Cutting grinding sheet and its manufacturing method

A manufacturing method and a technology of abrasive sheets, which are applied in the manufacture of tools, abrasives, metal processing equipment, etc., can solve the problem of reducing the bonding strength between abrasive grains and coatings, inconsistent positions and flatness of abrasive grains, and reducing the usable portion of abrasive grains and other problems, to achieve the effect of grinding accuracy and effectiveness improvement, high cutting and grinding efficiency, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The detailed structure and manufacturing process of the present invention are further given by the following description.

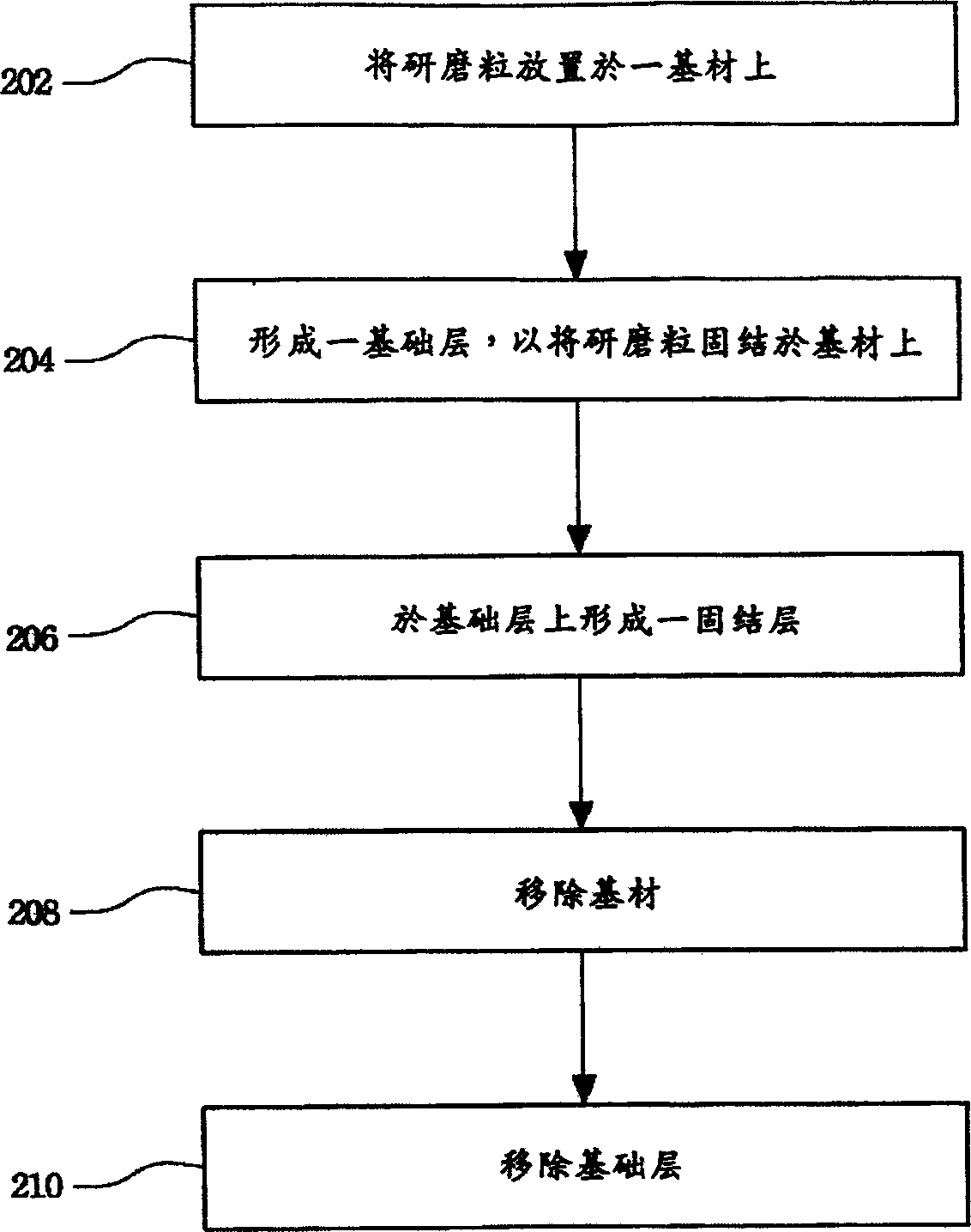

