Patents

Literature

139results about How to "Does not affect flatness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

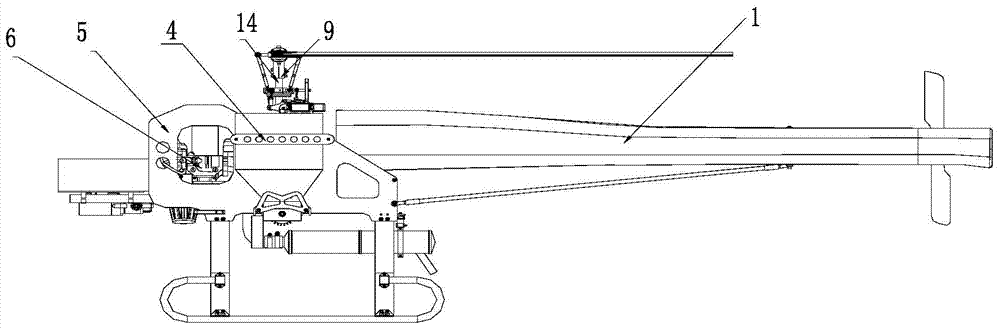

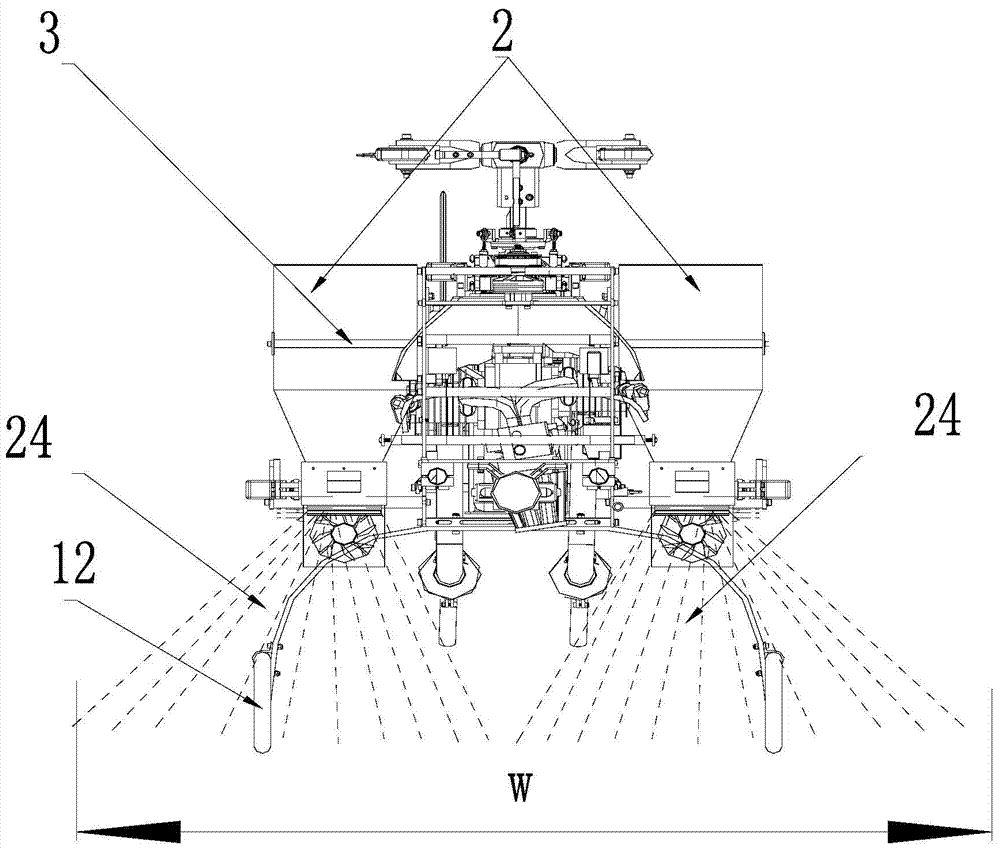

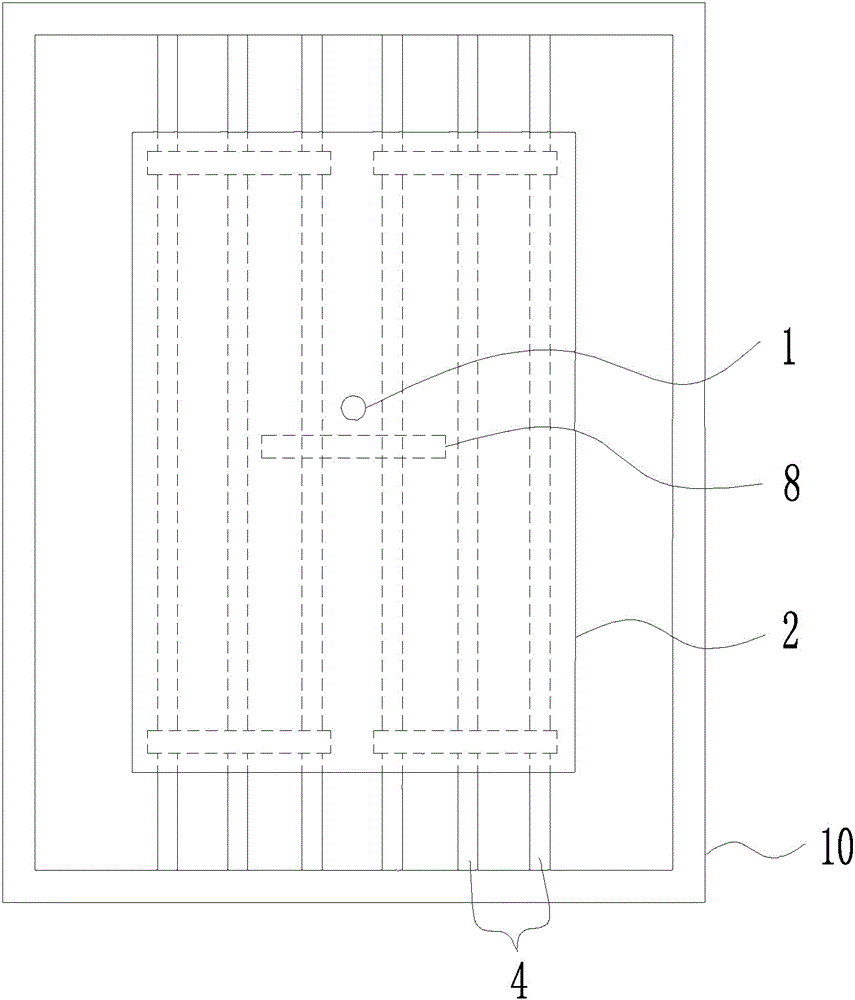

Precision seeding working system and method based on unmanned aerial vehicle platform

ActiveCN104255137AReduce labor intensityImprove work efficiencyAircraft componentsBroadcast seedersElectric machineryEngineering

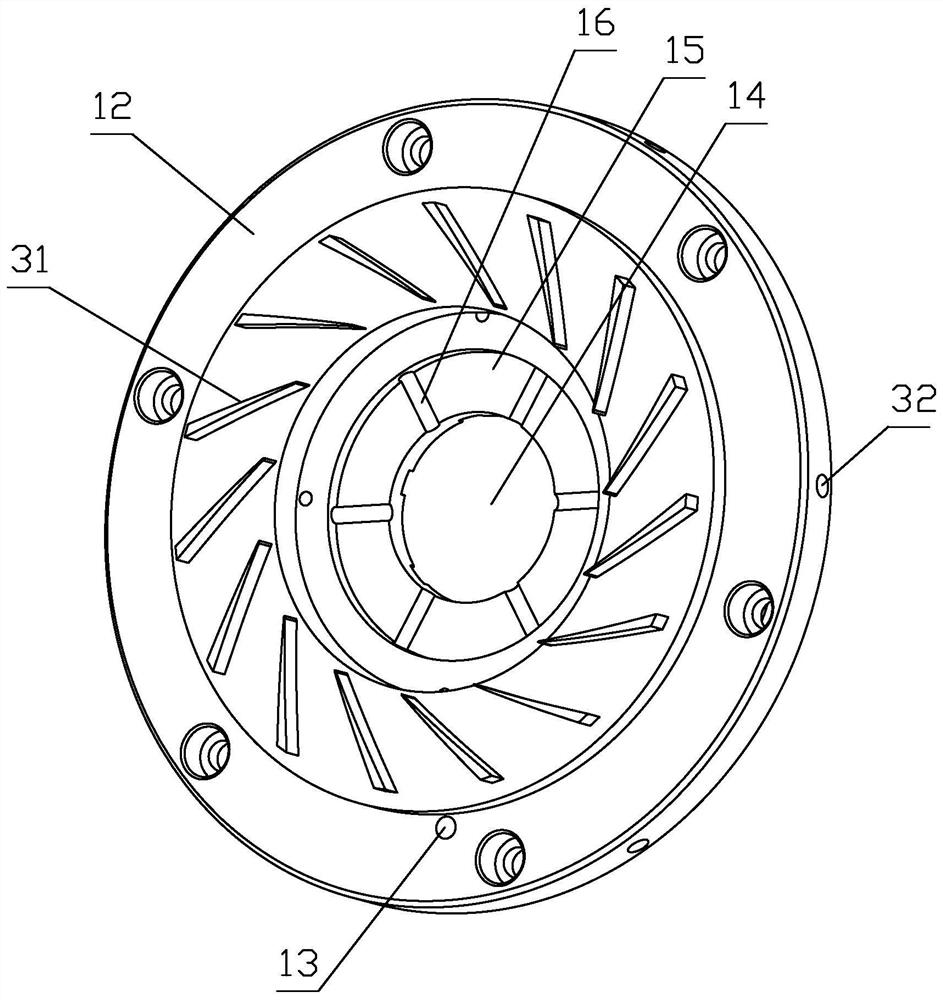

The invention discloses a precision seeding working system and method based on an unmanned aerial vehicle platform. The system comprises an unmanned aerial vehicle (1) and seeding devices (2) fixed on the unmanned aerial vehicle. Each seeding device (2) comprises a seed box (15), a fixed seat (16), a wind power seed scattering device, a quantitative seeding roller (18), roller blades (19) and a servo motor (22); the servo motor is driven by a battery; the wind power seed scattering device is a fan (17) only or an air supply channel consisting of a fan and a sleeve; the seed box (15) is fixed on the top of the fixed seat (16); the servo motor (22) is mounted on the fixed seat; the quantitative seeding rollers (18) controlled by the servo motor realize precision seeding; by the adoption of the wind power seed scattering device, seeding is uniform. The precision seeding working system based on the unmanned aerial vehicle platform can realize precision seeding work and is high in seeding efficiency and easy to implement.

