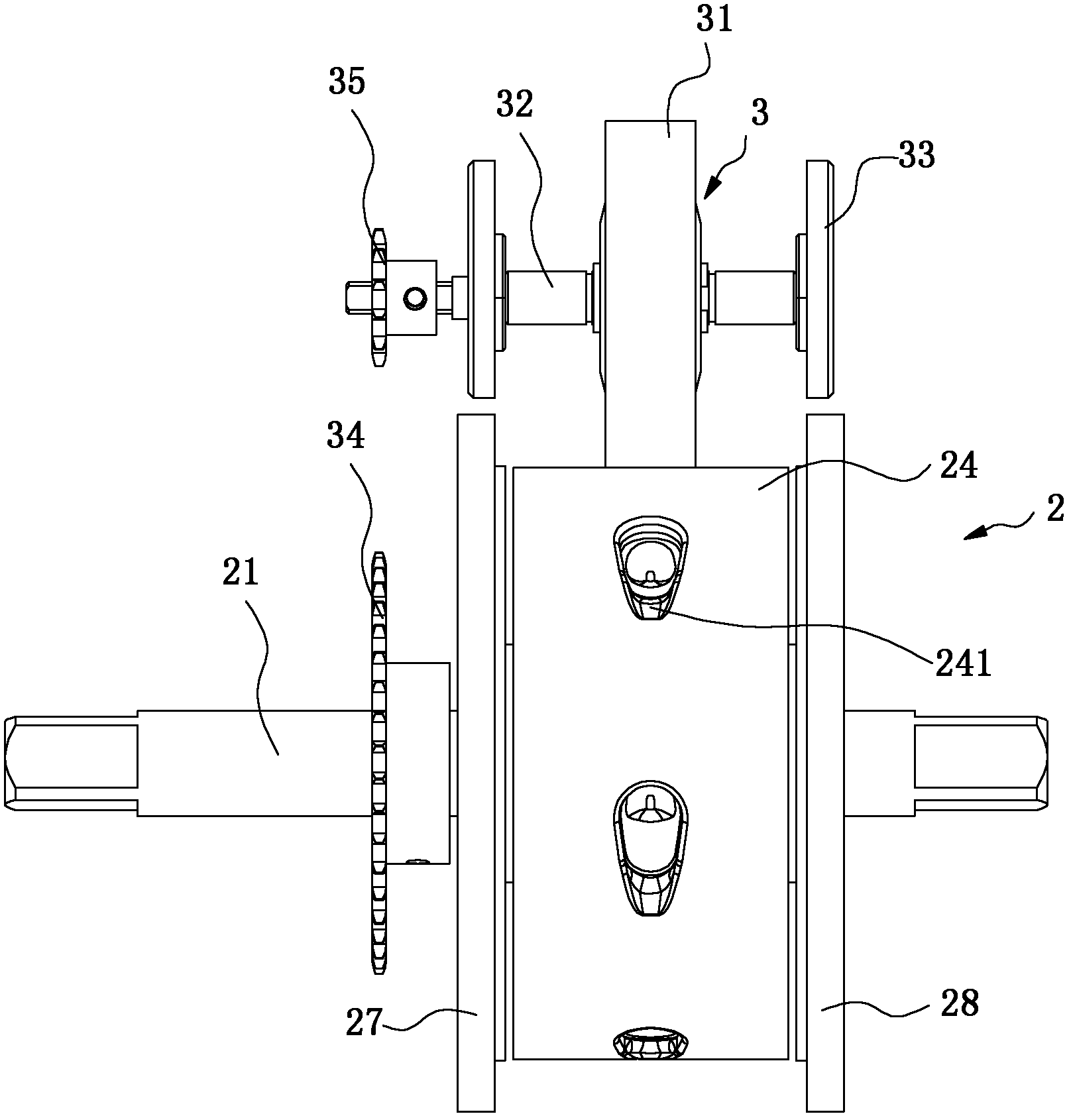

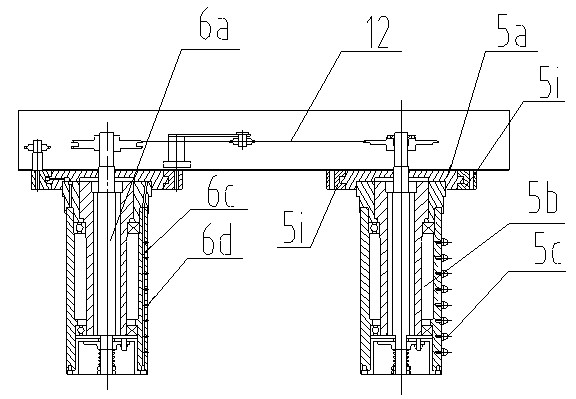

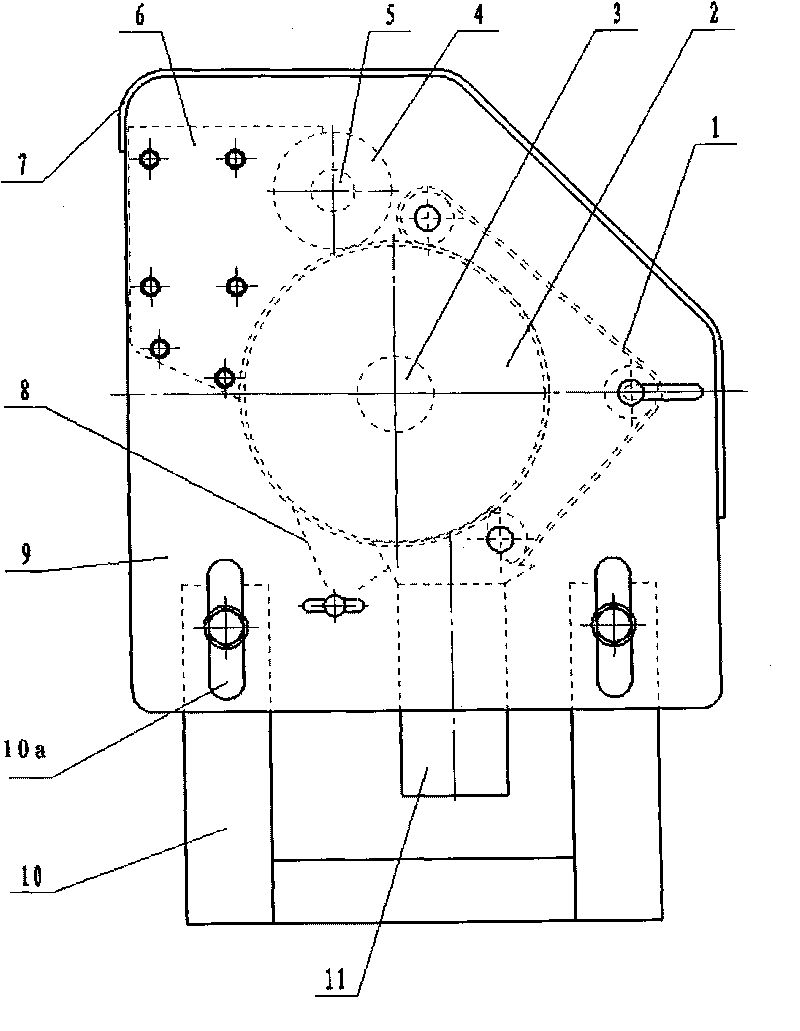

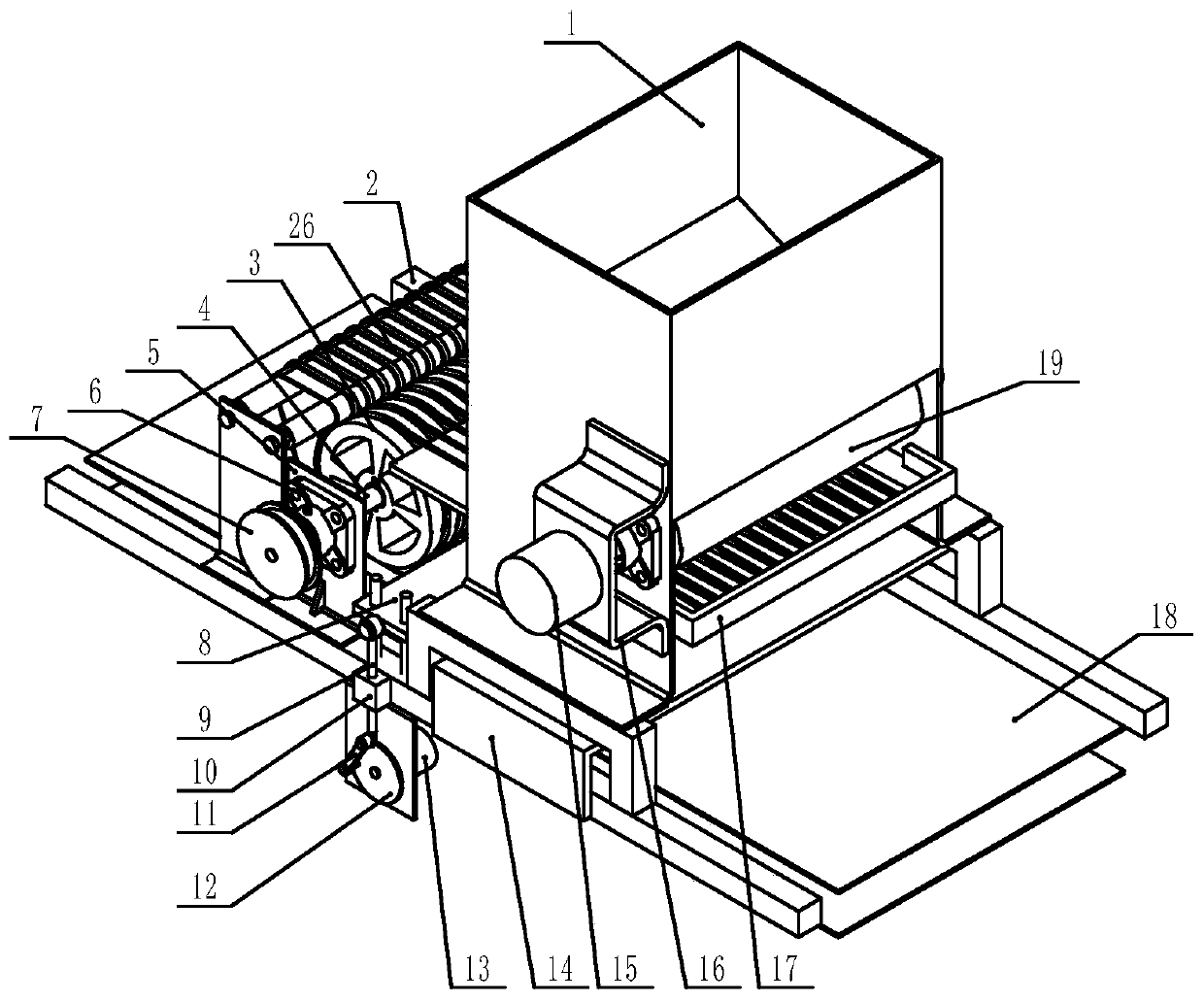

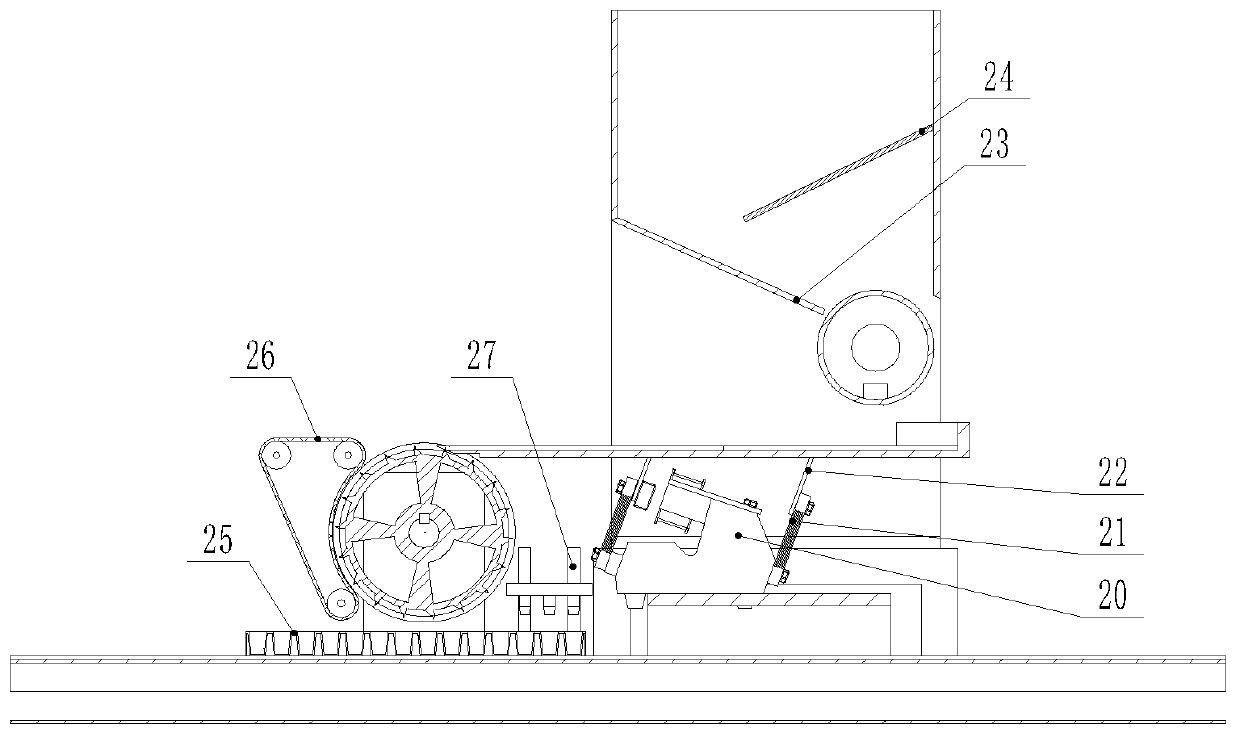

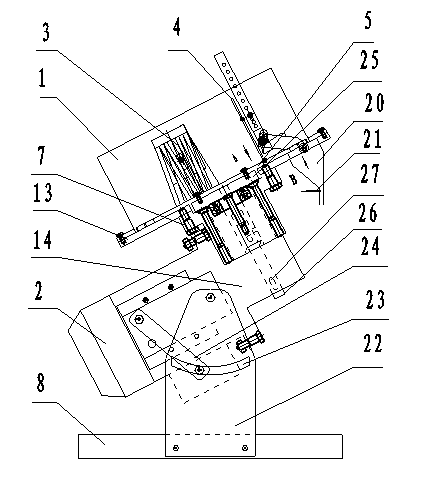

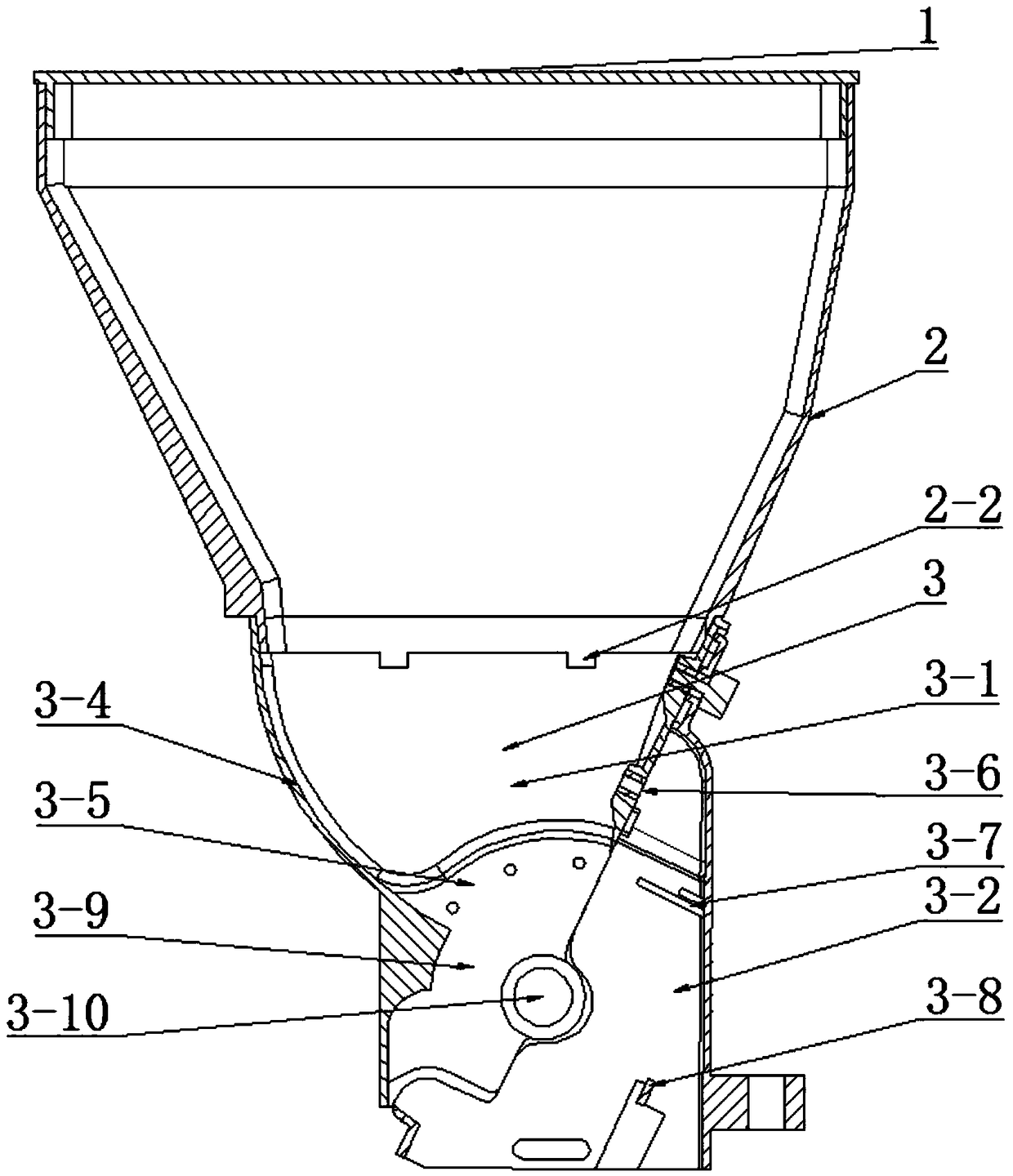

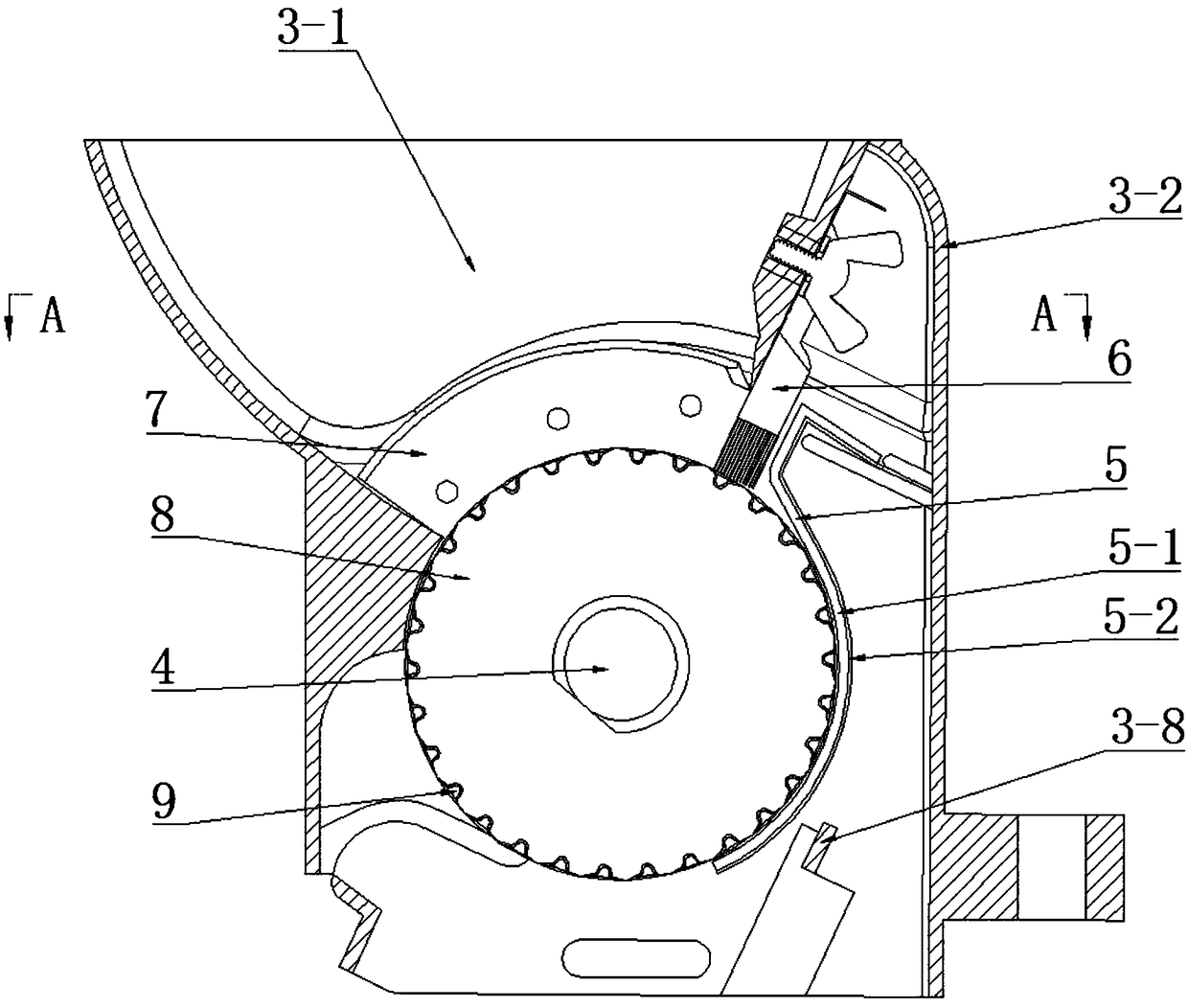

Vacuum adsorption plug seedling precision seeder

InactiveCN102273345ANot easy to damageAccurate broadcastSeed depositing seeder partsSingle grain seedersSeederCoupling

Vacuum adsorption seedling seedling precision seeder, including a conveying device (8) installed on the frame (2) driven by a geared motor (7), located above the conveying device and arranged in sequence from the input end to the output end of the conveying device The tray feeding device (1), covering soil flattening device (3), leveling device (4), pressure hole device (5), vacuum adsorption seeding device (6), in the pressure hole device (5) and vacuum adsorption sowing A synchronous transmission device (12) is connected between the devices (6), and horizontal push rods (10) are evenly distributed on the conveying surface of the conveying device. The invention can realize continuous and automatic completion of seeding and seedling raising work on the entire assembly line, improve seeding continuity and seeding efficiency, and realize seedling seeding seeding of various seed plug trays.

