Slope, pit bottom and foundation bottom seepage preventing method based on tailings composite anti-seepage material

A technology of composite anti-seepage and anti-seepage materials, which is applied in basic structure engineering, protection devices, buildings, etc., can solve the problems of small application scope, poor anti-seepage effect, high cost, and achieve high consolidation strength and good alkali resistance. , good workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

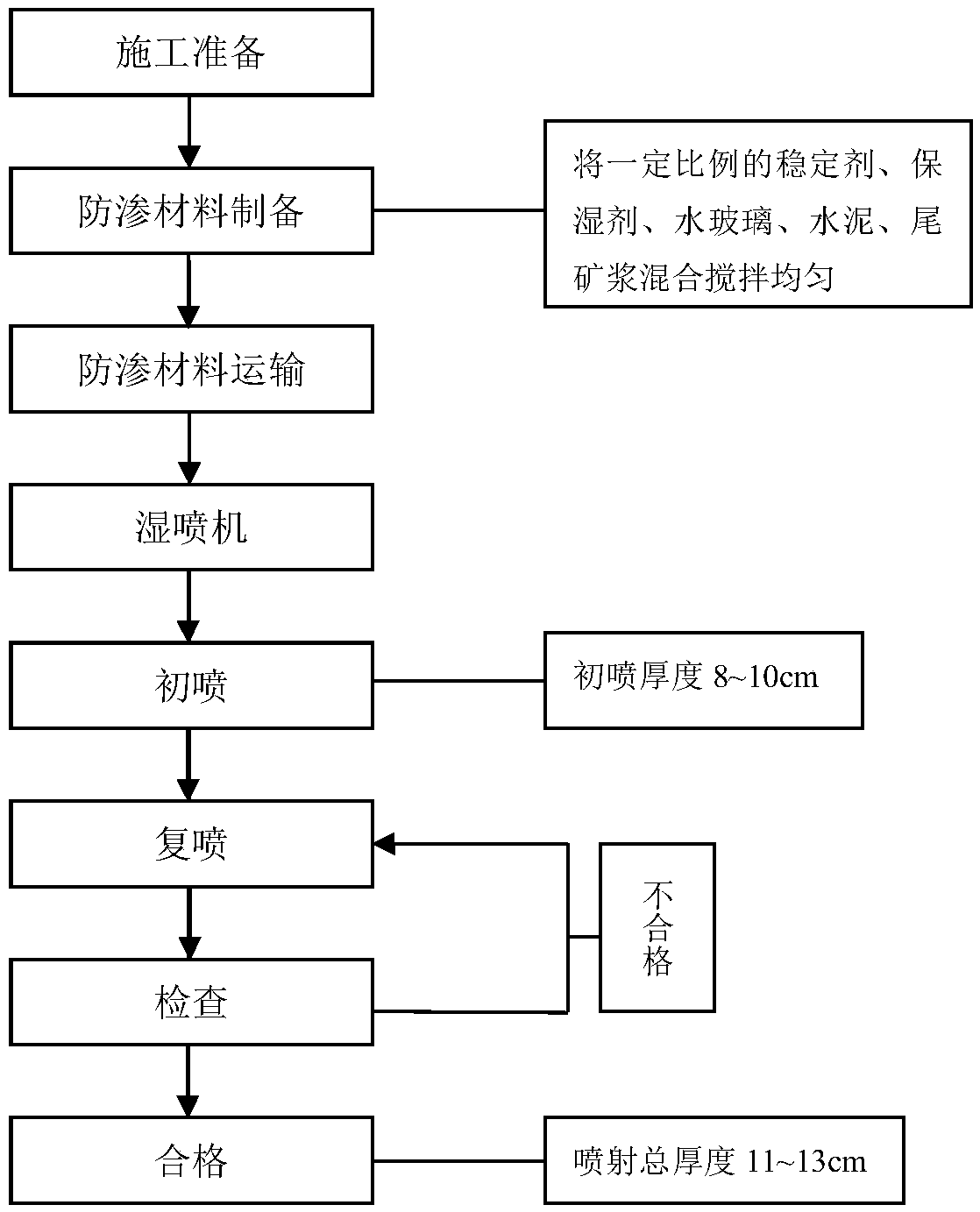

[0027] In order to better describe the present invention, a method for anti-seepage of slopes, pit bottoms and bases based on tailings composite anti-seepage materials of the present invention will be further described in detail below in conjunction with the accompanying drawings.