Owner:湖南星索尔航空科技有限公司

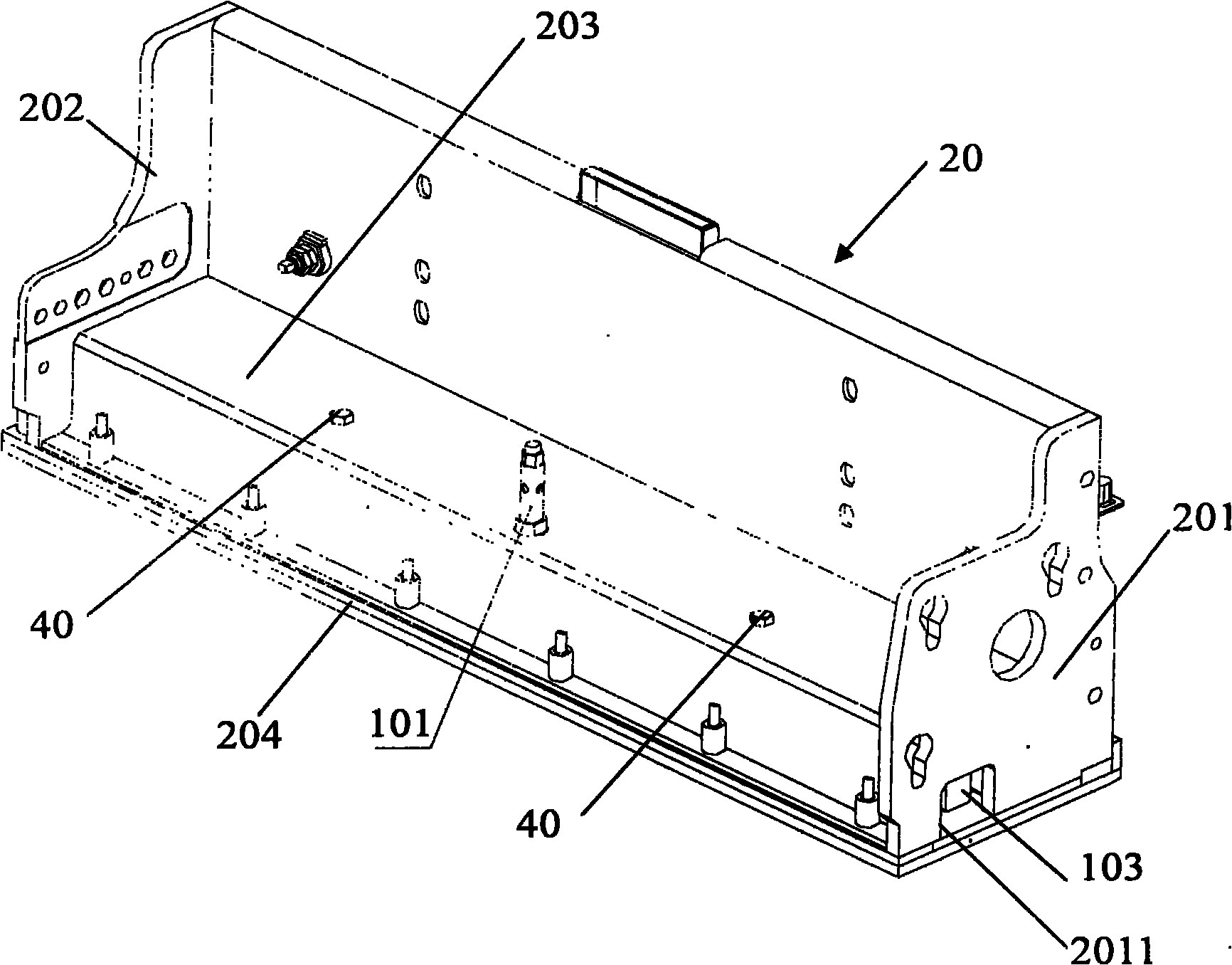

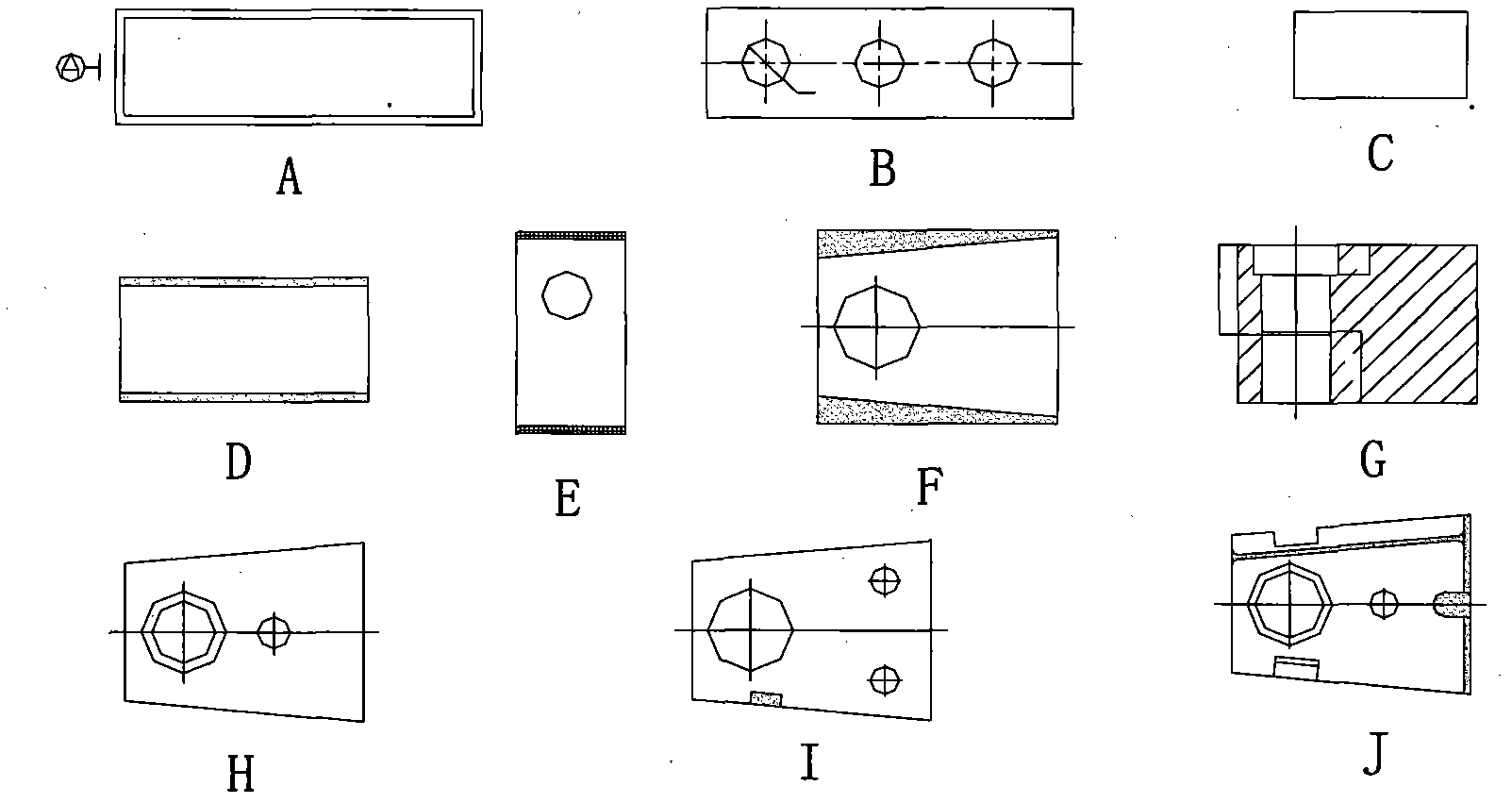

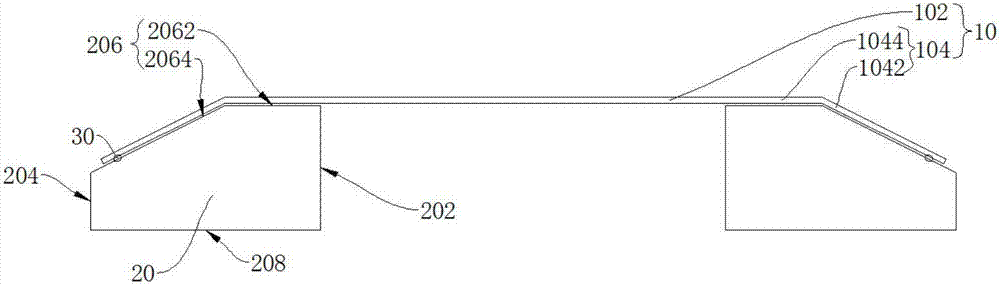

Paver

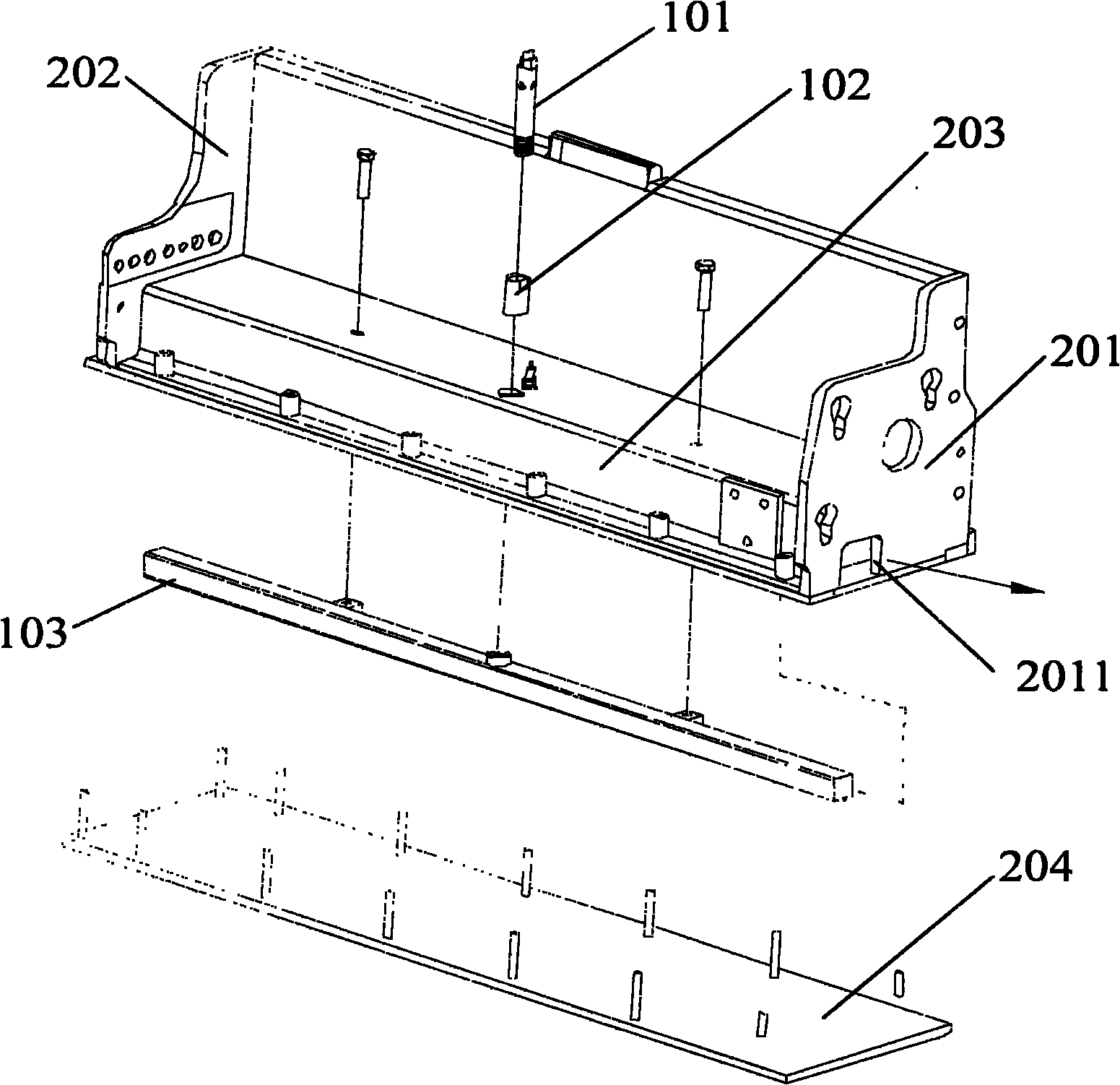

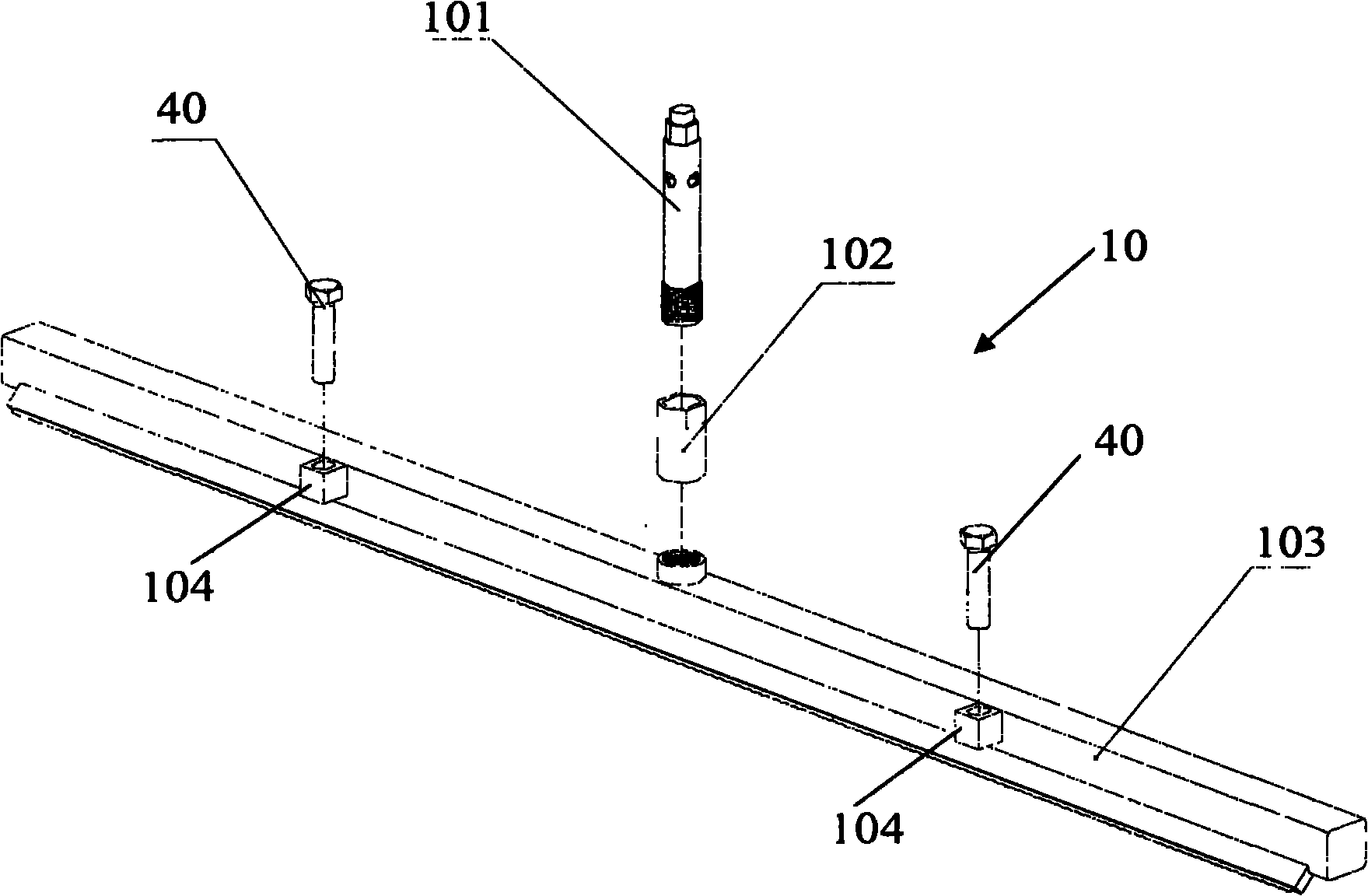

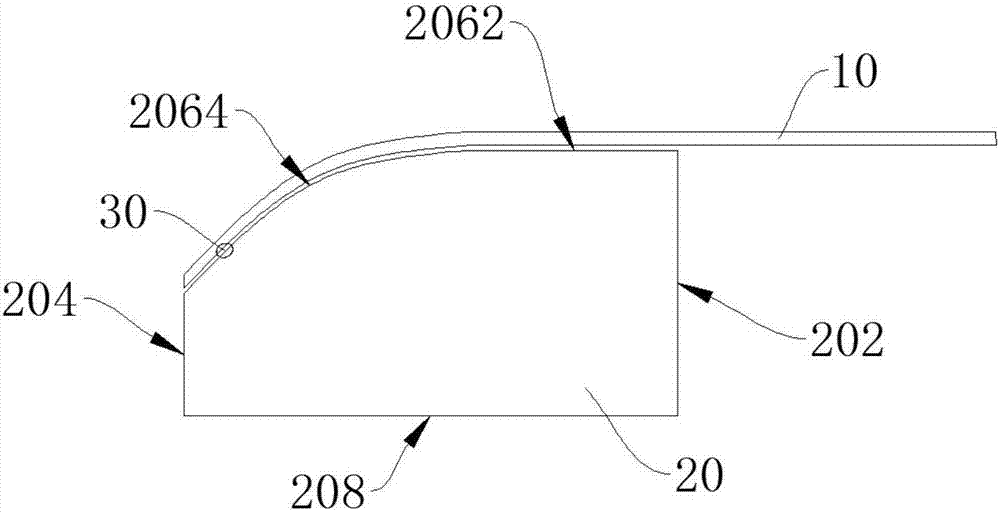

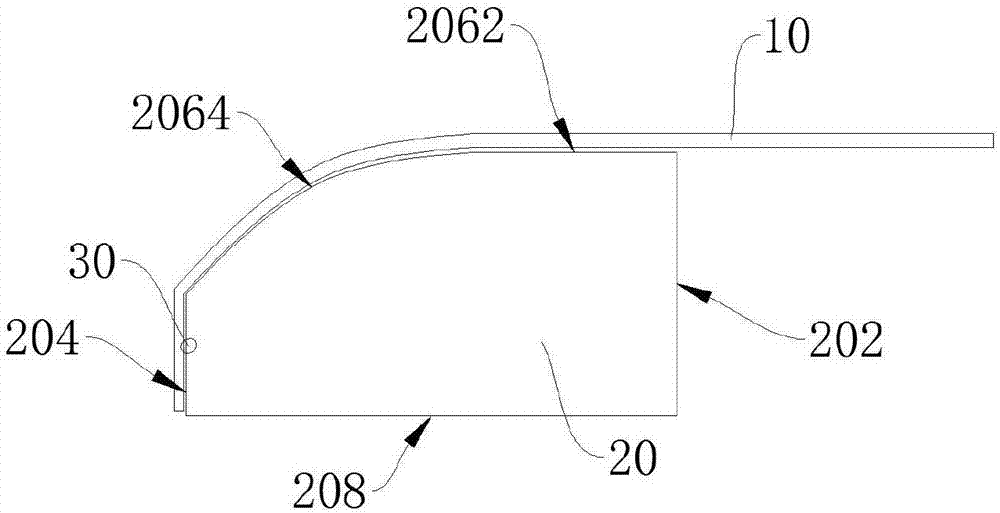

InactiveCN101864720ADoes not affect flatnessGuarantee the construction qualityRoads maintainenceScreedRear quarter

The invention provides a paver, which comprises a heating device (10) provided with a heating pipe (103) and an air pipe (101) and a screed box (20) provided with two lateral plates and a cover plate (203) and a bottom screed (204) arranged between the two lateral plates, wherein the heating pipe (103) is arranged in the screed box (20), the pore end of the air pipe (101) is arranged outside the screed box (20); the heating device (10) is connected with the screed box (20) in a detachable manner; the air pipe (101) is connected on the heating pipe (103) in a detachable manner; and an opening (2011) is arranged on the screed box (20) for taking the heating pipe out.

Owner:ZOOMLION HEAVY IND CO LTD

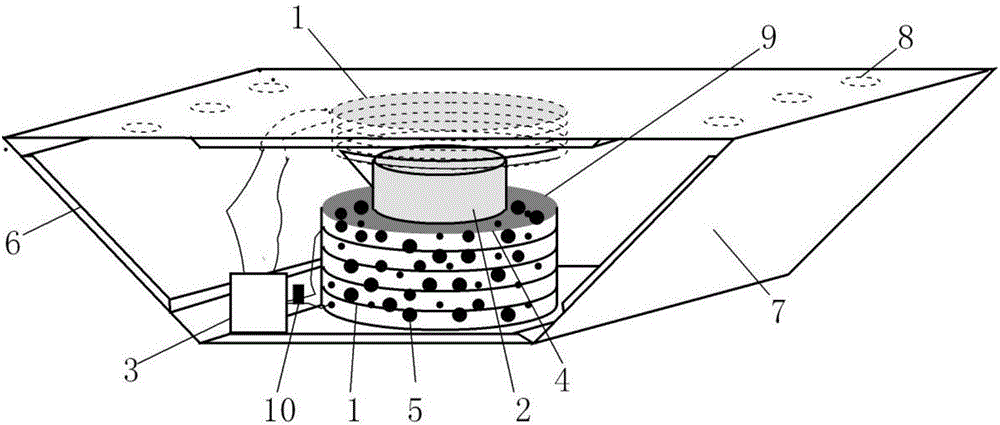

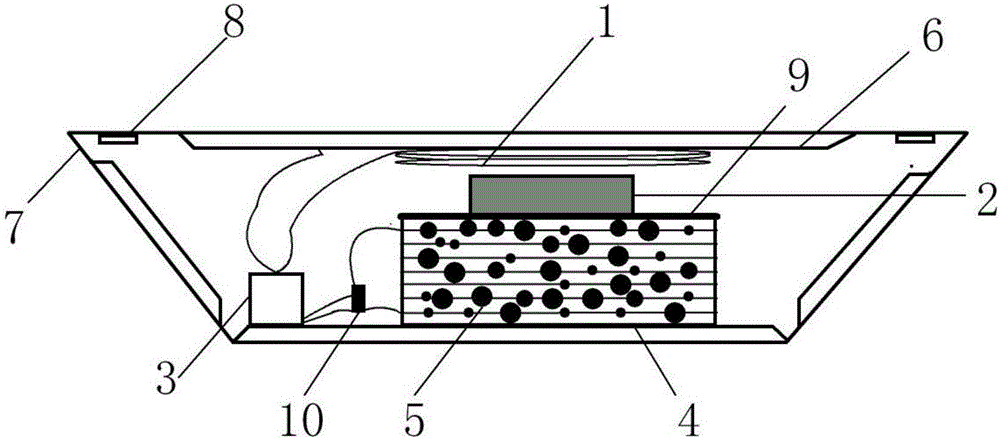

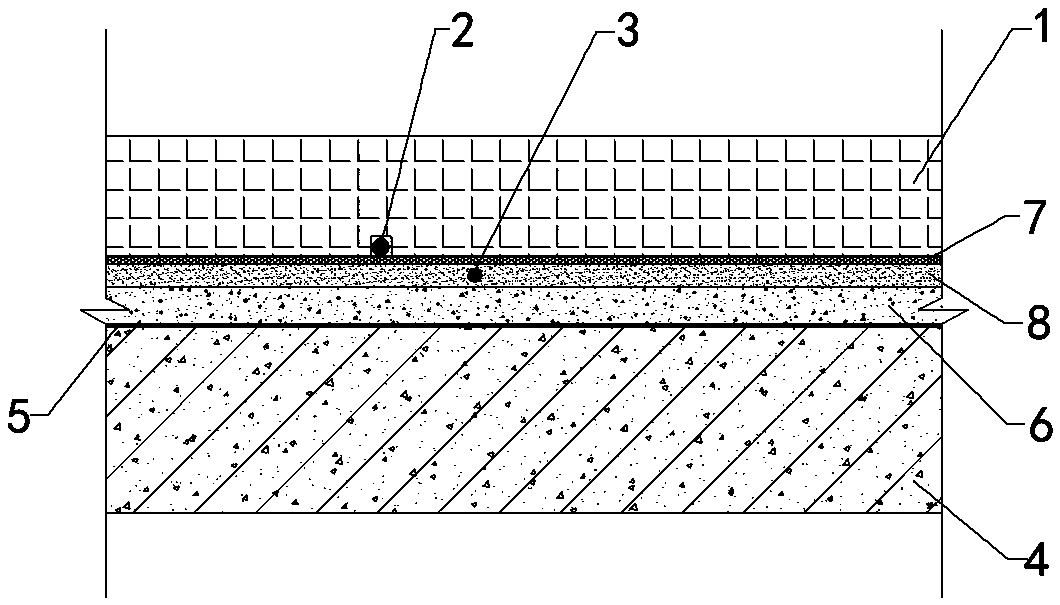

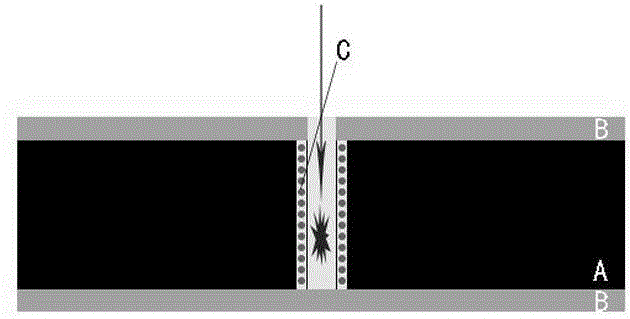

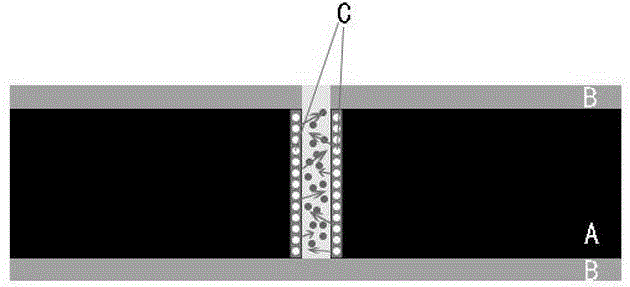

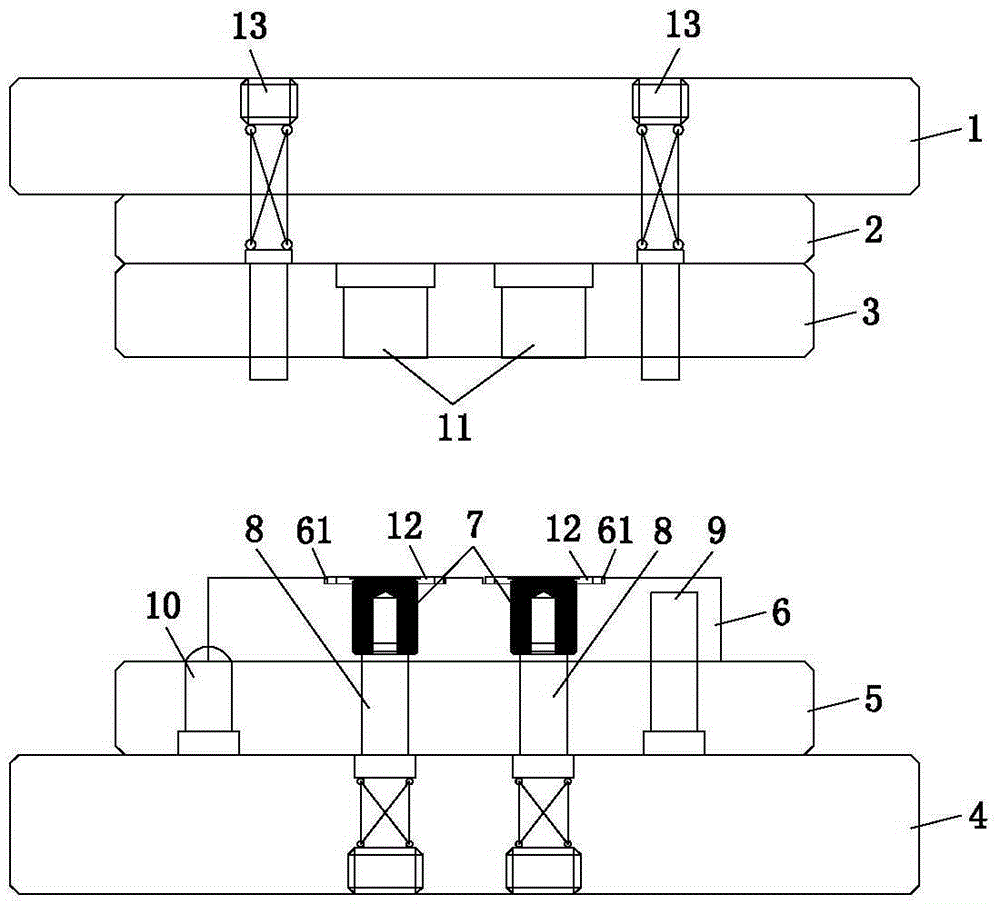

Piezoelectric-electromagnetic combined energy gathering vibration damping device

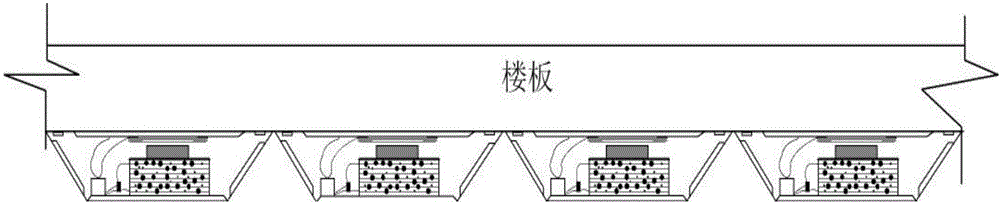

ActiveCN106499239AReduce vibrationIncrease contact pressureBatteries circuit arrangementsBridge structural detailsEngineeringLithium-ion battery

A piezoelectric-electromagnetic combined energy gathering vibration damping device is arranged below a floor or a decking, and aims to gather the kinetic energy in the floor or decking and convert same into electric power for storage; the electric power can be released so as to form a damping effect, thus alleviating the floor or decking vibrations; the piezoelectric-electromagnetic combined energy gathering vibration damping device mainly comprises an inductance coil, a permanent magnet, a lithium ion battery, a particle damping container, a multi-grading electromagnetic particle damping, a piezoelectric ceramics, a loading plate, anchoring bolts, an insulation pad, and an electric quantity identification and control induction member; anchoring bolts are reserved on the loading plate and the piezoelectric ceramics; each member is placed in the loading plate according to required positions; the whole device is fixed below the floor or decking through the anchoring bolts. The piezoelectric-electromagnetic combined energy gathering vibration damping device can gather and utilize the energy of vibrations in the environment, and can effectively alleviate the floor or decking vibrations.