Owner:中国机械总院集团云南分院有限公司 +1

Precision corn seeder

InactiveCN102265732AAchieve precision seedingNo crowding problemsSeed depositing seeder partsSingle grain seedersAgricultural engineeringSowing

The invention discloses a precision corn seeding machine. A structure of the precision corn seeding machine comprises a bottom board, a seed chamber housing connected with the bottom board, and a rotary seed-metering wheel arranged between the bottom boars and the seed chamber housing. The bottom of the seed chamber housing is provided with a sowing hole. A disk surface of the seed-metering wheel is provided with at least a seed holding mouth. A seed biting mechanism capable of opening and closing is arranged on the seed-metering wheel, wherein the position of the seed biting mechanism is relative to the position of the seed holding mouth. A seed-metering hole is arranged on the seed-metering wheel, wherein the position of the seed-metering hole is relative to the bottom of the seed holding mouth. An open of the end of the seed-metering hole is arranged on the outer surface of the seed-metering wheel. With the present invention, the seed biting mechanism is adopted to control one grain of the seed, such that the precision seeding can be realized; the precision corn seeding machine provided by the present invention has advantages of simple structure, low preparation cost and convenient maintenance.

Owner:石家庄市舜农农业机械有限公司

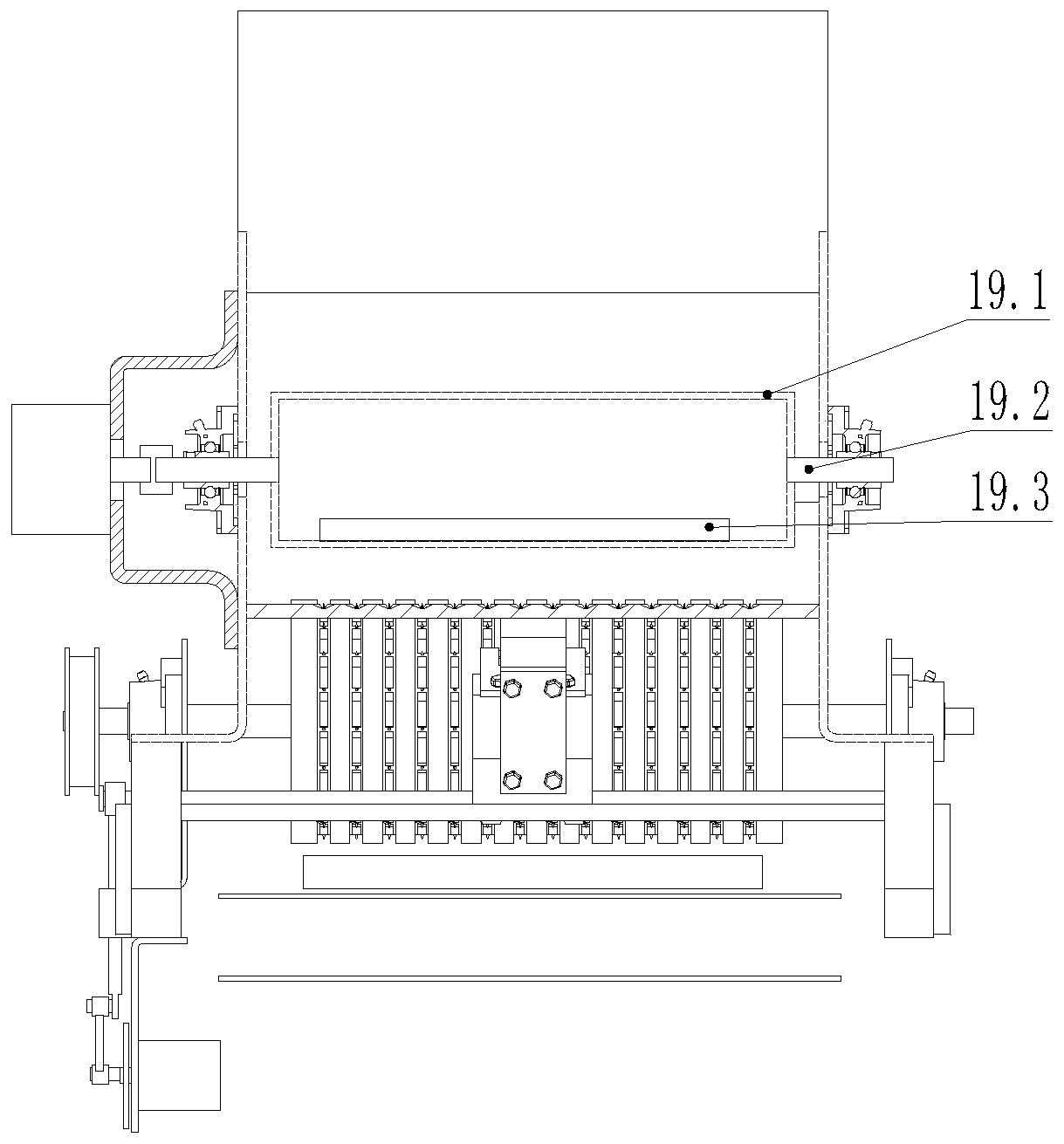

Internal inflation blow type compatible precision seed sowing device for rape and wheat

The invention which belongs to the technical field of seeders concretely relates to an internal inflation blow type compatible precision seed sowing device for rape and wheat. The precision seed sowing device has a closed cavity formed by connecting a seed sowing roller with cover casings, and the closed cavity is divided into a seed protecting zone, a seed inflating zone, a seed clearing zone and a seed unloading zone. The precision seed sowing device comprises the cover casings, the seed sowing roller, a seed protecting plate, a seed conveying tube, an air inlet tube, air separating plates, a seed unloading port, a seed sowing tube and the like; the cover casings are connected into one body through bolts, one cover casing is provided with a balance pore, and the part of one cover casing connected with the seed sowing tube is provided with the seed unloading port; the seed protecting plate and the air separating plates are welded on the inner side of one cover casing; the air inlet tube is welded on the outside of one cover casing; the seed conveying tube which traverses through the circular hole in the middle of one cover casing has a clearance fit with the seed sowing roller; and holes are uniformly distributed on the seed sowing roller along the circumferential direction, the seed sowing roller has a clearance fit with the cover casings, the seed protecting plate and the air separating plates, the seed unloading zone is connected with the positive pressure end of a fan through the air inlet tube, and the seed unloading zone adjusts the flow of an air chamber through the balance pore.

Owner:HUAZHONG AGRI UNIV

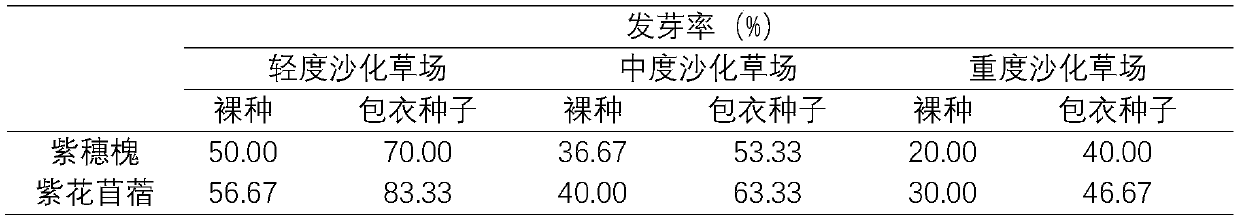

Seed coating agent for ecological remediation of desertified land, coating method and coated seed

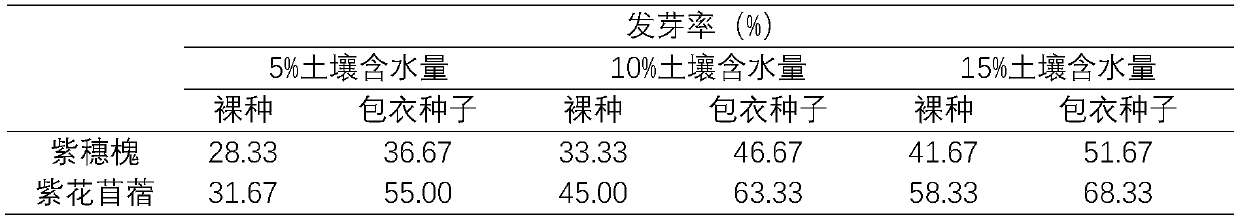

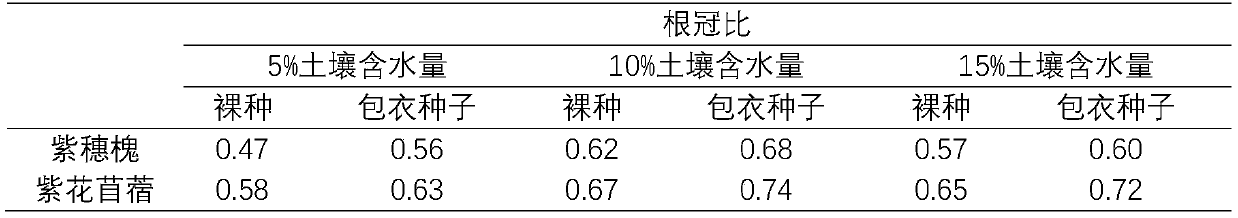

ActiveCN110622967AEasy sowingImprove seedling ratePlant growth regulatorsBiocideAdhesivePlant growth

The invention provides a seed coating agent for ecological restoration of desertified land. The seed coating agent comprises the following raw materials by mass: 80-110 parts of filler, 1-4 parts of super absorbent resin, 0.03-0.11 part of a plant growth regulator, 10-15 parts of humic acid and 0.5-1 part of a rhizosphere microbial strain, and also includes an adhesive, wherein the total mass of the filler, the super absorbent resin, the plant growth regulator, humic acid and the rhizosphere microbial strain and the massic volume of adhesive are in a ratio of (3-8):1, preferably 6.25:1 or 5:1.The germination rate of seeds coated with the seed coating agent is obviously increased, and the root cap ratio of seedlings is obviously increased, therefore the seed coating agent can be applied toagricultural production.