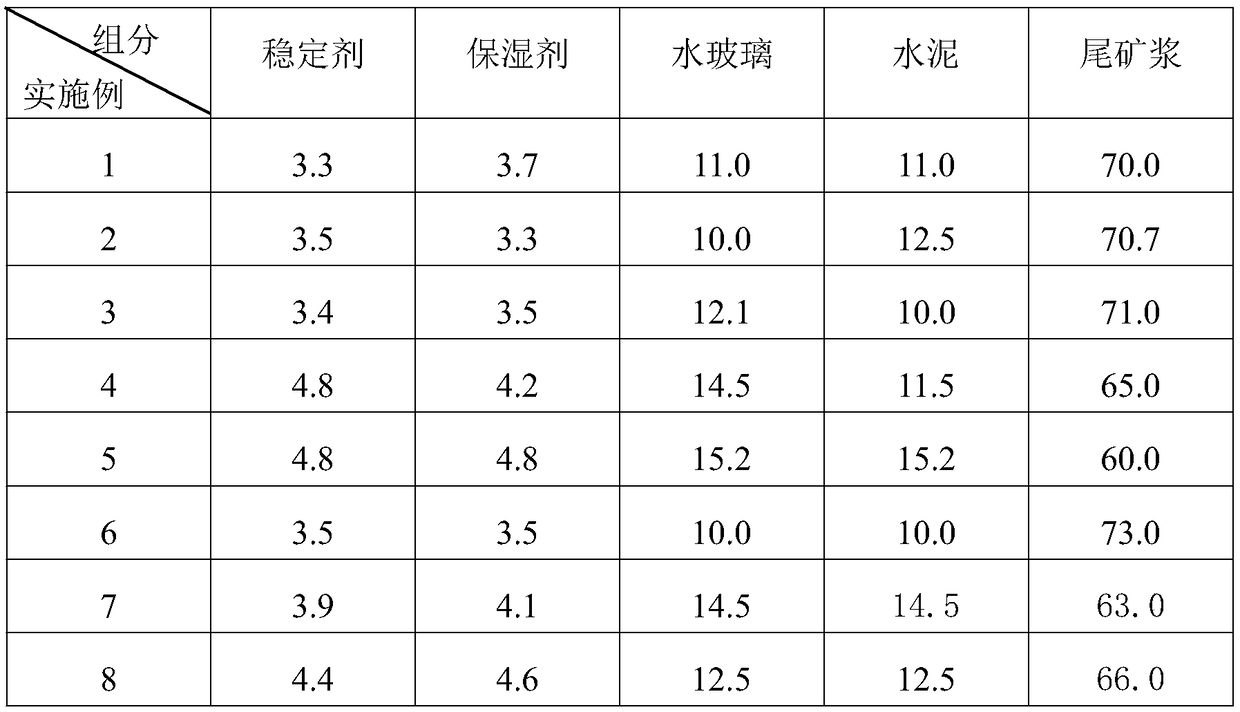

[0028] The components and mass percentages of the composite tailings anti-seepage material used in the slope, pit bottom and base anti-seepage method based on the tailings composite anti-seepage material of the present invention are: stabilizer 3.3% to 4.8%, moisturizer 3.3% to 4.8%, water glass 10.0% to 15.2%, cement 10.0% to 15.2%, tailings slurry 60.0% to 73.0%; the stabilizer is a mixture of calcium chloride and sodium borate tetrahydrate, and the proportion is chlorine 50% to 60% of calcium chloride, 40% to 50% of sodium borate tetrahydrate, and the composite compound is prepared with dry materials; the moisturizing agent is glyoxal.

[0029] Depend on figure 1 The implementation process flow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| osmotic coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com