Owner:北京东方中恒科技发展有限公司

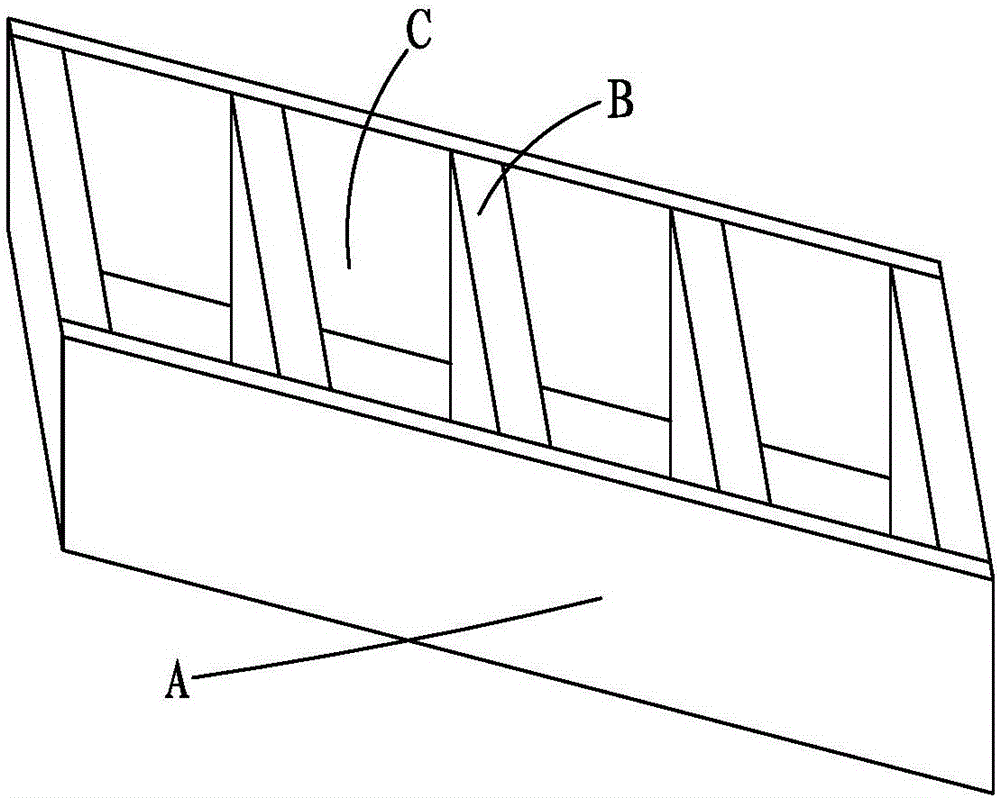

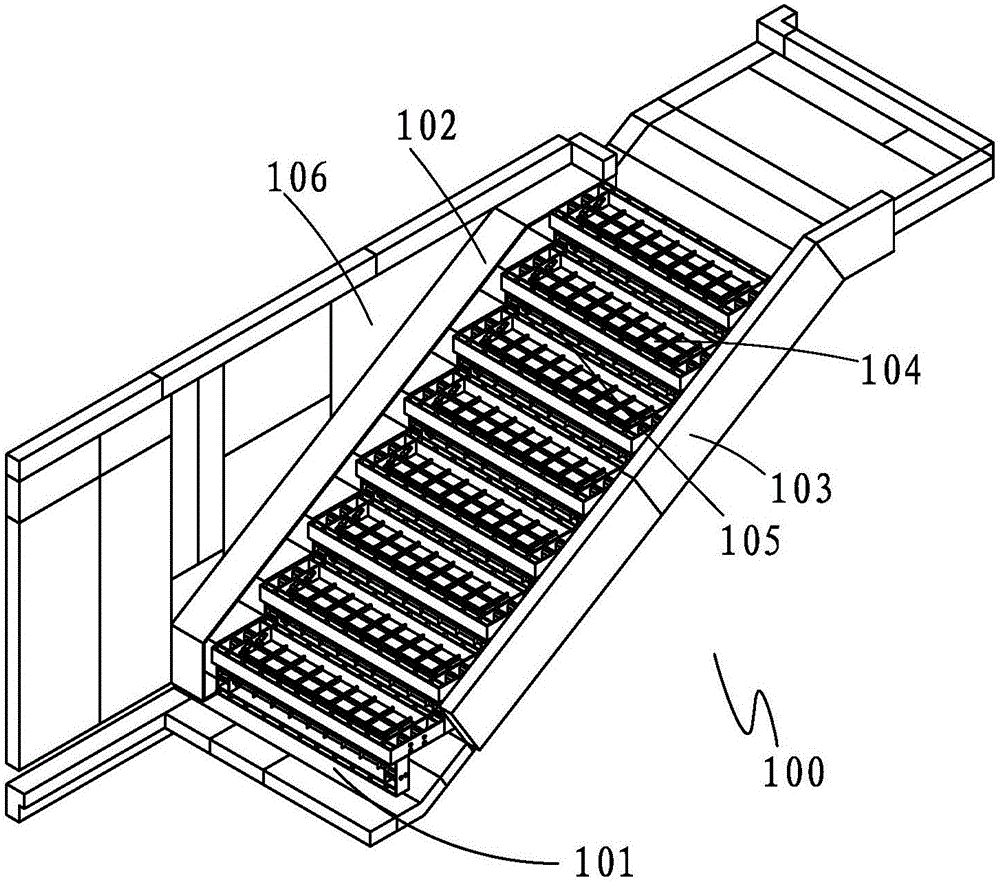

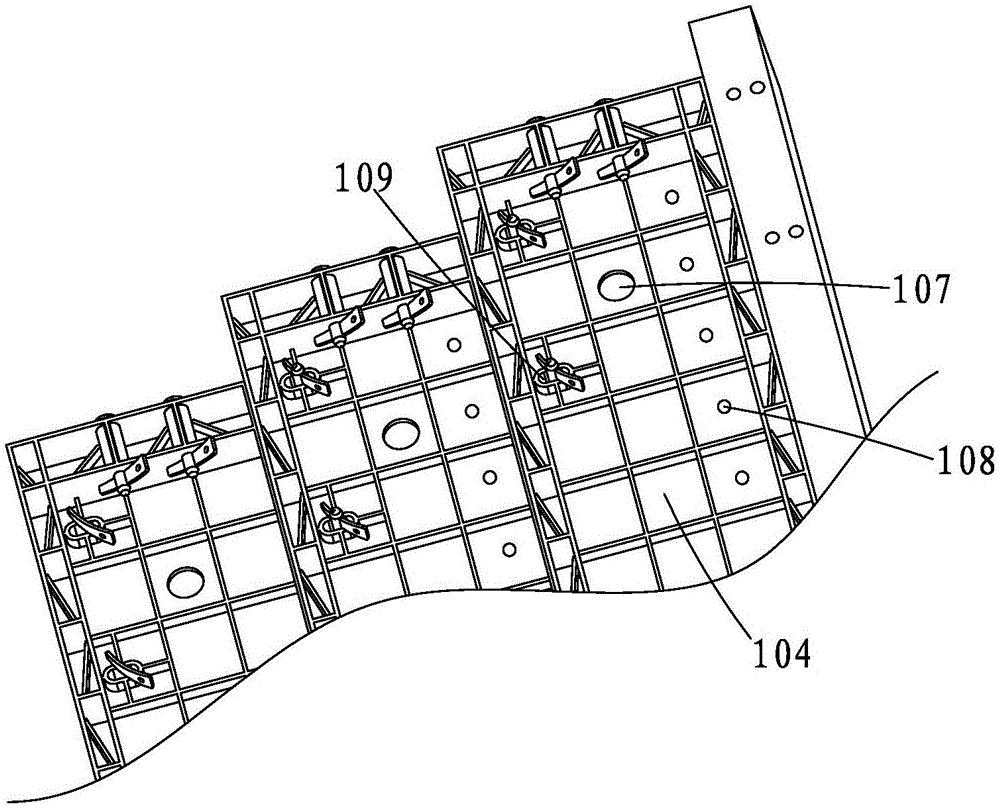

Composite building template compound system

InactiveCN106193582AReduce wasteLow costForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksEngineeringButt joint

The invention provides a composite building template compound system. The composite building template compound system comprises a stair template and a closed type internal corner template. The stair template comprises blocking plates, pinking teeth, stair side plates, stair treads and stair risers. The stair treads and the stair risers are arranged sequentially from bottom to top in a staggered mode to form steps. The steps are installed between the stair side plates and the inner side faces of the pinking teeth. The outer side faces of the pinking teeth are arranged on a wall. The blocking plates are arranged at the bottoms of the pinking teeth, the stair side plates and the steps. A closed-opening type pouring space is formed among the blocking plates, the pinking teeth, the stair side plates, the stair treads and the stair risers. The upper end faces of the stair treads are provided with feed inlets. The closed type internal corner template comprises first end plates and first side plates which are connected mutually to form a cuboid. Any two adjacent first side plates are provided with a connection part and an operation part. The operation parts are connected in a butt joint mode in the intersections of the first side plates. The connection parts are provided with first connection holes. The operation parts are provided with operation holes. The composite building template compound system is a complete set of system.

Owner:郭榕来 +1

Method for preparing non-PVA fiber hollow yarn and hollow fabric thereof

ActiveCN103938323ADoes not affect flatnessDegradation conditions are controllableFilament forming substance formingMelt spinning methodsSolubilityFiber

The invention discloses a method for preparing a non-PVA fiber hollow yarn and a hollow fabric thereof. The fiber comprises a filament, a short fiber yarn and a ribbon. According to the preparing method, the easily degradable fiber with the controllable degrading condition and zero formaldehyde residue is utilized for preparing a covering yarn, the degrading condition is controllable, and the formaldehyde residue does not exist. Compared with a traditional water solubility fiber hollow yarn, the hollow yarn prepared with the manufacturing method is friendly to the environment, free of residue, low in price and shrinking percentage and obvious in hollow phenomenon, the sizing technology can be carried out, and the hollow yarn can be made into the high-density fabric and the fabric with the single yarn capable of being woven. In addition, the hollow fabric is formed by weaving the hollow yarn prepared with the method for preparing the non-PVA fiber hollow yarn, and has the advantages of being light, fluffy, and good in heat preservation performance, moisture absorbing performance and flexibility.

Owner:余燕平 +1

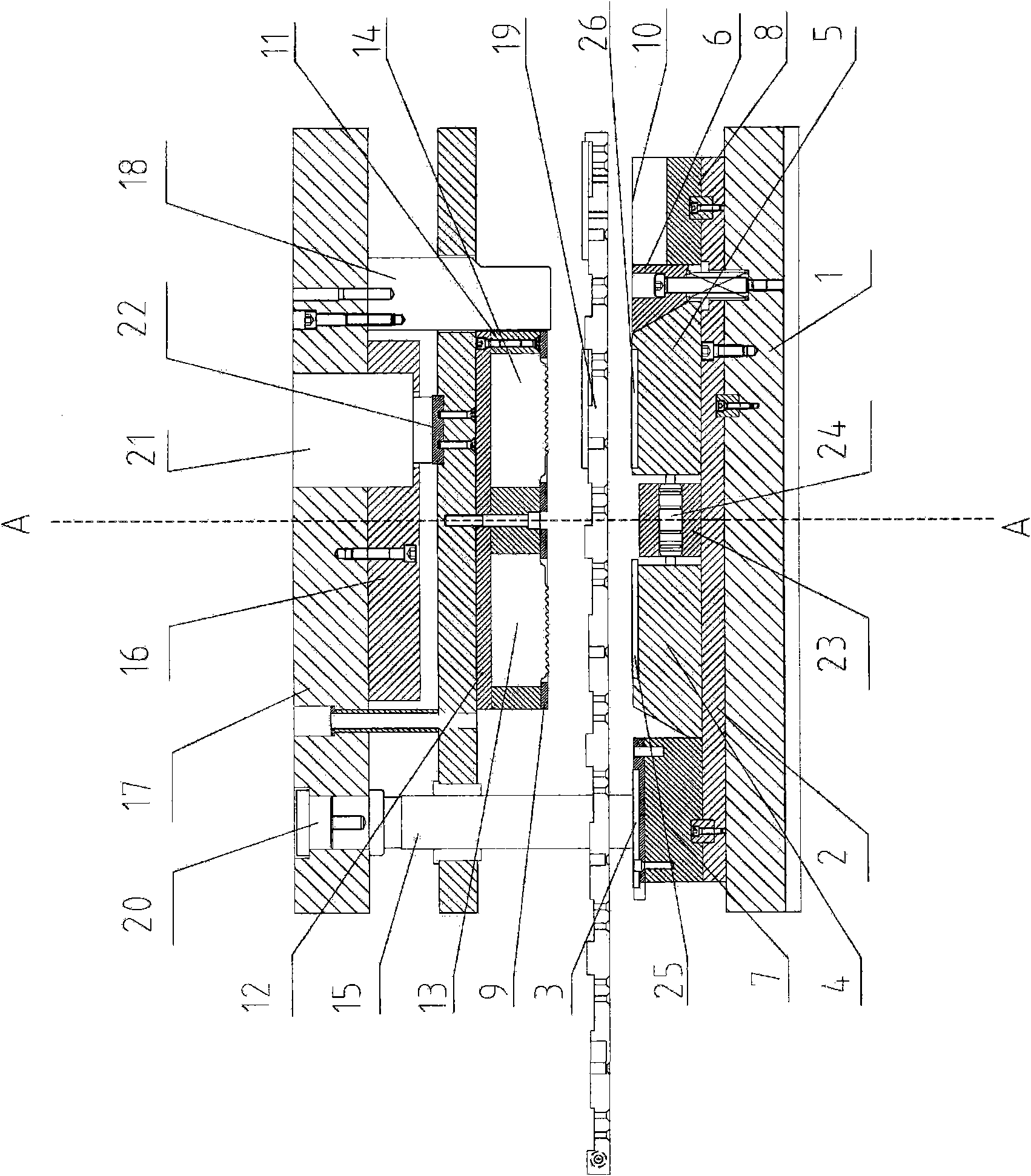

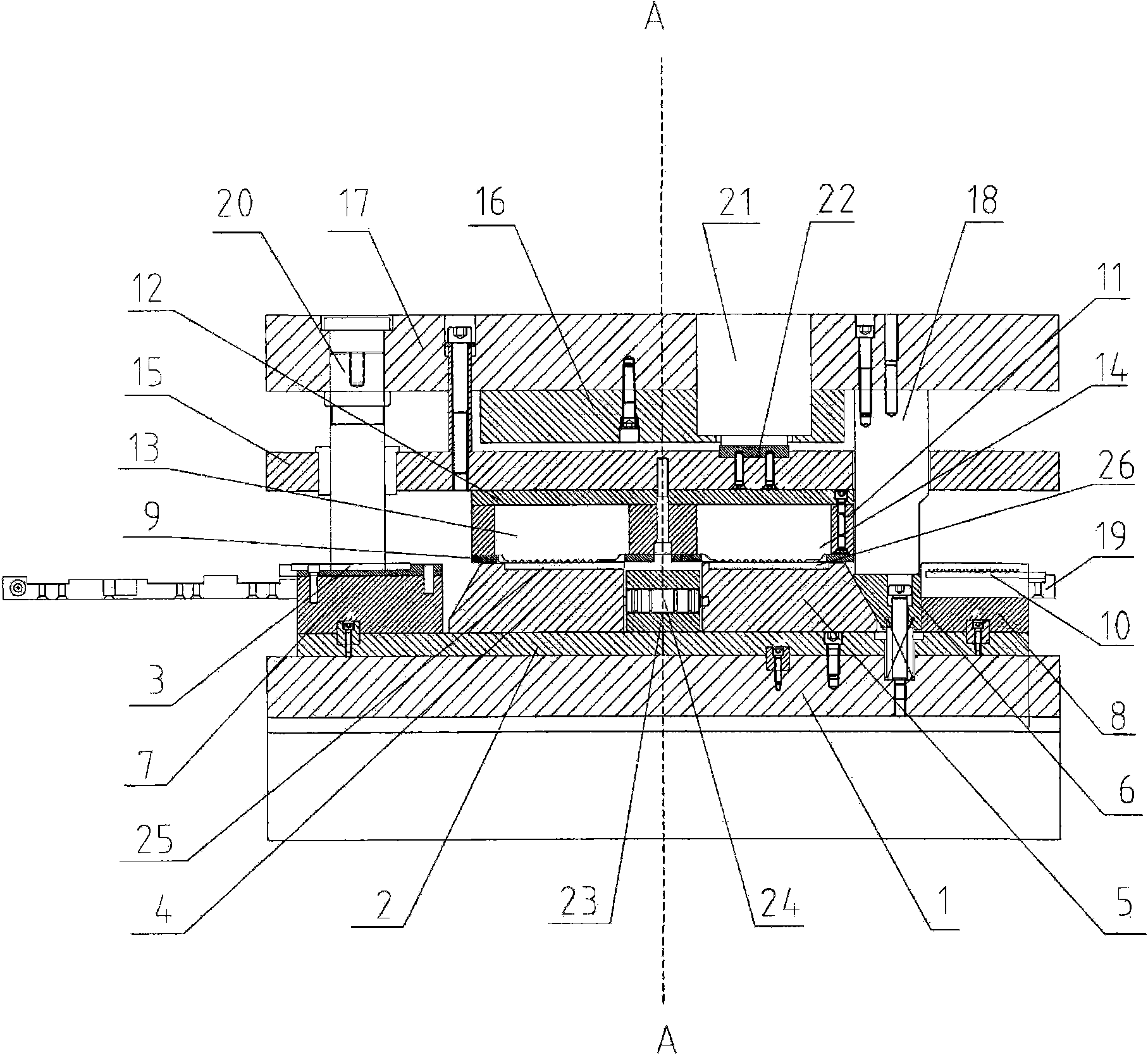

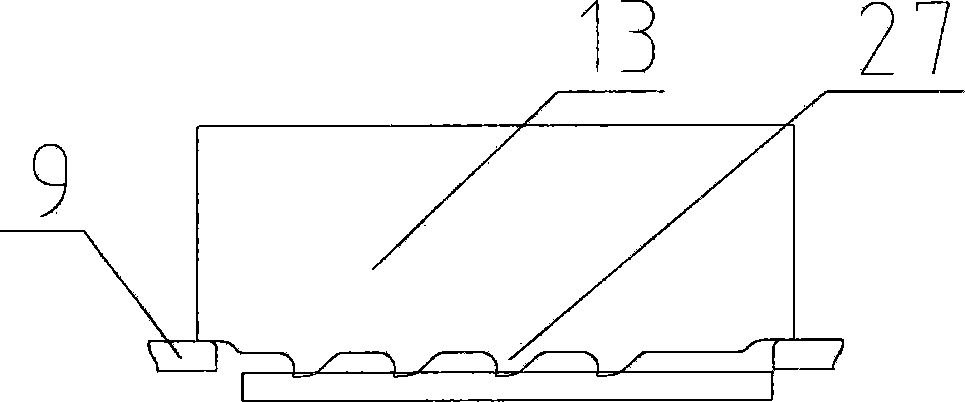

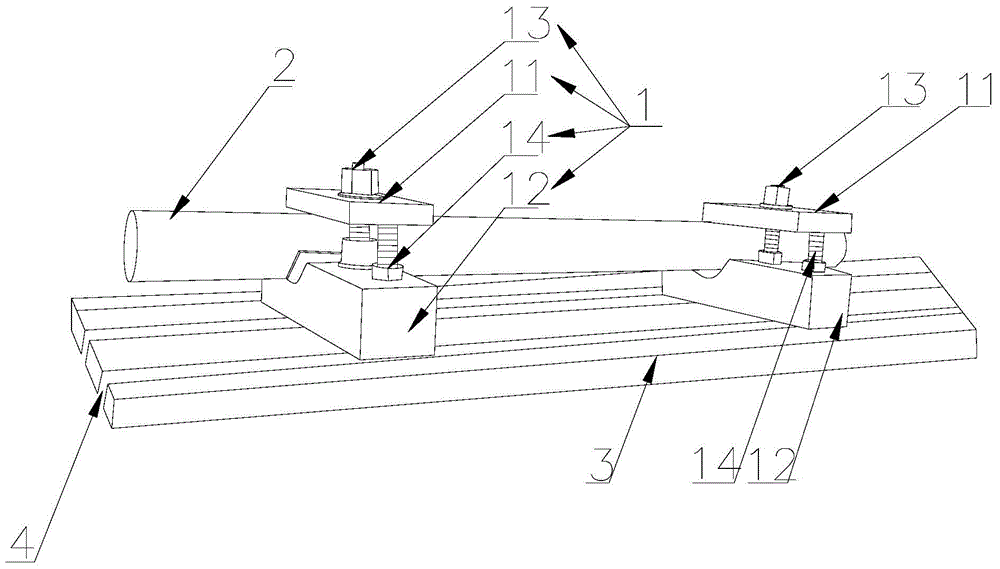

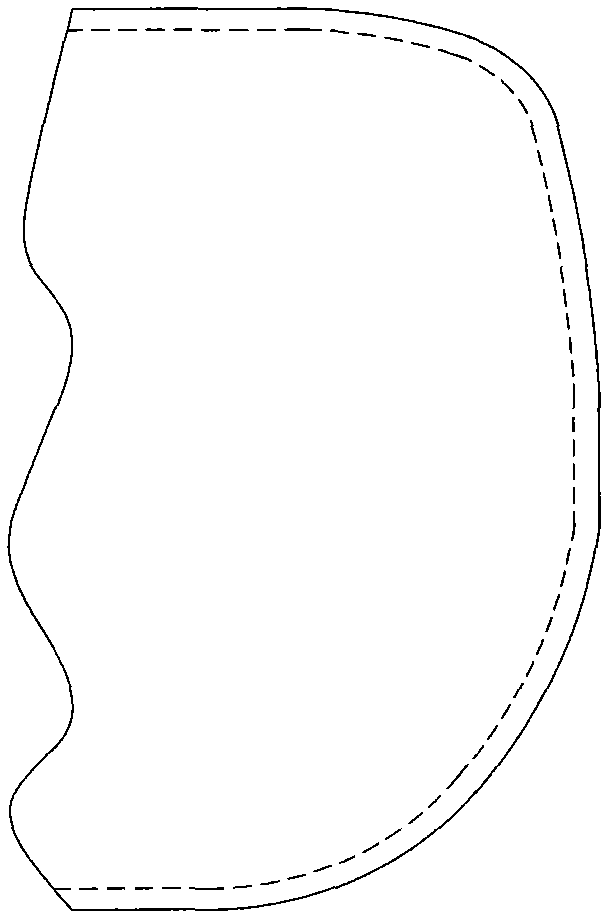

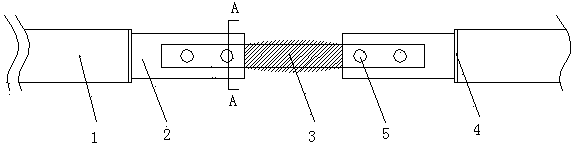

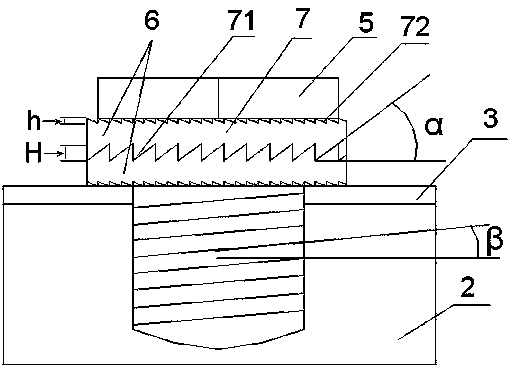

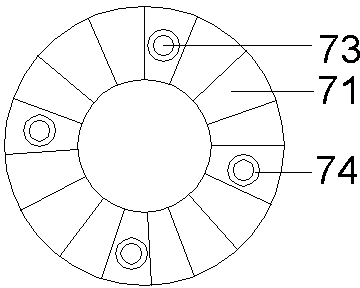

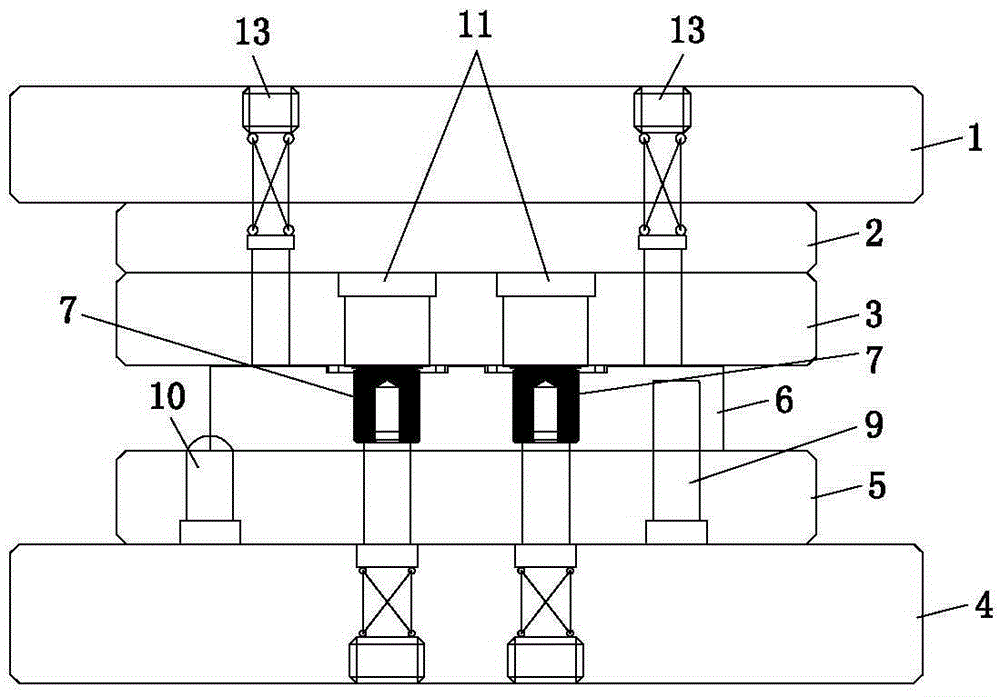

Automatic steel backing plate broaching device and using method thereof

ActiveCN101979200AHigh densityImprove adhesionBroaching machinesHigh volume manufacturingEngineering

The invention provides an automatic steel backing plate broaching device, which comprises an upper die base, a movable supporting plate, a lower die base and a forming device, wherein the upper die base is provided with a guide post and a pressure spring; the movable supporting plate is respectively connected with the guide post and the pressure spring; the lower die base is parallel to the movable supporting plate at an interval; and the forming device comprises a blade fixing device, a blade, a press block, a slide block, a fixed block and a wedge, wherein the blade fixing device is arranged under the movable supporting plate; the blade is arranged in the blade fixing device, and the surface of the blade is provided with broached teeth; the press block is arranged on the upper die base and is inserted in the movable supporting plate; the slide block is arranged on the lower die base; the fixed block is arranged on the lower die base; and the wedge is arranged between the slide blockand the fixed block. The broached steel backing plate has high braking safety, and is more suitable for brake sheets of heavy-duty automobiles and trucks; and the product appearance and flatness are not influenced. A die processing mode is adopted, so the whole production process is more stable, the tooth root is firm and difficult to fall off, and the device is suitable for mass production.

