Composite grid manufacturing equipment and manufacturing method and grid thereof

A composite material and manufacturing equipment technology, applied in the field of FRP grating production equipment, can solve the problems affecting the structural strength of the FRP grating itself, difficult to ensure the lifting force, product loss, etc., to achieve stable and effective demoulding methods, fast layout, The effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

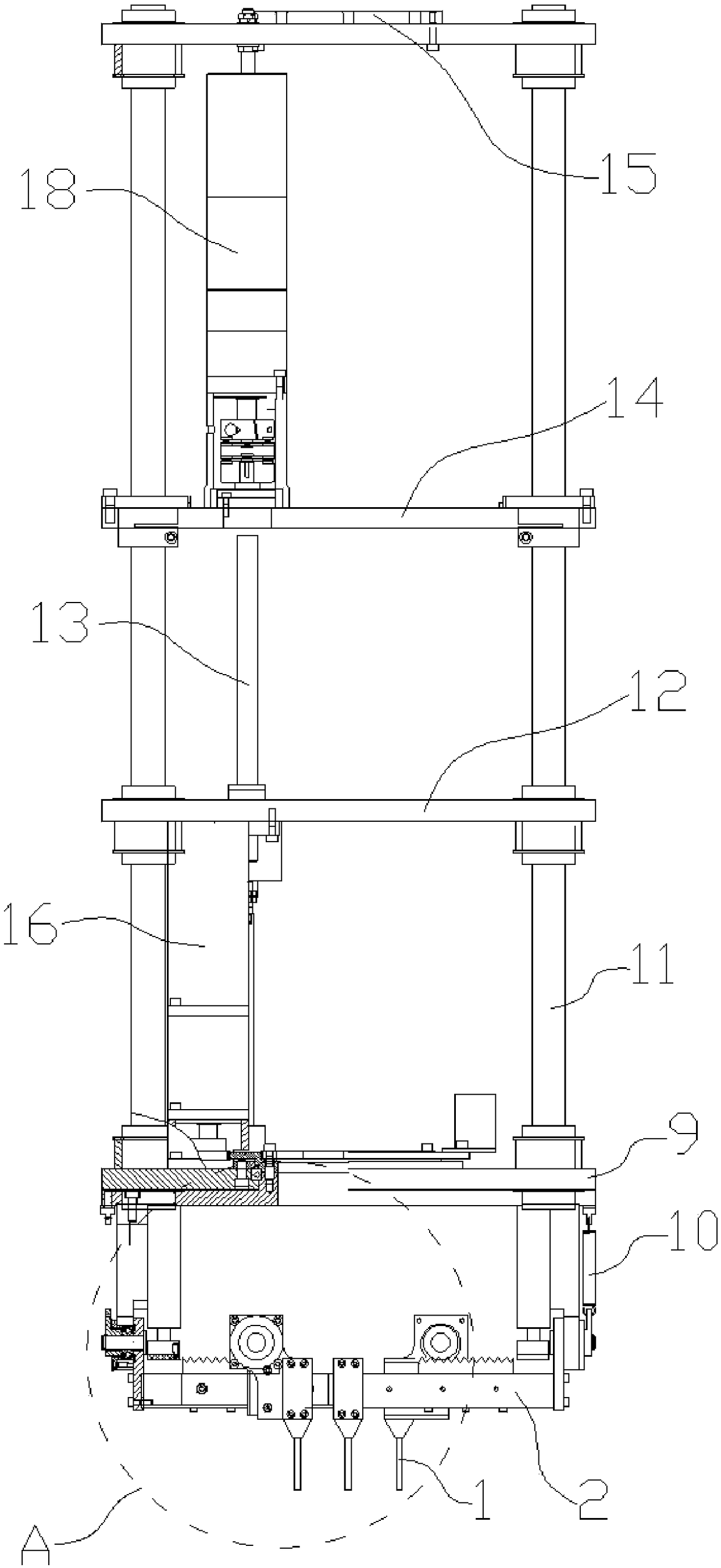

