Patents

Literature

125results about How to "High consolidation strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Methods and compositions for enhancing consolidation strength of proppant in subterranean fractures

InactiveUS20050006093A1High consolidation strengthFlushingGlass/slag layered productsCarrier fluidImproved method

Improved methods and compositions for consolidating proppant in fractures formed in subterranean zones are provided. An improvement of this invention comprises using proppant particles having a coating of hardenable resin including a gel breaker. The gel breaker facilitates removal of gelled carrier fluid from the surface of the proppant particles.

Owner:HALLIBURTON ENERGY SERVICES INC

Methods for preventing fracture proppant flowback

ActiveUS6892813B2Preventing fracture proppant particle flowbackHigh consolidation strengthFluid removalDrilling compositionPolymer chemistryLiquid composition

Owner:HALLIBURTON ENERGY SERVICES INC

Methods and compositions for enhancing consolidation strength of proppant in subterranean fractures

InactiveUS7021379B2High consolidation strengthFlushingDrilling compositionCarrier fluidImproved method

Improved methods and compositions for consolidating proppant in fractures formed in subterranean zones are provided. An improvement of this invention comprises using proppant particles having a coating of hardenable resin including a gel breaker. The gel breaker facilitates removal of gelled carrier fluid from the surface of the proppant particles.

Owner:HALLIBURTON ENERGY SERVICES INC

Pre-coated film propping agent, preparation method of the pre-coated film propping agent and sand prevention method adopting the pre-coated film propping agent

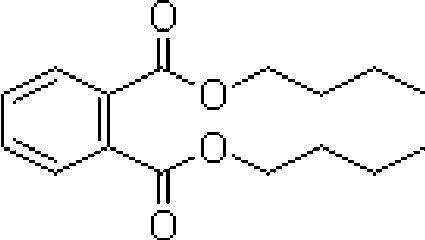

ActiveCN102660245AImproves breakage resistanceEasy to divertFluid removalDrilling compositionBisphenol FPolyamine

The invention relates to a pre-coated film propping agent, a preparation method of the pre-coated film propping agent and a sand prevention method adopting the pre-coated film propping agent. The pre-coated film propping agent comprises propping agents, one or more pre-coated resins, one or more pre-coating curing agents, a coupling agent and a lubricating agent. The one or more pre-coated resins comprise bisphenol-A epoxy resin, bisphenol-F epoxy resin and / or novolac epoxy resin. The one or more pre-coating curing agents are selected from alicyclic polyamines, aromatic polyamines, modified alicyclic polyamines and / or modified aromatic polyamines. The coupling agent is an organosilane coupling agent.