Owner:UTIL GUANGZHOU AUTO PARTS

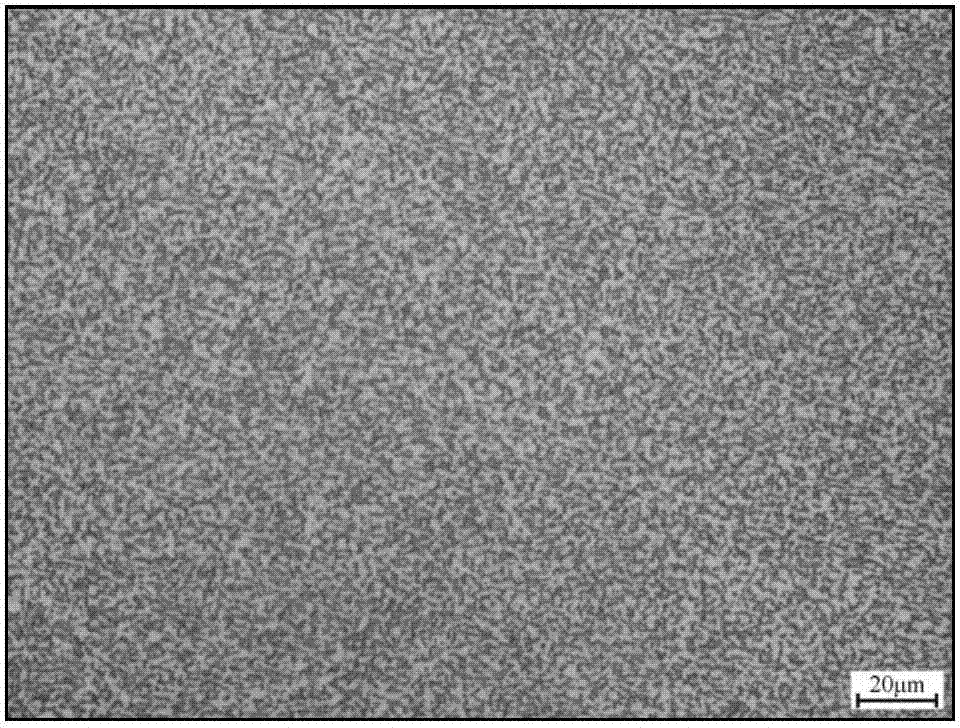

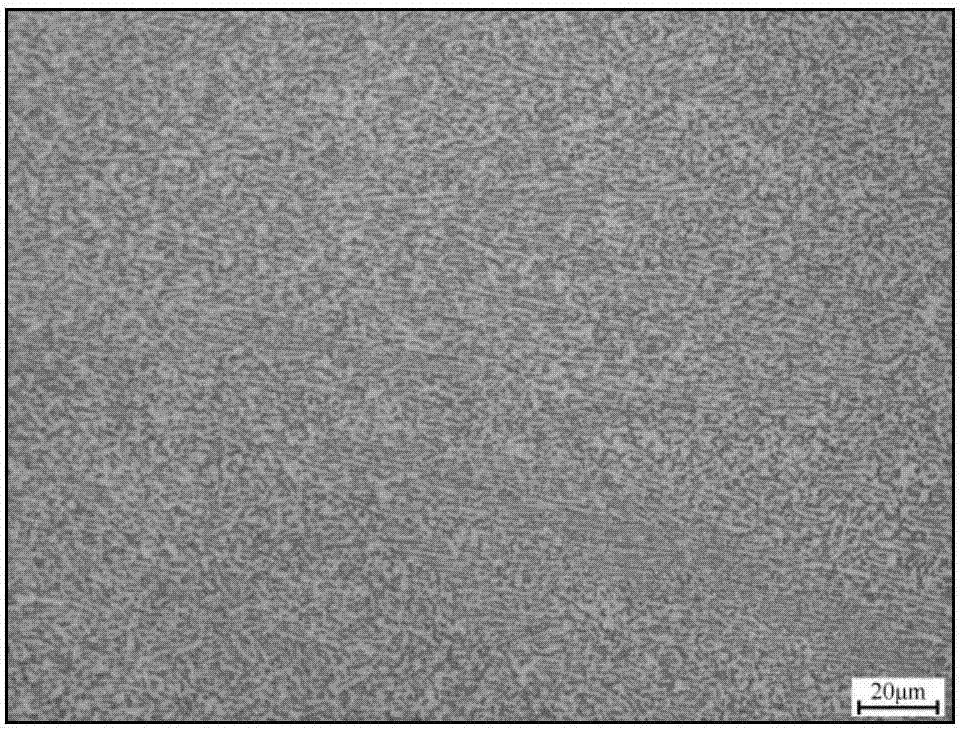

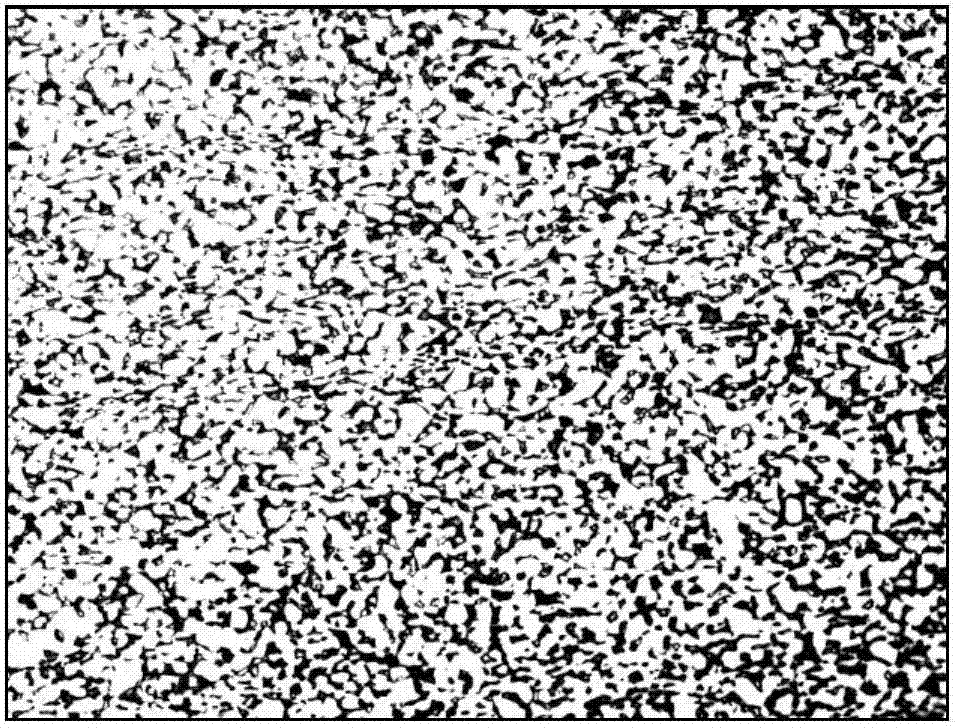

Method for manufacturing fine-grain TA15 titanium alloy sheet for superplastic forming

ActiveCN103785684AGrain refinementNo distortionTemperature control deviceMetal rolling arrangementsWater coolingSurface grinding

The invention provides a method for manufacturing a fine-grain TA15 titanium alloy sheet for superplastic forming. The method includes the following steps that firstly, primary rolling is carried out on a TA 15 titanium alloy board blank with a certain thickness, and surface grinding is carried out after water cooling; secondly, secondary rolling is carried out, and surface grinding is carried out after air cooling; thirdly, rolling is carried out for the third time, surface grinding is carried out after air cooling; fourthly, rolling is carried out for the fourth time, surface grinding is carried out after air cooling, and the fine-grain TA15 titanium alloy sheet with the thickness ranging from 0.6 mm to 2.5 mm for superplastic forming is obtained. A transverse metallographic structure and a longitudinal metallographic structure of the TA15 titanium alloy sheet are fine uniform isometric crystals, the size of crystalline grains is not larger than 6 micros, the extensibility is not less than 715 percent, and related technical requirements of superplastic forming are met.

Owner:WESTERN TITANIUM TECH

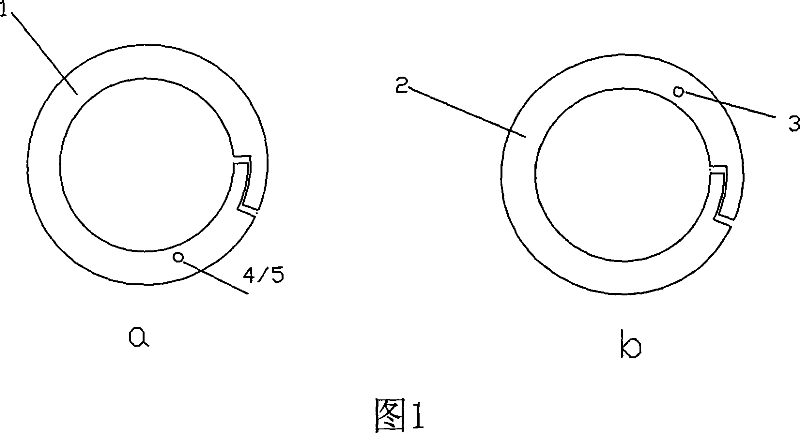

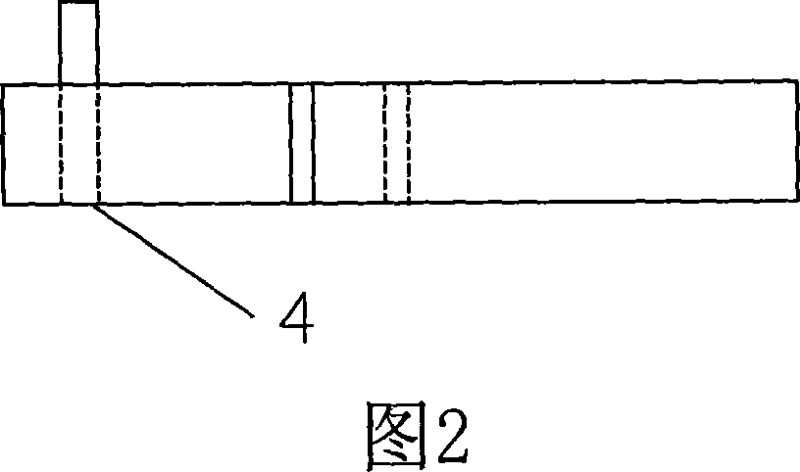

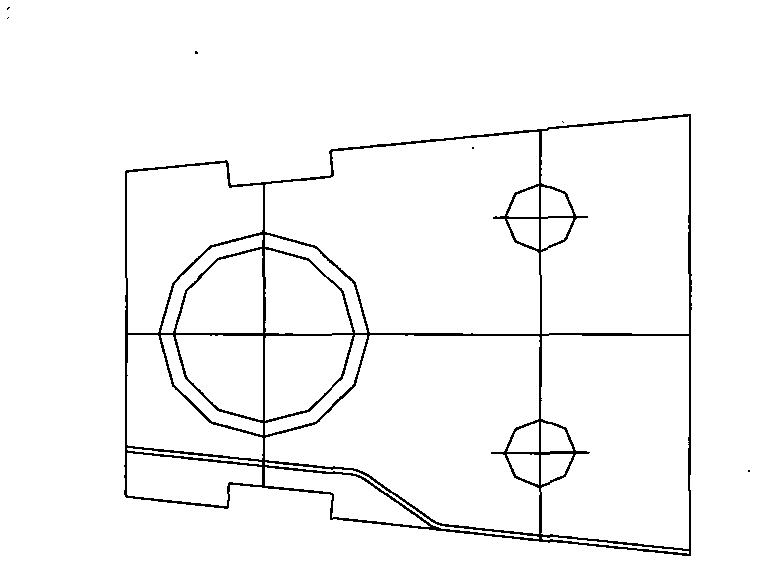

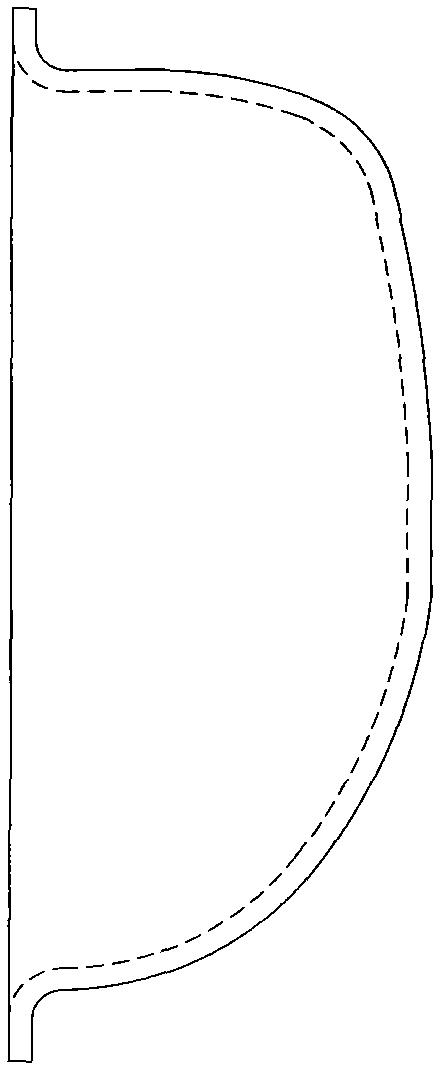

Combined piston ring with novel locating device and manufacturing method thereof

InactiveCN101037975ADoes not affect finishDoes not affect flatnessPiston ringsMachines/enginesSurface finishLaser processing

The invention discloses a combined piston ring having new type positioning device and manufacturing method thereof, comprising upper composing ring and lower composing ring and positioning device for positioning the two composing rings. The positioning device includes a positioning pin, positioning slot, and also a positioning pin jointing hole provided between inner edge and outer edge of the upper composing ring or lower composing ring, the positioning pin is closely jointed with one ring through the hole, which is then inserted to positioning slot of another composing ring, the upper composing ring and the lower composing ring are positioned and assembled, ports of the upper composing ring and the lower composing ring are interlaced. Positioning slot of the combined piston ring and the positioning pin jointing hole are formed by pulse laser processing. Positioning device of the invention does not damage the inner and outer edges of the piston ring, ring surface finish and flatness will not be destroyed, which can be provided on any position of the ring surface, processing of the device is easy, and cost is low, which can prolong using lives of the cylinder and the piston ring.

