Bonding encapsulation structure and method suitable for radio frequency MEMS and method

A packaging method and bonding technology, which are applied in the process of producing decorative surface effects, the coupling of optical waveguides, and the assembly of microstructure devices, etc., can solve the problems of not having much advantages, large stress of substrate materials, and high cost. Achieve low cost, high bonding efficiency, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] A bonding and packaging method suitable for radio frequency MEMS, which is particularly characterized in that it includes the steps of making a package cover, aligning and bonding the package cover with a package substrate, and leading out the wafer lead pads after bonding.

[0075] Specifically, the manufacturing steps of the adopted package cover plate are as follows,

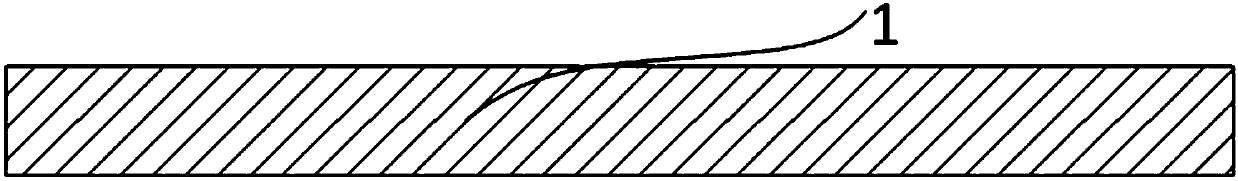

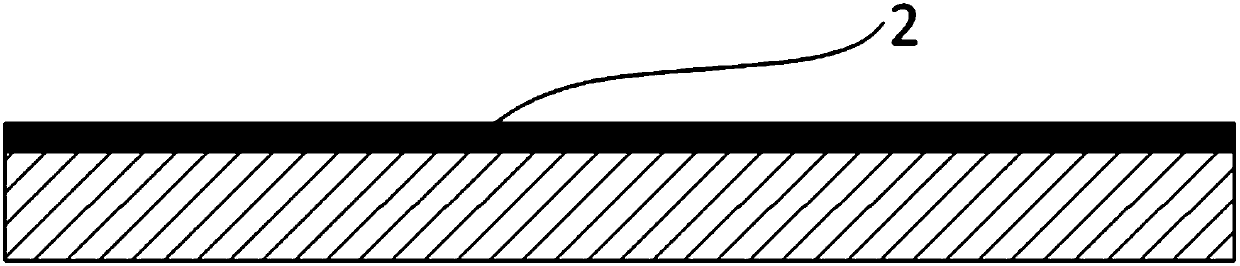

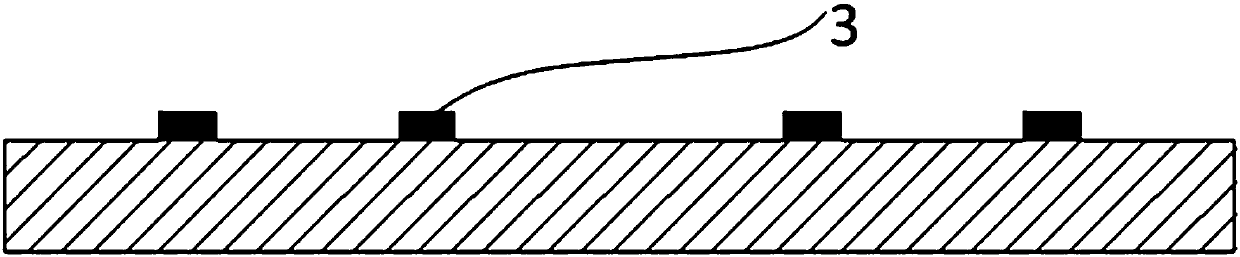

[0076] First, organic materials are spin-coated on a flat high-resistance silicon cover to obtain a high-resistance silicon cover with even distribution of organic materials. During this period, the organic material employed was benzocyclobutene (BCB). Afterwards, photolithography and development are performed on the organic material to form the required bonding pattern. Subsequently, a 520nm Cr layer and a 50nm Au layer were respectively sputtered on the cover plate to form a metal thin film. During this time, the Cr layer was used as an adhesion layer and the Au layer was used as a corrosion stop l...

Embodiment 2

[0084] A bonding and packaging method suitable for radio frequency MEMS, which is particularly characterized in that it includes the steps of making a package cover, aligning and bonding the package cover with a package substrate, and leading out the wafer lead pads after bonding.

[0085] Specifically, the manufacturing steps of the adopted package cover plate are as follows,

[0086] First, organic materials are spin-coated on a flat high-resistance silicon cover to obtain a high-resistance silicon cover with even distribution of organic materials. During this period, the organic material used was polyimide (PI). Afterwards, photolithography and development are performed on the organic material to form the required bonding pattern. Subsequently, a 20nm Cr layer and a 200nm Au layer were respectively sputtered on the cover plate to form a metal thin film. During this time, the Cr layer was used as an adhesion layer and the Au layer was used as a corrosion stop layer. Cr an...

Embodiment 3

[0094] A bonding and packaging method suitable for radio frequency MEMS, which is particularly characterized in that it includes the steps of making a package cover, aligning and bonding the package cover with a package substrate, and leading out the wafer lead pads after bonding.

[0095] Specifically, the manufacturing steps of the adopted package cover plate are as follows,

[0096] First, organic materials are spin-coated on a flat high-resistance silicon cover to obtain a high-resistance silicon cover with even distribution of organic materials. During this period, the organic material employed was epoxy resin. Afterwards, photolithography and development are performed on the organic material to form the required bonding pattern. Subsequently, a 15nm Cr layer and a 150nm Au layer were respectively sputtered on the cover plate to form a metal thin film. During this time, the Cr layer was used as an adhesion layer and the Au layer was used as a corrosion stop layer. Cr a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com