Owner:BEIJING QISINTAL SCI & TECH +1

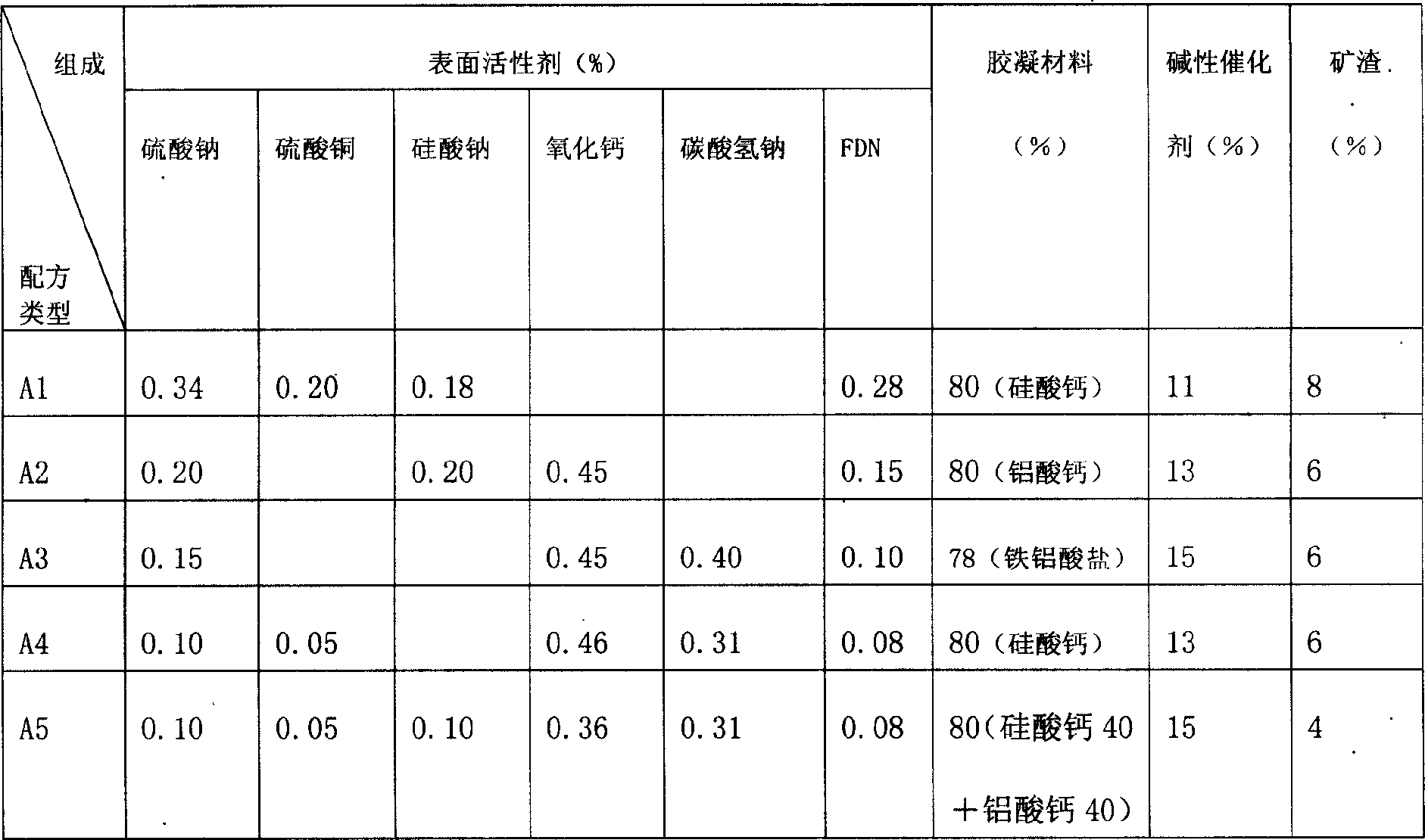

Soil curing agent

ActiveCN1632055AHigh consolidation strengthImprove water stabilityOrganic fertilisersSoil conditioning compositionsFirming agentSurface-active agents

Disclosed is a new soil curing agent, using cement, alkali catalyst, surface active agent and mine refuse as the raw material, mixing and grinding the components by reasonable weight ratio until the specific surface area is 400-900m2 / kg,. The invention has high consolidating strength, good water stability and resistance to coldness, small deformation and wide range of application, its consolidating principle is: In the time of making the basic structure of soil have no dispersion like lightly touching with interface, make use of the potential activity of minerals like silicate and aluminates to make the interface form stead multi-assemble, advancing the essence of soil particle interface, making it have higher strength and water stability. The curing agent can make effect both on interface and in the soil unit, further developing the theory of soil consolidation in the general temperature.

Owner:NORTHWEST A & F UNIV +2

Earth cementation agent in use for roadway construction

InactiveCN1562851AImprove responseGood water hardnessSolid waste managementOrganic fertilisersPower stationRoad surface

In the invention, two kinds of waste material dry dust discharging coal ash and desulfurize gyp produced by power plant burning sub-bituminous coal or lignitous coal are used as main composition, shell and or cement, calcined gypsum and aluminum sulfate or alunite are used as secondary composition, they are prepared to dry powder soil curing agent by weighing, matching, forced stirring and mixing. The soil can be concreted by mixing a proper quantity of curing agent into the soil and processes of stirring, compacting, soaking and maintaining.