Owner:何俊明

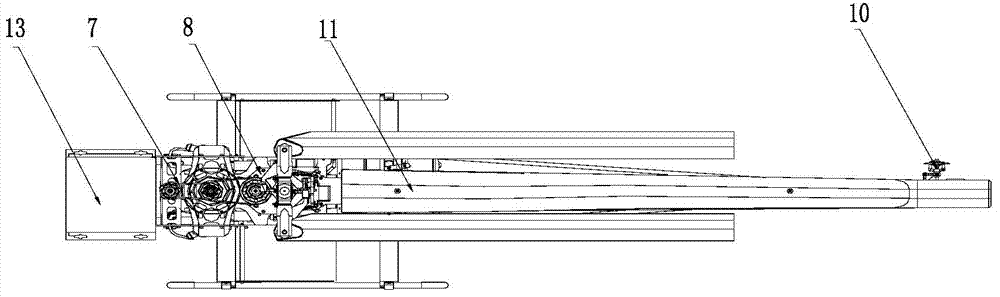

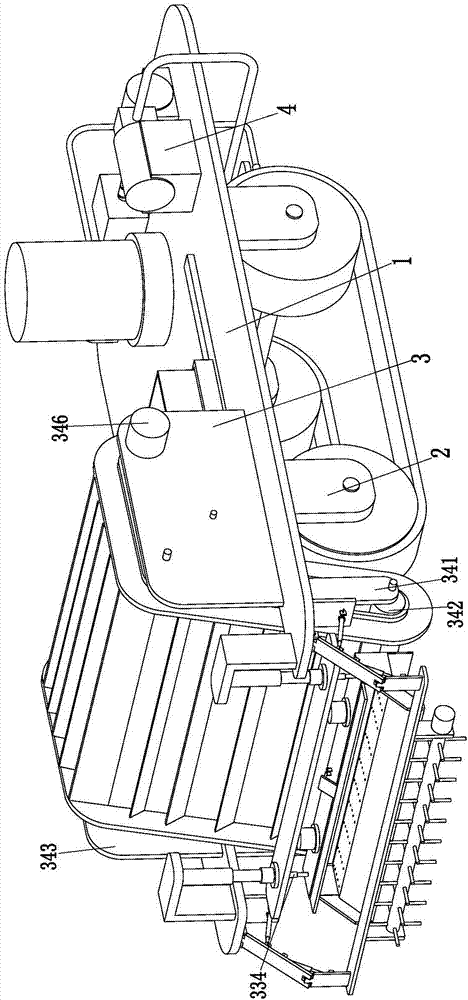

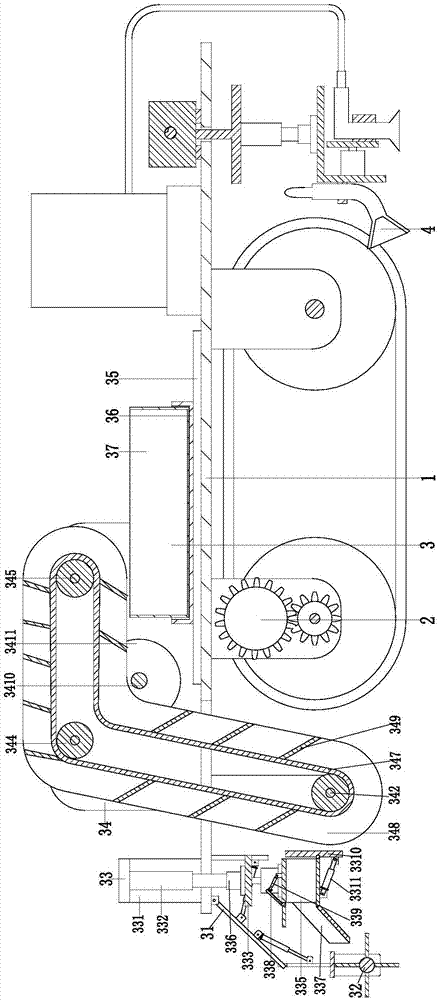

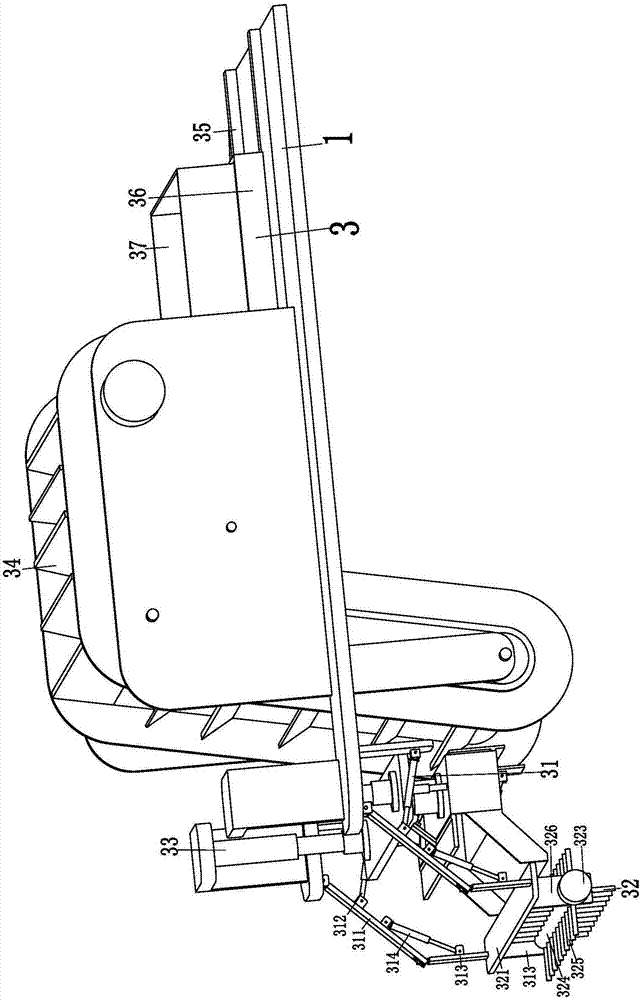

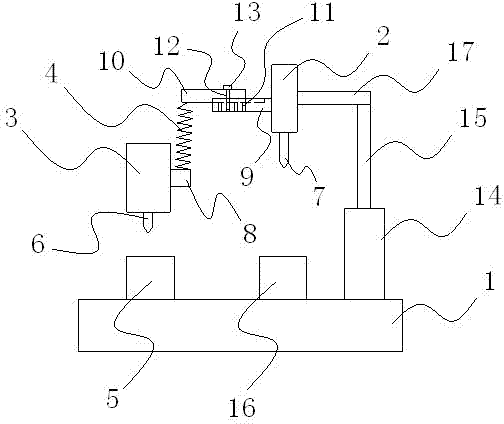

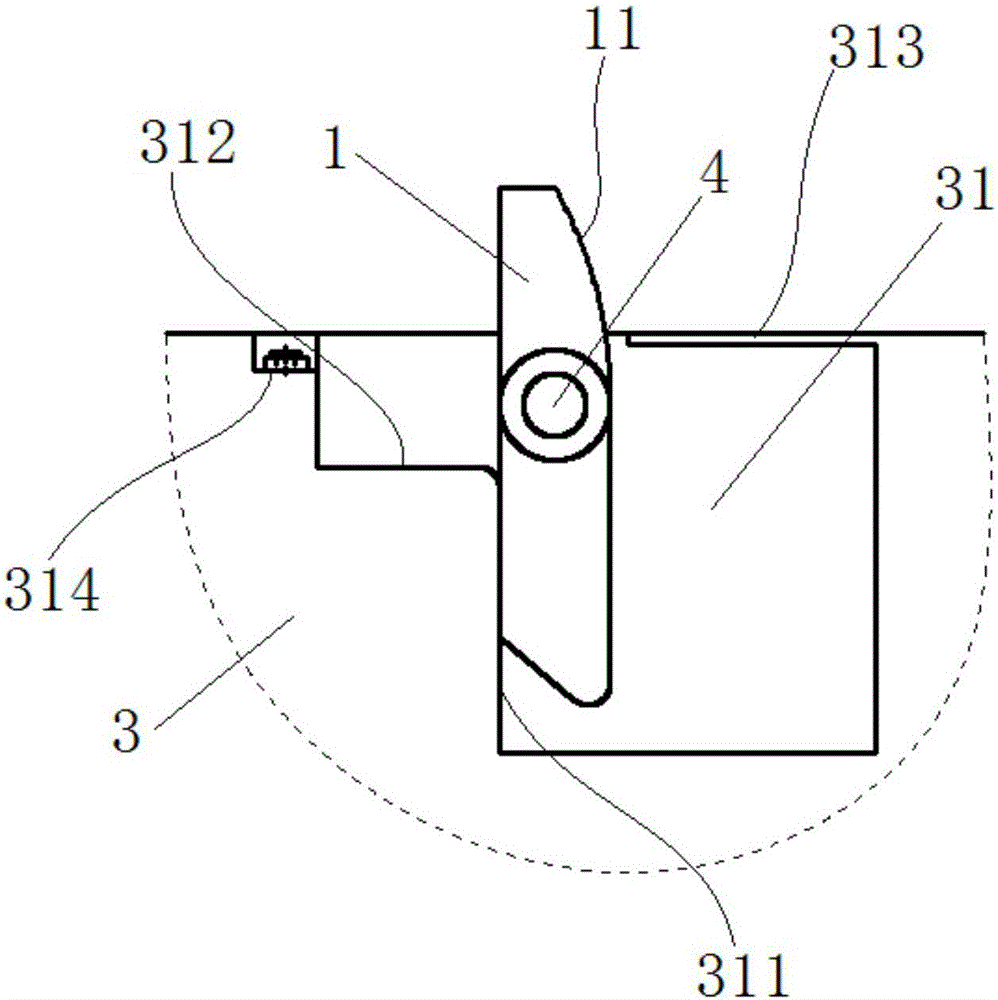

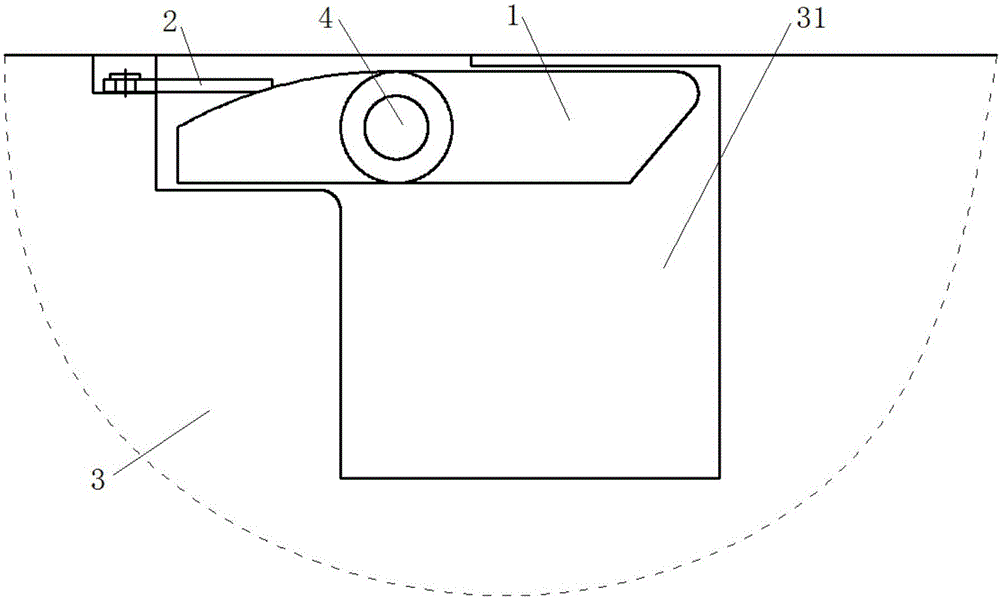

Automatic environment-friendly plastic runway glue spraying equipment with plastic particle recycling function

InactiveCN107321522AFlatness does not affectEasy to operatePretreated surfacesGround pavingsEngineeringMechanical engineering

The invention relates to automatic environment-friendly plastic runway glue spraying equipment with a plastic particle recycling function. The equipment comprises a bottom plate, a moving device is installed at the lower end of the bottom plate, a particle recycling device is installed on the front side of the upper end of the bottom plate, a glue spraying device is installed at the back end of the bottom plate, and an automatic mixed plastic runway particle recycling and automatic glue spraying technology is completed through cooperative use of the moving device, the particle recycling device and the glue spraying device. According to the equipment, the problems that in the existing plastic runway construction process, redundant particles on a plastic runway need to be manually cleaned and collected, the collected particles need to be manually screened, existing glue spraying equipment needs to be manually pushed to conduct glue spraying operation on the plastic runway according to regulations, dust on the plastic runway needs to be manually removed before glue spraying operation, and the glue spraying flatness is influenced, the consumed time is long, the labor intensity is high, and the working efficiency is low due to the fact that the speed that the glue spraying equipment is manually pushed to move is not uniform can be solved, and the automatic mixed plastic runway particle recycling and automatic glue spraying function can be achieved.

Owner:丁建丽

Plastic bag sealing machine

ActiveCN103612789AImprove reliabilityOvercoming elasticityWrapper twisting/gatheringEngineeringPlastic bag

The invention provides a plastic bag sealing machine which has the cutting function and is convenient to operate. The plastic bag sealing machine comprises a base, a heat-sealing base and a heat-sealing cutter, the heat-sealing base and the heat-sealing cutter are arranged on the base, and an electric heating unit is arranged in the heat-sealing base and / or the heat-sealing cutter. The plastic bag sealing machine is characterized in that the heat-sealing cutter is arranged on a heat-sealing support, a protruded portion is arranged at the side portion of the heat-sealing support, the protruded portion is connected with a sealing support through an elastic device, and a sealing cutter is arranged on the sealing support. The plastic bag sealing machine is simple in structure, capable of conducting cutting during the heat-sealing process and suitable for the requirements for sealing positions and cutting positions of different plastic bags, and has good practicality.

Owner:信宜奕龙实业发展有限公司

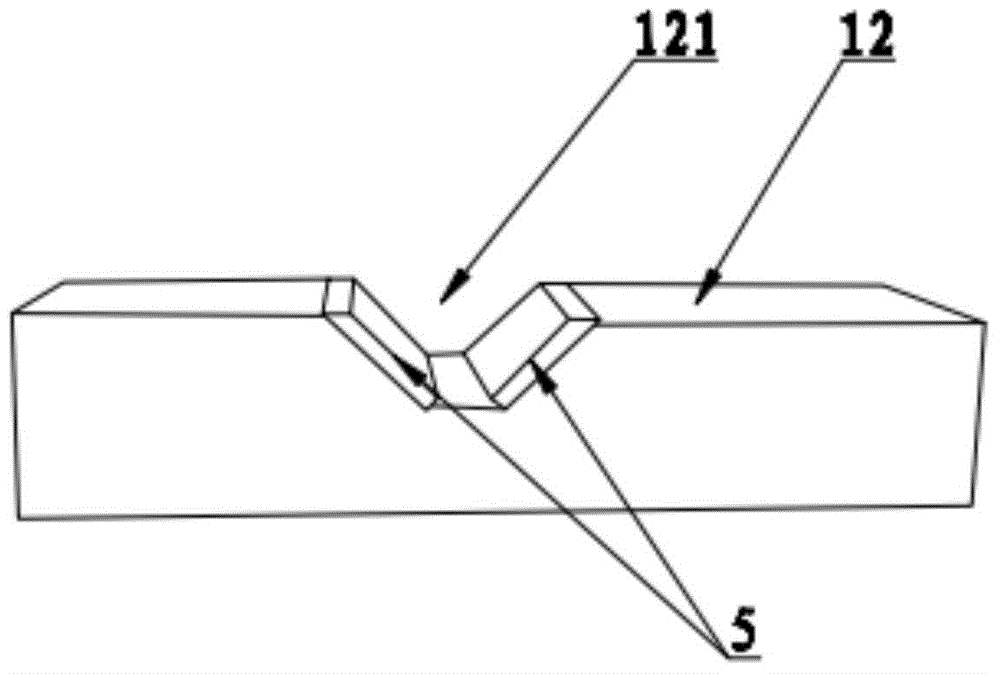

Clamp used for piston rod groove milling

InactiveCN104889768AHigh precisionQuality improvementPositioning apparatusMetal-working holdersEngineeringSpring steel

The invention provides a clamp used for piston rod groove milling. Regulating grooves are formed in the middles of upper clamping plates and suitable for piston rods of different sizes. Lower clamping blocks are fixed into slide grooves of a milling machine working table through second bolts, and therefore the whole clamp can be more stable. Matched spring steel plates are arranged on the two inner sides of each groove of the lower clamping blocks respectively, the grooves are protected against deformation caused by abrasion, clamping can be firmer and more stable, and the drilling and milling accuracy and the product quality are improved. Spring steel plates are locked through hexagon socket screws and are convenient to replace, and the spring steel plates are locked through the hexagon socket screws so that the flatness of the surfaces of the spring steel plates can not be influenced.

Owner:ANQING TIANRUN ENG MACHINERY

Bonding encapsulation structure and method suitable for radio frequency MEMS and method

PendingCN107814351AFlat distributionIncrease the effective bonding areaTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesEtchingRadio frequency

The invention relates to a bonding encapsulation structure and method suitable for radio frequency MEMS. The method comprises the steps that organic materials are spin-coated on an encapsulation coverplate and patterned, then Cr and Au are sputtered, and an encapsulation cover plate with the uniformly distributed organic materials and cavities is obtained by using a method that the cavities are etched with a TMHA solution. The cover plate full of the cavities is made from a high-resistance silicon material, and the cavities are obtained through wet etching by using the TMAH solution. By meansof the encapsulation method, the organic materials can be smoothly distributed in a bonding area, the effective bonding area of wafer-level bonding is increased, and then the airtightness, the reliability and other performance of the product obtained after bonding are improved. A low-temperature bonding technology is adopted to conduct low-temperature encapsulation of a radio frequency device, and while good mechanical strength and airtightness are achieved, the requirements for encapsulating the RF MEMS device which is sensitive to temperature are met.

Owner:SUZHOU XIMEI MICRO NANO SYST CO LTD

Processing method for carbon in high temperature gas cooling nuclear reactor and internal components in stack graphite, and special equipment for production line

ActiveCN102528915ADoes not affect flatnessCeramic shaping apparatusStone-like material working toolsProduction lineNuclear reactor core

The invention relates to a processing method for carbon in high temperature gas cooling nuclear reactor and internal components in stack graphite, meanwhile relates to special processing equipment for realizing the method, and belongs to the technical field of carbon block mechanical processing. The method comprises the following steps: sawing six surfaces of carbon block blank; taking the sum of carbon brick length and reserved machining allowance as an interval distance, and adopting a circumferential rotary-cut cutter, and carrying out water-cooling jacking rough machining through a set of runner holes formed on the carbon block after sawing; enabling carbon block after fixed-length jacking sawing and processing to be carbon block blank; drying and removing cooling water on the carbon block blank; and enabling dried carbon block blank to be a bottom carbon brick of a finished product through finish machining to surfaces and holes. Due to the adoption of the processing steps provided by the invention, long-term traditional processing steps are broken, the sawing step is advanced reasonably, and defects in carbon block are enabled to be discovered in time. Therefore, idle work is avoided, and advanced step is adopted for large hole trepanning, the cutting output is reduced greatly, the work efficiency is effectively improved, and wastes of precious carbon material is avoided.

Owner:JIANGSU CHENGUANG CNC MACHINE TOOL CO LTD +2

Processing technique for compressor shell

The invention relates to a processing method of a workpiece, in particular to a processing technique for a compressor shell. The processing technique for the compressor shell is characterized by comprising the following steps: 1, blanking, namely blanking after determining the new blanking size of the compressor shell in a novel technical process; 2 stretching, namely punching the blanked blank material on a blanking die to form a stretched blank piece needed by a stretched compressor shell, wherein it is required to make sure that the stretching length is at least 3 to 4 millimeters greater than the maximum depth of the part; and 3, trimming, namely trimming the stretched blank piece and obtaining the part. In conclusion, in the compressor shell produced by using the processing method and corresponding mold or equipment of the method, the material increasing the thickness of a stretched flange is transformed into the material required by the part and an overlapped edge; and thus, the material consumption in the production of the compressor shell is reduced by 0.046 to 0.07kg, the cost per product is reduced by 0.176 to 0.267 Yuan, and the production steps of the product are reduced.

Owner:QINGDAO HAILIDA STAMPING PARTS +1

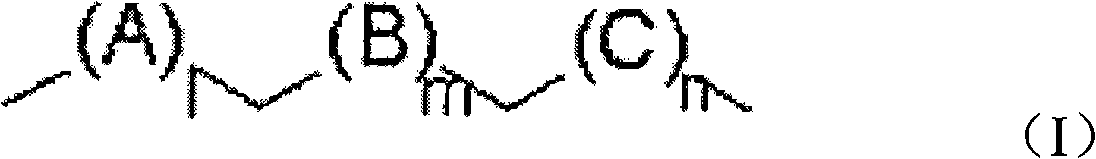

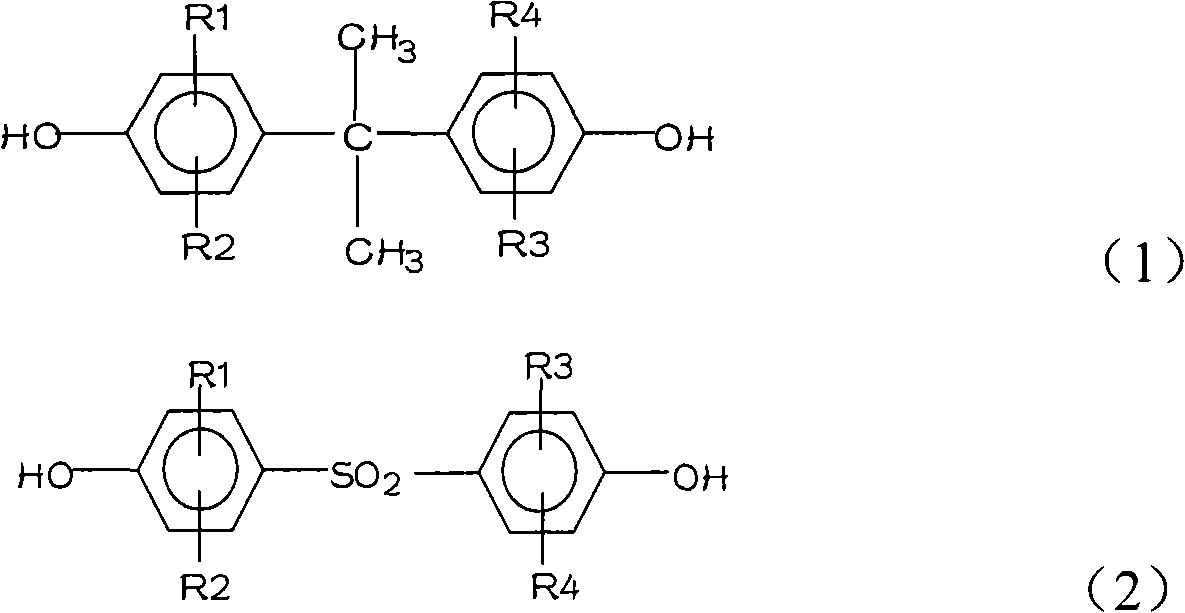

Film-forming resin and heat reactive resin compositions with the film-resin forming

InactiveCN101284891AHigh hardnessImprove heat resistanceNon-linear opticsOptical elementsTectorial membraneHeat resistance

The invention provides a film forming resin which comprises a unit formed by a monomer A and a unit formed by a monomer B, wherein, the monomer A is the methyl acrylate with an epoxide group, the monomer B is one or more than one of the (methyl) benzyl acrylate, the (methyl) acrylic acid phenethyl ester and the (methyl) acrylic acid phenyl ester, in the film forming resin, the mol ratio of the unit formed by the monomer A and the unit formed by the monomer B is between 1:1 and 8:1, the weight average molar mass of the film forming resin is between 5000 and 100000. The thermocuring resin compound greatly improves the hardness of a protective film for a colorful spectral filter and the heat-resistant polychromasia. In addition, the thermocuring resin compound has good storage stability; the protective film formed by the thermocuring resin compound has good heat resistance, leveling property, light-admitting quality, anti-ITO sputtering property, etching-proof characteristic, adhesive attraction and the uniformity of the film thickness.

Owner:BYD CO LTD

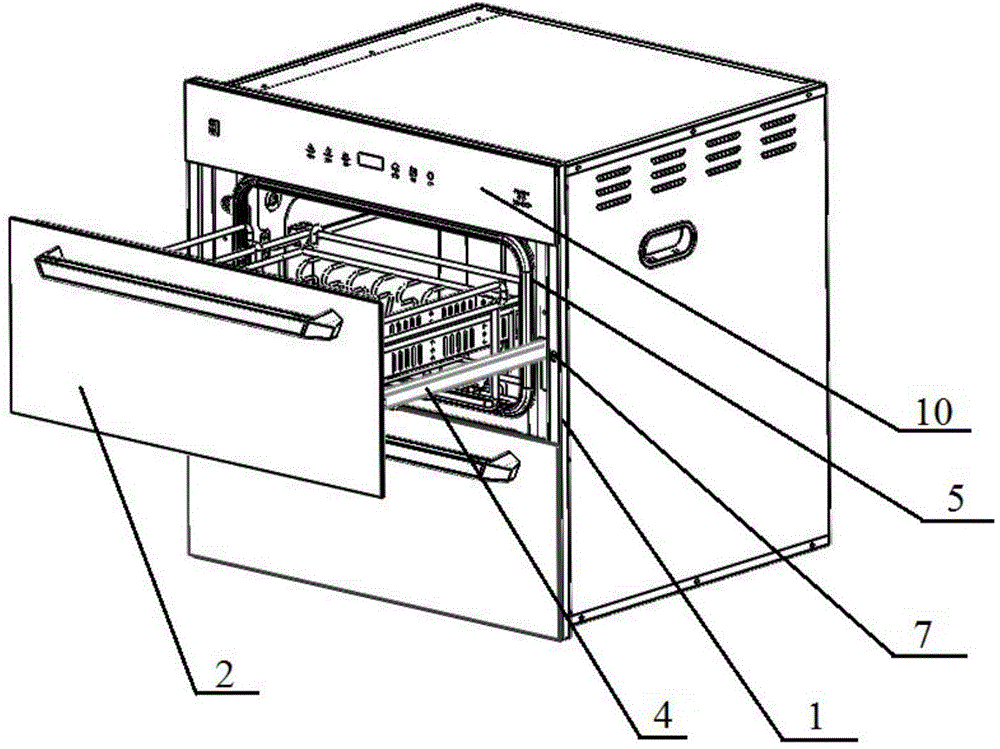

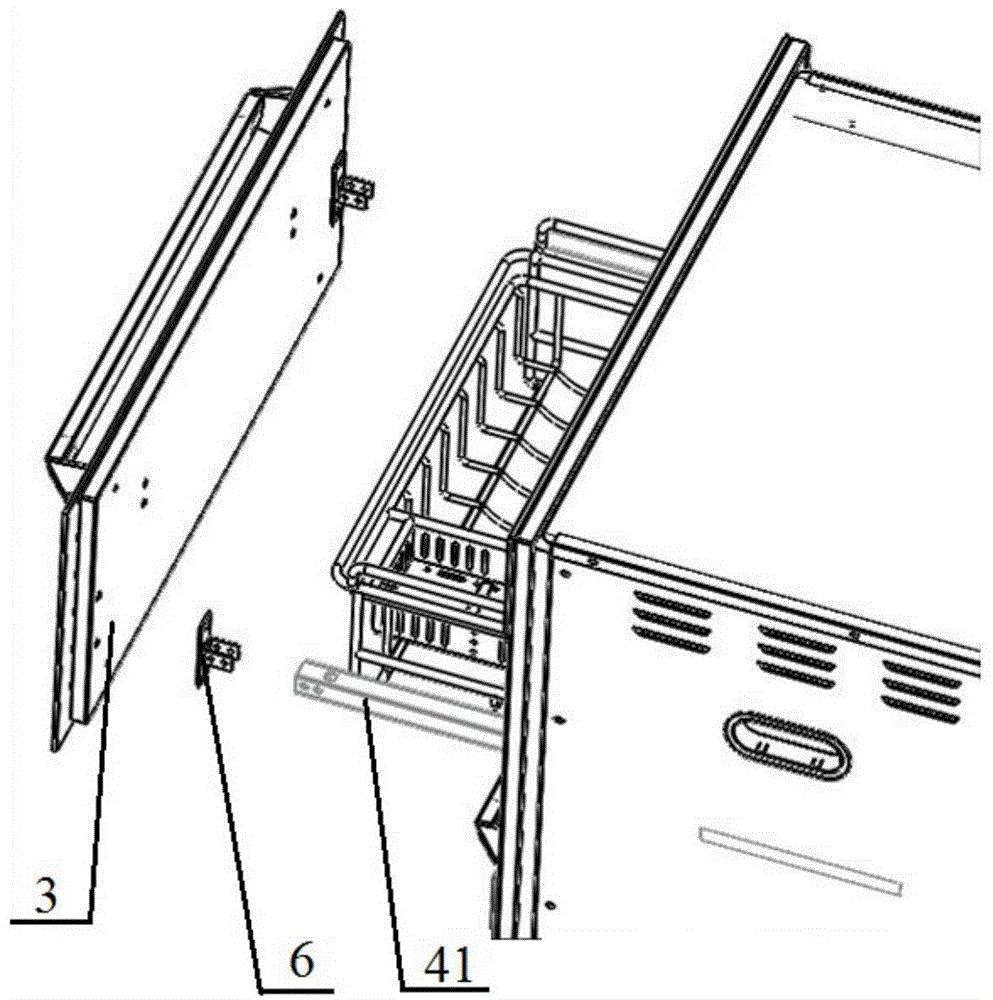

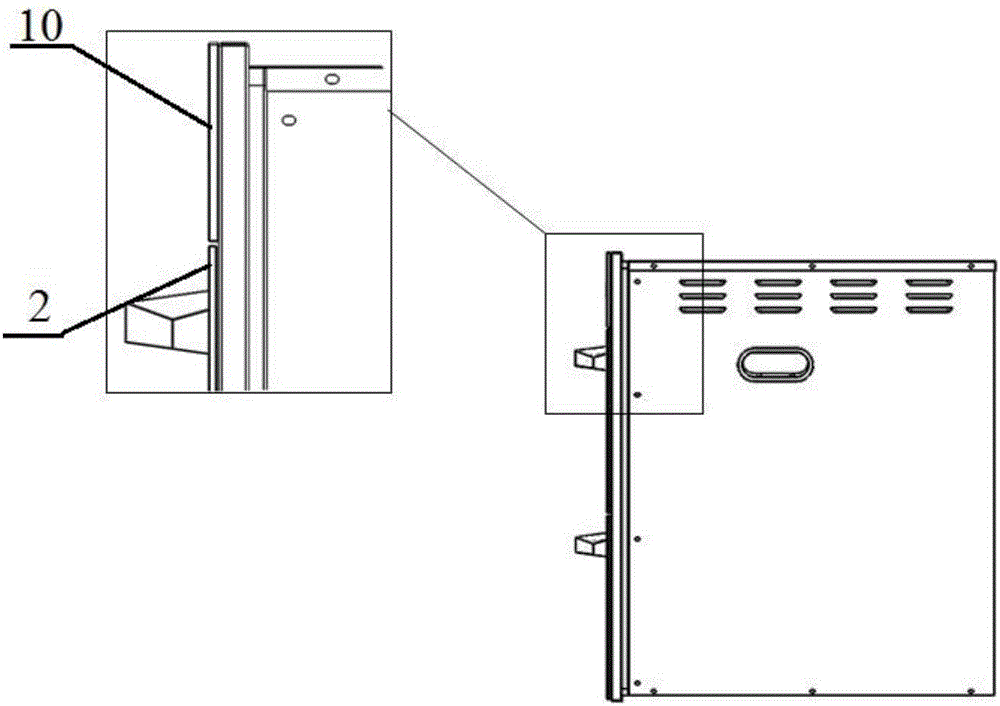

Sliding door system for embedded disinfection cabinet

InactiveCN106310298AImprove sealingDoes not affect flatnessEngine sealsLavatory sanitorySlow MovementCantilever