Owner:MEILIGUOTU BEIJING ECOLOGICAL ENVIRONMENT ENG TECH RES INST CO LTD

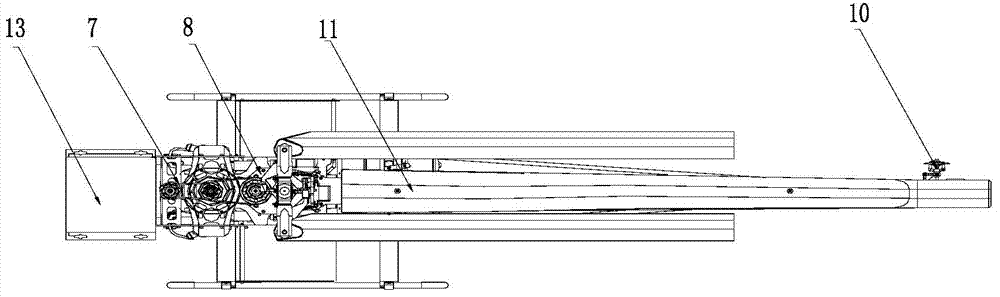

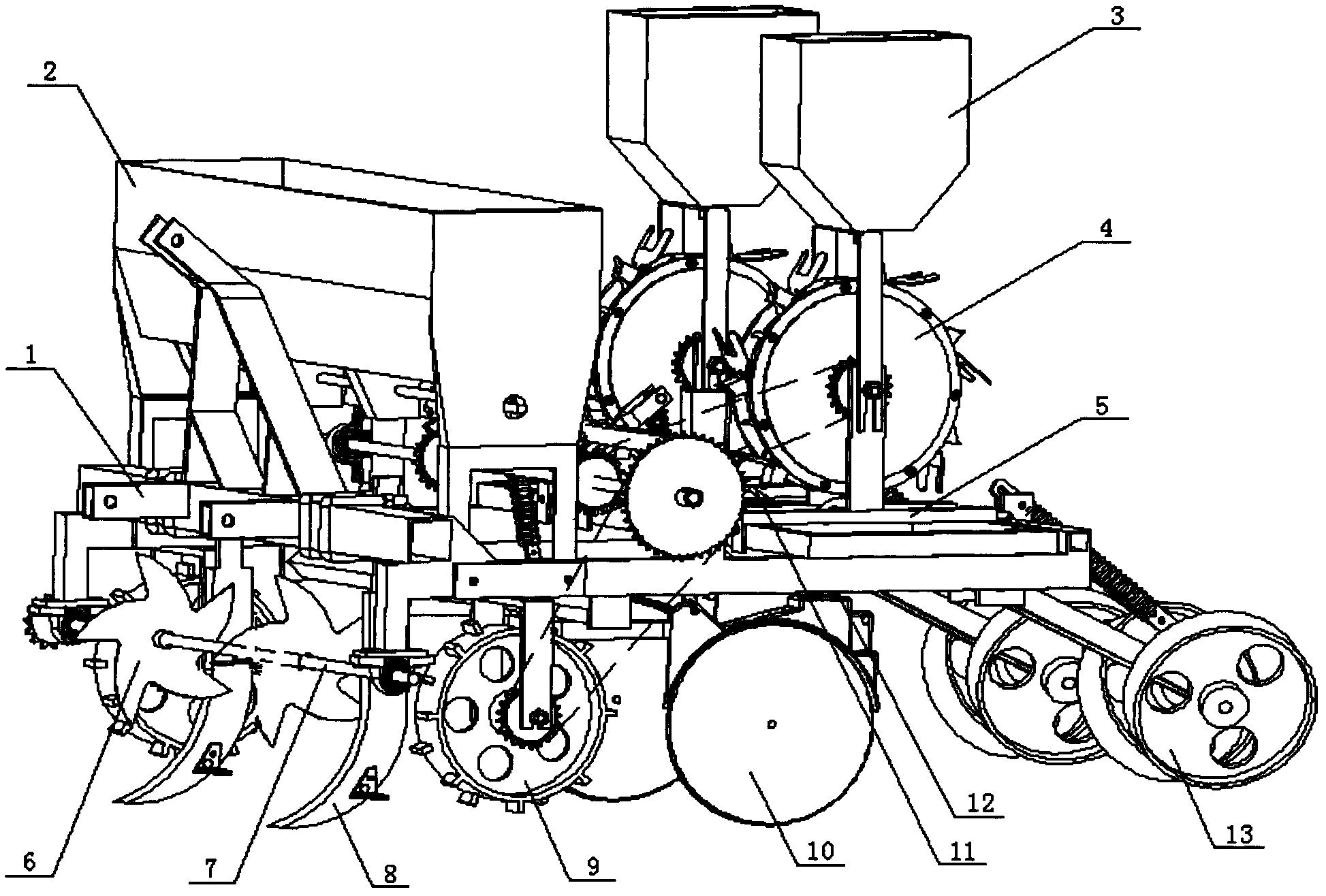

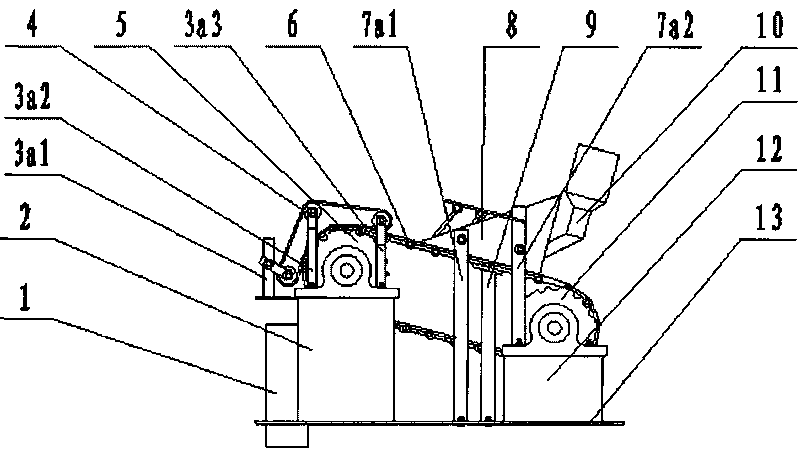

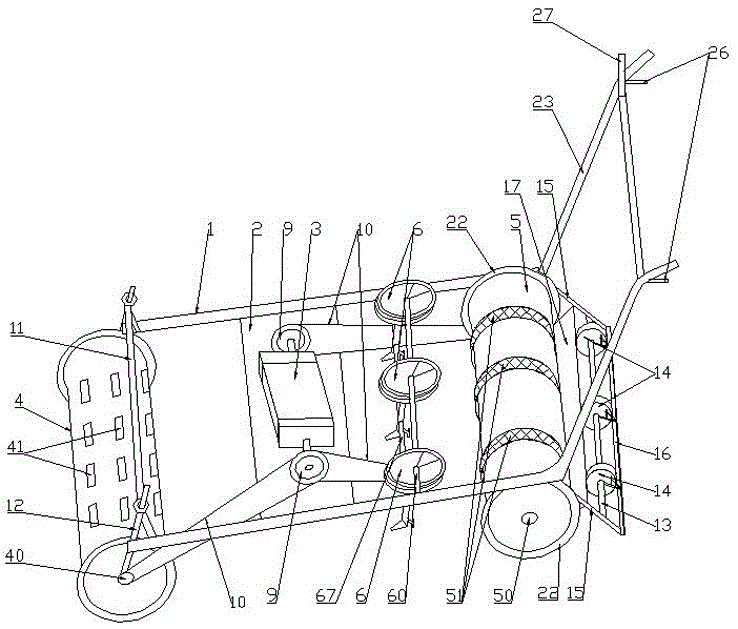

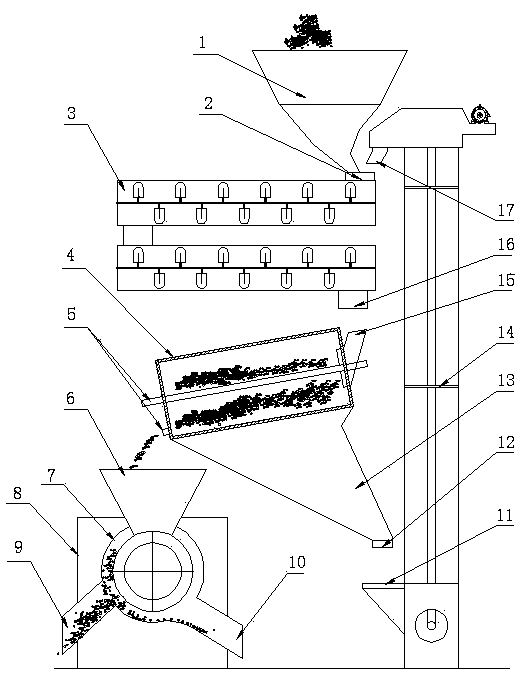

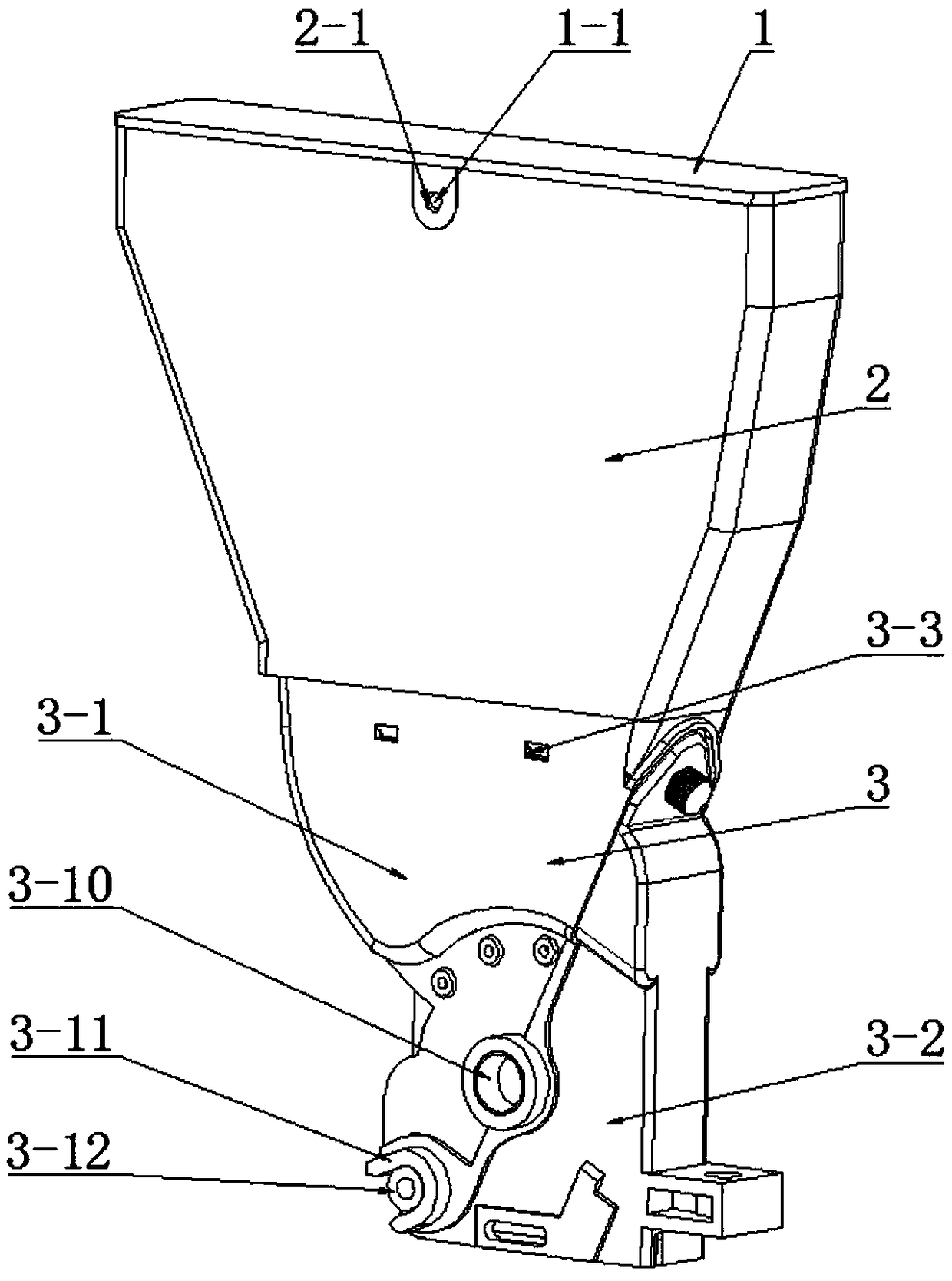

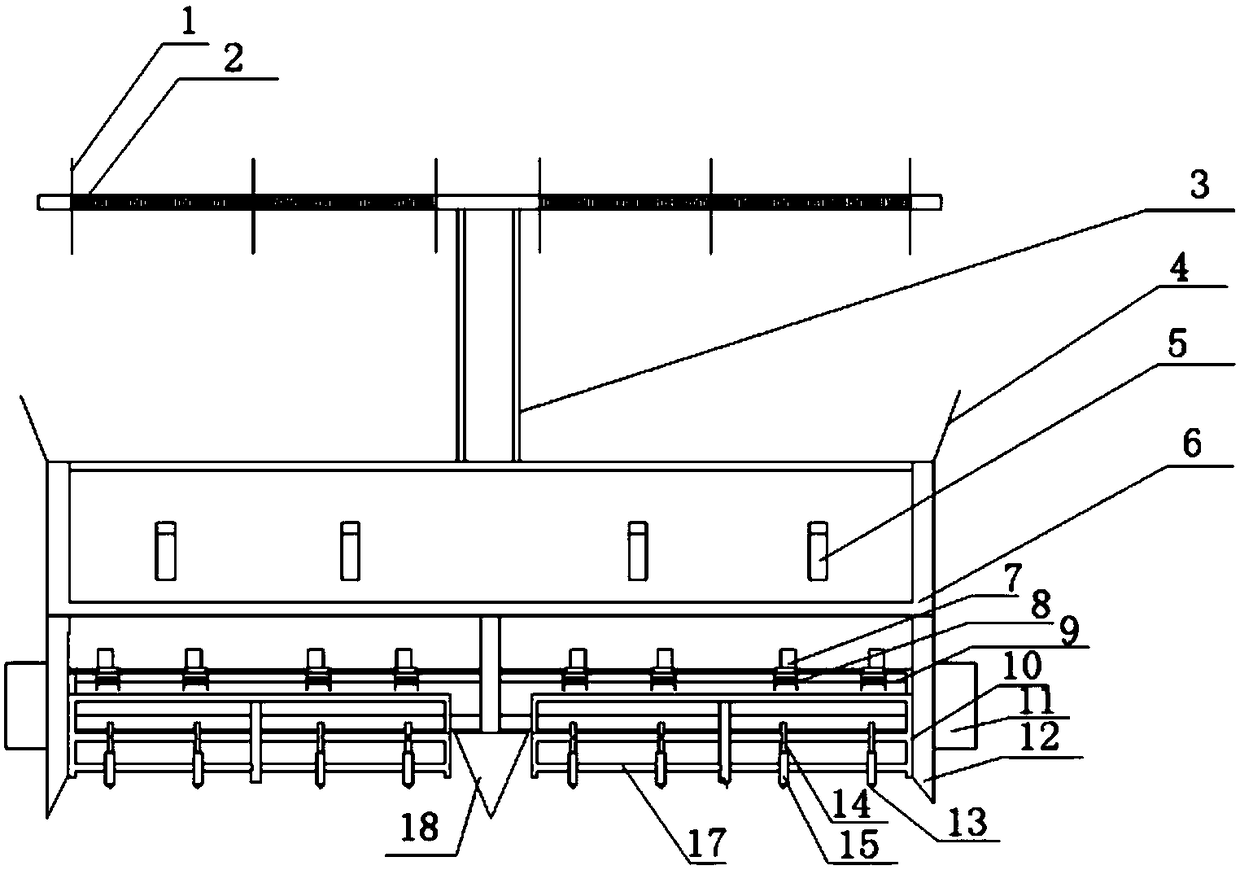

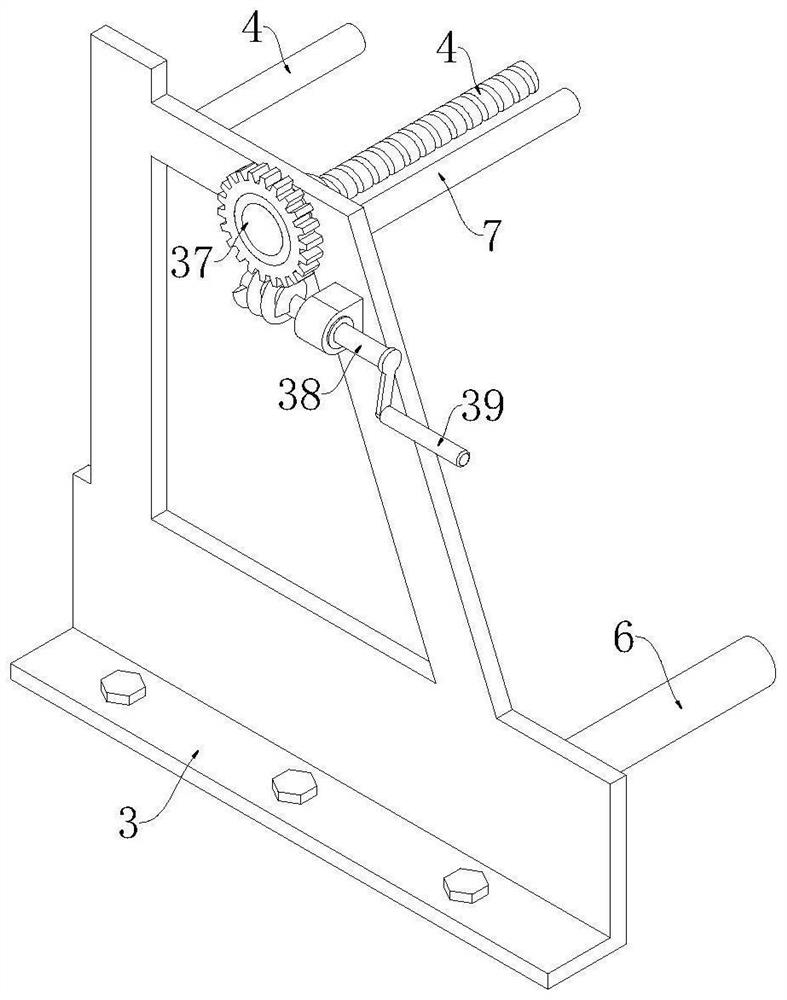

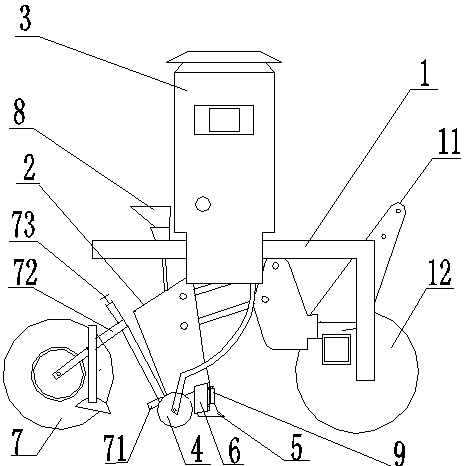

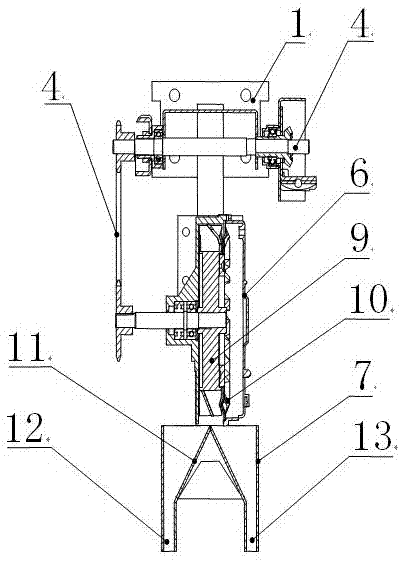

Active anti-blockage type zero-tillage precision seed planter

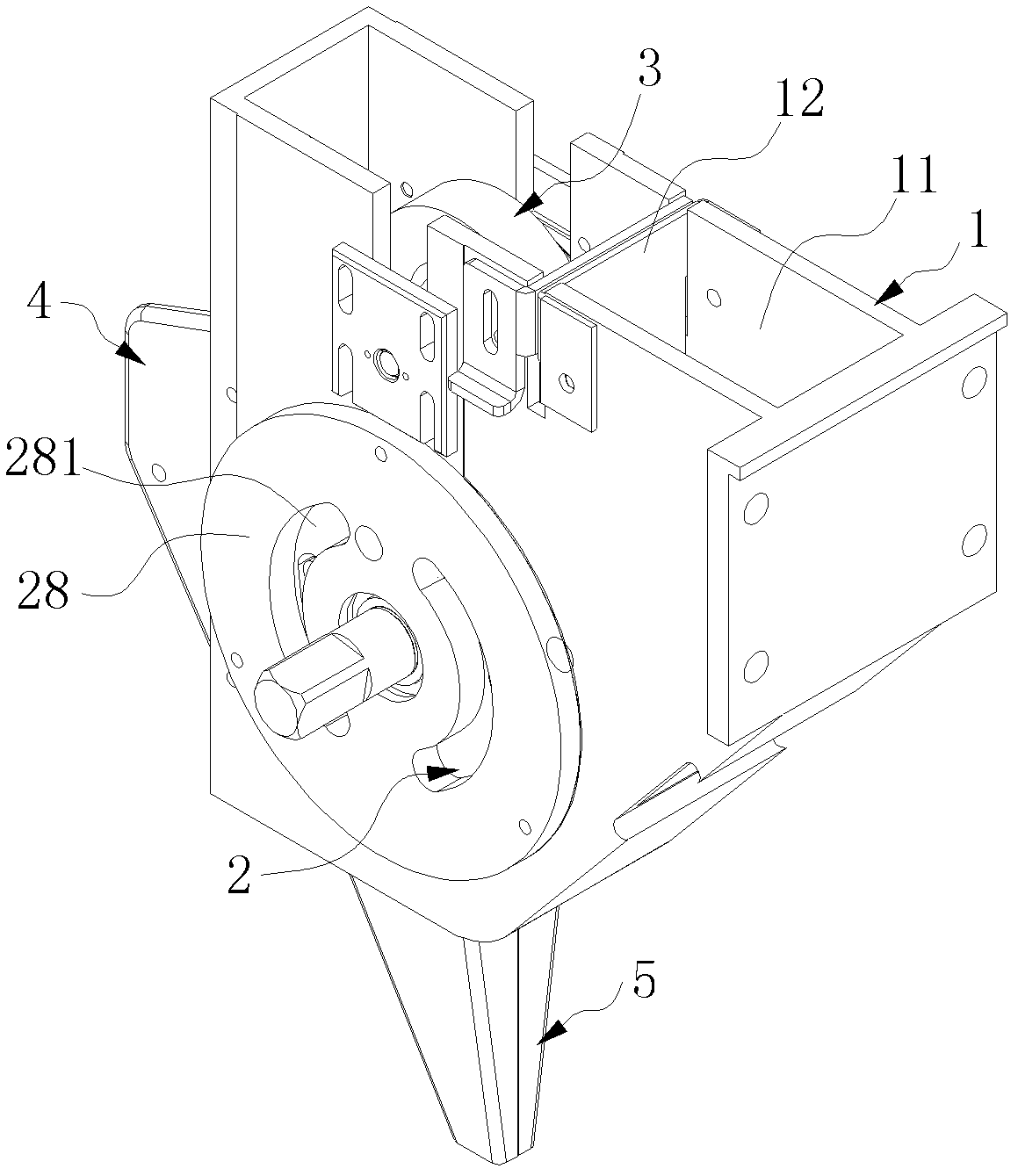

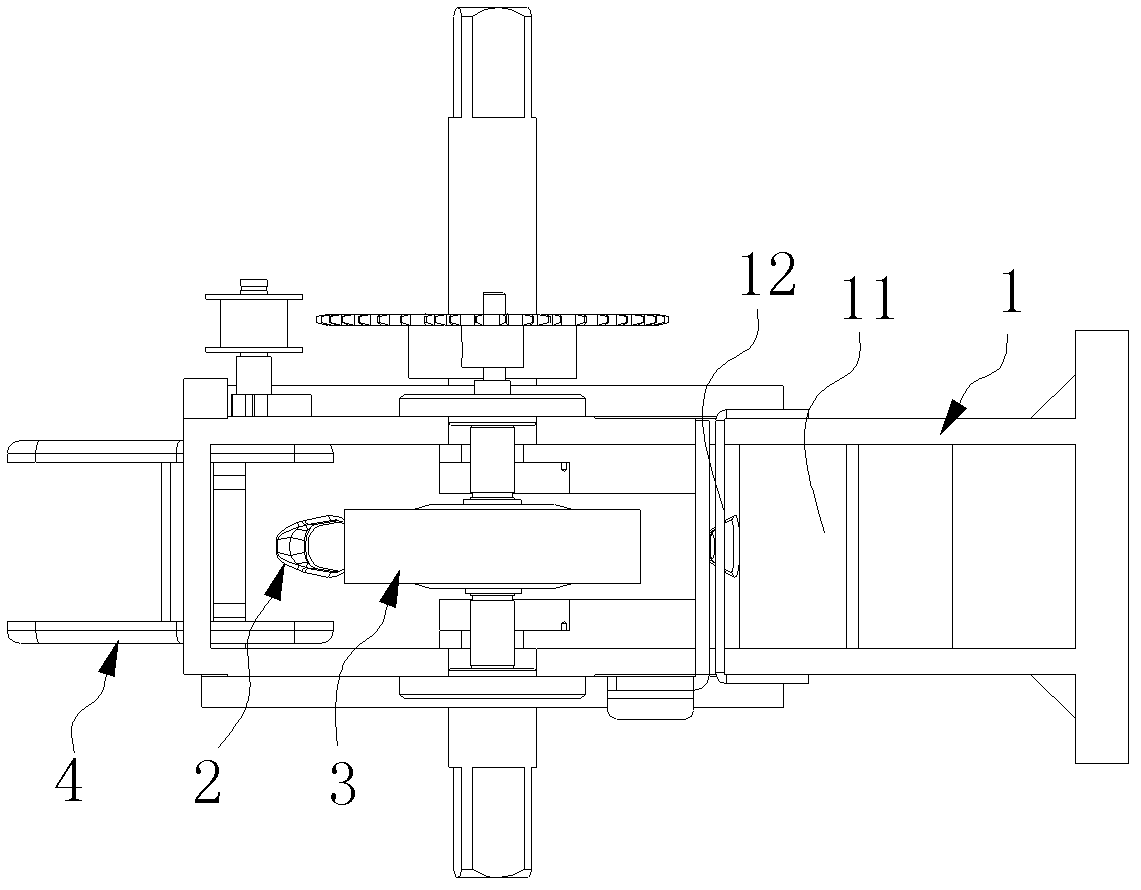

The invention relates to a corn zero-tillage seed planter capable of completing operations of stubble breaking, ditching, fertilizing, earthing, compacting, etc., belonging to the technical field of agricultural machinery. The zero-tillage seed planter comprises a machine frame (1), a fertilizer box (2), a seed box (3), a precision seed metering device (4), a bracket (5), anti-blockage blades (6), a shaft (7), a cutting edge stubble breaking opener (8), ground wheels (9), a double-disc opener (10), a duckbilled unfolding device (11), a seed receiving box (12), and earthing compacting wheels (13). During the working, the ground wheel at one side drives a chain wheel to drive the fertilizer device, the fertilizer falls into a ditch opened by the cutting edge stubble breaking opener, the ground wheel drives the anti-blockage blades to rotate so as to cut straws and weeds in a sliding way, the ground wheel at the other side drives the precision seed metering device by means of chain drive so as to force to open a duckbill to discharge the seeds, then the seeds fall into the ditch by the seed receiving box and a seed discharge pipe so as to realize secondary precision seed discharge, and the seeds are then earthed and compacted by the compacting wheels, in this way, the operations of stubble breaking, ditching, fertilizing, earthing, compacting, etc. are completed.

Owner:XINJIANG ACADEMY OF AGRI & RECLAMATION SCI

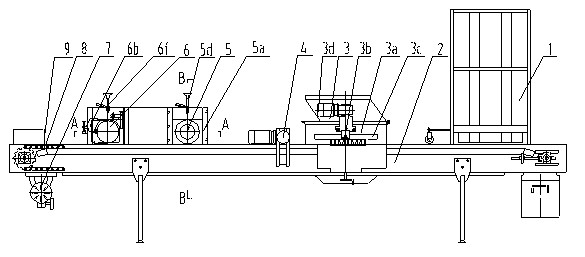

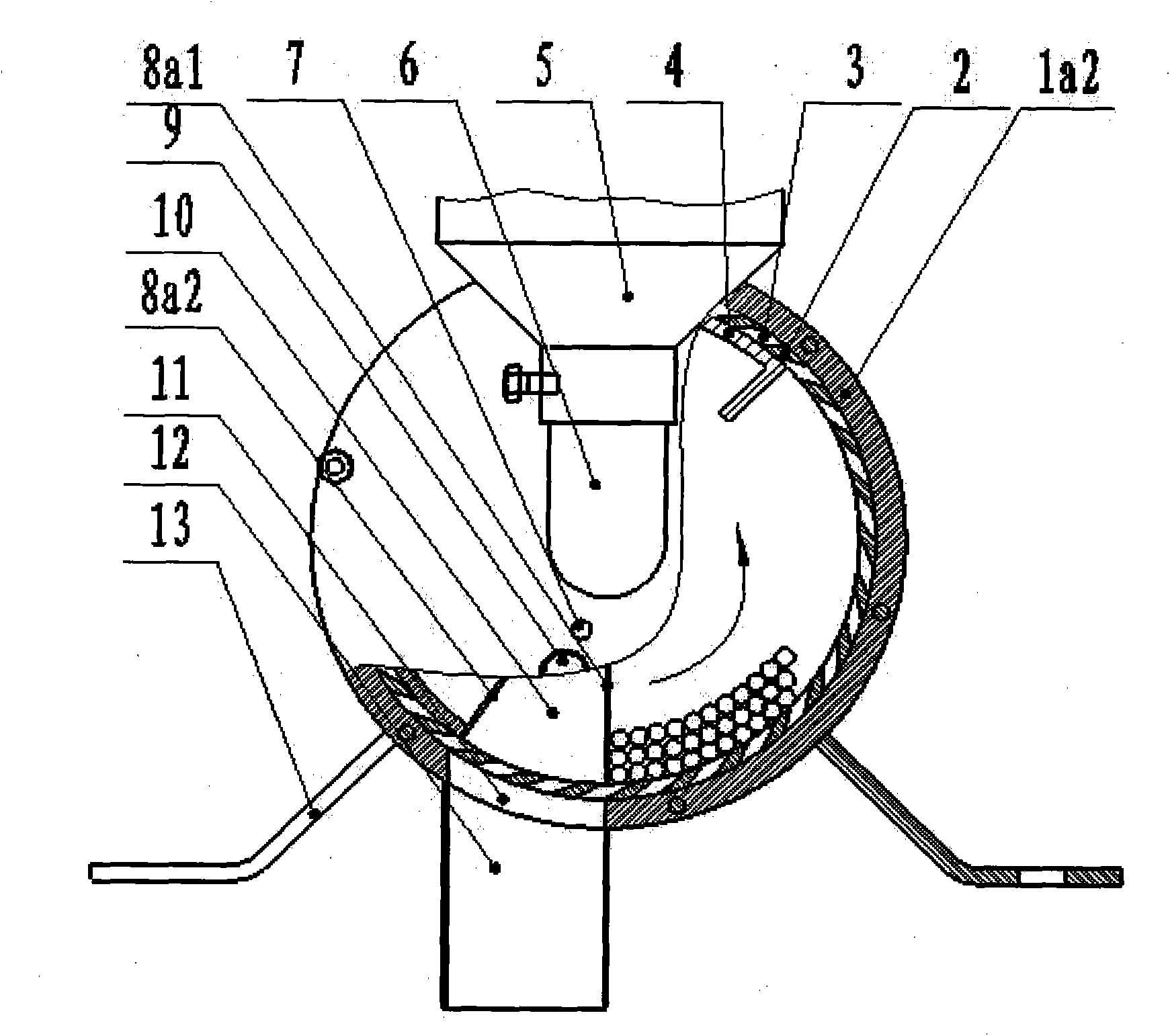

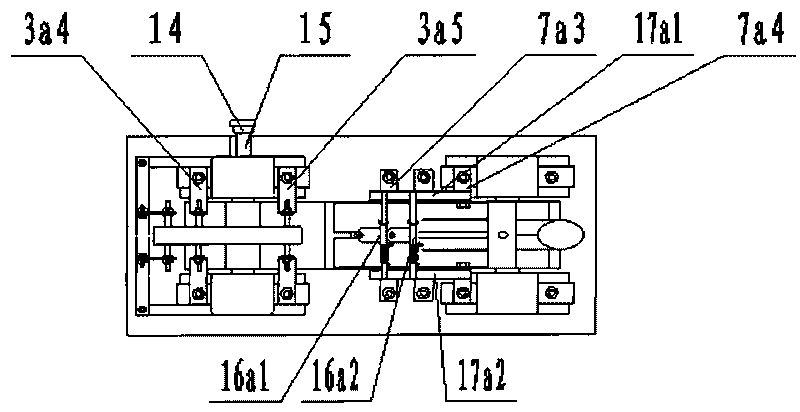

Belt type precision seed-metering device for rape

InactiveCN101702970AAchieve precision seedingAvoid damageSeed depositing seeder partsBroadcast seedersEngineeringDrive shaft

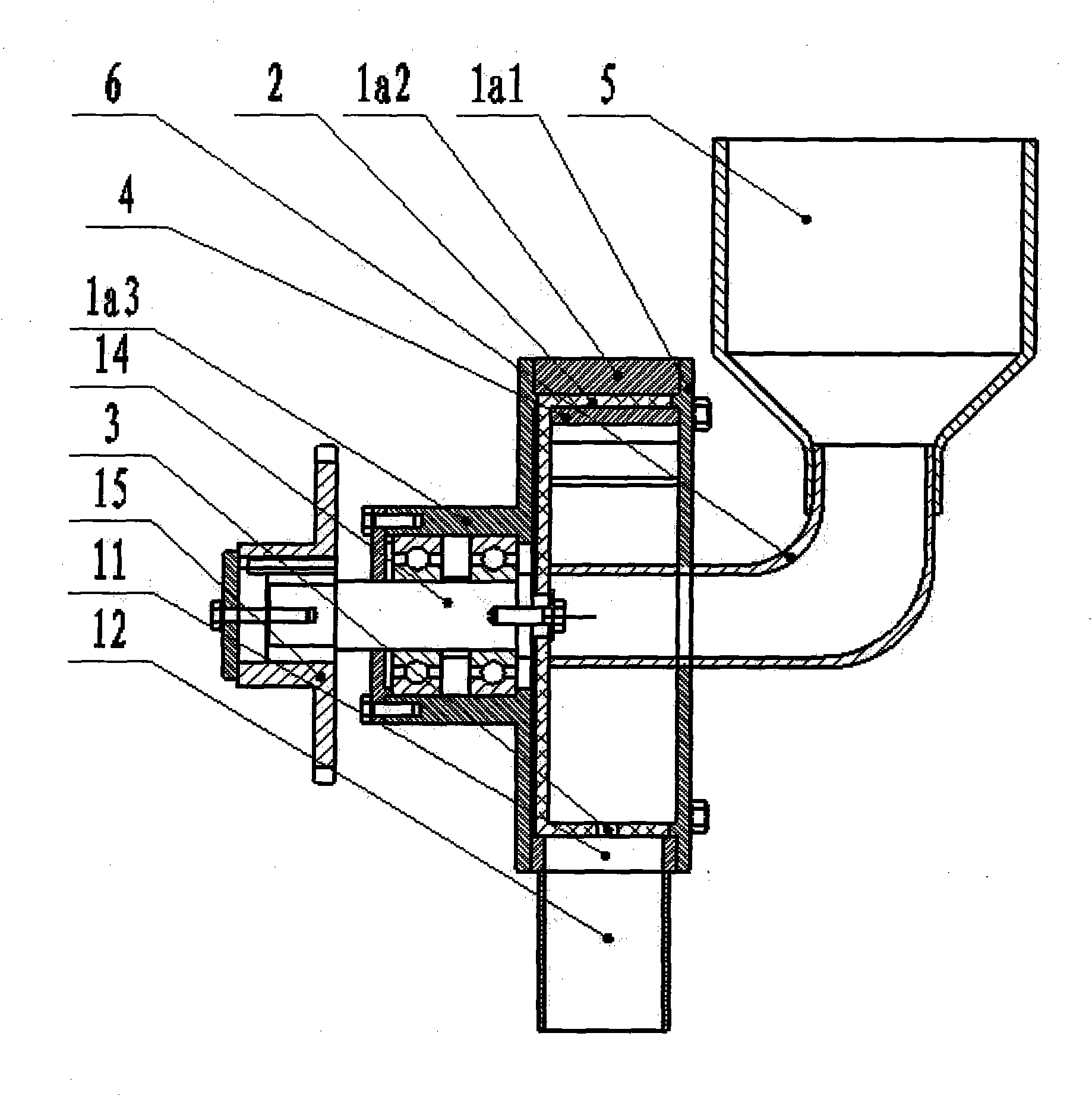

The invention relates to a belt type precision seed-metering device for rape, which comprises main devices such as a seed-metering belt (6), a seed protection device (4), seed cleaning devices (16) and the like, wherein a chain wheel (14) is connected with a driving shaft (15) through a key, and a driving belt wheel (5) is arranged on the driving shaft (15) and is connected with a driven belt wheel (8) through the seed-metering belt (6); the seed protection device (4) is connected with a front bracket (2) through seed protection brackets (3a1, 3a2, and 3a3) respectively; the seed cleaning devices (16a1 and 16a2) are connected to lower seed box brackets (7a2 and 7a4) through seed cleaning brackets (17a1 and 17a2); a seed guide tube (1) is arranged on a bottom plate (13); an upper seed box is arranged on a lower seed box (8); and the lower seed box (8) is connected with the bottom plate (13) and a rear bracket (12) through a lower seed box bracket (7a1) and a lower seed box bracket (7a2) respectively. The device can also be applied to plot seeders of other seeds with middle and small grain diameters.