Owner:徐尔昌

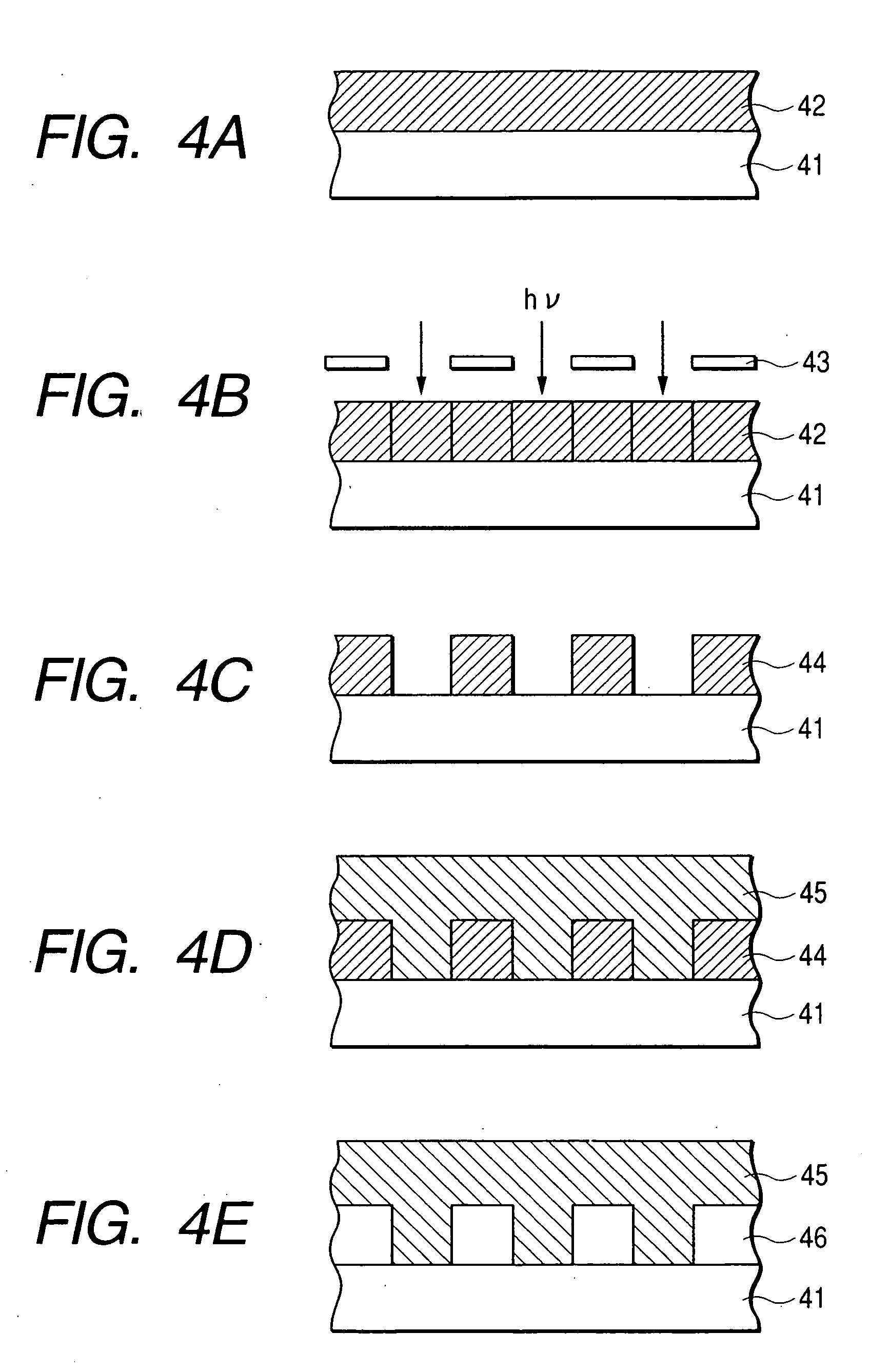

Epoxy resin composition

InactiveUS20060089466A1Improve accuracyEnhance friction strengthLiquid surface applicatorsPlastic/resin/waxes insulatorsEpoxyCationic polymerization

An embodiment of the invention relates to a novel epoxy resin composition. The epoxy resin composition comprises (i) a first epoxy resin having in the molecule thereof at least one water-repellency-imparting group and two or more cyclic aliphatic epoxy groups, and having a number average molecular weight ranging from 8,000 to 22,000 and a polydispersity ranging from 3.5 to 5.0, (ii) a second epoxy resin having in the molecule thereof at least one water-repellency-imparting group and two or more cyclic aliphatic epoxy groups, having a number average molecular weight ranging from 2,500 to 8,000 and a polydispersity ranging from 1.5 to 3.0, and (iii) a cationic polymerization catalyst.

