Precision corn seeder

A technology for seeder and corn, applied in the direction of single-seed seeder, seeder parts, etc., can solve the problems of inconvenient maintenance, high cost, easy damage, etc., and achieve the effects of convenient maintenance, low manufacturing cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The precision corn seeder is installed on mechanized sowing equipment to realize precision sowing of corn.

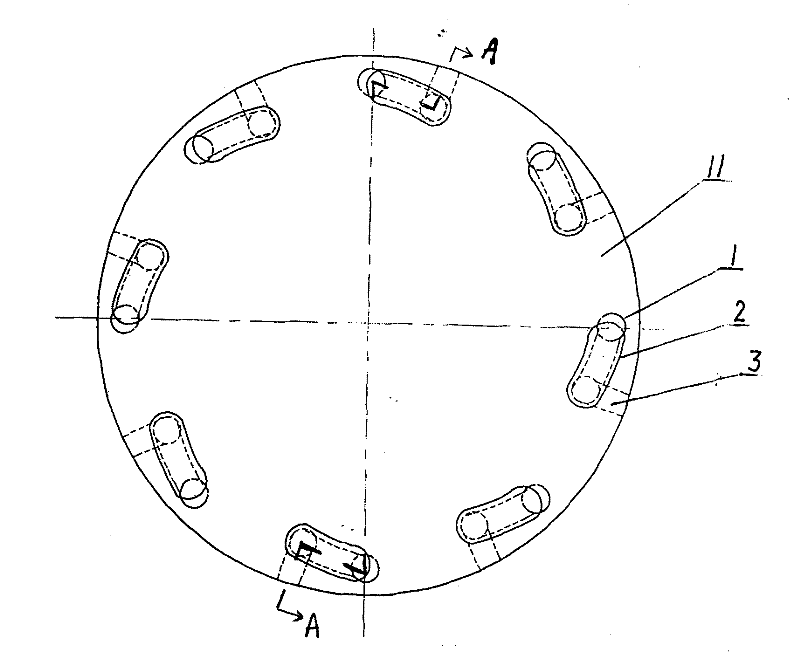

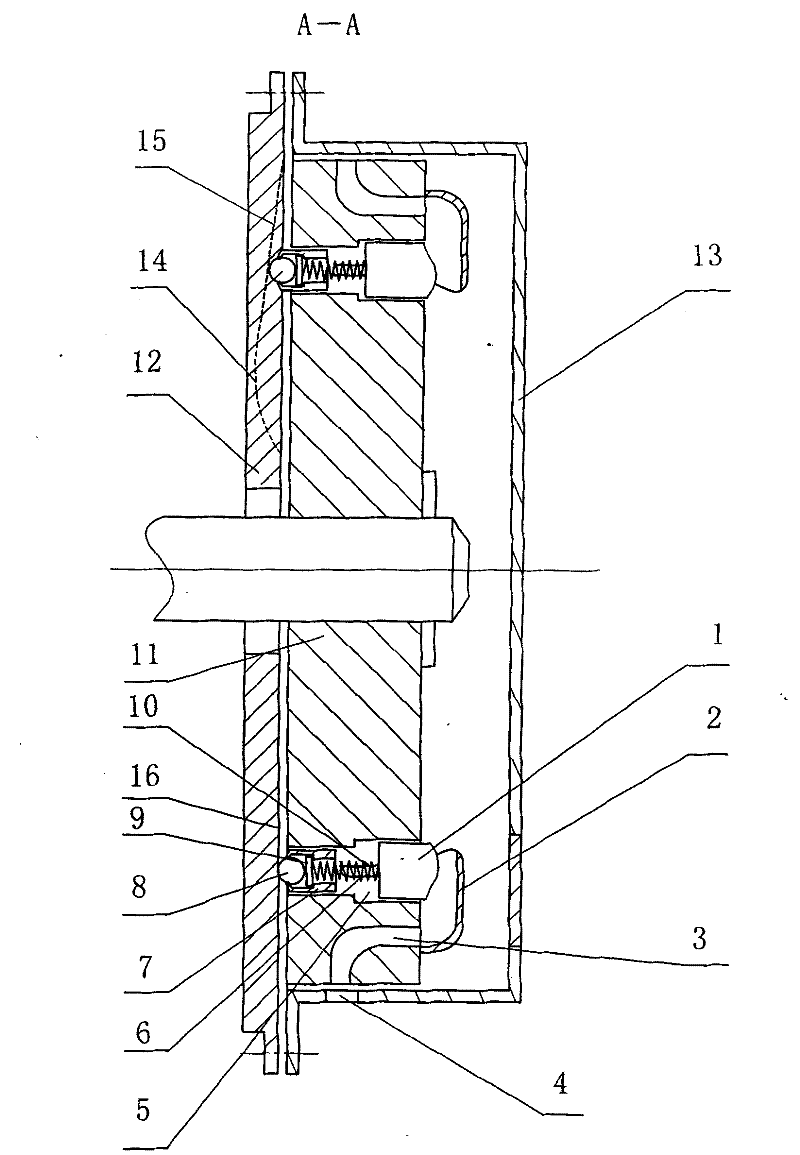

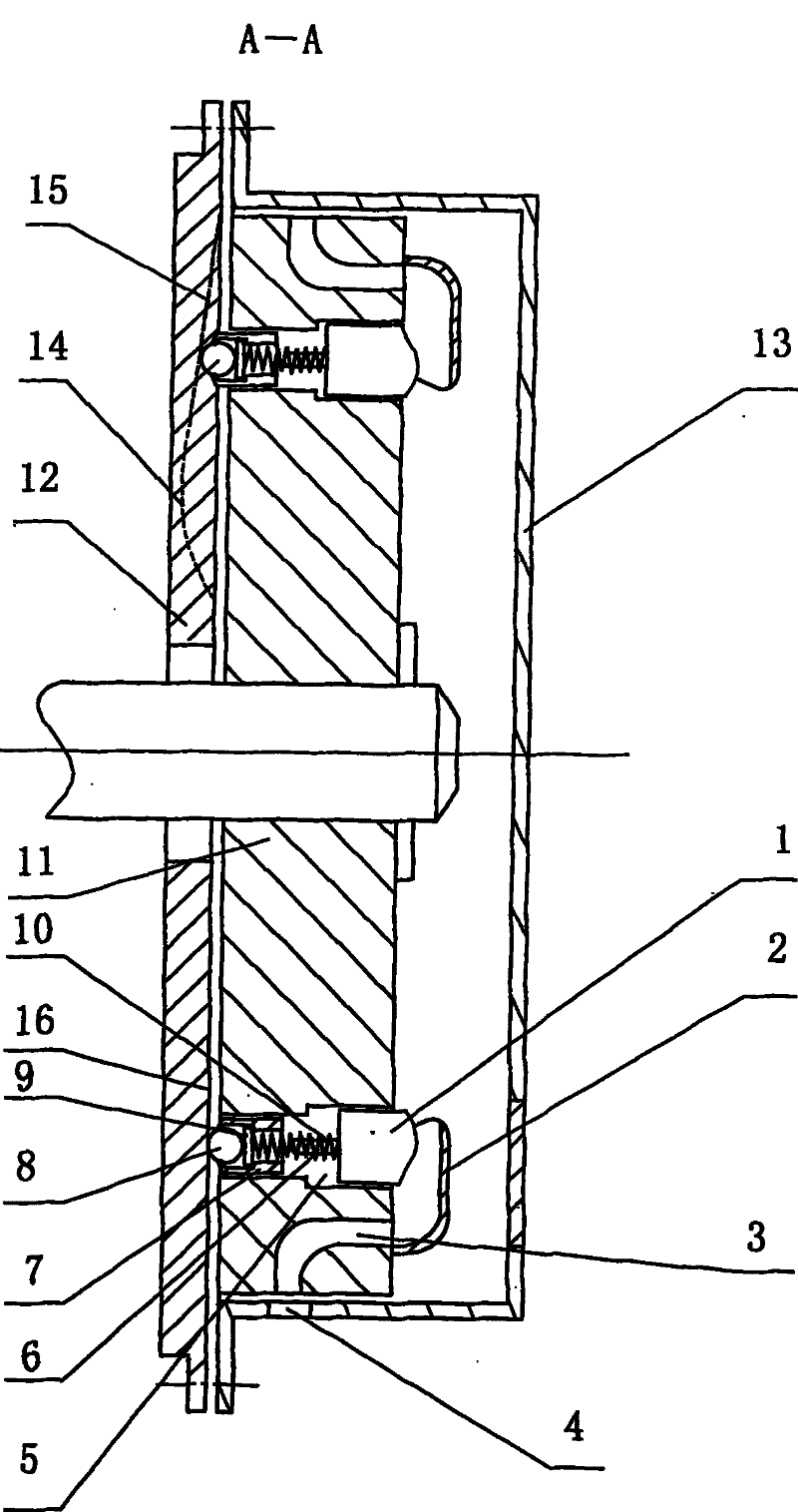

[0017] like figure 1 , figure 2 As shown, the present invention includes a circular bottom plate 12, a seed bin shell 13 connected to the bottom plate 12, and a rotating disc-shaped seed wheel 11 installed between the bottom plate 12 and the seed bin shell 13 . The space between the seed wheel 11 and the seed bin shell 13 forms a kind bin for holding corn. There is a sowing hole 4 at the bottom of the seed bin shell 13 . Several seed gripping mouths 2 are arranged on the disc surface of the seeding wheel 11, and an openable and closing seed biting mechanism is arranged on the seeding wheel corresponding to the positions of the mouths of the seed gripping mouths 2. A seeding hole 3 is formed on the seeding wheel corresponding to the bottom of the seed gripping mouth, and the end of the seeding hole opens on the outer edge of the seeding wheel. The position o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com