Owner:HUAZHONG AGRI UNIV

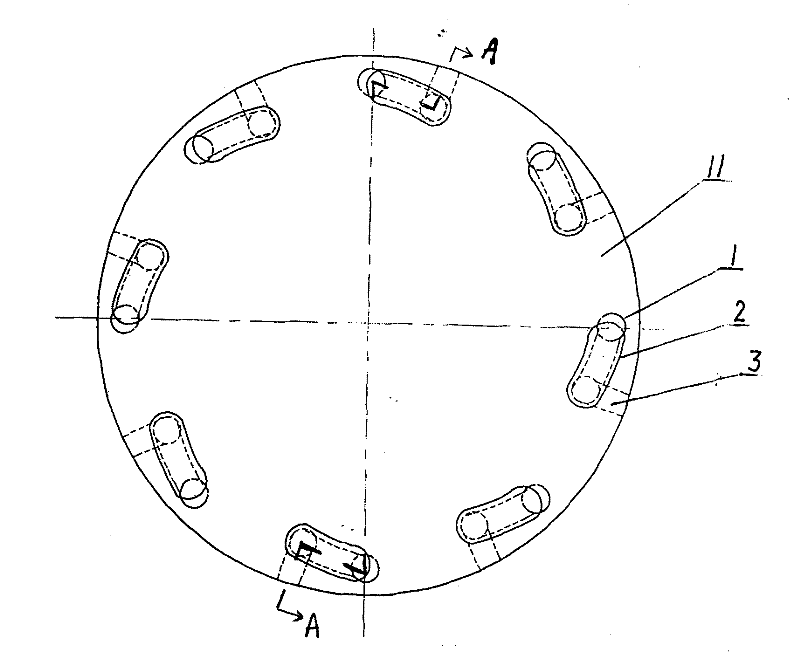

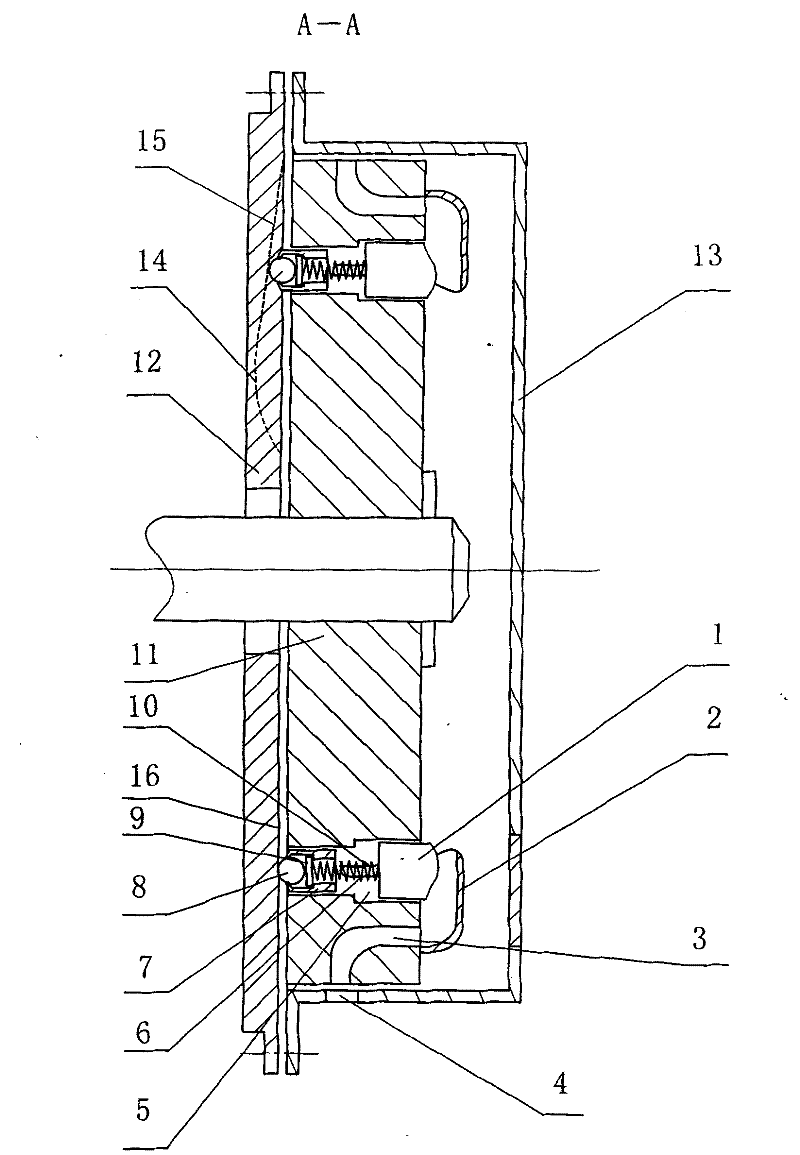

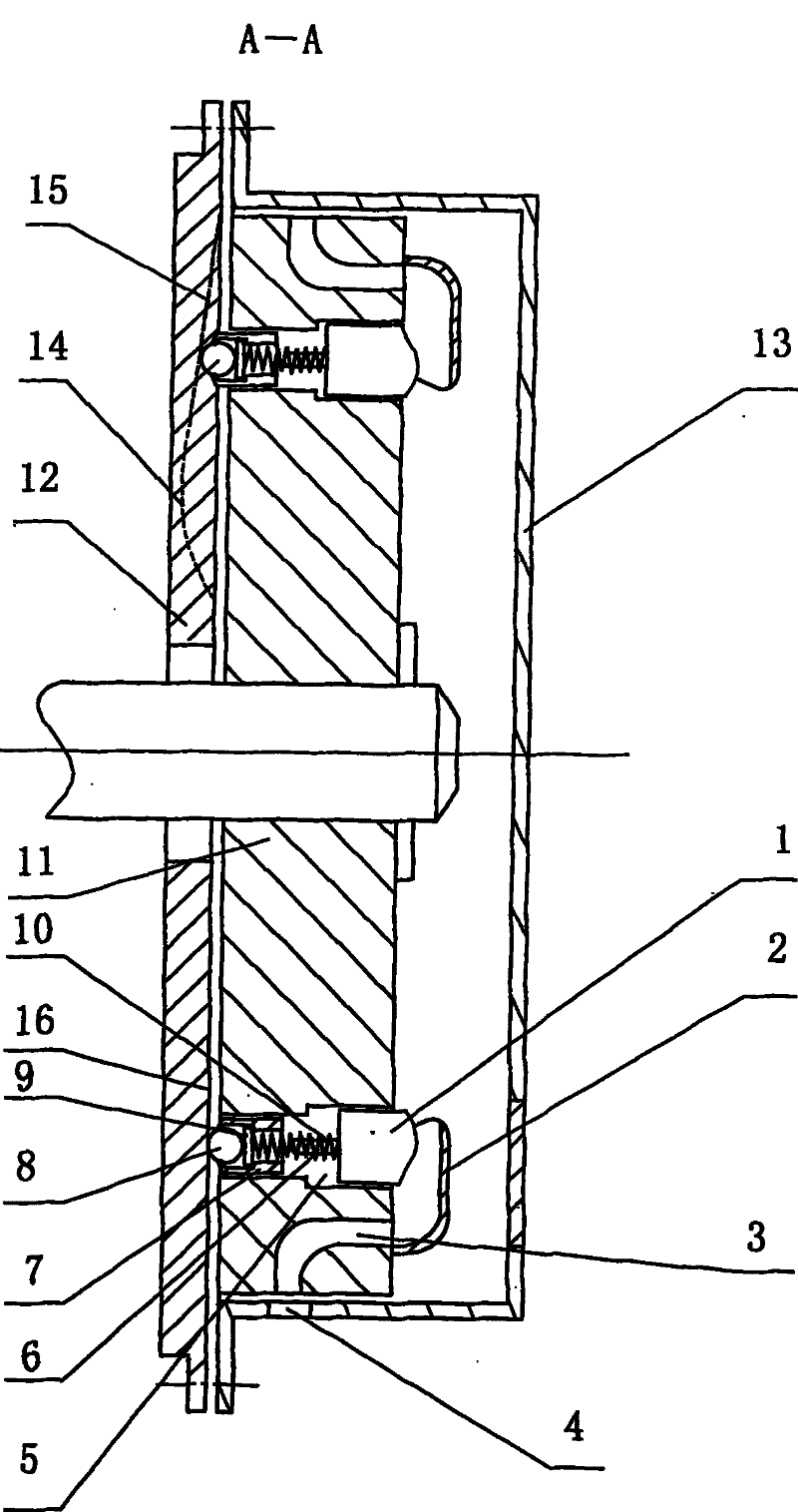

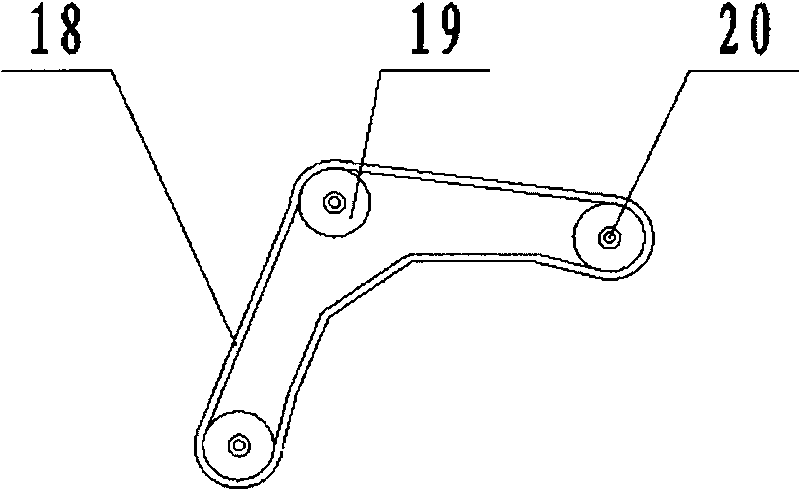

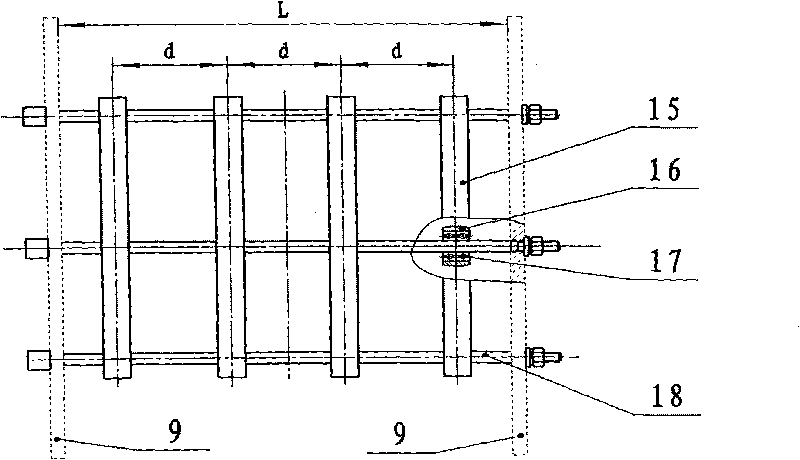

Multi-row slot-hole-wheel-type precise rape seeding device

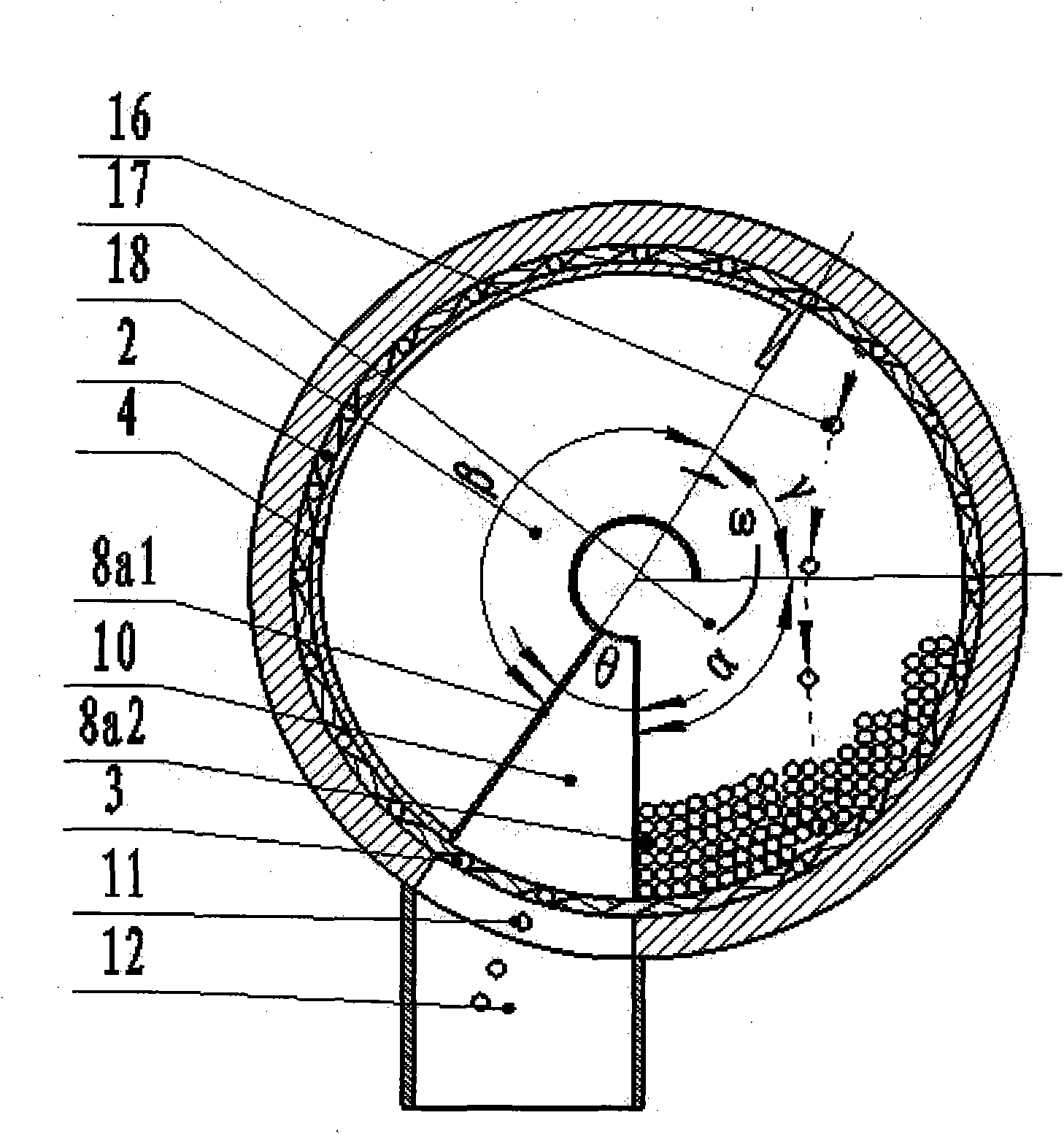

InactiveCN101720588AAchieve precision seedingHigh seeding precisionBroadcast seedersSeederAgricultural engineering

The invention belongs to the technical field of seeding devices of agricultural mechanical seeders. A multi-row slot-hole-wheel-type precise rape seeding device comprises a seed protecting device, a seeding roller, a seeding shaft, a seed emptying wheel, a seed emptying shaft, a seed box, a seeding device shell, a seed pushing steel wire, side plates, a seeding device bracket and a seed feeding opening, wherein the seeding roller is in key connection with the seeding shaft; the seeding shaft is arranged on bearing seats on a left side plate and a right side plate; the seed emptying wheel is in the key connection with the seed emptying shaft; the seed emptying shaft is arranged on the bearing seats on the left side plate and the right side plate; the seed box is positioned on one side of the seeding roller and is connected on the left and right side plates; the lower side of the seed box is provided with a seed roller in a closely contact way; the seeding device shell is positioned above the seeding device and is arranged on the left and right side plates through bolts; input power drives the seeding shaft through chain drive; the power on the seeding shaft is transmitted to the seed emptying shaft after changing speed through a pair of drive chain wheels; and the seed protecting device moves automatically under the action of the friction force of the seeding roller. The multi-row slot-hole-wheel-type precise rape seeding device has the characteristics of novel design, compact structure, four rows of one device, adjustable seeding height and low seed breakage rate.

Owner:HUAZHONG AGRI UNIV

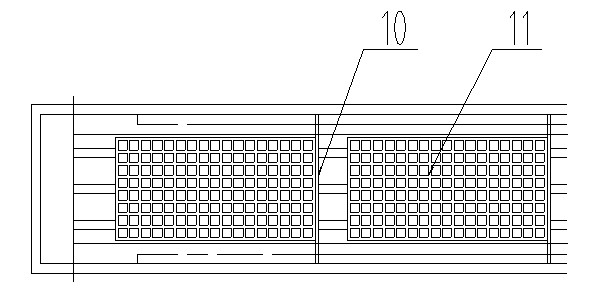

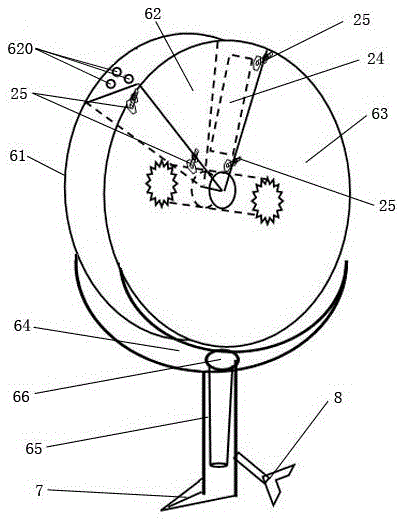

Rice single-kernel directional precision seeding device

InactiveCN110149850AAchieve precision seedingHigh single grain rateSingle grain seedersAgricultural engineeringSingle level

The invention relates to the technical field of agricultural machinery, in particular to a rice single-kernel directional precision seeding device, and overcomes the defect that the prior art experiences low single-kernel rate and high damage rate during seeding. The rice single-kernel directional precision seeding device comprises a seed box, a frame, a shift-needle rice seed feeding wheel, a reciprocating hole compression plate, a V-groove vibrating conveying plate, an eccentric vibrating feeding roller, a vibrator, a vibration damping plate and a synchronous seed-protecting belt. A mountingplate is connected to the top of the frame through screws; rice seeds are supplied nondestructively according to the principle of vibrational fluidization; the V-groove vibrating conveying plate allows seeds to be arranged and conveyed orderly in single layer; the shift-needle rice seed feeding wheel is used with the V-groove vibrating conveying plate; a seed supply direction matches with a seedfeeding direction, shift needles provide assistance to the V-groove vibrating conveying plate, the single seeds arranged orderly above are charged into holes, and therefore, high single kernel rate, high operating efficiency, low empty hole rate and good operating reliability are achieved, and precision seeding is also achieved.

Owner:苏州事泽科技有限公司

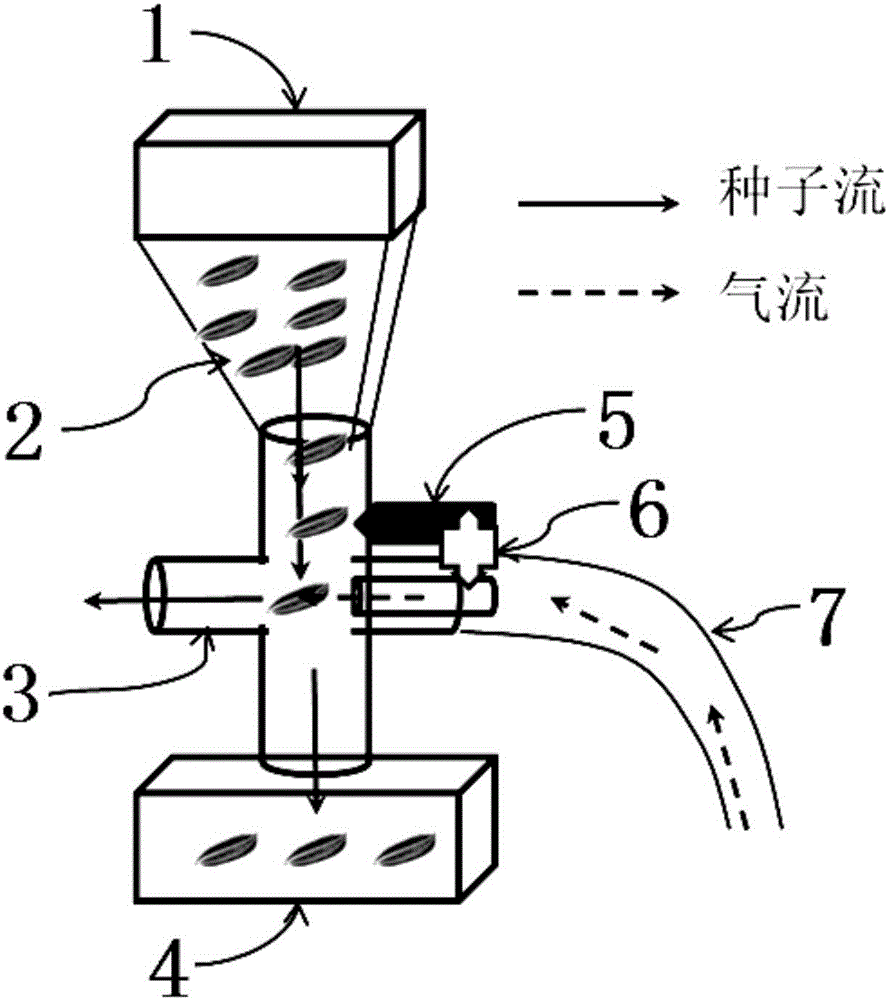

Seed spray device and sowing method

InactiveCN106576528AAchieve precision seedingPrecise control of particle numberSeed depositing seeder partsRegular seed deposition machinesEngineeringSowing

The invention discloses a seed spray device and a sowing method. The seed spray device comprises a seed box, a seed groove, an spray pipe and a blowing device, wherein the seed box is located above the seed groove; the seed groove is communicated with the spray pipe through a seed guidance pipe; the blowing device is communicated with the spray pipe through a pipeline to blow seeds falling down from the seed groove into the spray pipe. The blowing device of the seed spray device blows the seeds falling down from the seed groove into the spray pipe through the pipeline, and then the seeds fall into a field to achieve precise sowing, thus achieving the effects of saving the seeds, improving the efficiency and increasing the yield.