Owner:CANON KK

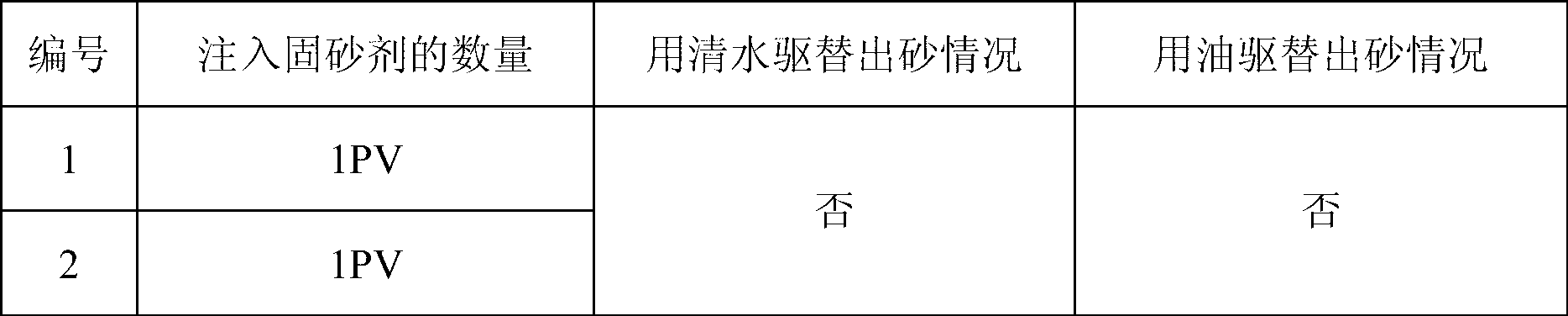

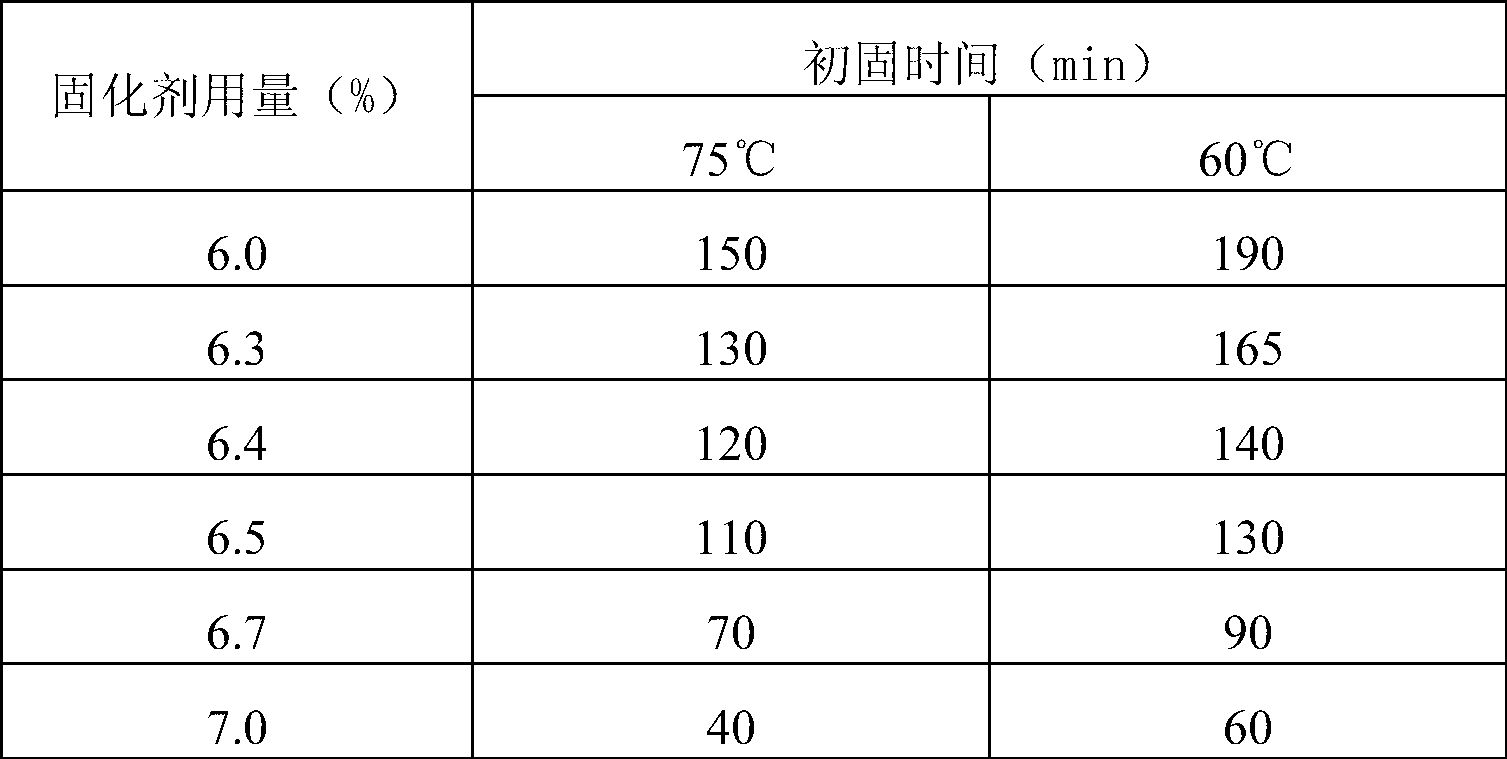

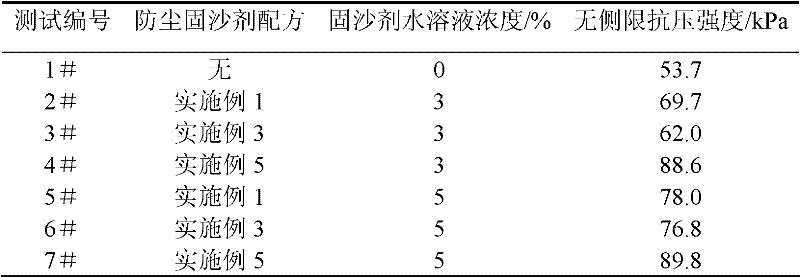

Modified resin sand consolidation agent as well as preparation method and application thereof

ActiveCN103013485AReduce harmHigh consolidation strengthFluid removalDrilling compositionGlass fiberEpoxy

The invention relates to a modified resin sand consolidation agent as well as a preparation method and an application of the modified resin sand consolidation agent. The sand consolidation agent mainly consists of epoxy resin as a main agent, 6.0-7.0% of a curing agent, 15% of a softener, 20-22% of a diluent, 2% of a coupling agent and 10% of glass fiber; and the dosages of the other components expect the epoxy resin is weighed by 100% of the epoxy resin in percentage by weight. The preparation comprises that the modified resin sand consolidation agent is used for preventing and curing sand production in oil wells. The application method comprises the steps of: pre-treating the stratum by using pre-cleaning fluid, then pouring the sand consolidation agent from an oil tube, and finally replacing the sand consolidation agent to the deep of the stratum by using replacement pore-broadening liquid. The formula of the sand consolidation agent disclosed by the invention can solve the problem of influence of sand production in oil wells on the production and is suitable for different sand grains.