The invention discloses a sliding door system for an embedded disinfection cabinet. The sliding door system mainly consists of a nonmagnetic soft sealing strip and a self-attraction buffer slide rail mechanism together with a check member and an adjusting bracket of the sliding door; in a drawer closing process, the drawer is slightly pushed and then quickly moves toward the door body along the movement track of the slide rail; when the drawer moves to a reset point of a spring and under the action of a hydraulic cylinder connected with the spring, the quick movement of the drawer is changed into slow movement; after the contact with the sealing strip, the drawer continuously moves to compress the sealing strip under the tension of the spring, and stops moving after reaching the limiting position of the check member to finish the drawer closing action; in production, through the cooperation between the adjustable bracket at the joint between a slide bar and the drawer and the check member structure on the door frame, the adjustment of the appearance roughness is realized; and moreover, the sealing strip is a nonmagnetic soft sealing strip and a soft compressible cantilever is arranged at the end part, thus the airtightness can be improved without influencing the appearance roughness.

Owner:SAKURA BATH & KITCHEN PRODS CHINA

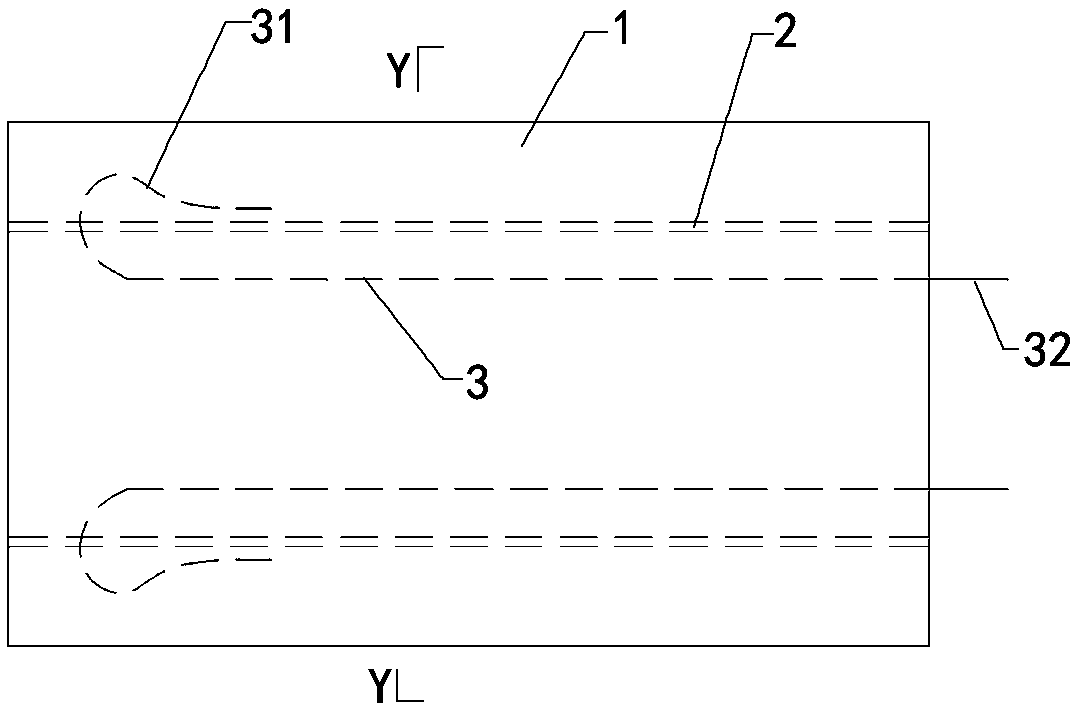

Macroplate stone paving method

ActiveCN108385932AImprove integrityImprove stabilityFlooringClimate change adaptationRebarCement mortar

The invention relates to the technical field of floor decoration of macroplate stones, and discloses a macroplate stone paving method. The macroplate stone paving method specifically comprises the following steps: arranging a reinforcing rebar on the adhesion surface of the plate stone; processing a base layer; snapping a line; numbering the plate stone; painting a neat cement on a concrete cushion before paving a mortar layer; sequentially paving according to the number, knocking with a rubber hammer, compacting the mortar to the paving height, lifting up the plate stone, detecting and filling the mortar layer, levelling; arranging an exhaust rope between the plate stone and the mortar layer, paving the plate stone, drawing out the exhaust rope before the initial setting of the cement mortar to exhaust the bubble below the plate stone and the heat in the cement mortar; spraying water to cure after paving the plate stone for 24 hours; using a crack sealer to grout a crack between slabjoints of the stone after the curing period is expired; and maintaining a finished product. The macroplate stone paving method is convenient to construct and operate, the conditions of hollowing and fracturing are effectively avoided in the process of paving the stone, and the macroplate stone paving method is suitable for the large-sized plate stone.

Owner:北京市建筑工程装饰集团有限公司

High-extinction low-VOC (volatile organic compound) nano matte assistant and preparation method thereof

InactiveCN109836879AHigh transparencyStrong mattingPaints for electrolytic applicationsVolatile organic compoundIon

The invention discloses a high-extinction low-VOC (volatile organic compound) nano matte assistant and a preparation method thereof, and the assistant is used for solving the problems that the existing matte paint film is poor in film transparency, and the coating flatness of an original paint liquid can be influenced, so that the paint film surface is rough, and poor in scratch resistance and mark brightening the like; the assistant comprises the following raw materials in parts by mass: 1-20 parts of a nano-modifier, 50-100 parts of nano-powder, 1-10 parts of a pH regulator and 50-100 partsof deionized water. The assistant is added into cathode electrophoretic resin to prepare matte paint, so that the film transparency of the matte paint can be improved, the extinction property is strong, the coating flatness of the original paint liquid cannot be influenced at the same time, and the hardness, fullness and the like of the paint film are improved.

Owner:江西省龙海化工有限公司

Shadow mask assembly and reuse method of shadow mask assembly

InactiveCN106884138ADoes not affect flatnessReduce the number of polishingVacuum evaporation coatingSputtering coatingEngineeringYield rate

The invention discloses a shadow mask assembly comprising a shadow mask membrane and frame bodies. Each frame body comprises an outer wall, an inner wall and a binding face connected with the outer wall and the inner wall, wherein the outer wall and the inner wall are arranged oppositely. The binding faces are bound with the shadow mask membrane. Each binding face comprises a welding area and a tiling area which are not coplanar. The welding areas are located between the tiling areas and the outer walls. The frame bodies fix the edge of the shadow mask membrane through welding spots arranged in the welding areas. The tiling areas are located between the welding areas and the inner walls and used for supporting the shadow mask membrane and keeping the shadow mask membrane being a plane. When the shadow mask membrane is replaced to be a new shadow mask membrane, the remaining welding spots of an original shadow mask membrane in the welding areas do not affect flatness of the shadow mask membrane, and therefore the yield rate of an AMOLED glass base plate used for vapor deposition is increased. After the shadow mask membrane is replaced for multiple times, one-time polishing and burnishing are conducted on all the welding spots in the welding areas, so that the burnishing times of the welding spots are decreased, and flatness of the shadow mask membrane is improved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

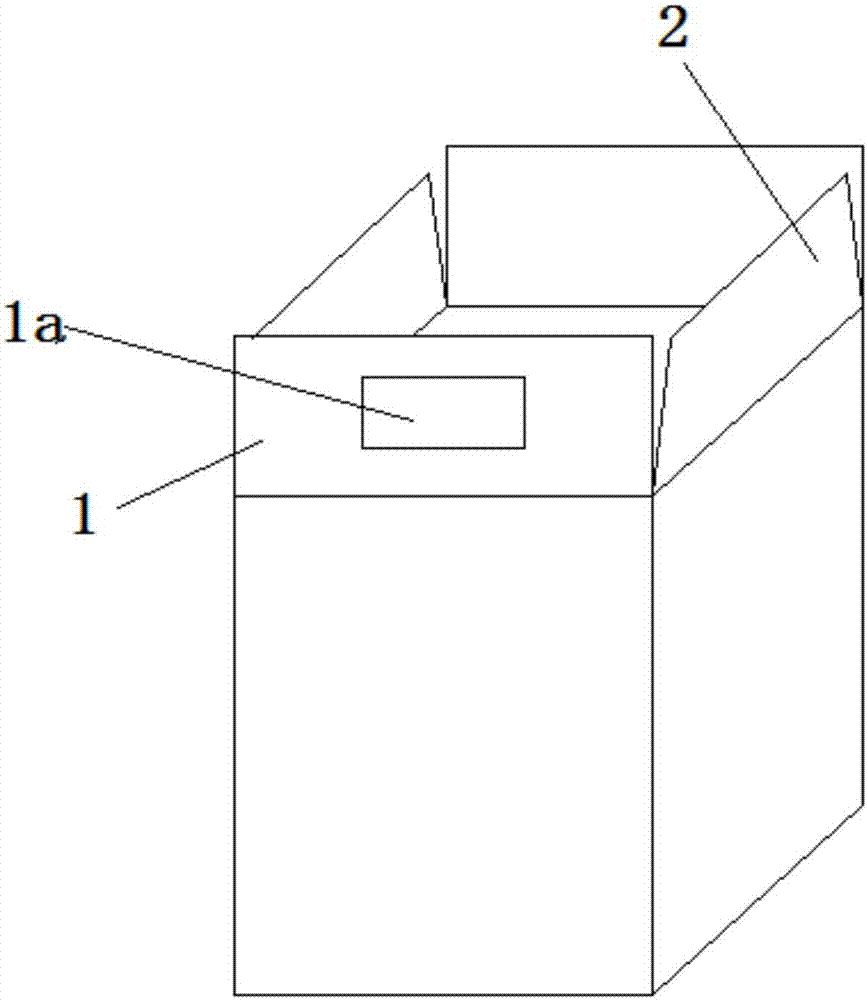

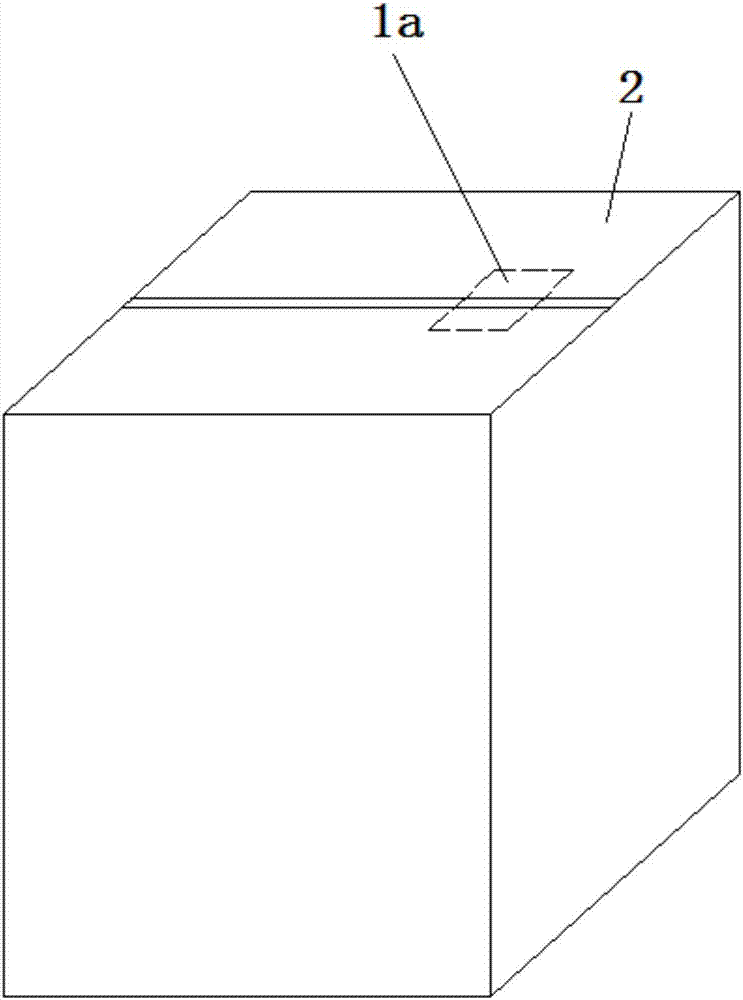

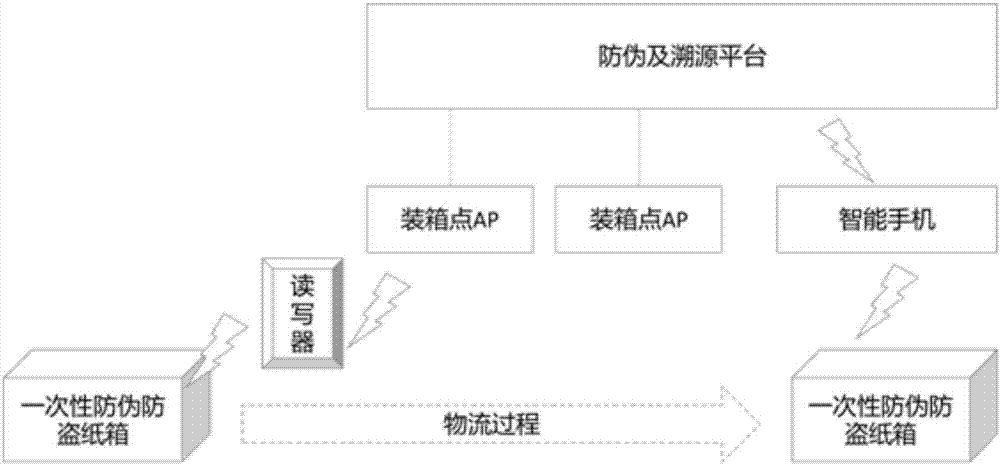

Disposable antitheft intelligent carton

ActiveCN107336912APrevent theftAvoid disputes such as inconsistenciesCo-operative working arrangementsPackagingCartonEngineering

The invention relates to a carton, in particular to a disposable antitheft intelligent carton, and belongs to the technical field of cartons. The disposable antitheft intelligent carton is characterized in that a pair of inner side cover plates (1) and a pair of outer side cover plates (2) are included; a non-penetrable groove hole is formed in the middle of the upper surface of one inner side cover plate (1), and a buffer material is fixedly arranged in the groove hole; the inner side face of an RFID label (1a) with a dual-face adhering function adheres to the buffer material, and after adhering, the RFID label (1a) and the surface of the corresponding inner side cover plate (1) are flushed or basically flushed; after covering of the pair of outer side cover plates (2), the RFID label (1a) is covered, and the outer side cover plates (2) each adhere to one part of the upper surface of the RFID label (1a); and readable cargo information is stored in the RFID label (1a), and when the carton is opened, the RFID label (1a) is immediately destroyed.