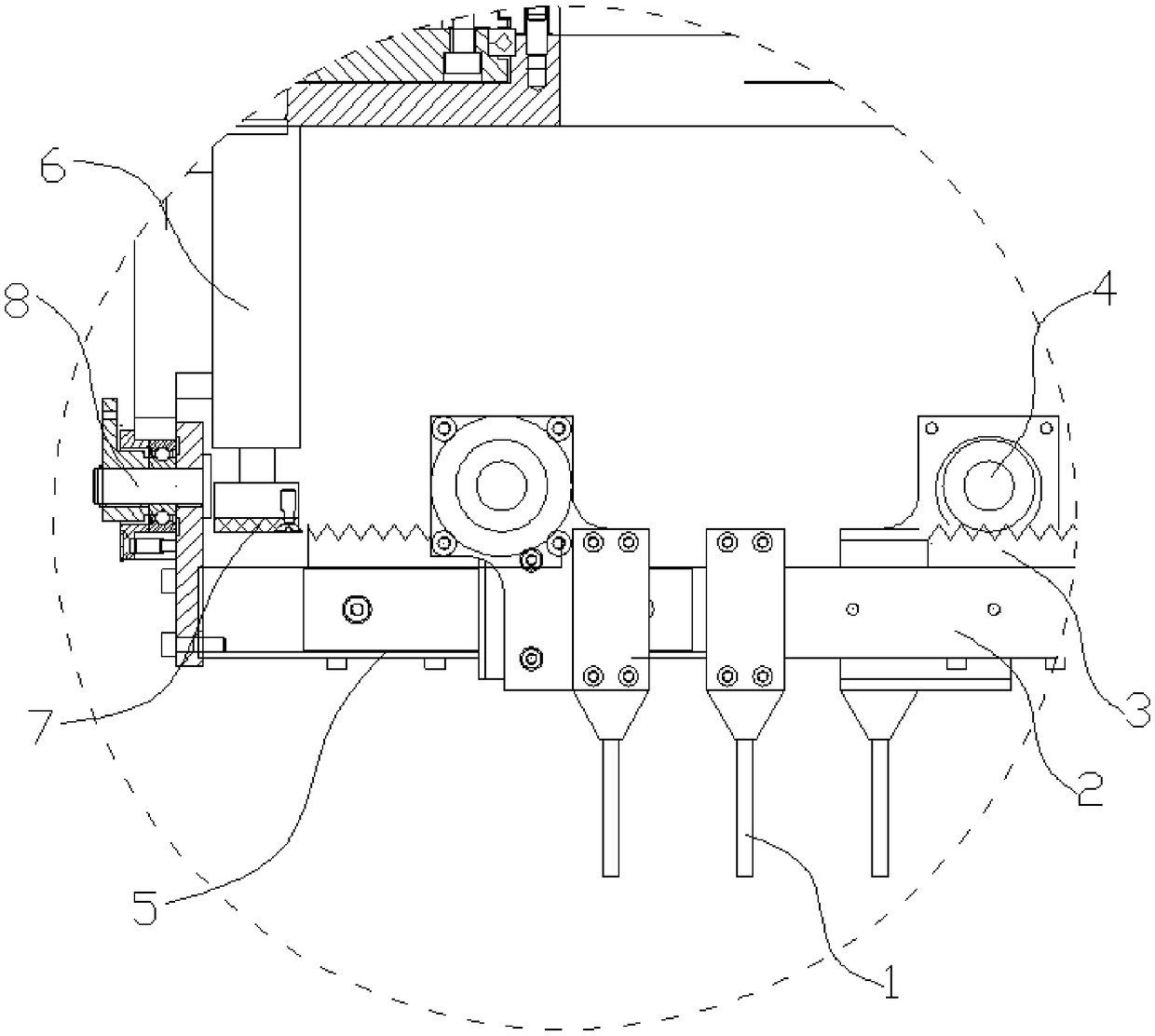

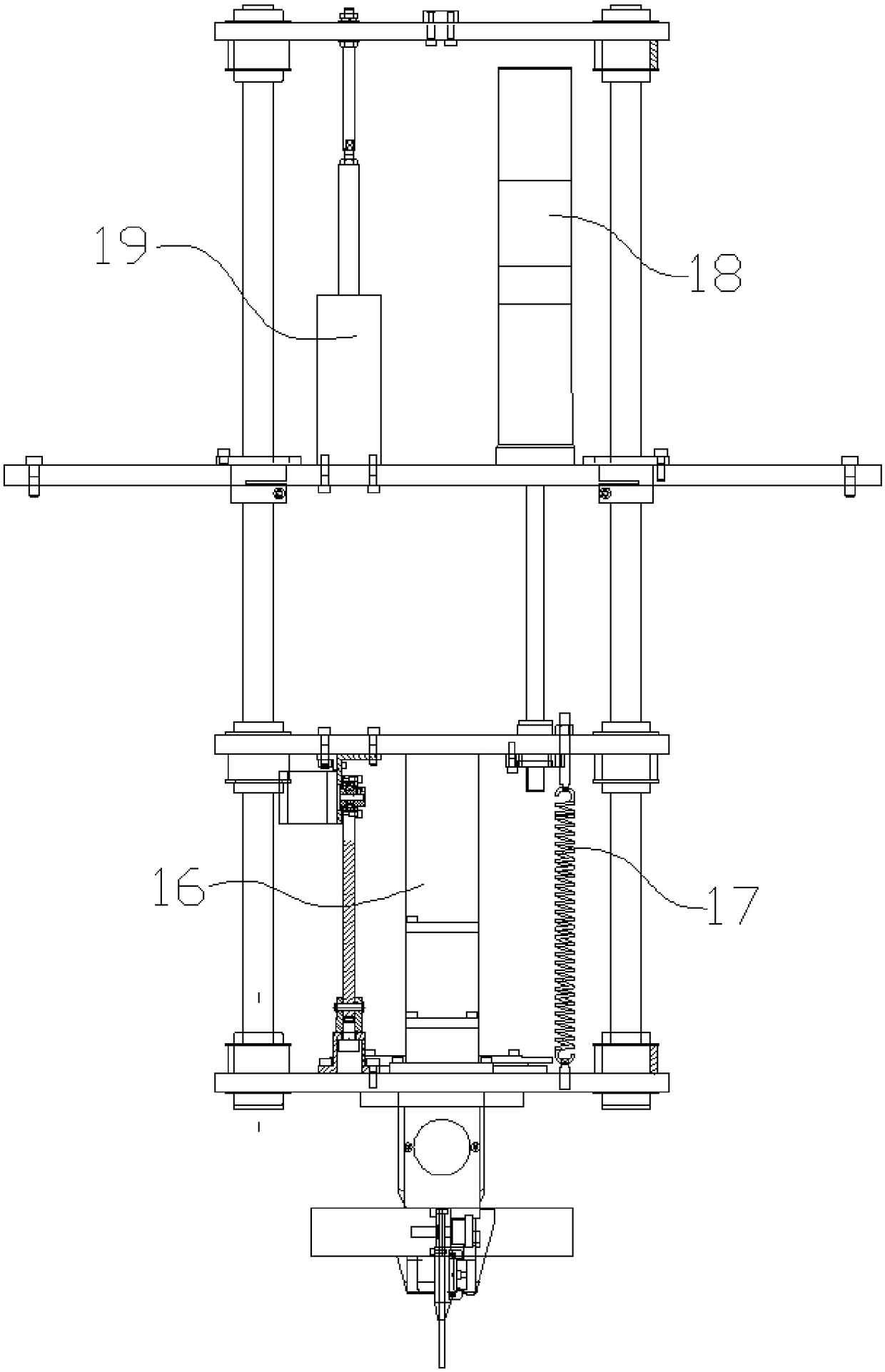

[0061] The yarn running mechanism includes: the yarn distributing tube 1, which has a hollow pipe for the yarn to pass through; the plane traveling mechanism, which drives the yarn distributing tube 1 to translate in the horizontal plane, and has at least translational freedom along the x-axis and y-axis degree; the vibration mechanism applies periodic vibration to the cloth tube 1.

[0062] The x-axis and y-axis are two horizontal lines that cross each other perpendicularly. Such as Figure 9 As shown, the yarn cloth tube 1 needs to extend into the groove in the mold 24 . figure 1 , image 3 . Figure 4 The plane running gear is hidden. Figure 9 is a schematic diagram of the whole. The material of the yarn is glass fiber.

[0063] The beneficial effect of adopting the above technical solution is: the yarn cloth tube ensures that the yarn will not b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com