Owner:PETROCHINA CO LTD

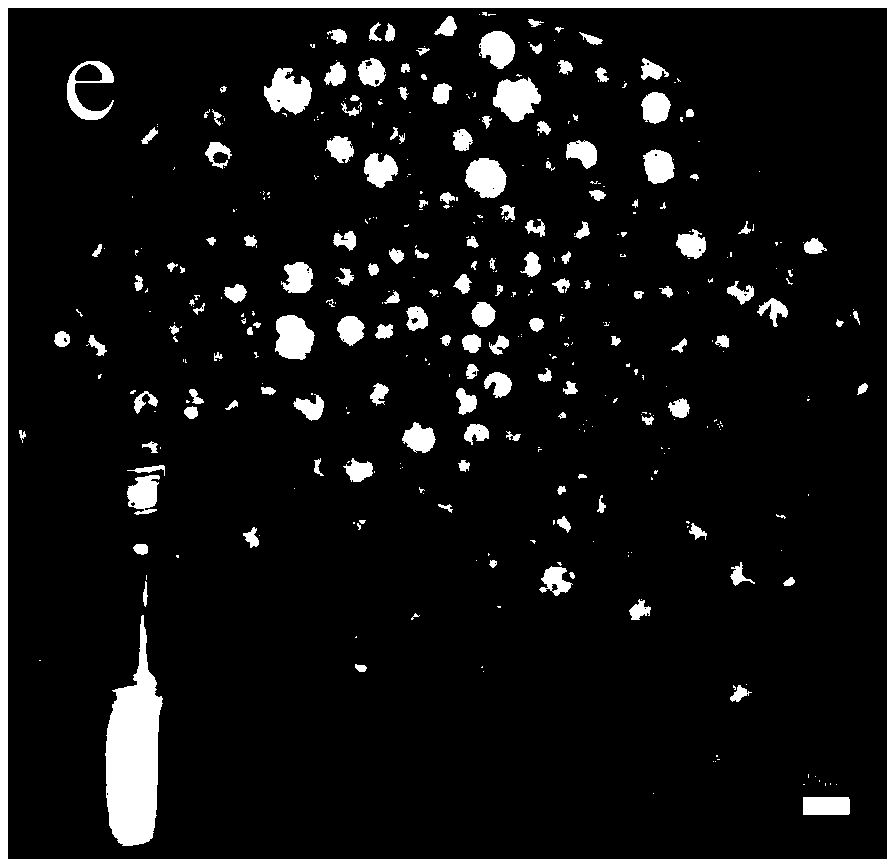

Polyurethane-based ecological sand-fixing agent and preparation method thereof

ActiveCN102226088AGood strength bearing capacityEasy to adjustOrganic fertilisersSoil conditioning compositionsPolymer sciencePolyol

The invention relates to a polyurethane-based ecological sand-fixing agent and a preparation method thereof. The sand-fixing agent comprises the following components: 25-29 parts of polyurethane prepolymer, 0.5-2.1 parts of dispersion stabilizer and 27-36 parts of solvent, wherein the polyurethane prepolymer is obtained by polycondensation reaction of polymer polyol and diisocyanate, the polymer polyol comprises polypropylene oxide diol, polyoxyethylene diol and easily-degradable polymer diol, the mass ratio of polypropylene oxide diol to polyoxyethylene diol is (1:3)-(5:1), and the easily-degradable polymer diol accounts for 13-23wt% of the polymer polyol; and the mass ratio of the polymer polyol to diisocyanate is (4:1)-(7:1). The preparation method comprises the following steps: controlling the temperature at 85-100 DEG C under nitrogen gas protection, allowing reaction between the polymer polyol and diisocyanate to obtain a polyurethane prepolymer, and homogeneously mixing the polyurethane prepolymer, the dispersion stabilizer and the solvent to obtain the polyurethane-based ecological sand-fixing agent.

Owner:NANJING UNIV

High-temperature-resistant sand-control support agent and high-temperature-resistant sand-control curing system

ActiveCN103173195AAchieve initial solidificationAvoid cakingDrilling compositionPhysical chemistryFirming agent

The invention discloses a high-temperature-resistant sand-control support agent, which comprises aggregate and a resin film wrapped on the surface of the aggregate, wherein the resin film comprises a heat-resistant solid phenolic resin film and a mixed resin film formed by mixing heat-resistant solid phenolic resin with liquid epoxy resin. The invention further discloses a high-temperature-resistant sand-control curing system, which comprises the high-temperature-resistant sand-control support agent and a curing liquid matched with the high-temperature-resistant sand-control support agent. The high-temperature-resistant sand-control support agent is thermally coated by adopting the heat-resistant solid phenolic resin and the liquid epoxy resin; a film coated layer is initially cured, so that the high-temperature-resistant sand-control support agent has initial compressive strength; when the curing liquid is injected into a stratum, the liquid epoxy resin can be reacted with a curing agent at a low temperature to carry out particle adhesion; solidification intensity required before injecting steam is achieved; along with rising of the temperature, the high-temperature-resistant phenolic resin begins to be reacted to generate high-temperature adhesion; and the solidification intensity of the sand-control support agent is further increased, therefore, normal-temperature curing and high-temperature-resistant performance are realized.