Owner:HUNAN AGRICULTURAL UNIV

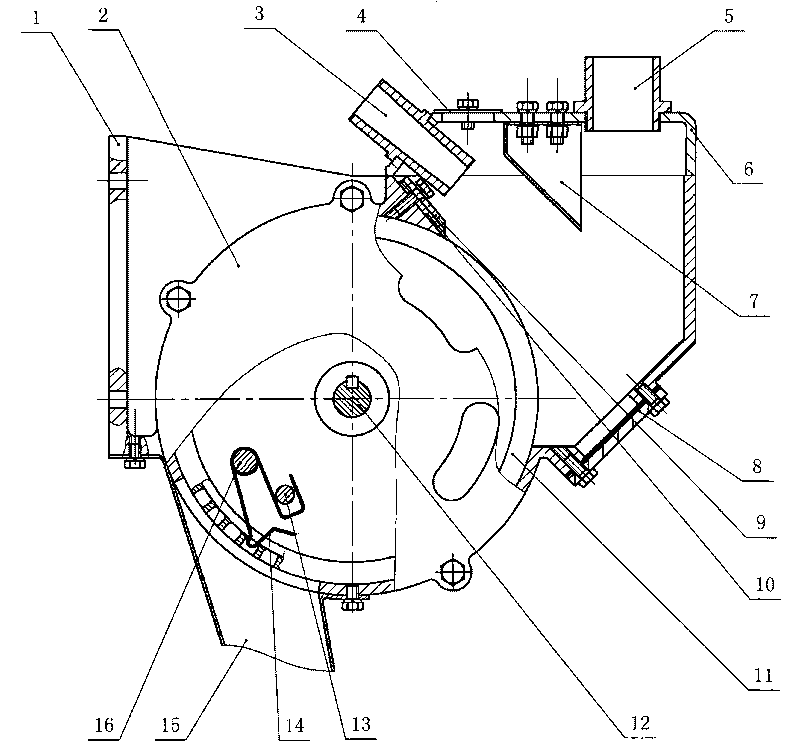

Universal pneumatic seed-metering device for soy beans and corn

InactiveCN101690448AImprove versatilityAchieve precision seedingSeed depositing seeder partsSingle grain seedersAgricultural machinerySoya bean

The invention relates to a universal blowing-type precision seed-metering device for soy beans and corn, which belongs to an agricultural machine. The universal pneumatic precision seed-metering device for the soy beans and the corn comprises a seed shell (1), an inoculated tube (5), an upper cover (6), a seed cleaner (10), a seed wheel (11) and a seed tube (15). The universal pneumatic precision seed-metering device for the soy beans and the corn is characterized in that: the seed wheel (11) is arranged in the seed shell (1); an inner side of the seed wheel (11) is provided with a seed cleaning groove communicated with the bottom of a shaped hole; the top of the upper cover (6) is provided with the inoculated tube (5) and a seed guide plate (7); the seed guide plate (7) is positioned above the seed wheel (11); a front end and the top of the upper cover (6) are provided with blowing nozzle mounting holes; a blowing nozzle (3) is arranged in one of the mounting holes and the other blowing nozzle mounting hole is sealed by a cover board (4); and a seed-metering device cover (2) is provided with a seed cleaning mechanism. The seed-metering device can overcome the defects of sowing leakage and seed blocking of the blowing-type seed-metering device and improve the universality of the seed-metering device.

Owner:JILIN UNIV

Circular-disc type precision drill seeding device of small-seed crops

ActiveCN105532135AAccurate locationEasy to disassemblePlantingFurrow making/coveringAgricultural engineeringThinning

The invention provides a circular-disc type precision drill seeding device of small-seed crops. The device comprises a bracket, a front roller, a rear roller, a plurality of seeding mechanisms and an engine, wherein each seeding mechanism comprises a sleeve, a seeding box for containing seeds and a seeding box case; a furrow opener is arranged at the lower end of each sleeve, and the upper end of each sleeve is fixedly connected with the corresponding seeding box case; a case opening penetrating through the sleeve is formed in each seeding box case; the bracket is further provided with fixed connecting rods for connecting the sleeves; each seeding box is of a round structure formed by a first sector-shaped seeding disc and a second sector-shaped seeding disc, which are in butt joint; seed discharging holes are formed in the outer peripheries of the first sector-shaped seeding discs; one side face of each first sector-shaped seeding disc and one side face of each second sector-shaped seeding disc, which are arranged adjacently, are sealed; the other side faces, which are arranged adjacently, of each first sector-shaped seeding disc and each second sector-shaped seeding disc are communicated with each other; seeds passing through the seed discharging holes drop off from the case openings and fall into seed furrows opened by the furrow openers through the sleeves. When the device is used for seeding, the device does not slip and has a good compaction effect, and a precision seeding effect with less thinning is realized.

Owner:SHANXI AGRI UNIV

Broken seed cleaning method and equipment

InactiveCN104226467AChange the disadvantages of traditional artificial selectionAchieve precision seedingMagnetic separationSowingElectromagnetic field

The invention belongs to the technical field of seed processing. Broken seed cleaning equipment comprises a seed and metal powder mixing mechanism and an electromagnetic separation mechanism, wherein the electromagnetic separation mechanism is provided with a rack, an upper feeding hole, a lower finished seed outlet and a broken seed outlet; A broken seed cleaning method comprises the following steps: I, mixing seeds and metal powder fully by adopting the seed and metal powder mixing mechanism, wherein the metal powder are adhered onto or permeated in the broken seeds, and qualified seeds cannot be adhered or permeated by the metal powder; and II, separating out the broken seeds by the electromagnetic separation mechanism, putting the seeds in the step I in the electromagnetic separation mechanism and separating the broken seeds and the qualified seeds under the action of an electromagnetic field. According to the broken seed cleaning method and equipment, the broken seeds adhered or permeated by the metal powder can be effectively separated out from the qualified seeds, the disadvantages of traditional artificial seed selection are overcome and the precision sowing can be achieved.

Owner:石河子市华农种子机械制造有限公司

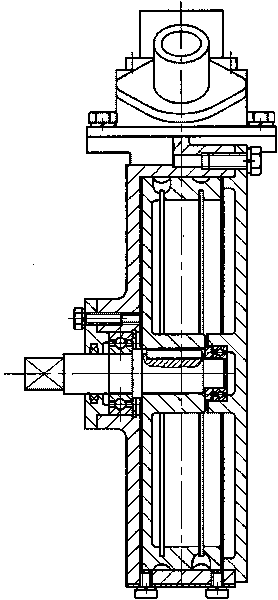

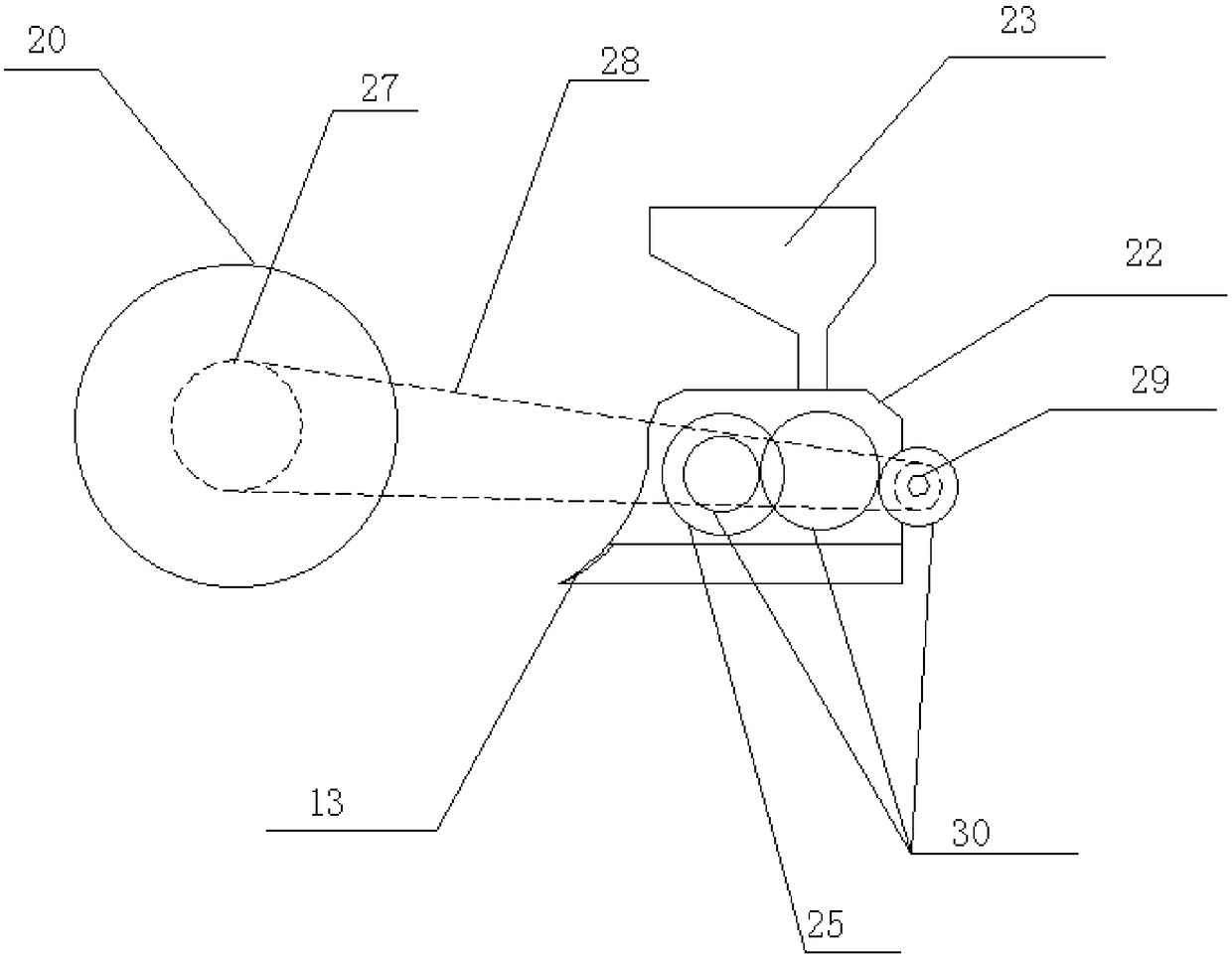

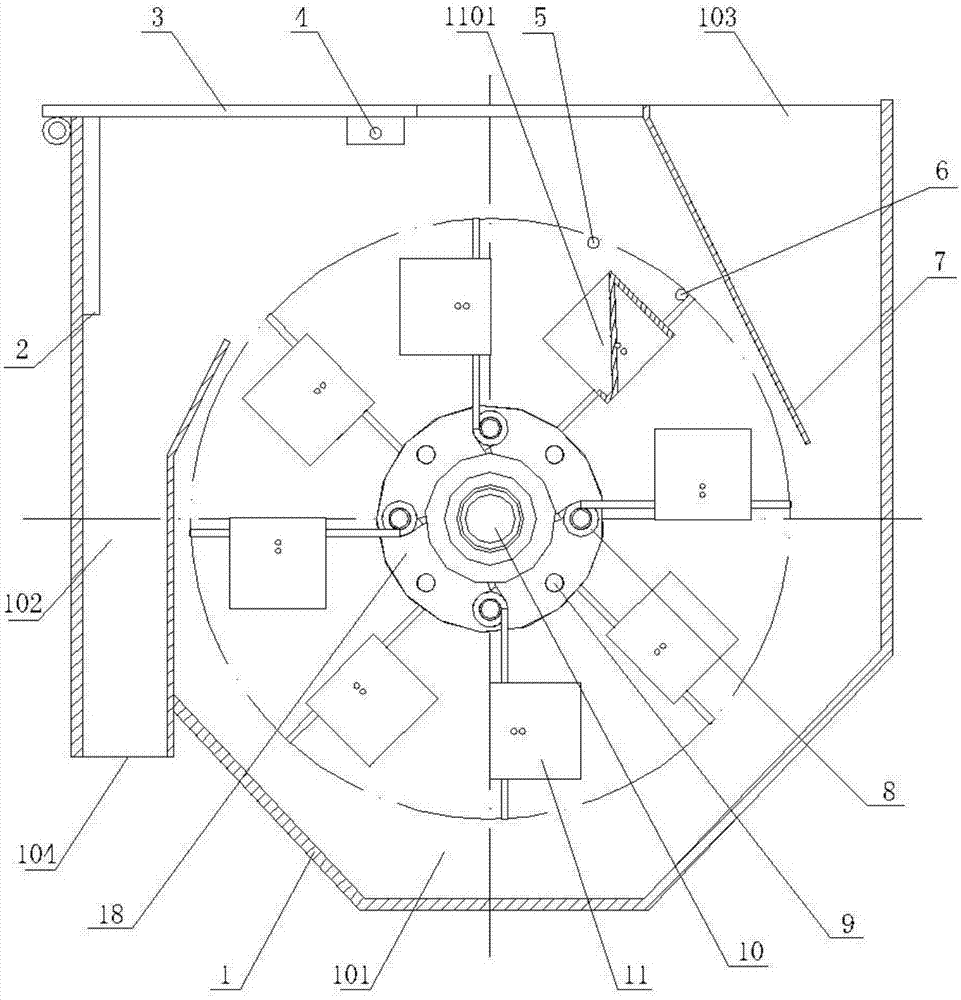

Electronic reseeding and seeding device

InactiveCN103262695ALong refill timeNo damageSeed depositing seeder partsElectric machineAgricultural engineering

The invention provides an electronic reseeding and seeding device, which comprises a seed warehouse, a seed feeding mechanism and a reseeding mechanism, wherein the seed warehouse is positioned above a motor; the seed feeding mechanism, a seed cleaning brush and a position sensor are fixedly arranged on the inner circumferential surface of the seed warehouse; the position sensor is positioned above a seed filling disk; a moving trace of the position sensor is positioned on the radius of an induction sheet; a seed feeding wheel is positioned above the seed filling disk in the seed warehouse; a moving trace of the seed feeding wheel is positioned on the radius of a seed filling hole in the seed filling disk; a push-pull electromagnet, a seed baffle and a resetting spring form the reseeding mechanism; a transmission mechanism consists of the motor and a worm wheel and worm speed reducer; the motor is fixedly connected with a side vertical plate; the side vertical plate is fixed on a base; a cambered adjustment slot is arranged on the side vertical plate; one end of a connection plate is fixed on the motor, and the other end of the connection plate is fixed on the cambered adjustment slot; an angle of 35-40 degrees is formed between the motor and the horizontal panel of the base; when the motor rotates, the seed filling disk is driven to rotate; seeds in the seed warehouse enter the seed filling hole and a reseeding hole; and when the seed filling hole falls into a seed falling region, the seed feeding wheel feeds the seeds in the seed filling hole to a funnel.

Owner:曹天一

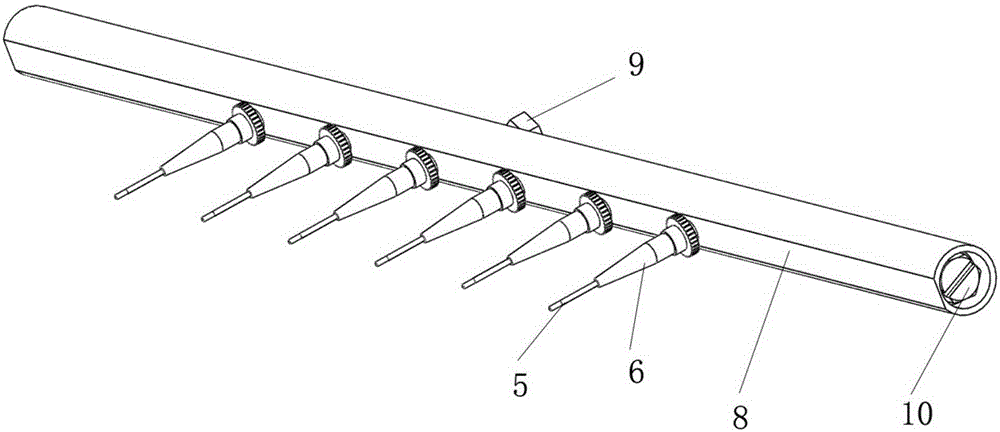

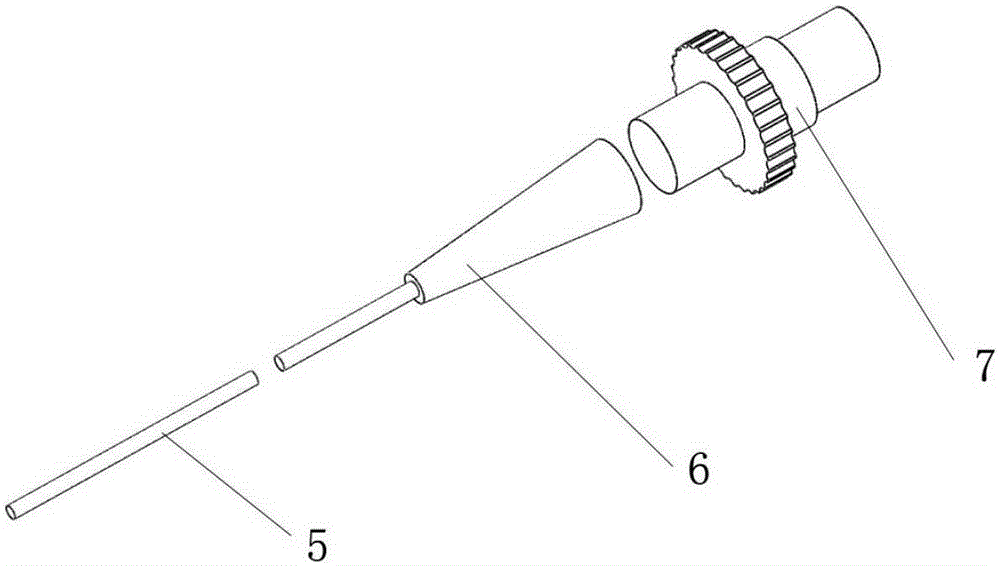

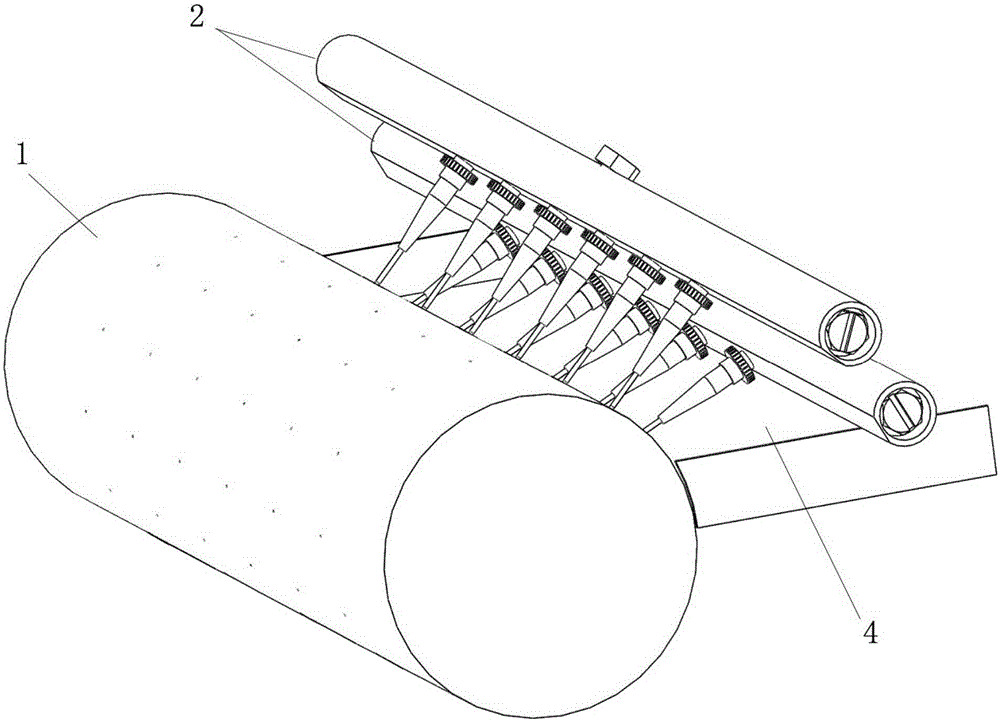

Scraping and touching air flow type seed removing device of seeding machine

ActiveCN105210517ALow removal rateSowing realizedSeed depositing seeder partsEngineeringScrew thread

The invention discloses a scraping and touching air flow type seed removing device of a seeding machine. The seed removing device is arranged on a roller body of the seeding unit and comprises at least one set of seed removing pipes which are externally connected with an air supply system. Each seed removing pipe comprises a seed removing pipe body, air needles, thread rotary needle heads, seed pulling needles and a quick plug connector, wherein the thread rotary needle heads are distributed on one side of the cylindrical face of the seed removing pipe body, the quick plug connector is arranged on the other side of the cylindrical face of the seed removing pipe body, each thread rotary needle head corresponds to one air needle and one seed pulling needle, each thread rotary needle head, the corresponding air needle and the corresponding seed pulling needle are sequentially connected, and the quick plug connector is externally connected with the air supply system. According to the seed removing device, pneumatic power seed removing and mechanical power seed removing are combined, the seed removing effect is good, small round seeds and smell flat seeds can be removed so that the seeding unit can be used for sowing small flowering cabbage round seeds and the like and can also be suitable for sowing small tomato flat seeds and the like, single seeds can be precisely sown, and the seeding qualified rate is increased.

