Method for etching super-conduction quantum chip containing niobium film

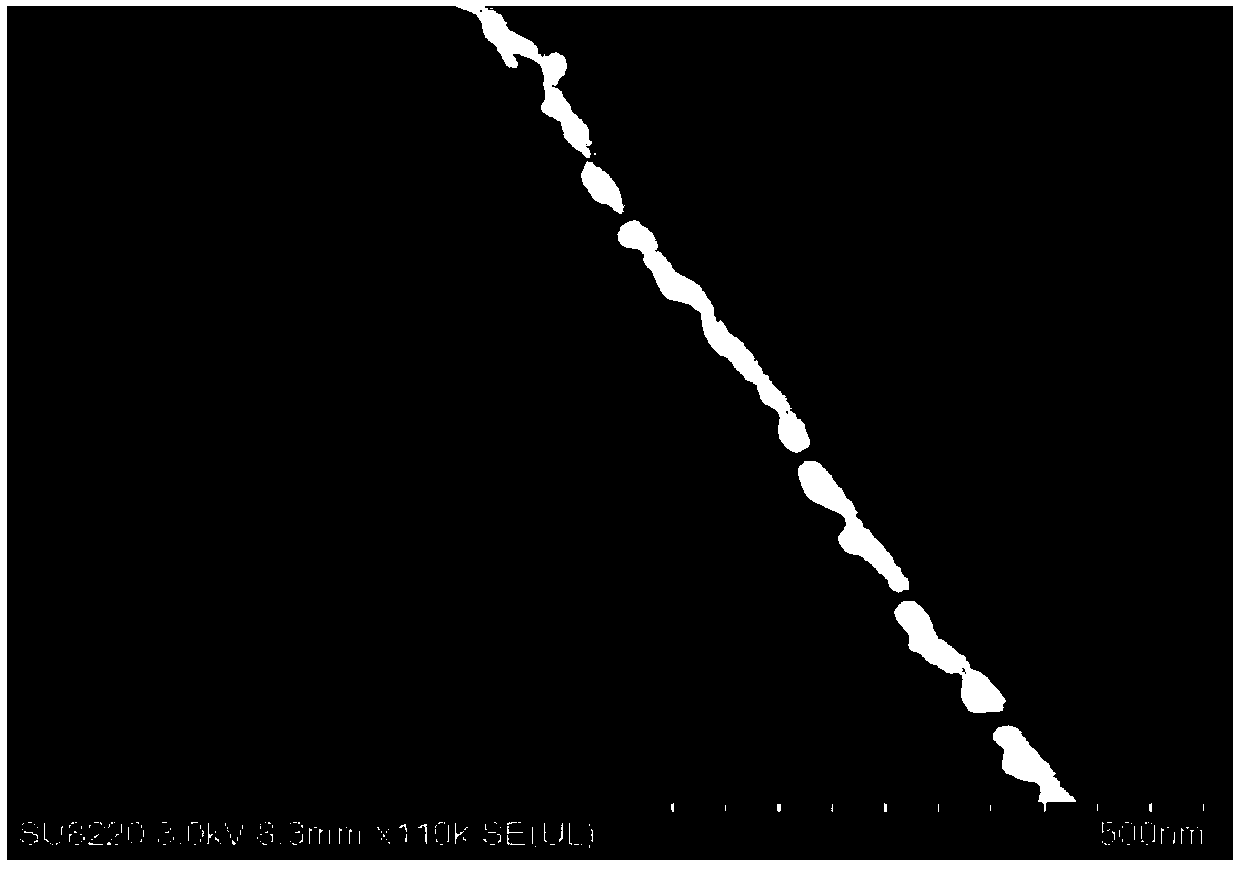

A superconducting quantum and chip technology, which is applied in the manufacture/processing of superconductor devices, etc., can solve the problems of rough film edges, dotted residues, and difficulty in removal, so as to reduce etching time, smooth film edges, and save etching time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Using a high-density plasma etching machine for post-processing, the obtained superconducting quantum chip containing niobium film, the etching method is as follows:

[0053] (1) Substrate cleaning: select high-purity silicon wafers as the substrate of the chip. The substrate is the substrate, and the substrate is cleaned with 1-methyl-2-pyrrolidone solution at room temperature for 3 minutes, then transferred to isopropanol at 20°C for 3 minutes, and then in deionized water at 20°C for 3 minutes, then taken out and dried , and then put into a mixed solution composed of concentrated sulfuric acid and 30% mass concentration of hydrogen peroxide, the volume ratio of the concentrated sulfuric acid and the 30% mass concentration of hydrogen peroxide is 7:3, heated to 100°C, soaked for 5min, and then Rinse it with deionized water, dry it with nitrogen, put it into the BOE solution, soak for 3 minutes, take it out, rinse it with deionized water and blow it dry with nitrogen. T...

Embodiment 2

[0064] Using a high-density plasma etching machine for post-processing, the obtained superconducting quantum chip containing niobium film, the etching method is as follows:

[0065] (1) Substrate cleaning: select high-purity silicon wafers as the substrate of the chip. The substrate is the substrate, and the substrate is cleaned with 1-methyl-2-pyrrolidone solution at room temperature for 9 minutes, then transferred to isopropanol at 25°C for 12 minutes, and then in deionized water at 25°C for 12 minutes, taken out and dried , and then put into a mixed solution composed of concentrated sulfuric acid and 30% mass concentration of hydrogen peroxide, the volume ratio of the concentrated sulfuric acid and the 30% mass concentration of hydrogen peroxide is 7:3, heated to 115 ° C, soaked for 12min, and then used Rinse with deionized water, dry with nitrogen, put in BOE solution, soak for 4min, take out, rinse with deionized water and blow dry with nitrogen. The BOE solution consists...

Embodiment 3

[0076] Using a high-density plasma etching machine for post-processing, the obtained superconducting quantum chip containing niobium film, the etching method is as follows:

[0077] (1) Substrate cleaning: select high-purity silicon wafers as the substrate of the chip. The substrate is the substrate, and the substrate is cleaned with 1-methyl-2-pyrrolidone solution at room temperature for 15 minutes, then transferred to isopropanol at 30°C for 15 minutes, and then in deionized water for 15 minutes at 30°C, then taken out and dried , and then put into a mixed solution composed of concentrated sulfuric acid and 30% mass concentration of hydrogen peroxide, the volume ratio of the concentrated sulfuric acid and the 30% mass concentration of hydrogen peroxide is 7:3, heated to 130 ° C, soaked for 20min, and then used Rinse with deionized water, dry with nitrogen, and finally put in BOE solution, soak for 5 minutes, take it out, rinse with deionized water, and dry with nitrogen. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com