Owner:BEIJING RECHSAND SCI & TECH GRP

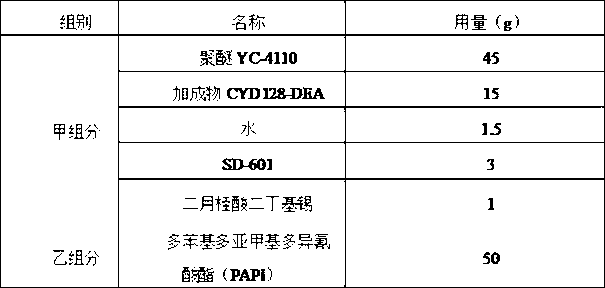

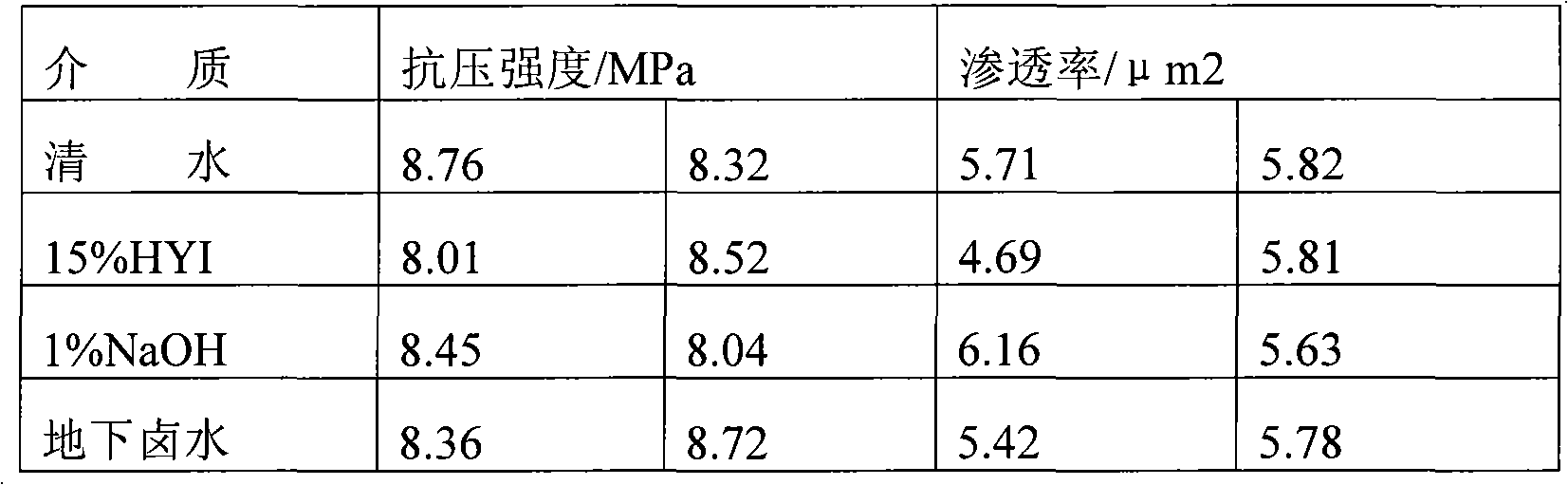

Epoxy modified polyurethane double-component grouting material for road engineering maintenance and preparation method thereof

InactiveCN102702473ASynthetic reaction conditions are mild and efficientIt has the function of self-catalysisEpoxyPolyol

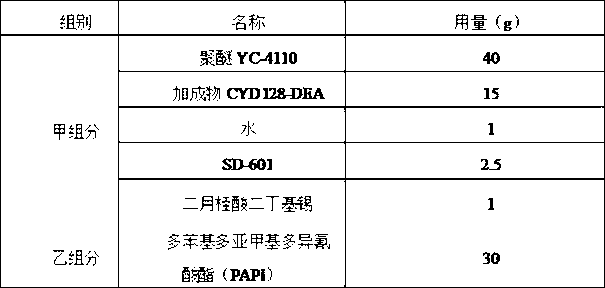

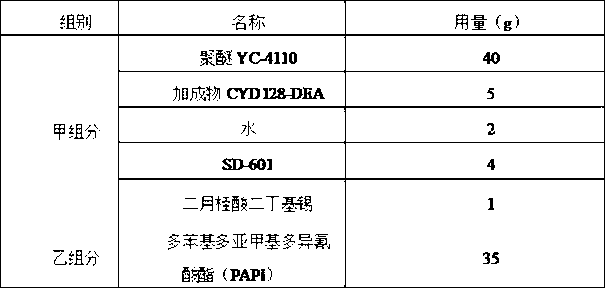

The invention relates to an epoxy modified polyurethane double-component grouting material for road engineering maintenance and a preparation method thereof, wherein the grouting material comprises a component A and a component B; the component A comprises following components in part by weight: 700-800 parts of polyether glycol, 100-300 parts of epoxy resin addition product, 20-40 parts of foaming agent, 40-80 parts of foam stabilizer and 10-40 parts of catalyst; and the component B is polyphenyl polymethylene polyisocyanate. The preparation method comprises the step of mixing and stirring the component A and the component B according to the mass ratio of (0.8-1.5): 1 uniformly. The grouting material has the advantages that: when the material participates in foaming reaction and is cured, the compression strength and bonding force of the formed liquid cement are improved, and the maximum tensile shear strength can reach 4.3Mpa, so that the grouting material is better than the grounding material mixed by polyurethane and epoxy resin; and the grouting material reduces builder body damage and has a certain economic benefit.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