Owner:SOUTH CHINA AGRI UNIV

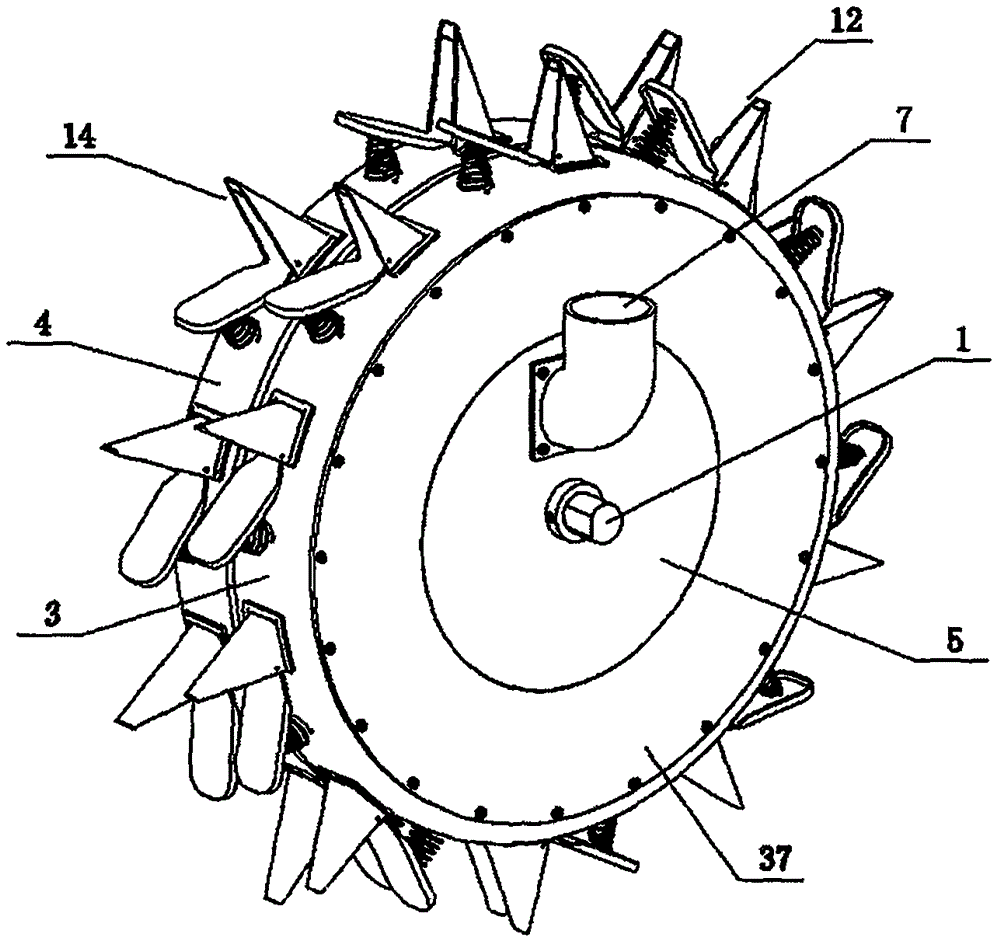

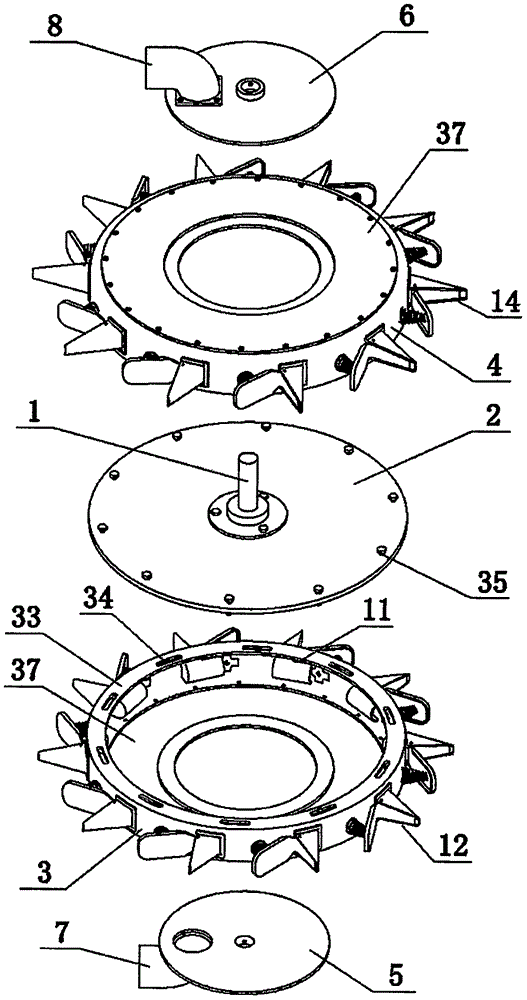

High-speed precise-sowing vegetable seed discharging device with combined structure cell wheel

ActiveCN108886927AImprove seed filling rateLarge working area for effective seed fillingSeed depositing seeder partsRegular seed deposition machinesFilling rateEngineering

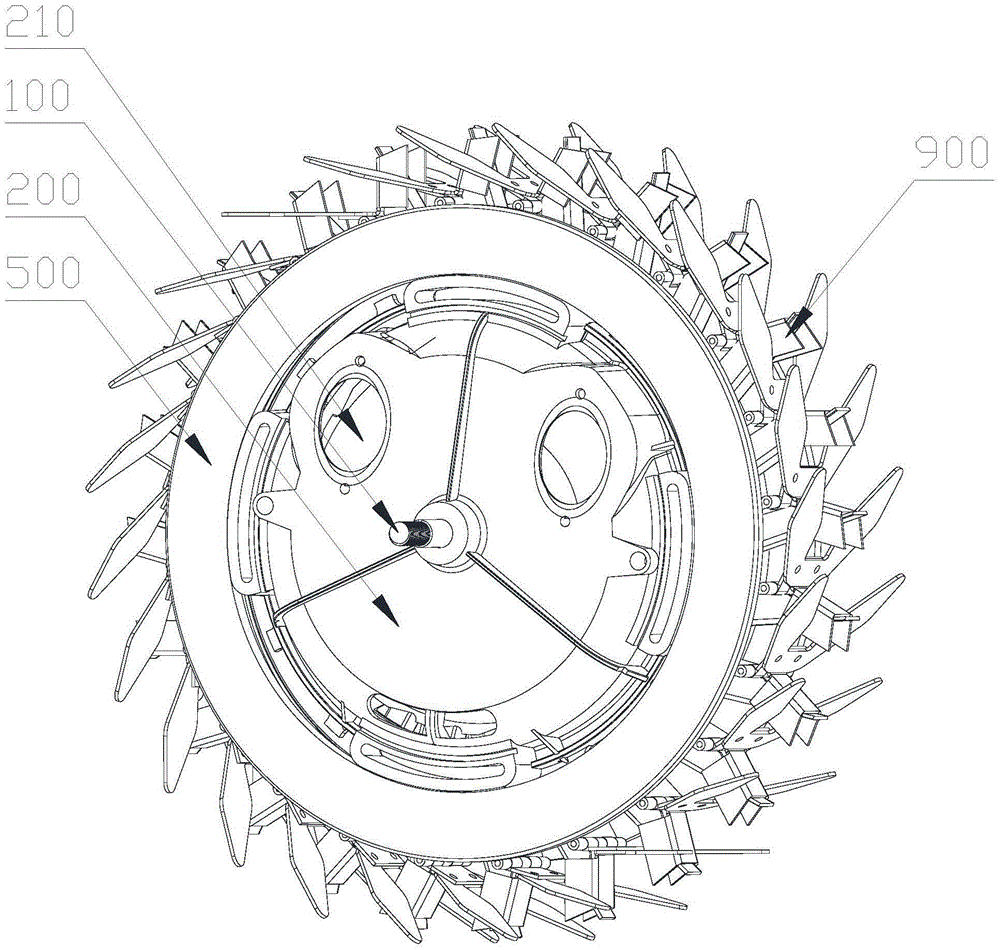

The invention provides a high-speed precise-sowing vegetable seed discharging device with a combined structure cell wheel. The device comprises a seed storage box and the combined structure cell wheelarranged in the seed storage box, one or more combined structure cell rings are axially arranged on the outer cylindrical face of the combined structure cell wheel, multiple combined structure cellswhich are arranged in sequence in the circumferential direction are arranged in the combined structure cell rings, seed filling slide ways, seed filling transition circular arc faces, inner circular arc cell holes, seed returning transition circular arc faces and seed returning slide ways are sequentially connected inside the combined structure cells in the outer circumference direction of the combined structure cell wheel, the openings of the inner circular arc cell holes are rectangular, the bottom faces of the inner circular arc cells are circular arc faces, the inner circular arc cell holes are located in the middles of the combined structure cells, the seed filling slide ways and the seed returning slide ways are rectangular inclined walls which extend from the two ends of the combined structure cells to the two ends of the inner circular arc cell holes, and the bottom ends of the seed returning slide ways are higher than those of the seed filling slide ways. Under the condition of high-speed operation, the seed filling rate is high, the seed discharging device is low in sowing repetition rate and sowing missing rate, the variable coefficient of row spacing is small, and sowing uniformity is good.