[0040] Such as figure 1 As shown, the manufacturing steps of the present invention are: 1. placing abrasive grains on a substrate (step 202), and 2. forming a base layer to consolidate the abrasive grains on the substrate (step 204). 3. Form a consolidation layer on the base layer (step 206). 4. The substrate is removed (step 208). 5. Optionally remove the base layer (step 210), thereby forming a cutting abrasive sheet.

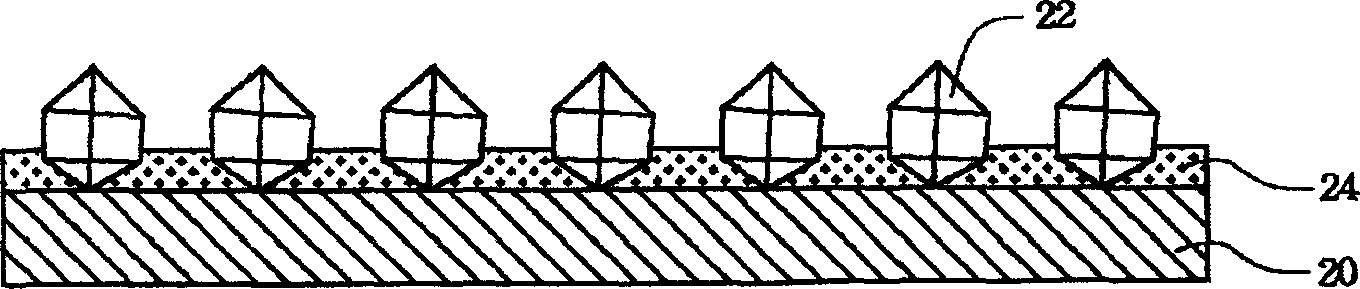

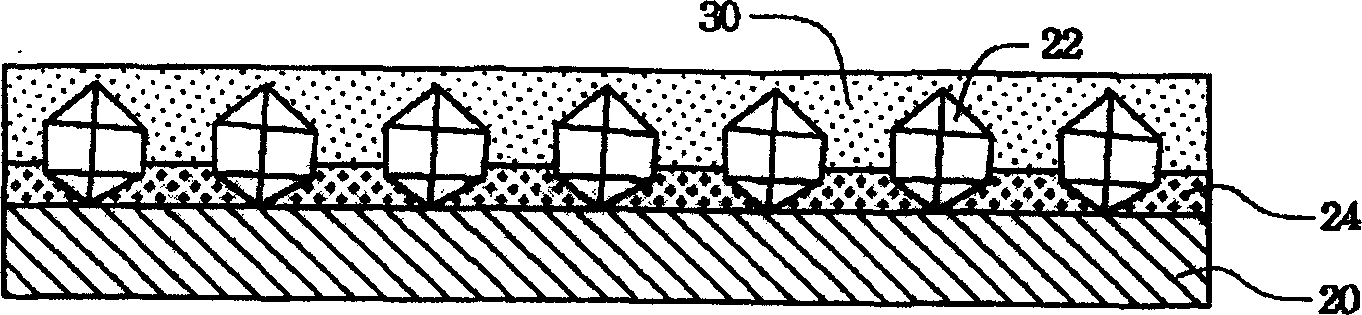

[0041] figure 2 It is used to illustrate the step of forming a base layer 24 to fix the abrasive grains 22 on the base material 20 . The abrasive particles 22 are made of abrasive materials, such as diamond, boron nitride, and aluminum oxide. The material of base layer 24 can be polymer material, metal, metal compound or carbide, for example can be iron, chromium, nickel, copper, zinc, tin etc. or its alloy, and by plating t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com