Owner:上海煜霖包装技术有限公司

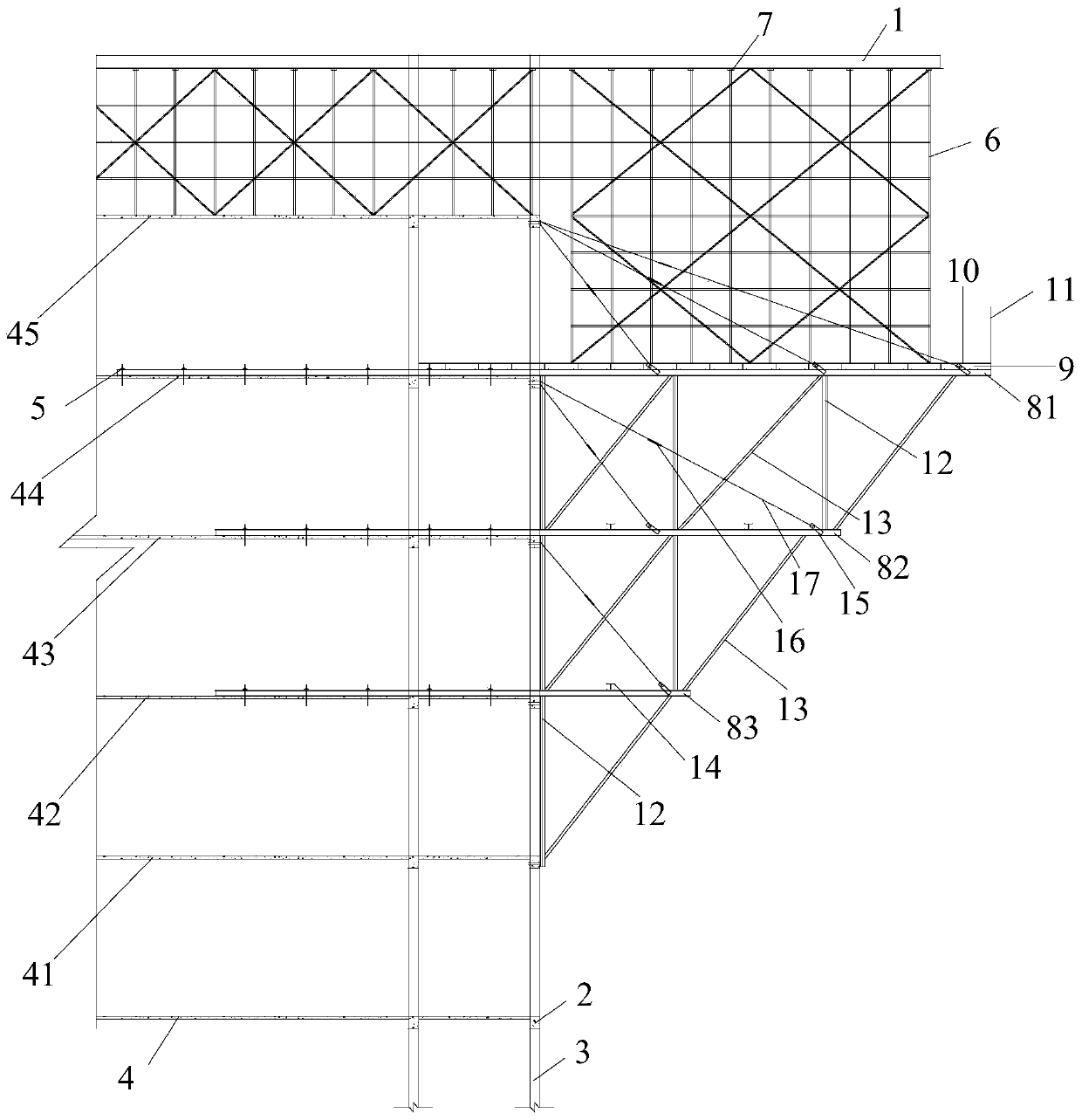

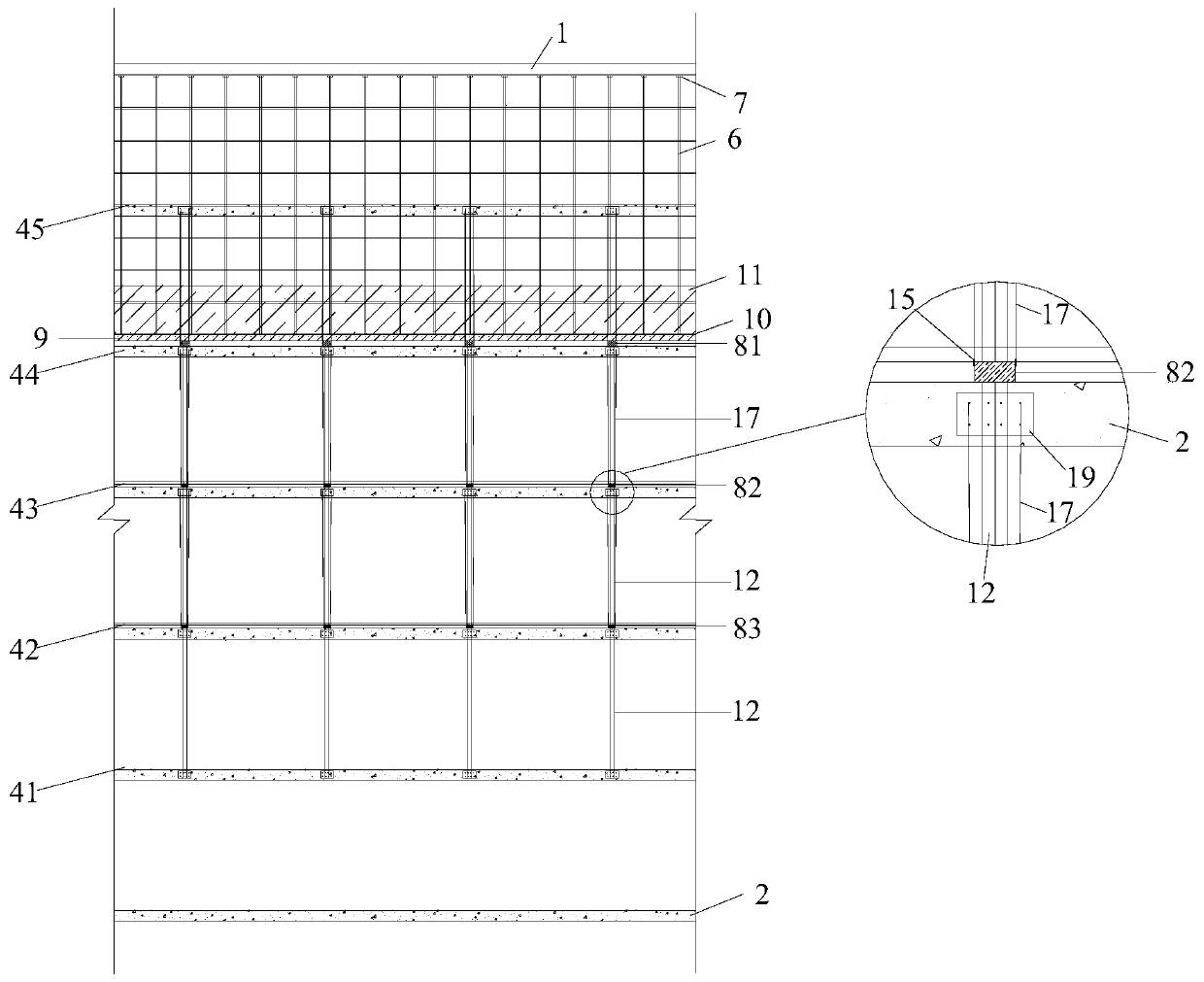

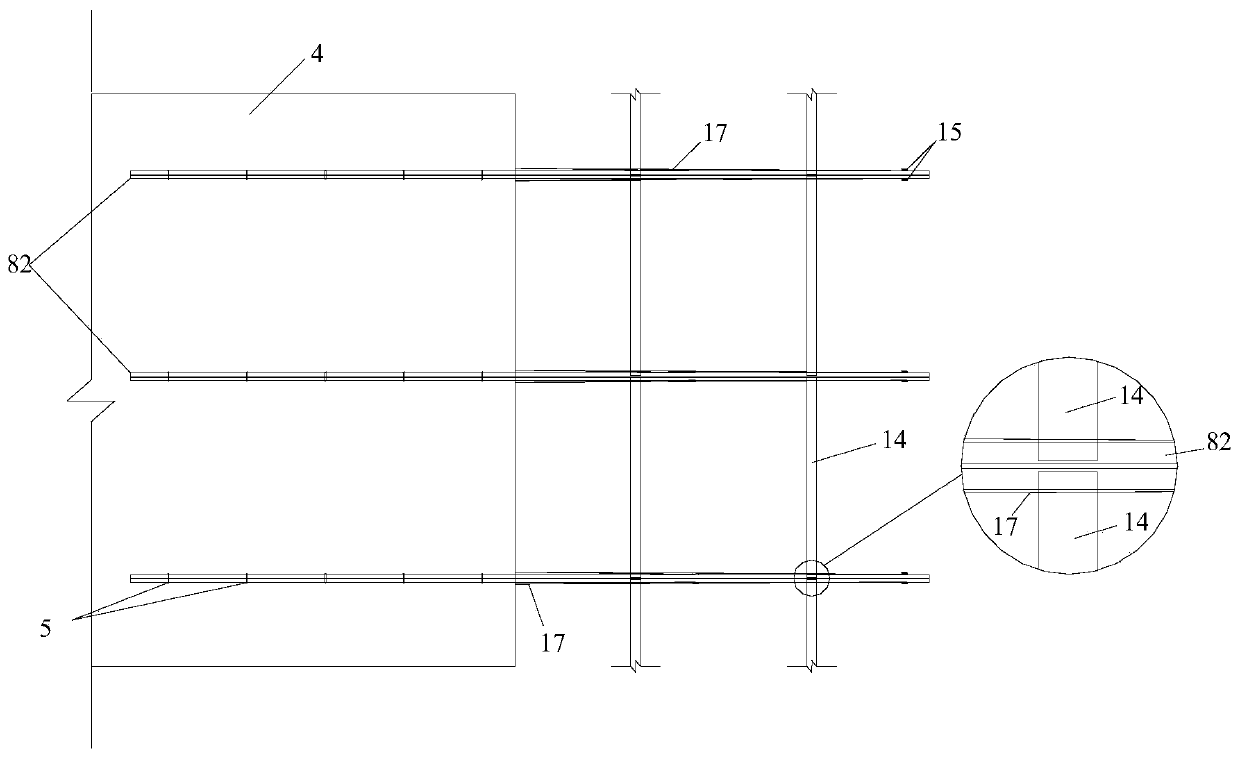

Construction method of multi-storey section steel-stay cable three-dimensional support ultra-large span cast-in-situ cantilever beam

The invention relates to a construction method of a multi-storey section steel-stay cable three-dimensional support ultra-large span cast-in-situ cantilever beam. The construction method is characterized by comprising constructing typical floors, mounting overhung section steel, constructing a stay cable, mounting a support rod piece, setting up a construction platform, constructing a scaffold anda large-span cantilever beam and dismantling the construction platform. The stay cable, overhung type steel beams with different lengths, the vertical support rod piece, a slant rod and a longitudinal connecting rod are combined and connected to form a triangular truss support structure; the construction load is distributed in a 4-6 storey structure; the support structure is reliable in form andthe bearing force meets the requirement; a U-shaped anchor ring, a hoisting ring and other fixing parts involved in the support structure are mounted through a beam body and a floor plate pre-embeddedPVC pipe; the support structure is convenient to mount and dismantle; after construction of the cantilever beam, all materials can be recycled, and higher economical and social benefits are realized.

Owner:杭州悦为科技有限公司

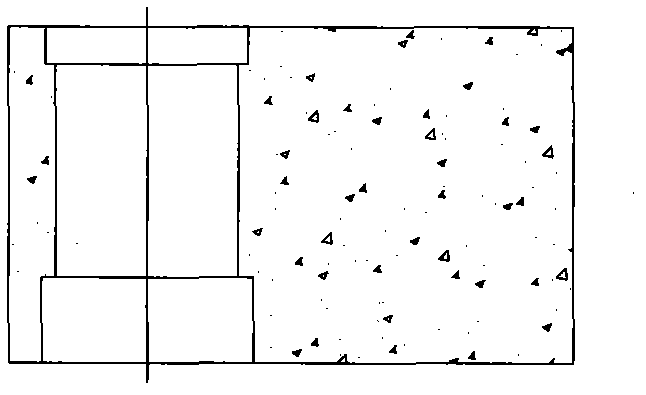

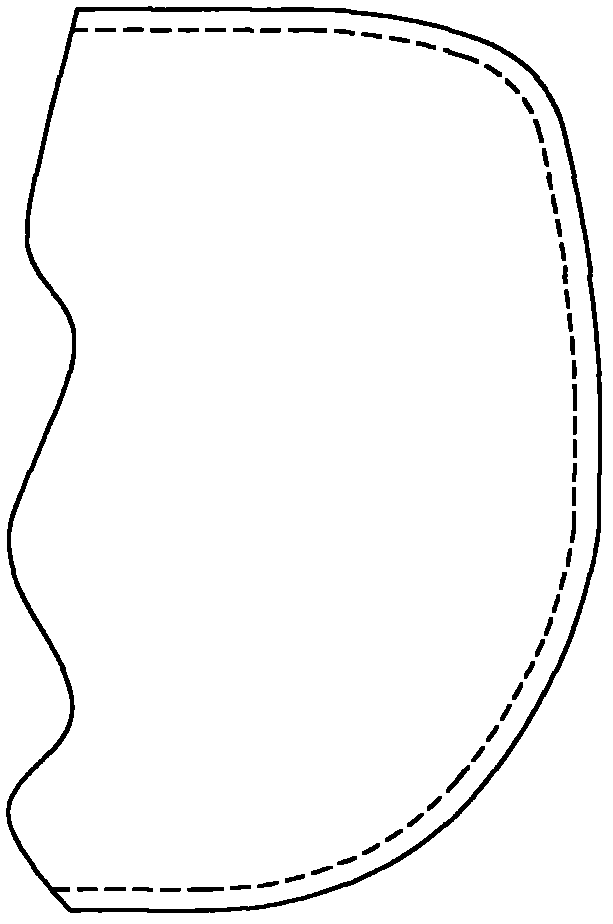

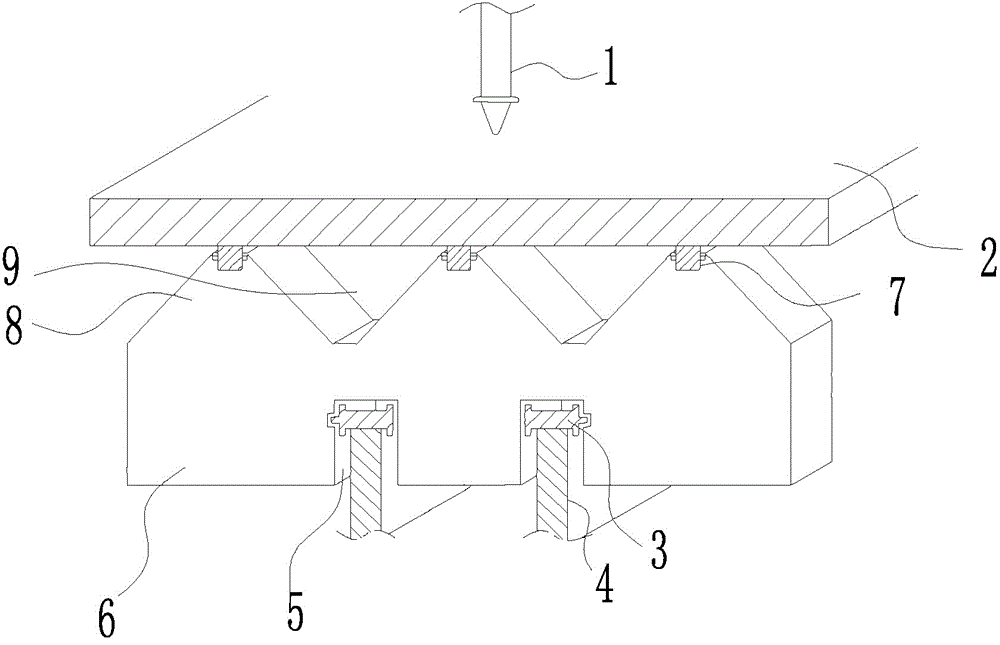

Door panel drilling tooling

PendingCN104476261AFlexible adjustment of support positionDoes not affect flatnessPositioning apparatusMetal-working holdersEngineeringElectrical and Electronics engineering

The invention discloses a door panel processing apparatus, and particularly relates to a door panel drilling tooling. The door panel drilling tooling comprises a drilling tool, a door panel, a supporting frame arranged below the door panel and supporting shafts arranged in the supporting frame, wherein the length direction of each supporting shaft is consistent, door panel lower pressing blocks are arranged on the supporting shafts, the lower parts of the door panel lower pressing blocks are slideably connected with the supporting shafts, a group of open slots are formed in the upper parts of the door panel lower pressing blocks, and the arrangement direction of the group of open slots is perpendicular to the length direction of the supporting shafts; slot walls are processed between adjacent open slots, the width of the upper end surface of each slot wall is one tenth of the width of the corresponding open slot, the depth of the open slots is consistent with the width of the open slots, the width direction of the open slots is consistent with the arrangement direction of the open slots, the length direction of the open slots is consistent with the length direction of the supporting shafts, and the door panel is arranged on the door panel lower pressing blocks. The invention overcomes the defect that the entire panel is bent downwards during drilling in the prior art and provides the door panel drilling tooling which can control the deformation area.

Owner:CHONGQING OFAN DOOR IND

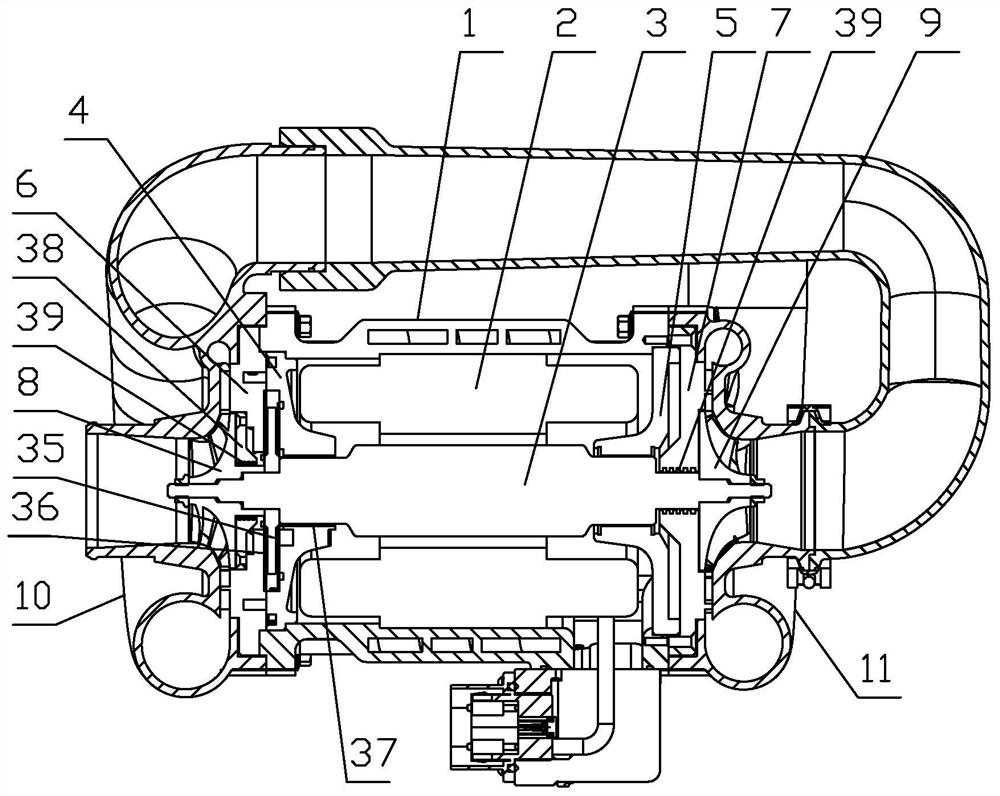

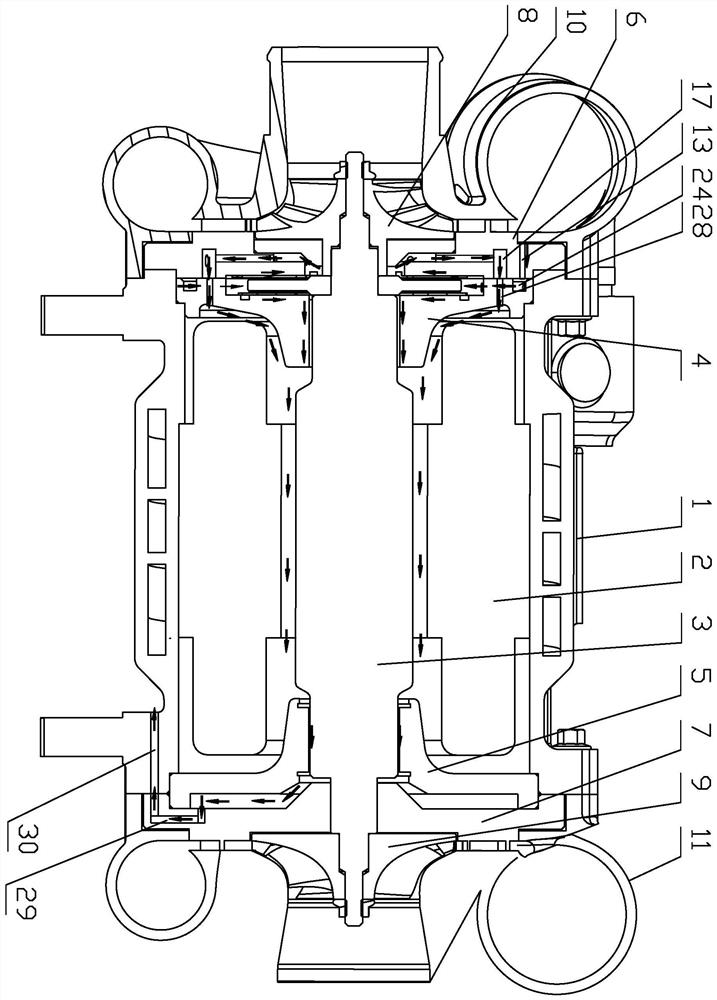

A high-speed centrifugal compressor

ActiveCN112879318BImprove compression efficiencyImprove sealingPump componentsRadial flow pumpsAir bearingCooling effect

Owner:YANTAI DONGDE IND CO LTD

Shower plate, method for manufacturing the shower plate, plasma processing apparatus using the shower plate, plasma processing method and electronic device manufacturing method