Owner:JIANGSU UNIV

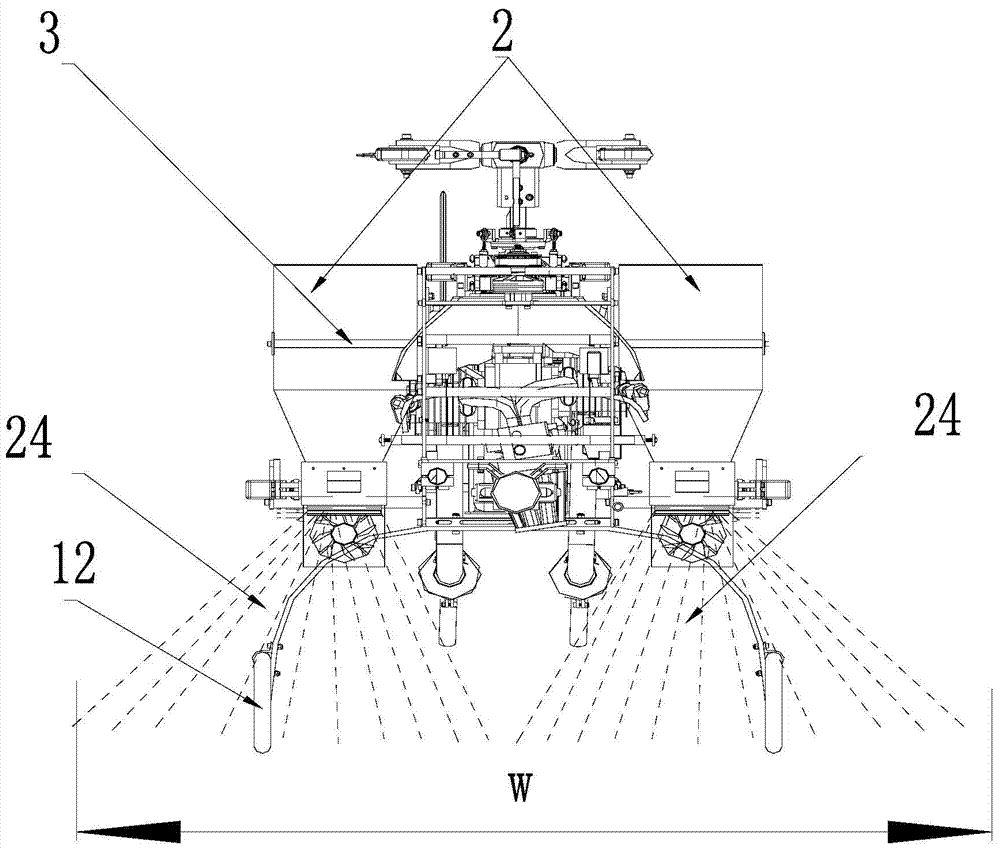

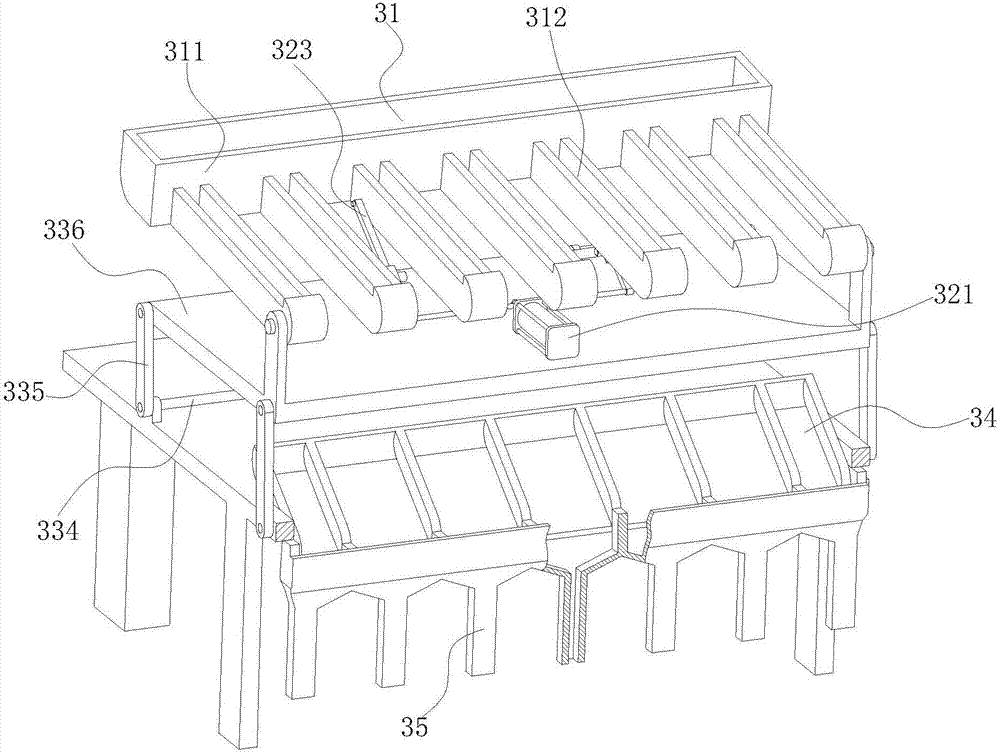

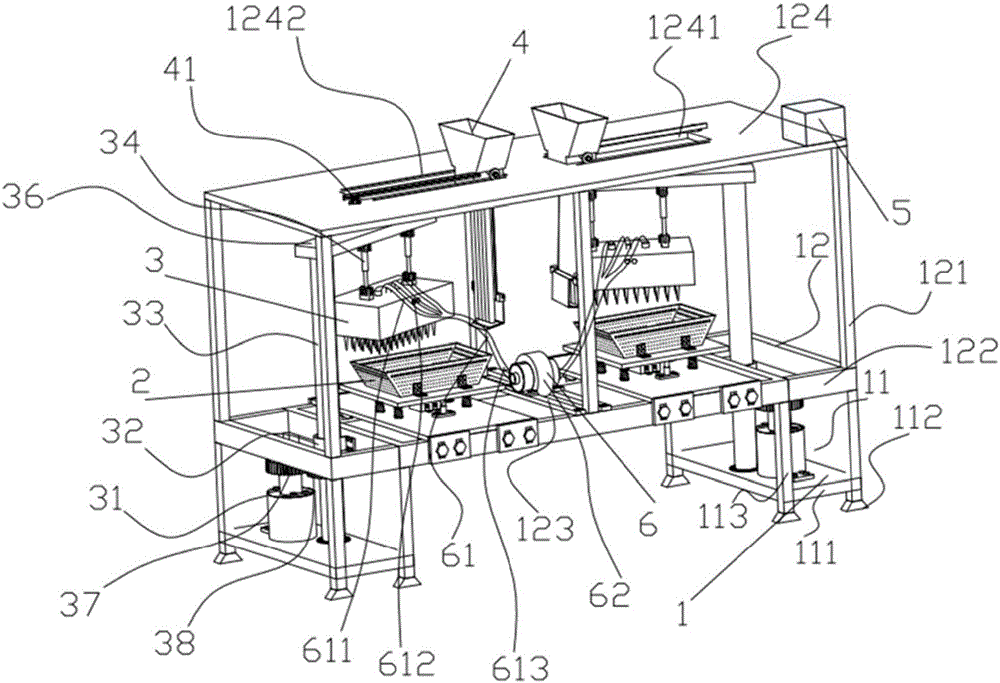

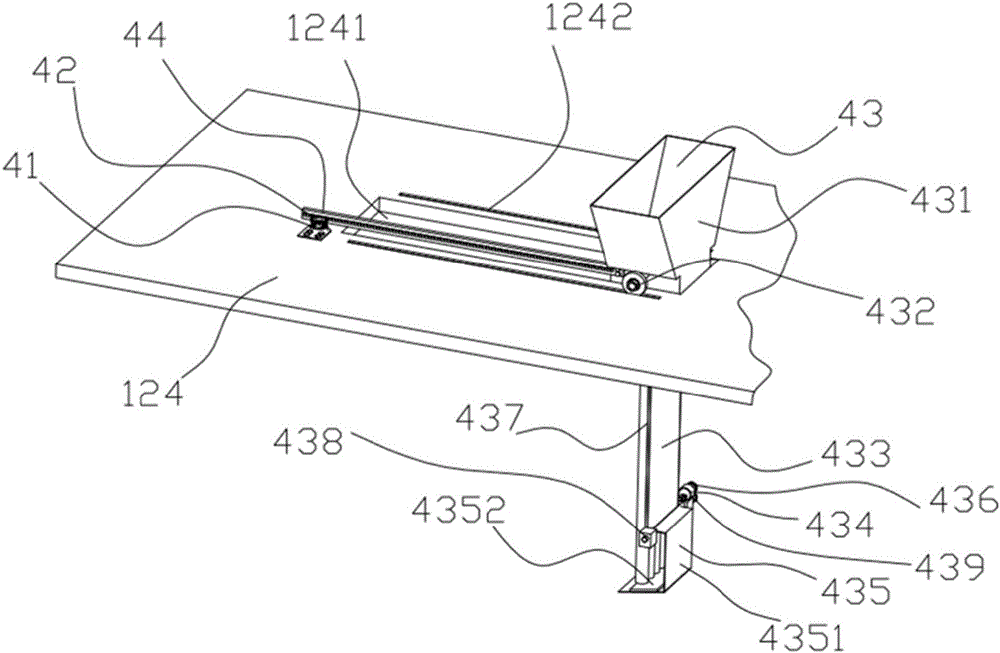

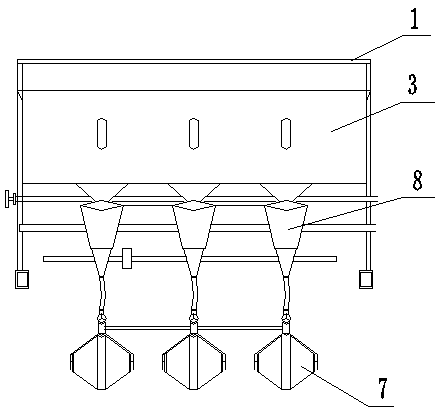

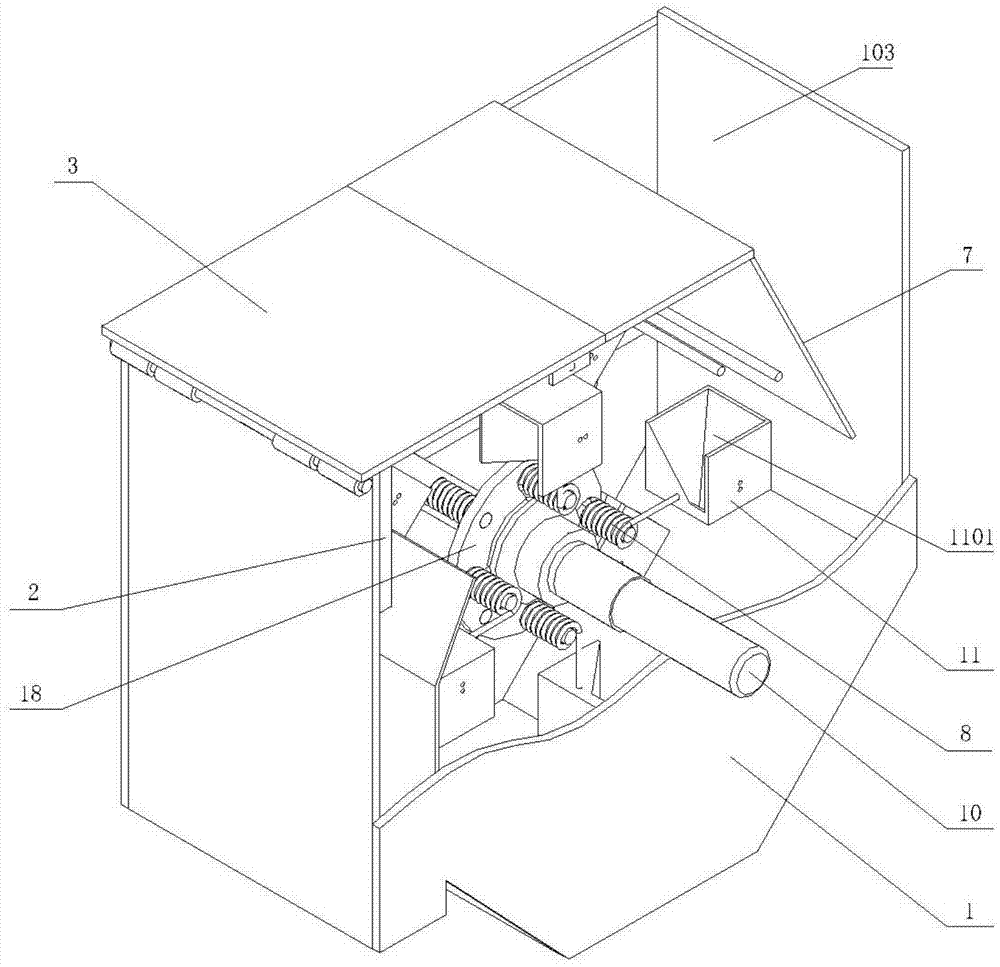

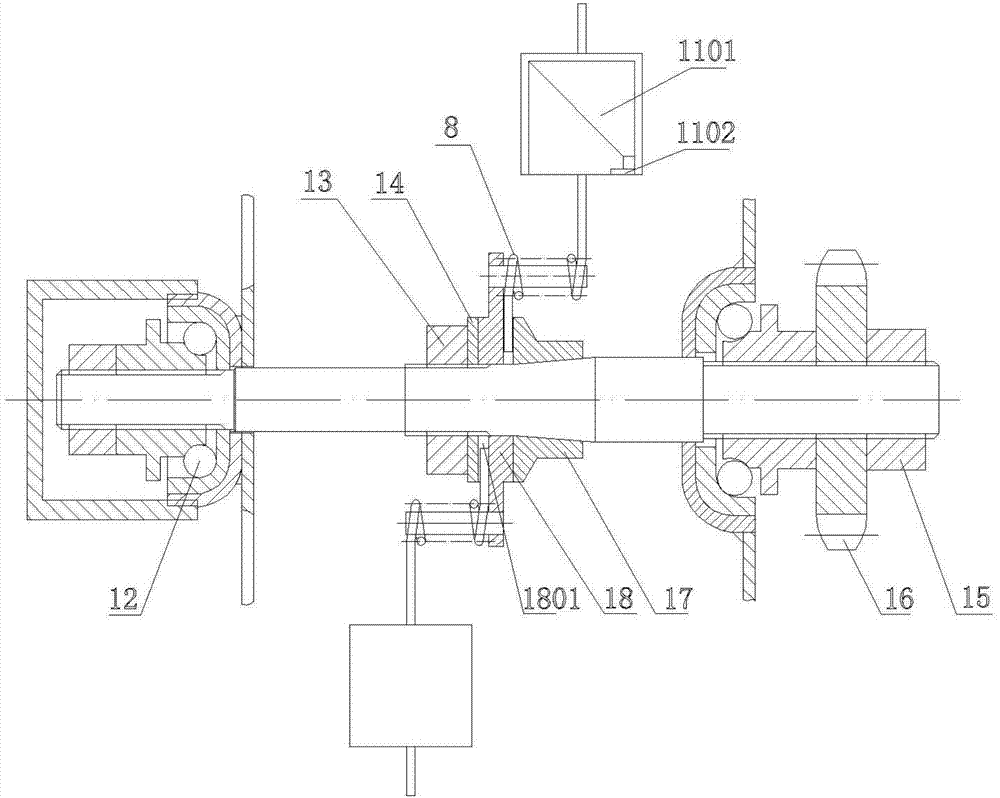

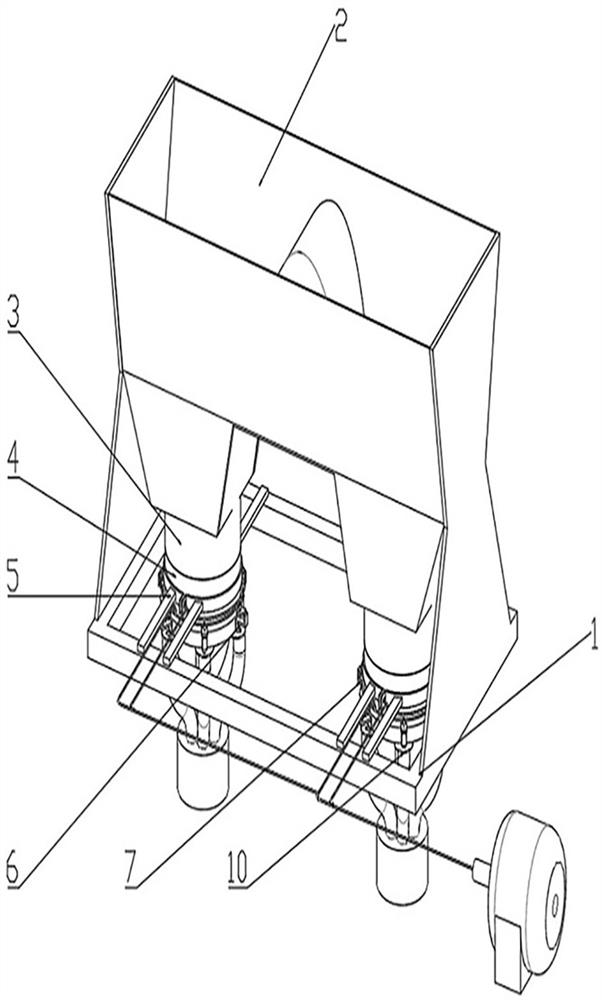

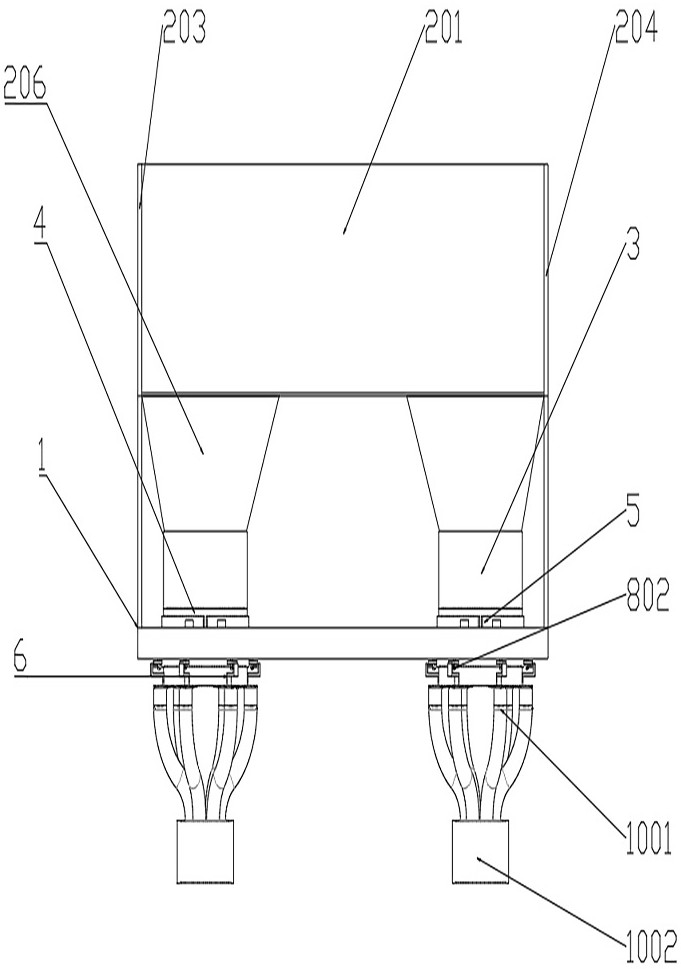

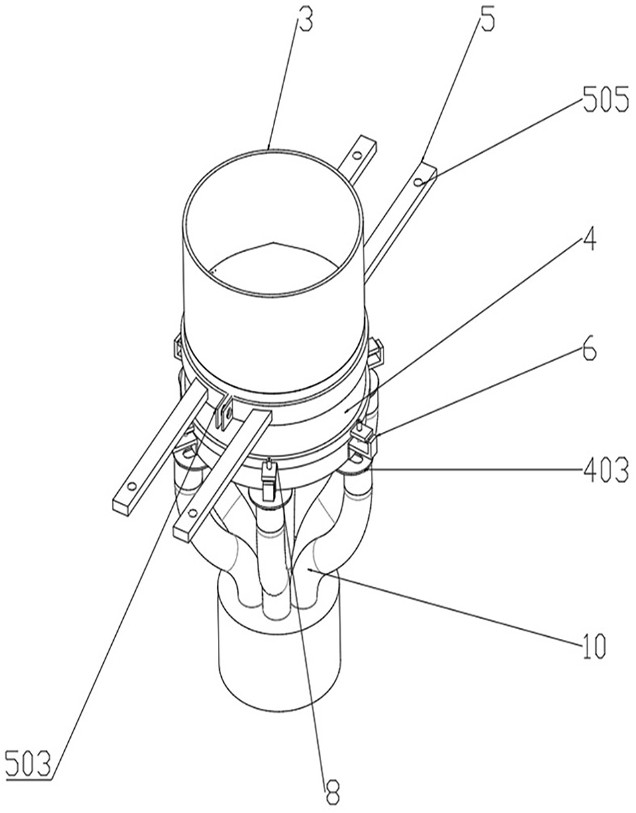

Large particle seed gas-absorption seed-leakage type precision sowing apparatus

ActiveCN107155457AOvercoming technical deficienciesAchieve precision seedingSingle grain seedersEngineeringLarge particle

The invention discloses a large particle seed gas-absorption seed-leakage type precision sowing apparatus, which comprises a rack body, seed box devices, a seed sucking device, seed leakage devices and the like, wherein the seed box devices positioned on both sides of the rack body are used for adding seeds or supplementing seeds to the seed leakage devices, the seed sucking device is positioned in the middle of the rack body, and the seed leakage devices are positioned on both sides of the seed sucking device. According to the present invention, the large particle seed gas-absorption seed-leakage type precision sowing apparatus has advantages of simple and convenient operation, low manufacturing cost, uniform and stable sowing, low damage on seeds, high efficiency and the like, can effectively prevent the sucking nozzle from clogging during the sowing process, is mainly used for the precise sowing of large particle seeds, and can be suitable for sowing of various types of large particle seeds after the replacement of different sucking nozzles.

Owner:定远县吴圩镇严华种植养殖家庭农场

Carrot rotary tillage ridging and accurate-sowing all-in-one machine

PendingCN109196986AApplicable Seeding RequirementsImprove work efficiencySpadesPlantingAgricultural engineeringTillage

The invention discloses a carrot rotary tillage ridging and accurate-sowing all-in-one machine, which comprises a machine frame, a rotary tillage part, a ditching and ridging part and a seeding part.The rotary tillage part, the ditching and ridging part and the seeding part are installed on the machine frame. The ditching and ridging part is located between the rotary tillage part and the seedingpart. A suspension connecting device is arranged at the front end of the machine frame and is used for being connected with a traction device. The rotary tillage part comprises a rotary tillage machine main shaft, a soil loosening baffle plate and a rotary tillage blade. The rotary tillage machine main shaft is rotationally arranged at the bottom of the front end of the machine frame. The rotarytillage blade is fixedly arranged on the rotary tillage machine main shaft. The rotary tillage blade can rotate along with the rotary tillage machine main shaft. The soil loosening baffle plate is arranged at the two ends of the rotary tillage machine main shaft. The ditching and ridging part comprises a plurality of first ditching devices which are arranged at the bottom of the machine frame at equal intervals. The seeding part comprises a linear seed sowing part or a grain seeding part. According to the invention, the ridging process and the accurate sowing process are integrated, so that the ridged soil is uniform in height and not soft. The seeding depths of sown seeds are consistent, and the false burying of seeds is avoided. The accurate sowing operation can be carried out.

Owner:景禄平

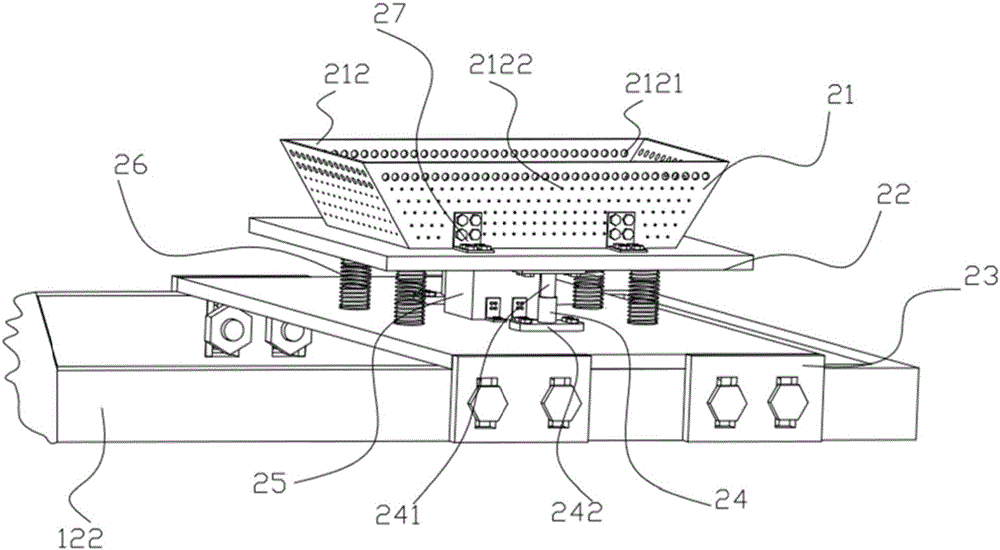

Vibrating seeding device

InactiveCN105917814AReduce manufacturing costEasy to manufactureSeed depositing seeder partsBroadcast seedersElectrical and Electronics engineeringNozzle

