Precision seeding working system and method based on unmanned aerial vehicle platform

A technology of precision seeding and operation system, which is applied in sowing seeders, aircraft parts, launching devices, etc., can solve the problems of reducing the efficiency of UAV sowing operations, affecting the quality of seeds, and wasting farmland resources. Simple structure, the effect of reducing the difficulty of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

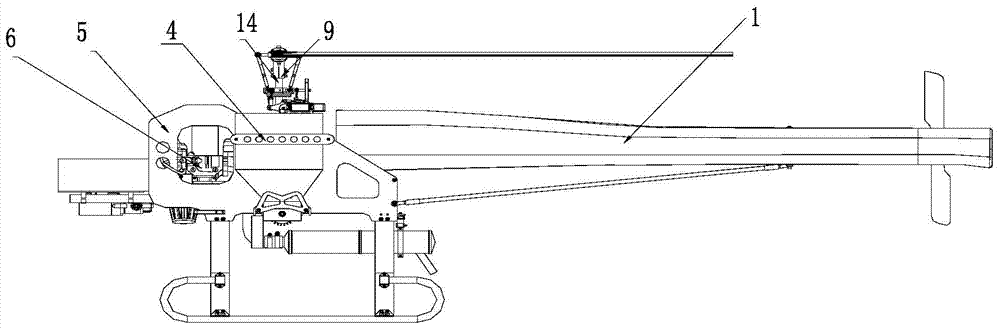

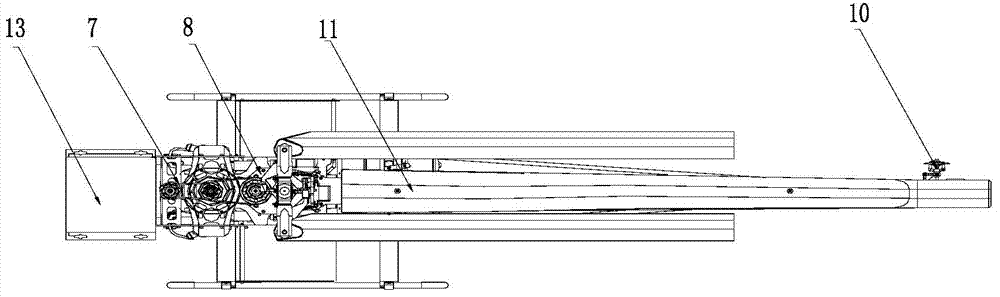

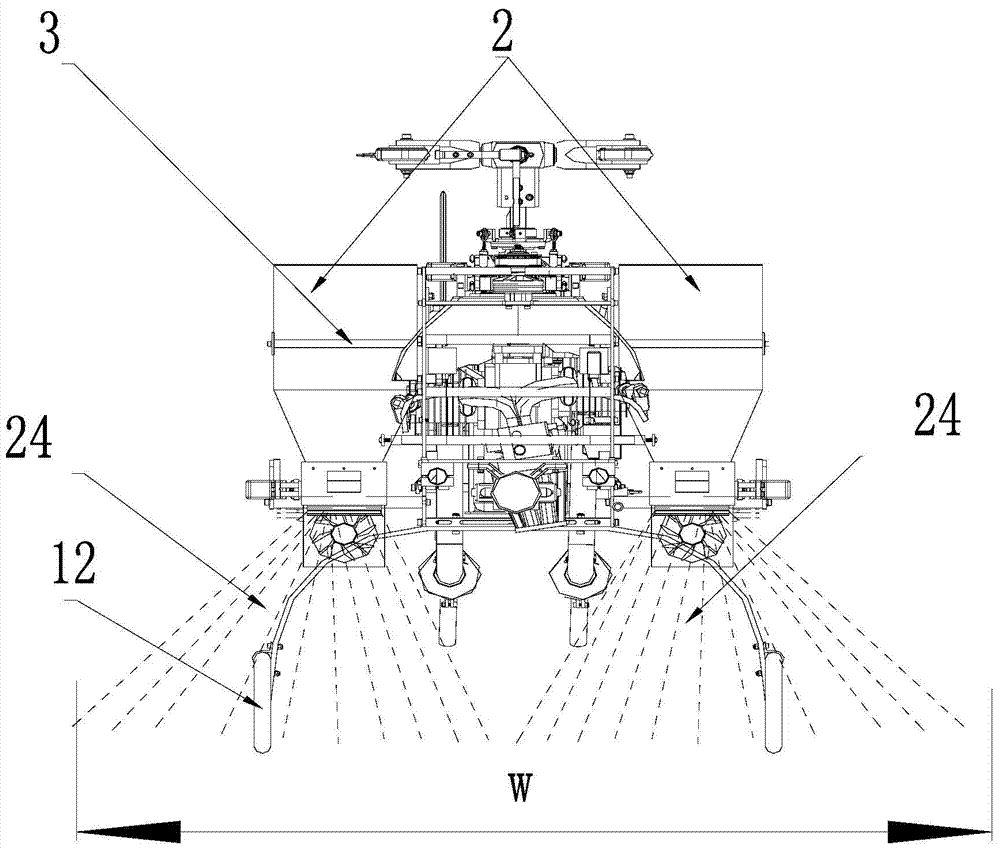

[0063] Such as Figure 1-6 , a precision seeding operation system based on an unmanned aerial vehicle platform, comprising an unmanned aerial vehicle (1) and a sowing device (2) fixed on the unmanned aerial vehicle;

[0064] The sowing device (2) comprises a seed box (15), a fixed seat (16), a wind force seeding device, a quantitative sowing roller (18), a roller blade (19) and a servo motor (22); the servo motor is driven by a battery ;【The battery belongs to the electronic control component part (13)】

[0065] The wind power seeding device is a separate fan (17), and the fan is fixed on the bottom of the holder (16);

[0066] The seed box (15) is fixed on the top of the fixed seat (16); the servo motor (22) is installed on the fixed seat;

[0067] The quantitative sowing roller (18) is installed in the fixed seat; the roller blades 19 are evenly distributed on the quantitative sowing roller 18; the rotating shaft (20) of the quantitative sowing roller (18) passes through t...

Embodiment 2

[0081] Embodiment 2: The difference from Embodiment 1 is that the wind-force scattered seeding device adopts a duct;

[0082] A precision seeding operation system based on an unmanned aerial vehicle platform, comprising an unmanned aerial vehicle (1) and a sowing device (2) fixed on the unmanned aerial vehicle;

