Processing method for carbon in high temperature gas cooling nuclear reactor and internal components in stack graphite, and special equipment for production line

A nuclear reactor, high-temperature air-cooled technology, which is applied to special equipment for processing, processing of carbon and graphite reactor internal components of high-temperature gas-cooled nuclear reactors, and carbon brick processing fields, can solve the problems of low material utilization rate, low processing efficiency, easy bumping and damage, etc. Achieve the effect of avoiding carbon material waste, improving work efficiency, and avoiding clogging of accumulated chips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

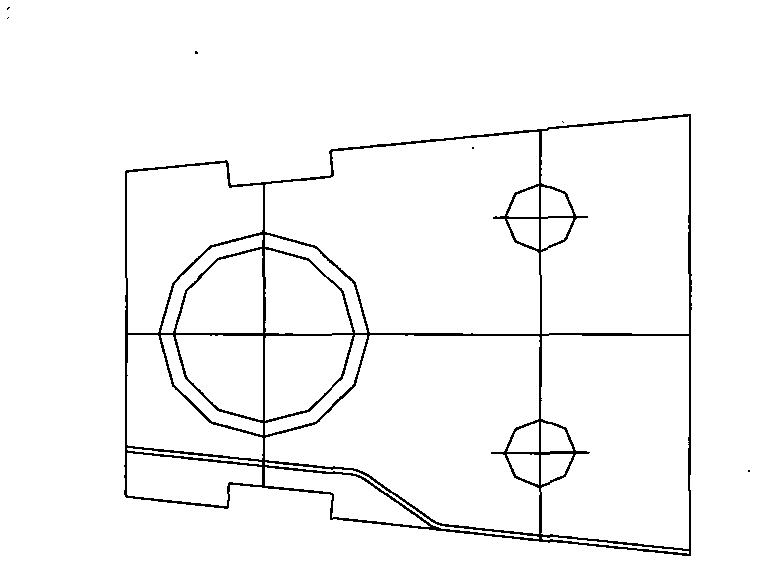

[0023] The carbon brick at the bottom of the internal member of this embodiment is as figure 1 and figure 2 As shown, the cross-section is isosceles trapezoidal, and there are cold helium flow channel holes (large holes) for cooling, heat insulation, absorption and blocking of nuclear radiation, temperature measurement channels, absorption ball holes, ball unloading pipes and thermocouples. slot etc. The processing method of the bottom carbon layer brick comprises the following steps:

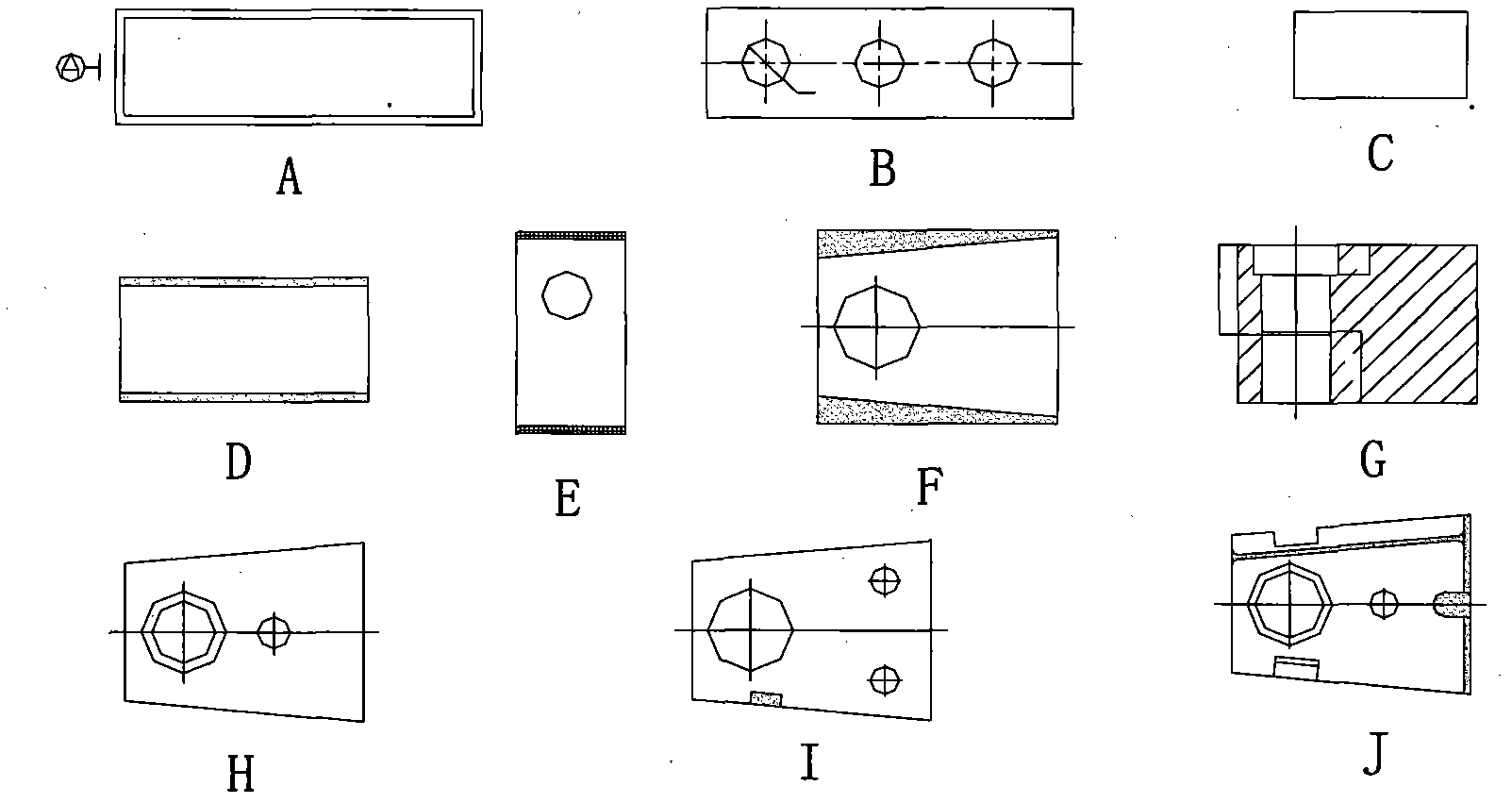

[0024] The first step is to saw six sides of the carbon block blank, leaving a margin of 10mm on each side in the width and height directions. Terminate processing ( image 3 -A).

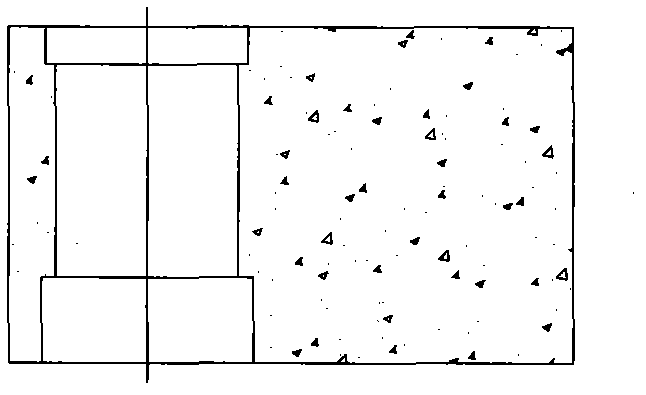

[0025] The second step is to take the sum of the length of the carbon brick and the reserved processing allowance as the interval distance, use a circular rotary cutting tool, water-cooled nesting rough machining and sawing a group of flow channel holes on the carbon block with a diameter greater than 100; this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com