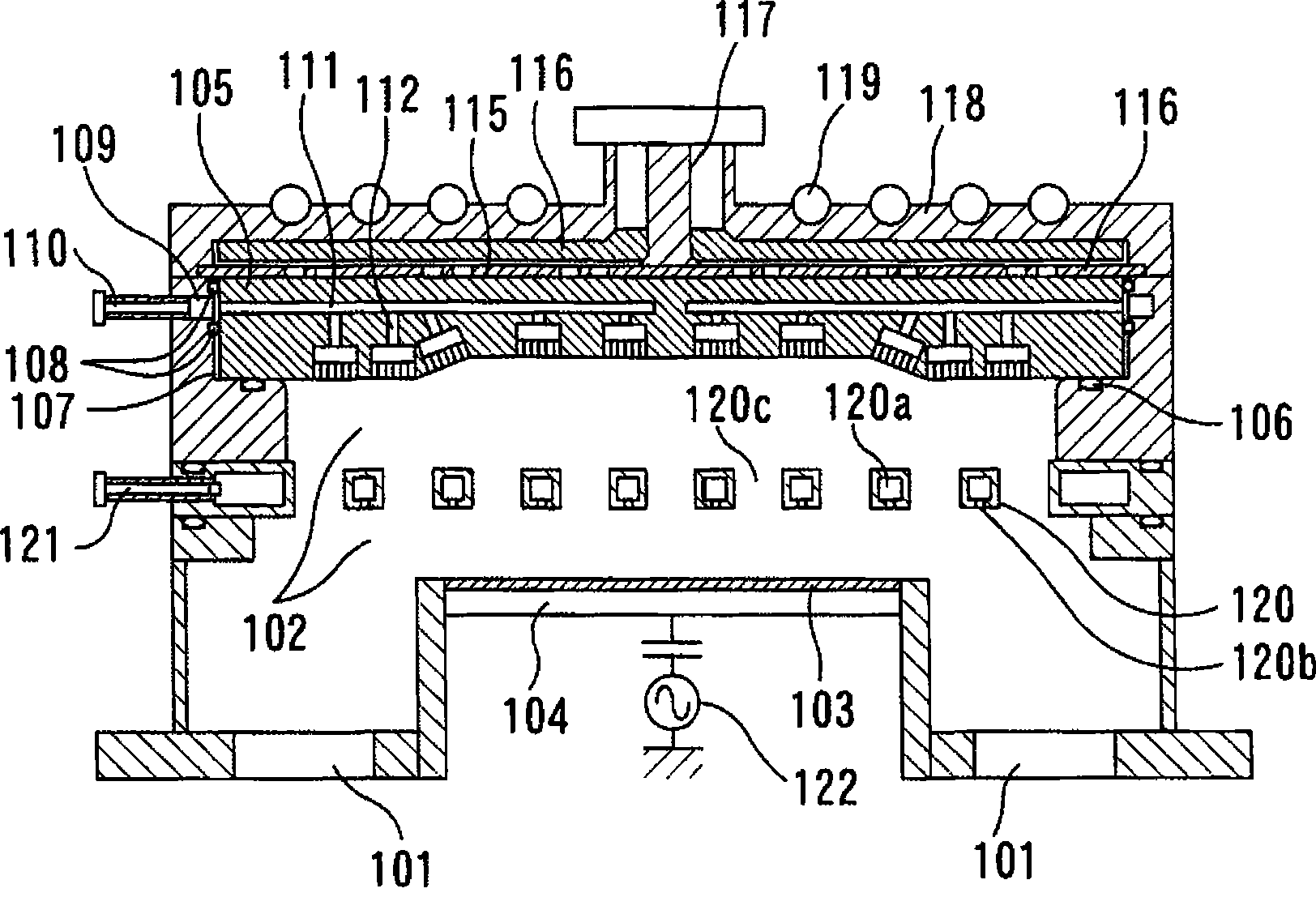

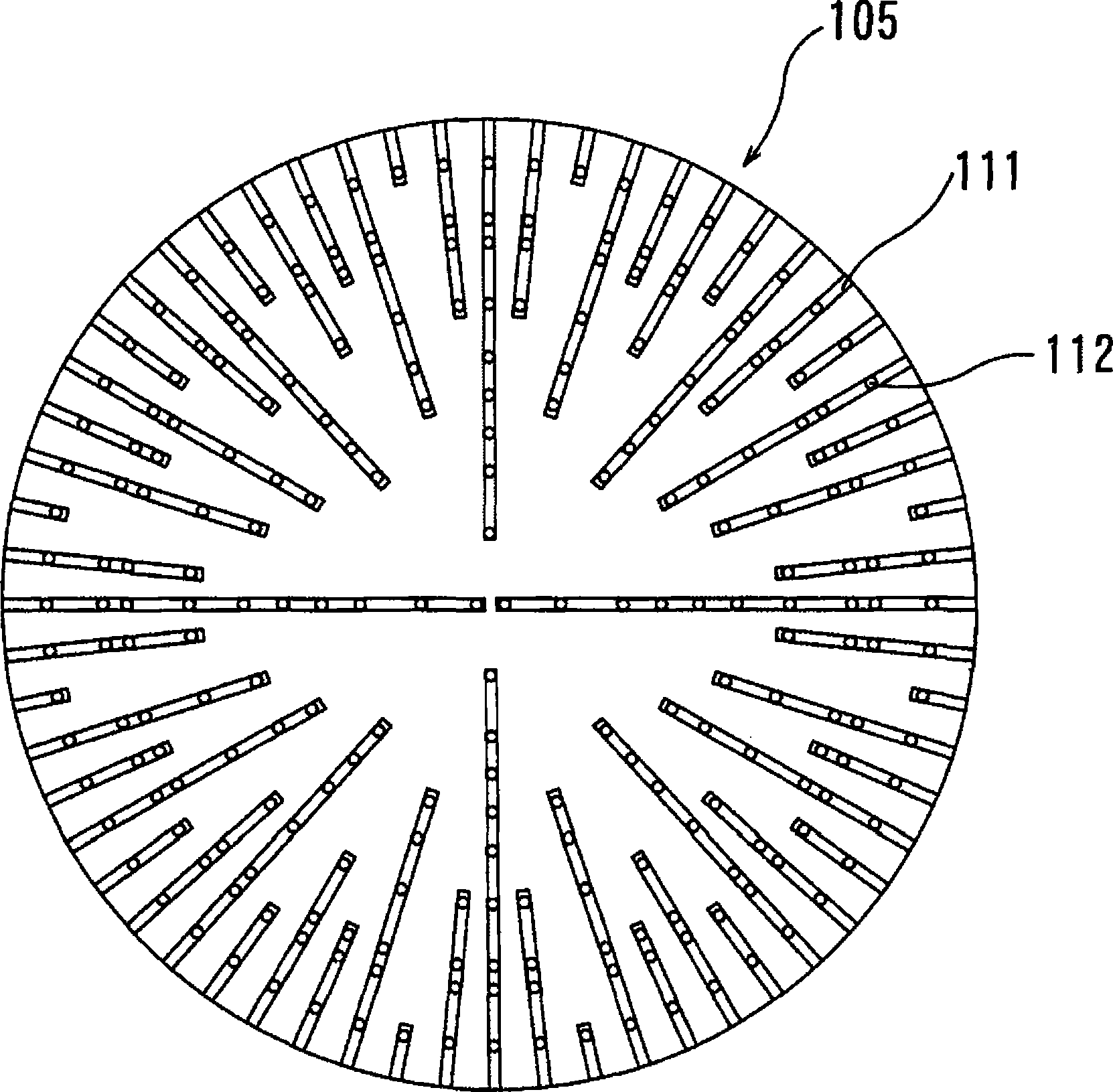

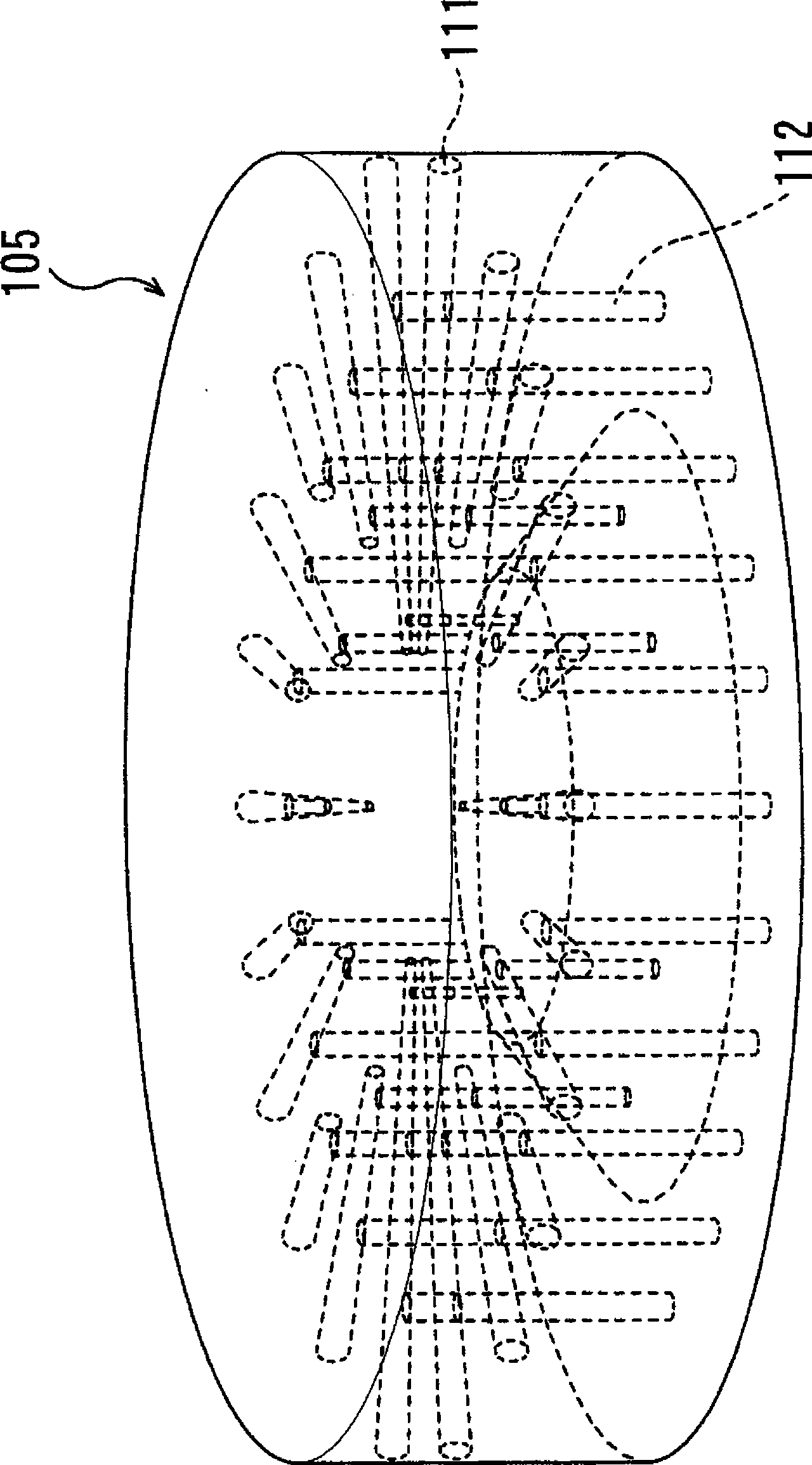

InactiveCN101467498APrevent backflowProduce uniformSemiconductor/solid-state device manufacturingChemical vapor deposition coatingPore diameterEngineering

Provided is a shower plate which can completely prevent generation of plasma reverse flow or ignition of plasma excitation gas at a vertical hole section for more efficient plasma excitation. A shower plate (105) is arranged in a processing chamber (102) in a plasma processing apparatus, and discharges plasma excitation gas for generating plasma in the processing chamber (102). A porous gas communicating body (114) having pores communicating in a gas communicating direction is mounted on a vertical hole (112) to be a discharge path for the plasma excitation gas. The pore diameter of an overflow path in a gas communicating path formed by the communicating pores of the porous gas communicating body (114) is 10[mu]m or less.

Owner:TOKYO ELECTRON LTD +1

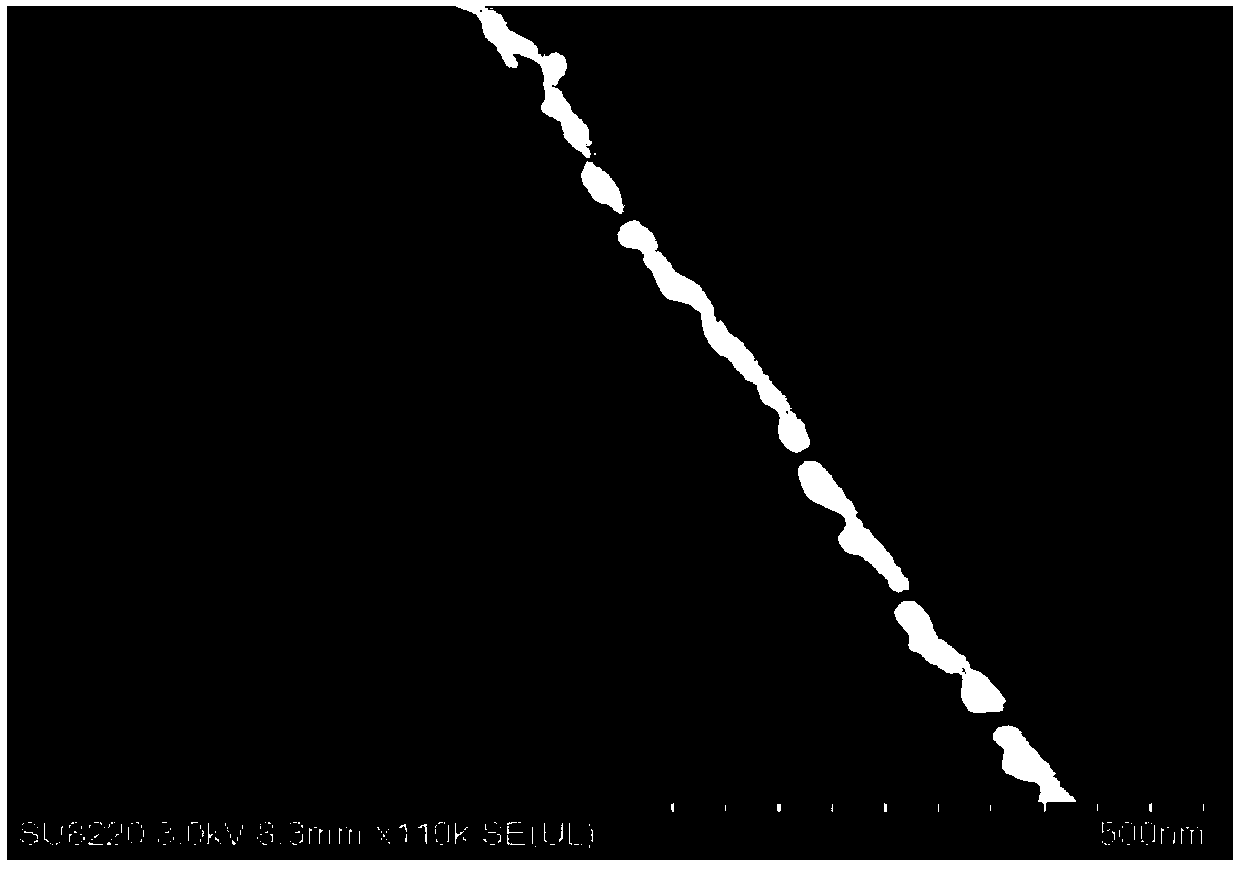

Hole metallization method based on laser activation technology

ActiveCN104661449ADoes not affect flatnessGood adhesionPrinted element electric connection formationPrinted circuit boardAtomic physics

The invention discloses a hole metallization method based on a laser activation technology. The method comprises steps as follows: holes are drilled in a printed circuit board base material with lasers, and special laser radiation is adjusted, so that drilled hole walls form nanoscale holes; catalytic particles permeate the holes to adsorb the hole walls to form an activation catalyst layer; finally, metal is deposited on hole wall surfaces by the aid of the catalyst layer, and electroplating-free metallization of micro hole walls is finished. The method has the advantages that drilling and hole wall roughening procedures are combined into one step, the process cost is reduced, and a coating is excellent in bonding performance and environment-friendly.

Owner:ZHUHAI YUANSHENG ELECTRONICS SCI & TECH

Cargo retaining device

InactiveCN105947647ADoes not affect flatnessTwo-way stop implementationConveyor partsEngineeringMechanical engineering

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

Wind power bus jointing element

InactiveCN103531922AIncrease clamping forceImprove locking effectSoldered/welded conductive connectionsClamped/spring connectionsElectricityElectrical conductor

The invention relates to a wind power bus jointing element which comprises two sections of tubular conductors to be connected, a joint and a flexible coupling part. A connection plane is formed at the bottom of the wind power bus jointing element; the connection plane is welded with the joint into one whole body; the flexible coupling part is fixedly connected with the joint through a bolt, wherein an anti-loose gasket is arranged between the bolt and the joint; the whole anti-loose gasket is formed by a pair of spacers meshed through sawteeth on meshing surfaces. The wind power bus jointing element is locked more firmly, can effectively stop the bolt from being loosened, is safer and greatly improves working efficiency.

Owner:JIANGSU SHILIN ELECTRIC EQUIP

Mould capable of directly riveting studs on products

The invention relates to the technical field of moulds, in particular to a mould capable of directly riveting studs on products. The mould comprises an upper mould and a lower mould which cooperate with each other; the upper mould comprises an upper mould base, an upper base plate and an upper clamping plate which are connected in sequence; the lower mould comprises a lower mould base, a lower base plate and a lower mould plate which are connected in sequence; studs are arranged on the lower mould plate; rivet inner jacking pieces propped against the studs are arranged on the lower base plate in a penetrating manner; a first positioning pillar is fixed at one end of the lower base plate; a second positioning pillar is fixed at the other end of the lower base plate; the first positioning pillar and the second positioning pillar extend to the lower mould plate; mould cavities are formed in the lower mould plate; the studs extend to the mould cavities; and rivet punches used for pressing the studs are fixed on the upper clamping plate. According to the mould capable of directly riveting studs on the products, the studs are pressed into the products in the mould cavities through the rivet punches, so that studs can be conveniently riveted onto the formed products and the mould has the advantages of preventing the products from deformation, not influencing the flatness of the products and being high in production efficiency.

Owner:DONGGUAN HAOSHUN PRECISION TECH CO LTD

Method for etching super-conduction quantum chip containing niobium film

ActiveCN108231992AEfficient removalSolve the contradiction of being smooth and flat, without dot residue on the surfaceSuperconductor device manufacture/treatmentEtchingNiobium

The invention discloses a method for etching a super-conduction quantum chip containing a niobium film, belongs to the field of super-conduction quantum chips, and aims to solve the problems of over-etching due to high etching speed, severe damage of a substrate, rough edge of a film even if the etching speed is low, and difficulty in removing dotted residues in the existing quantum chip niobium film etching process are solved. The method comprises the following steps: (1) cleaning the substrate to obtain a clean substrate; (2) plating the substrate with the niobium film to obtain a substrateplated with the niobium film; (3) exposing and developing the niobium film on the substrate plated with the niobium film to obtain a developed substrate; (4) etching the substrate; (5) performing post-treatment on the etched substrate to obtain a post-treated substrate; and removing glue from the post-treated substrate. By adopting the method, the niobium film can be rapidly etched, simultaneously, the dotted residues can be removed effectively, over-etching is avoided, and the effects of clean etching surface and flat graphic edge are achieved.

Owner:ORIGIN QUANTUM COMPUTING TECH (HEFEI) CO LTD

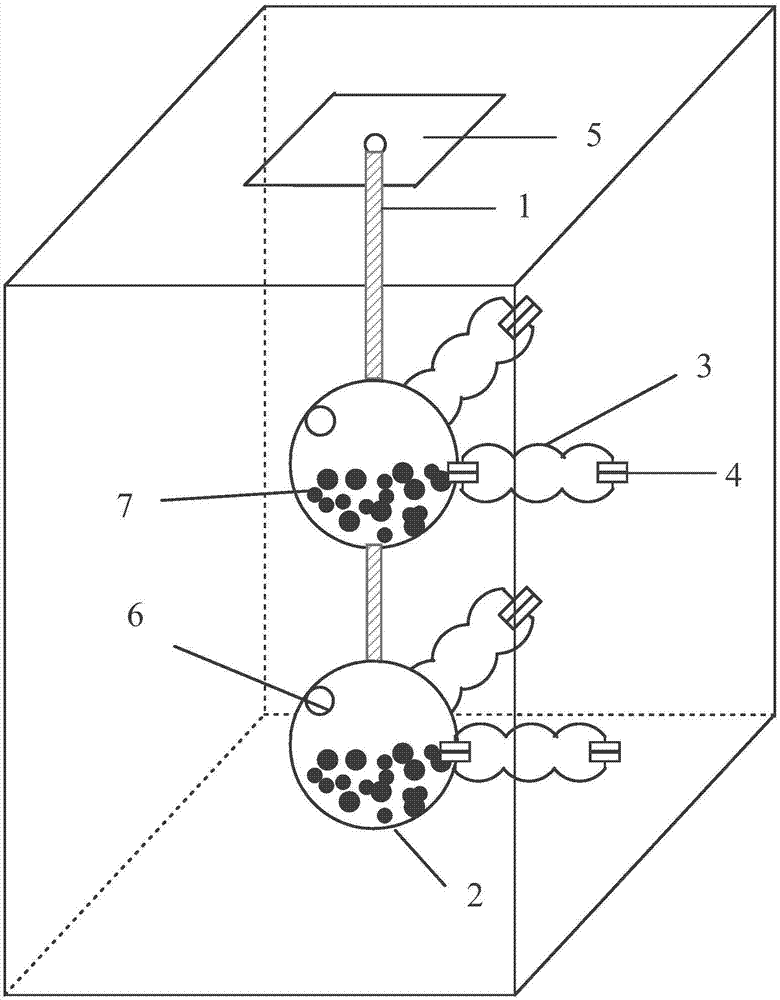

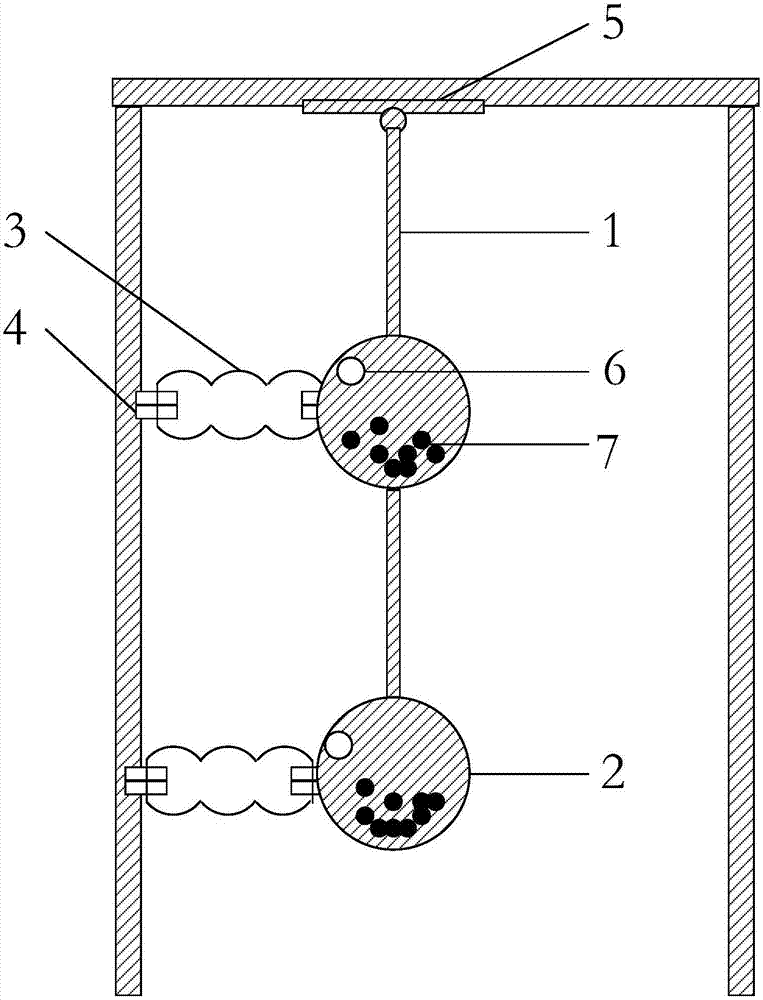

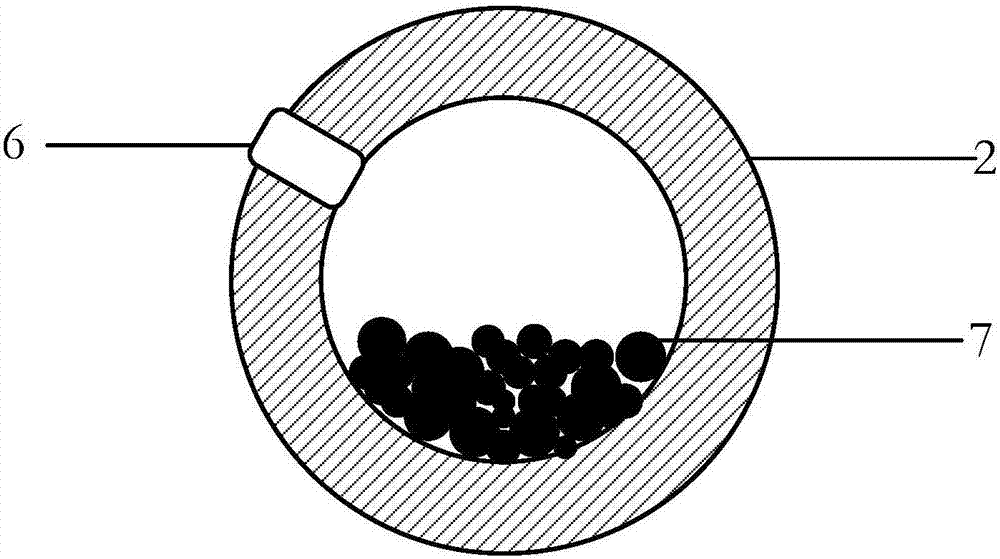

Mass tuning type vibration reduction multi-pendulum structure with air springs and damping particles

ActiveCN106894535AAchieving tuned damping controlReduced structural dynamic responseProtective buildings/sheltersShock proofingAir springEngineering

A mass tuning type vibration reduction multi-pendulum structure with air springs and damping particles mainly comprises a rigid hanging rod, tuning mass balls, the air springs, anchoring bolts, a top hinged seat, reserved filling holes and the damping particles. The device is connected with a structural floor. By using the characteristic that the period, mass, pendulum length and rigidity of the multi-pendulum structure are all related, the mass of the tuning mass balls, the length of each section of the hanging rod, rigidity of the air springs and the overall damping of the damping particles are reasonably set, so that the multiple natural vibration periods of the mass tuning type vibration reduction multi-pendulum structure is equal to or close to the corresponding multi-order period of the structure, and accordingly tuning vibration reduction control over the structural multi-vibration mode is achieved and dynamic response of a structural body under earthquakes and wind loads is reduced.

Owner:北京宝和源装备科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com