Owner:淮南市德飞机电设备制造有限公司

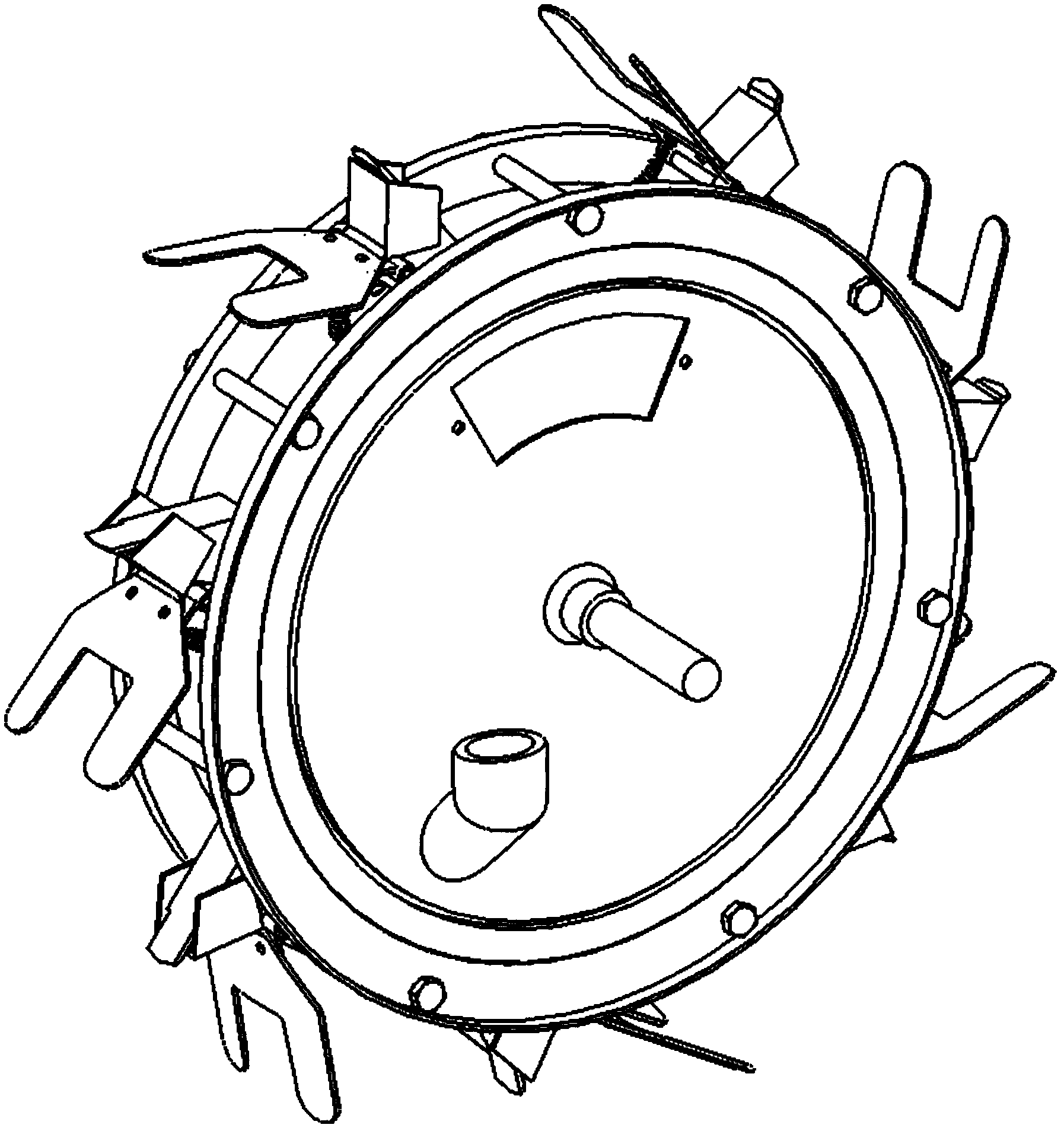

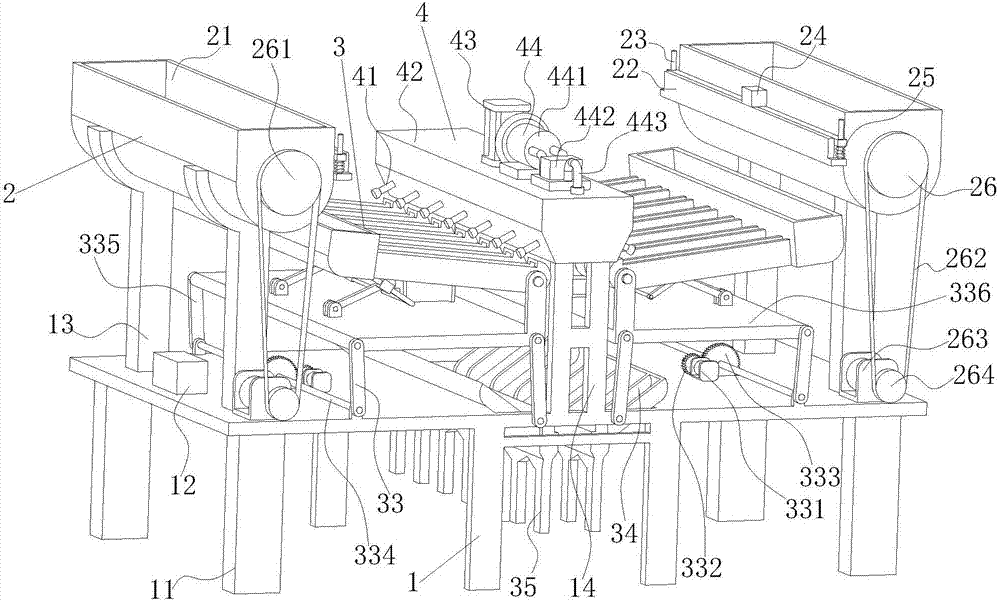

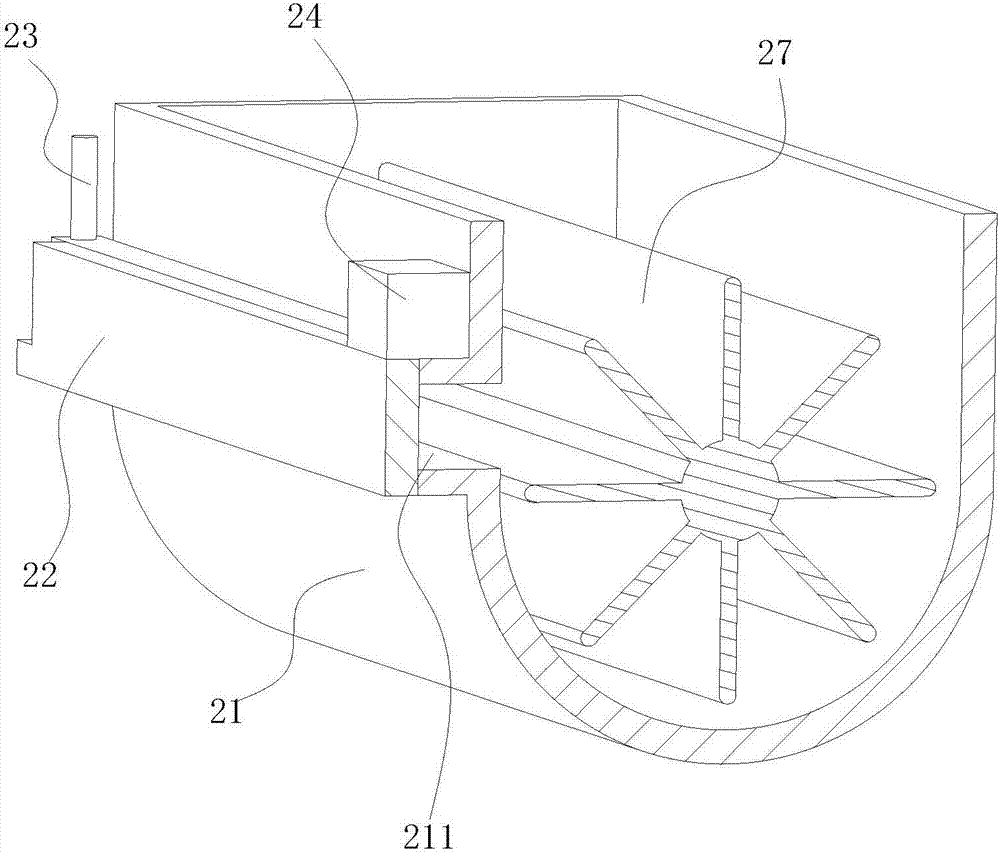

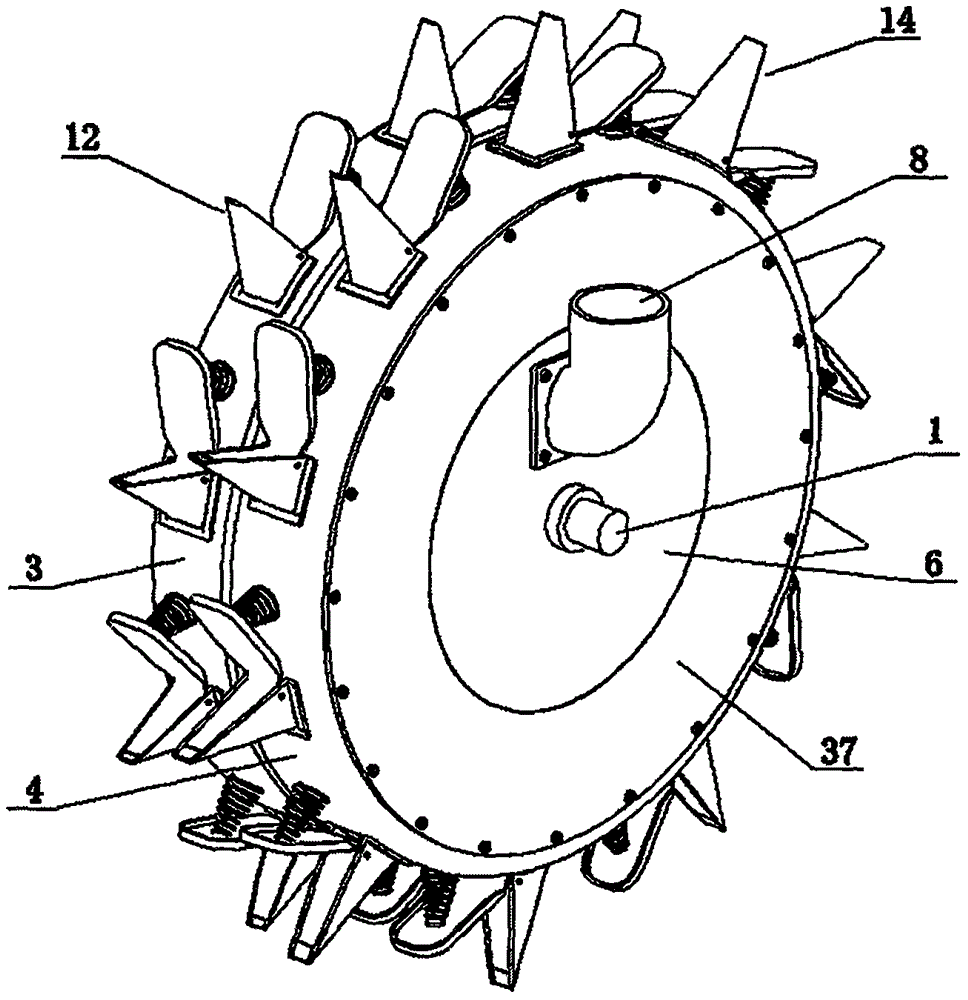

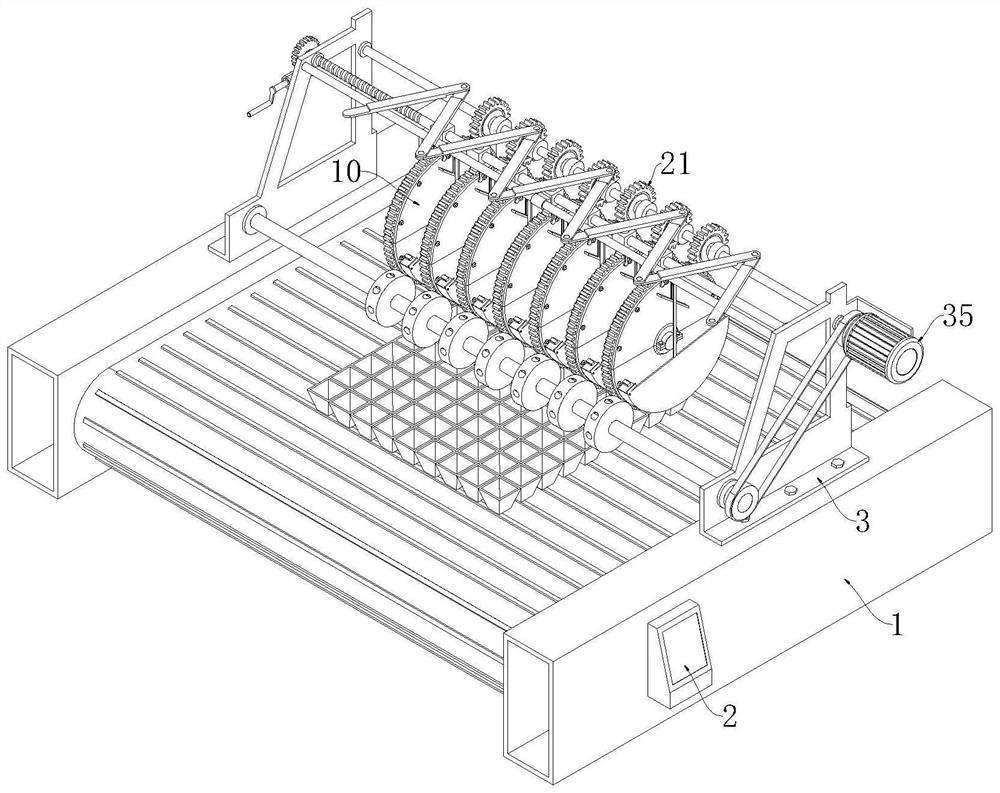

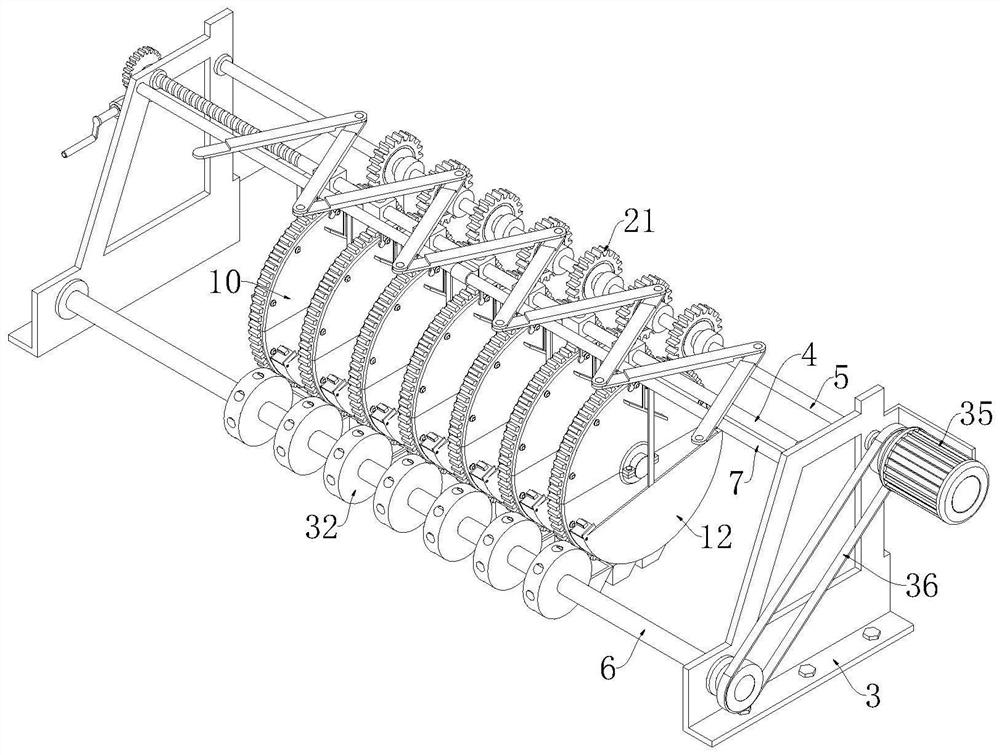

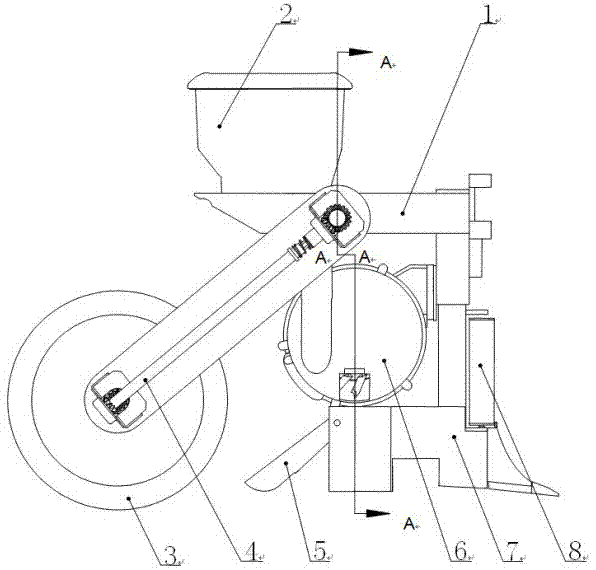

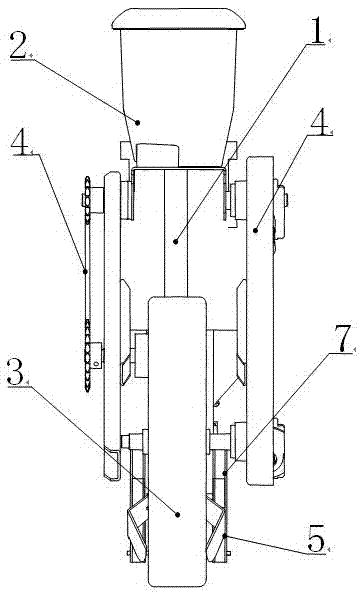

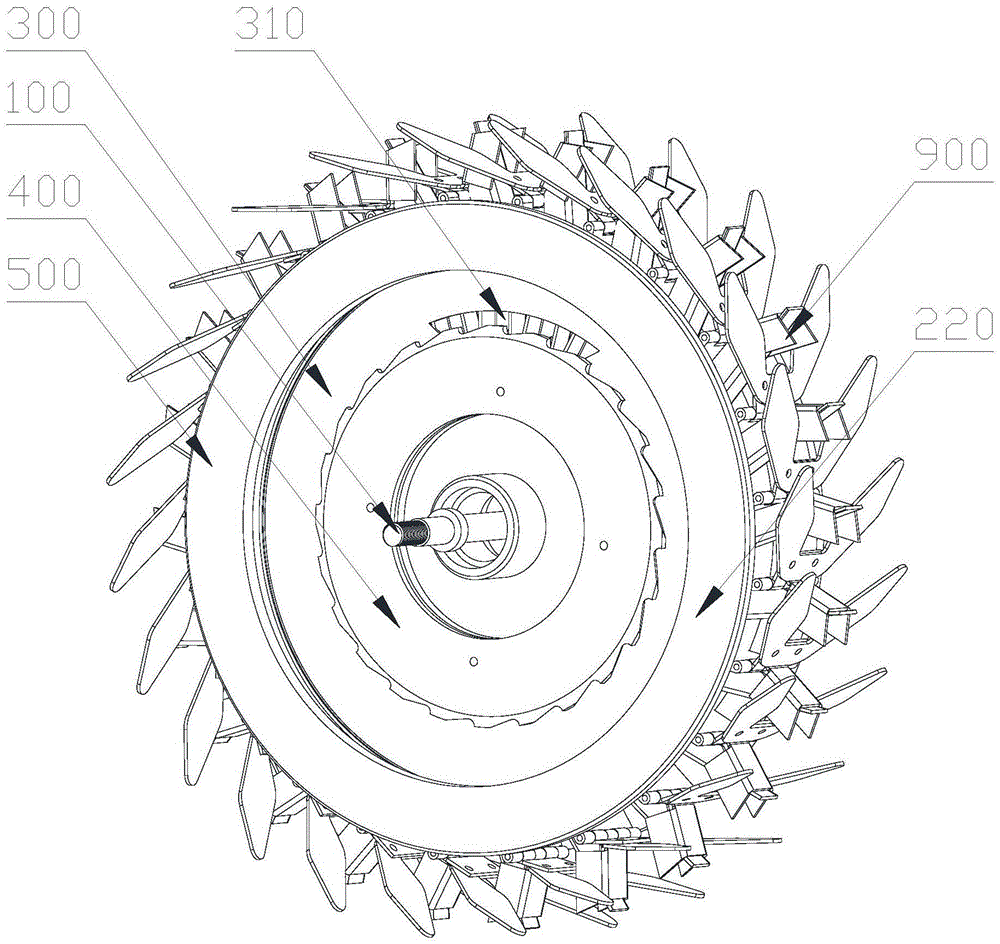

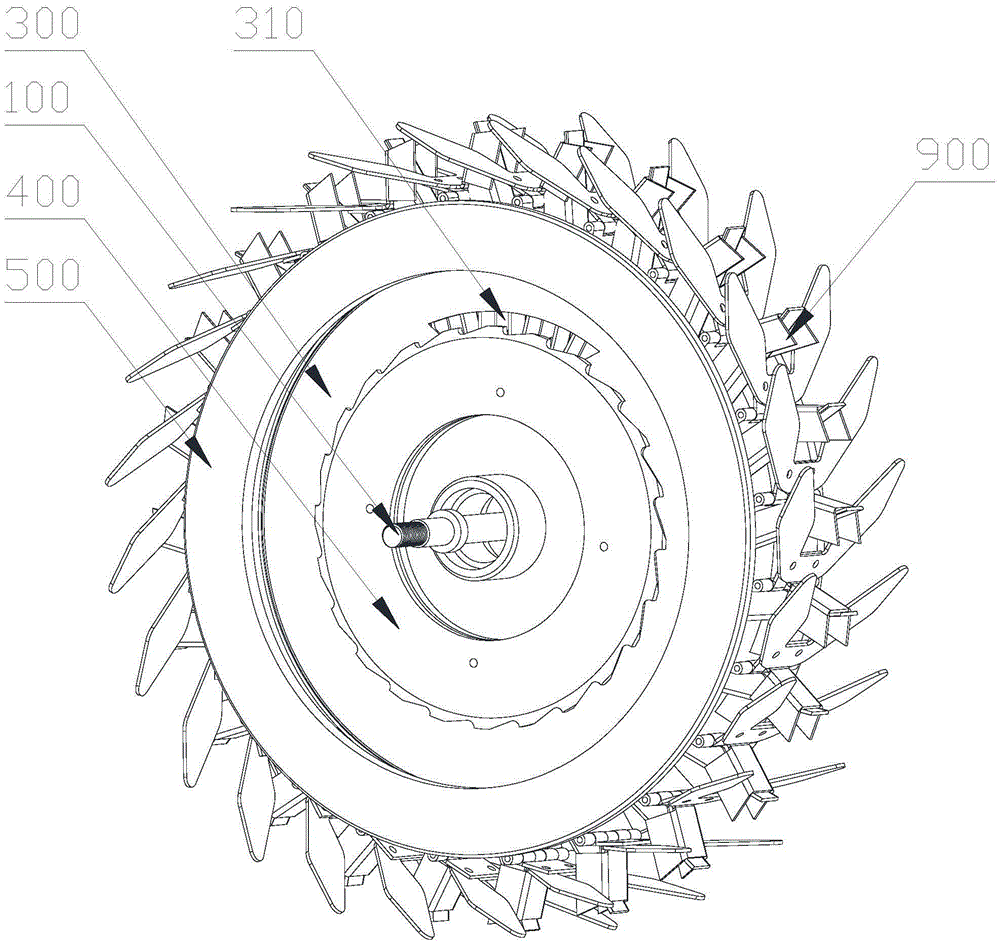

Drum type seed dibble seeding and hole fertilizing seeder

ActiveCN106068818AIncrease profitImprove fertilizer efficiencyFertiliser and seeding apparatusAgricultural engineeringFertilizer

The invention discloses a drum type seed dibble seeding and hole fertilizing seeder. The drum type seed dibble seeding and hole fertilizing seeder comprises a main shaft and a drum, wherein the drum comprises a middle disk; a seeding movable disk and a fertilizing movable disk are respectively arranged at two sides of the middle disk; the main shaft is arranged at the center of the middle disk through a bearing; the seeding movable disk and the fertilizing movable disk are respectively and internally provided with a seeding device and a fertilizing device; seeding openings and fertilizing openings which are in the same quantity are uniformly formed in the periphery walls of the seeding movable disk and the fertilizing movable disk; duckbilled type seeding holing devices are arranged at the outer sides of the seeding openings; duckbilled type fertilizing holing devices are arranged at the outer sides of the fertilizing openings. The drum type seed dibble seeding and hole fertilizing seeder disclosed by the invention has the advantages that the structure is simple, the cost is low, seed dibble seeding and fertilizer hole application can be carried out at the same time, and precise seeding can be realized.

Owner:赤峰市晨勋农机有限公司

Intelligent agricultural seeding machine

InactiveCN114342607AAvoid easy cloggingNot easy to cause blockageSeed depositing seeder partsSingle grain seedersAgricultural scienceAgricultural engineering

The invention discloses an intelligent agricultural seeding machine which comprises a conveying device and a PLC, the top of the conveying device is fixedly connected with two racks, a plurality of seeding parts distributed in the axial direction are arranged on a guide shaft, and an adjusting part for adjusting the distance between every two adjacent seeding parts is arranged between the two racks. According to the device, the driving piece drives the rotating disc assembly to rotate, the suction head sucks seeds and moves the seeds to pass through the first check block and the second check block, the seeds move back and forth on the suction head under the blocking effect of the two check blocks, therefore, redundant seeds are separated from the suction head due to extrusion, the two check blocks extrude the seeds from the upper direction and the lower direction respectively, and the seeds are separated from the suction head. And the suction head covers half of the area of the air inlet end of the suction head, so that the device can effectively remove the seeds which are adsorbed on the suction head and have smaller particle sizes, the effects of saving the seeds and reducing the cost are achieved, and the normal development and growth of the seeds are facilitated.

Owner:王少平 +2

Factory-like sowing method for green Chinese onions

ActiveCN105660109AImprove qualityIncrease resistancePlant cultivationCultivating equipmentsSproutingSeedbed

The invention discloses a factory-like sowing method for green Chinese onions. The method specifically includes the first step of variety breeding, the second step of seed coating and pelleting, the third step of precise sowing, the fourth step of matrix soil covering, the fifth step of placing in a seedbed, the sixth step of water spraying and the like. By means of the sowing method, precise sowing of seeds is achieved, the sprouting rate of seeds and the utilization rate of seed green Chinese onions are greatly increased, the requirement for uniform, neat, complete and strong seedlings can be effectively met, and a technical support is provided for the sowing technical link in the factory-like seedling growing process of green Chinese onions.

Owner:沃华农业科技(江苏)股份有限公司

Small-sized seed furrow sowing method and equipment

PendingCN109121592AReduce human and material resources inputRealize moisture exploration and seedingPlantingFurrow making/coveringAgricultural engineeringSowing

The invention provides a small-sized seed furrow sowing method and related equipment. The small-sized seed furrow sowing method comprises the following steps: furrowing with a furrow opener and sowing; while furrowing with the furrow opener, arranging liftable soil dividing plates on two sides at the rear part of the furrow opener for soil division; arranging a disc fertilizer-applying furrow opener at the rear part of the soil dividing plate on one side, wherein the disc fertilizer-applying furrow opener is used for opening a fertilizer furrow in one side of a sowing furrow and applying a fertilizer; pressing through a spindle-shaped pressing wheel with a groove in the middle and enabling the groove in the middle of the spindle-shaped pressing wheel to be positioned on a same straight line with the furrow opener during pressing. By adopting the small-sized seed furrow sowing method, small-sized seeds can be sowed on a ridge side, and the method has the advantages that soil is not easyto harden and good in moisture retention performance, so that not only can no seedling emergence caused by soil hardening after rain be prevented, but also flooding can be prevented.

Owner:山西省农业科学院谷子研究所

Universal fine-seeding machine

ActiveCN104718852AImprove versatilityAchieve precision seedingSeed depositing seeder partsRegular seed deposition machinesEngineeringPyramid

The invention discloses a universal fine-seeding machine. The universal fine-seeding machine comprises a shell, wherein a feeding hole and a discharging hole are formed in the shell, and a rotatable main shaft is arranged on the shell; a mounting disc is arranged on the main shaft, a plurality of seed throwing torque springs are respectively uniformly distributed on two sides of the mounting disc along the circumference, seed cup bodies are arranged on straight rods on the outer ends of the torque springs, rectangular-pyramid-shaped pits are formed in the seed cup bodies, the bottoms of the pits are close to one corners of the lower ends of the seed cup bodies, and ladder-shaped openings I are formed in one sides, corresponding to the mounting disc, on the seed cup bodies; two clamping pins are arranged on the shell and are arranged on the rotating circumferences at the outer ends of the seed throwing torque springs; the seed cup bodies are respectively detachably sleeved with a plurality of square sleeves in an overturning manner, and after the square sleeves overturn, seed containing depths formed between the upper ends of four walls of the square sleeves and the bottoms of the pits are different. The universal fine-seeding machine has the advantages that various seeds can be seeded, and the universality is good; different seed containing depths can be changed by overturning the square sleeves, so that the adjustment is convenient, and the fine seeding can be realized according to different seeds; different seeding row distances can be achieved.

Owner:徐精学

Corn broad sowing mechanism

The invention discloses a corn broad sowing mechanism. The mechanism comprises a fixing frame (1), a seed box (2), and a land wheel (3), a seed-metering device (6), an opener (7) and an anti-weed-winding device are mounted on the fixing frame (1) in sequence. The corn broad sowing mechanism is reasonable in structure and strong is practicability. Therefore, the working intensity is reduced, the working efficiency is improved, and precise sowing can also be achieved, so that the majority of farmers trust the corn broad sowing mechanism.

Owner:HENAN HAOFENG AGRI EQUIP CO LTD

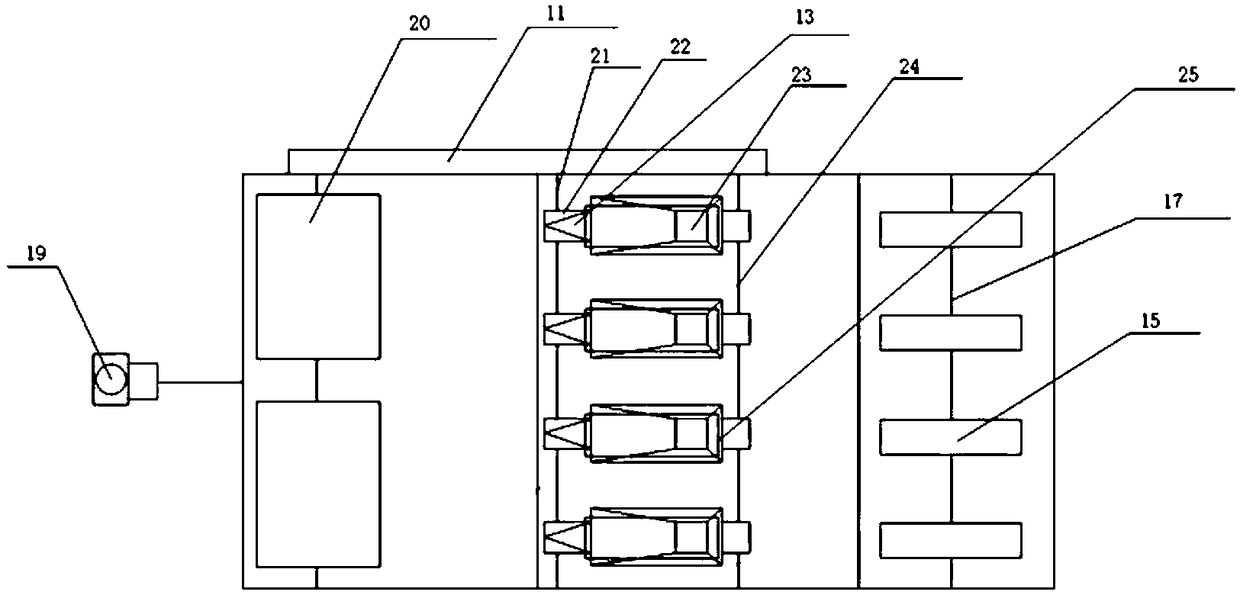

Seed-pushing and air-blowing combined high-speed precise seed-metering device

ActiveCN112930790ASimple structureSowing method changedAgriculture gas emission reductionSeed depositing seeder partsAgricultural scienceAgricultural engineering

The invention belongs to the technical field of agricultural machinery, and relates to a seed-pushing and air-blowing combined high-speed precise seed-metering device. The seed-metering device mainly comprises a seed box, seed-metering single bodies and a rack, wherein the seed box is fixed on supporting plates on two sides of the rack; the seed-metering single bodies are mounted on a front beam and a rear beam of the rack; and each seed-metering single body is composed of a seed disc, an outer disc, an outer disc fixing frame, a seed pushing device, a spring mounting frame, an outer ring air injection device, a motor-driven rotating wheel device, a seed guiding device and a spring. The one-time seed-metering amount is determined by designing the size of a seed filling area; the seed-metering speed and the movement of the seed pushing device are adjusted by controlling the rotating speed of rotating wheels and the stretching of the springs; and nozzle blocking rods mounted on the seed pushing devices are matched with nozzles of the outer ring air injection devices, so that synchronous work of seed pushing, seed blowing, seed filling and air closing is realized. The seed-pushing and air-blowing combined high-speed precise seed-metering device provided by the invention is simple in structure and reasonable in design, and can effectively solve the problems of high working consumption and low seed-metering speed of an existing seed-metering device, so that precise sowing operation and high-speed sowing operation are realized.

Owner:SHANDONG UNIV OF TECH

Electric air-suction-type sowing machine and sowing method

InactiveCN110583164AEasy to manage centrallyReduce noiseSievingScreeningEngineeringCentralized management

The invention discloses an electric air-suction-type sowing machine and a sowing method and relates to the technical field of sowing machines. The sowing machine comprises a sowing box and a handrailframe, wherein the left side of the sowing box is fixedly connected with the right side of the handrail frame. According to the electric air-suction-type sowing machine and the sowing method, a functional box is fixedly connected with one side of the top of the inner wall of the sowing box, and the top of the functional box is communicated with the bottom of a feeding hopper; a sieve plate is movably connected with the back surface, between the two sides of the inner wall, of the functional box, a screen is fixedly connected with the inside of the sieve plate, and the middle of the back surface of the bottom of the sieve plate is fixedly connected with a vibration motor; an inclined guide block is fixedly connected to the portion, right below the sieve plate, of the bottom of the inner wall of the functional box, and the sieve plate, the screen and the vibration motor are utilized to provide power for the sieve plate; the specification of seeds to be sown is screened, excessively largeseeds are removed, the specification of the seeds falling in each sowing pit is similar, and the centralized management of the growth of crops by planting personnel in the later period is facilitated.

Owner:山东沃华农业科技股份有限公司 +1

High-density precise dibbler

InactiveCN105660004AMeet the needs of high densitySimple structureSeed depositing seeder partsHigh densityEngineering

The invention relates to a high-density precise dibbler which comprises a fixed shaft, a seed chamber outer shell fixed on the fixed shaft, and a retaining plate rotationally connected on the fixed shaft; a floating separating plate is arranged between the seed chamber outer shell and the retaining plate; a plurality of seed guiding slots uniformly distributed around the axis of the fixed shaft are fixed between the floating separating plate and the retaining plate; the high-density precise dibbler also includes a seed taking mechanism; the seed taking mechanism is fixed on the retaining plate and above the floating separating plate; one duckbill combination body is fixed at a position, far away from the end part of the fixed shaft, of each seed guiding slot and is used for sowing seeds into soil. The high-density precise dibbler has the beneficial effects of high-density sowing realization, simple structure and low manufacturing and assembly costs; a process of the seeds rolling from a seed chamber to the duckbill combination bodies is smooth and has no seed clamping; precise sowing is realized, adjustment of the seed taking quantity is convenient, and no tools are required; and the duckbill combination bodies easily penetrate into the soil and pierce a mulching film, to ensure smooth sowing and the seed germination rate.

Owner:AKSU JINTIANCHENG MACHINERY EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com