Circular-disc type precision drill seeding device of small-seed crops

A small-grain, disc-type technology, used in planting methods, sowing planters, planter parts, etc., can solve problems such as difficulty in thinning, lack of seedlings, ridge breakage, and many seedlings, and achieve convenient seed replenishment, disassembly, and location. accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with specific examples, the disc-type precision drilling device for small-grain crops of the present invention will be further described, so that those skilled in the art can better understand the present invention and can implement it, but the examples given are not intended as a reference to the present invention. limit.

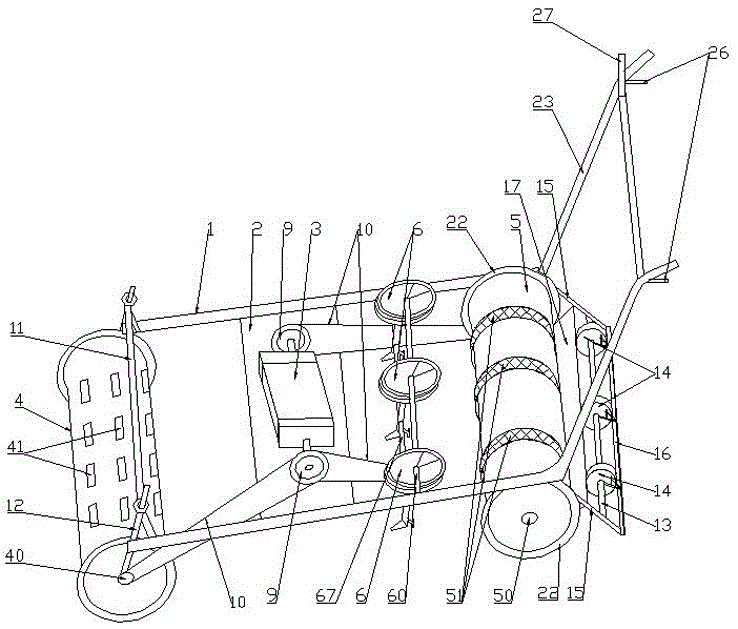

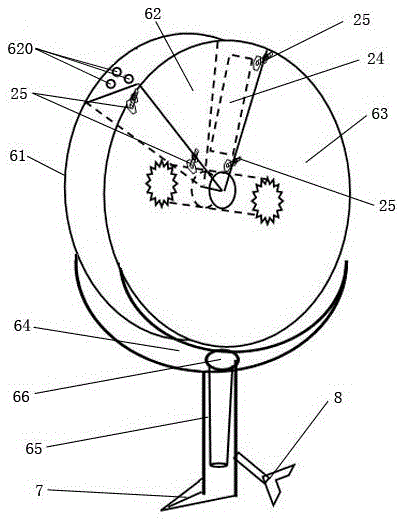

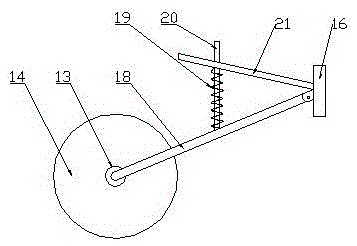

[0025] A disc-type precision drill device for small-grain crops, such as figure 1 As shown, the device includes a bracket 1, a support 2 for fixing the engine 3, a front drum 4, a rear drum 5, a plurality of seeding mechanisms 6, and a power supply for the front drum 4, the rear drum 5, and the seeding mechanisms 6. Engine 3, the rear end of support 1 is provided with handrail 23, and the front end of support 1 is provided with horizontal lifting plate 11, and front cylinder 4 plays smooth ground and suppression function, can lift front cylinder 4 by horizontal lifting plate 11.

[0026] Wherein, the front cylinder 4 and the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com