[0083] The sowing device (2) comprises a seed box (15), a fixed seat (16), a wind force seeding device, a quantitative sowing roller (18), a roller blade (19) and a servo motor (22); the servo motor is driven by a battery ;【The battery belongs to the electronic control component part (13)】

[0084] The wind power seeding device is an air supply duct composed of a fan and a sleeve; the outlet of the air supply duct is located at the bottom of the fixing seat (16);

[0085] The seed box (15) is fixed on the top of the fixed seat (16); the servo motor (22) is installed on the fixed seat;

[0086] The quantitative sowing roller (18) is installed in the fixed seat; the r...

Embodiment 3

[0101] Such as Figure 1-6 , a precision seeding method based on an unmanned aerial vehicle platform, using an unmanned aerial vehicle as a sowing platform; setting a sowing device (2) on an unmanned aerial vehicle to realize sowing;

[0102] The sowing device (2) comprises a seed box (15), a fixed seat (16), a wind force seeding device, a quantitative sowing roller (18), a roller blade (19) and a servo motor (22); the servo motor is driven by a battery ;【The battery belongs to the electronic control component part (13)】

[0103] The sowing device (2) comprises a seed box (15), a fixed seat (16), a wind force seeding device, a quantitative sowing roller (18), a roller blade (19) and a servo motor (22); the servo motor is driven by a battery ;【The battery belongs to the electronic control component part (13)】

[0104] The wind power seeding device is a separate fan (17), and the fan is fixed on the bottom of the holder (16);

[0105] The seed box (15) is fixed on the top of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com