High osmosis type soil hardener and application method thereof

InactiveCN102643652AEfficient curingLow viscosityBuilding constructionsOrganic fertilisersSoil scienceAcrylate ester

The invention discloses a high osmosis type soil hardener, which is bicomponent seriflux containing materials of hardener and main liquid, and is characterized in that the volume ratio of hardener to main liquid is 1: (0.8-2). Since bicomponent seriflux disclosed by the invention is aqueous solution with low viscosity, the bicomponent seriflux can effectively seep into a small gap of 0.001mm, and good hardening of soil can be realized; the strength of sodium silicate in the components is large by hardening of acidity and ester materials, additionally, soil plays a role of enhancement, so that the strength of consolidation materials reaches around 10-15MPa; by the adoption of polyacrylic acid materials and polyacrylic ester materials as hardener for sodium silicate, the tenacity is good, additionally, certain amount of flexible materials such as polyacylamide are used for increasing the tenacity of sodium silicate hardener, certain tenacity of sodium silicate hardener is realized after hardening soil, the mechanical property of hardened soil can be increased; and the hardener disclosed by the invention is low in cost, non-toxic and environmental-friendly.

Owner:重庆融极环保工程有限公司

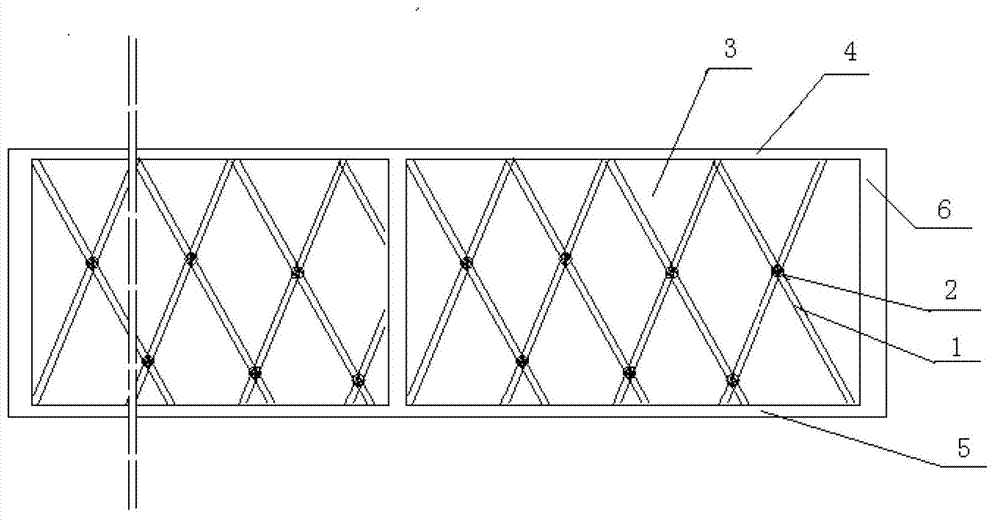

Netted sand prevention material

The invention relates to a liquid and solid two-phase netty sand control material used for oil fields. The technical proposal is that the liquid and solid two-phase netty sand control material consists of an auxiliary material and a sand fixation material; the auxiliary material is semi-rigid solid material with 1.0 to 20 portions by weight; the sand fixation material is used with 20 to 80 portions by weight. The liquid and solid two-phase netty sand control material has the advantages of low viscosity, injecting the components once, safety and stability, high fixation strength, little injury to the stratum, good resistivity to heat and water, convenient construction and so on. Compared with the prior liquid chemical sand control material, the sand control material further has the characteristics of capability of adjusting the injection profile of a sand control agent in a heterogeneous oil zone; keeping the liquid chemical sand control material uniformly entering each perforated hole of the sand control horizon; overwhelming the problem of nonuniform spreading of the prior liquid chemical sand control material in heterogeneous oil layers and affecting the sand controlling result, thus ensuring the sand control success rate and the effective period of sand production wells.

Owner:DONGYING HUIYOU GASOLINEEUM NEW TECH DEV

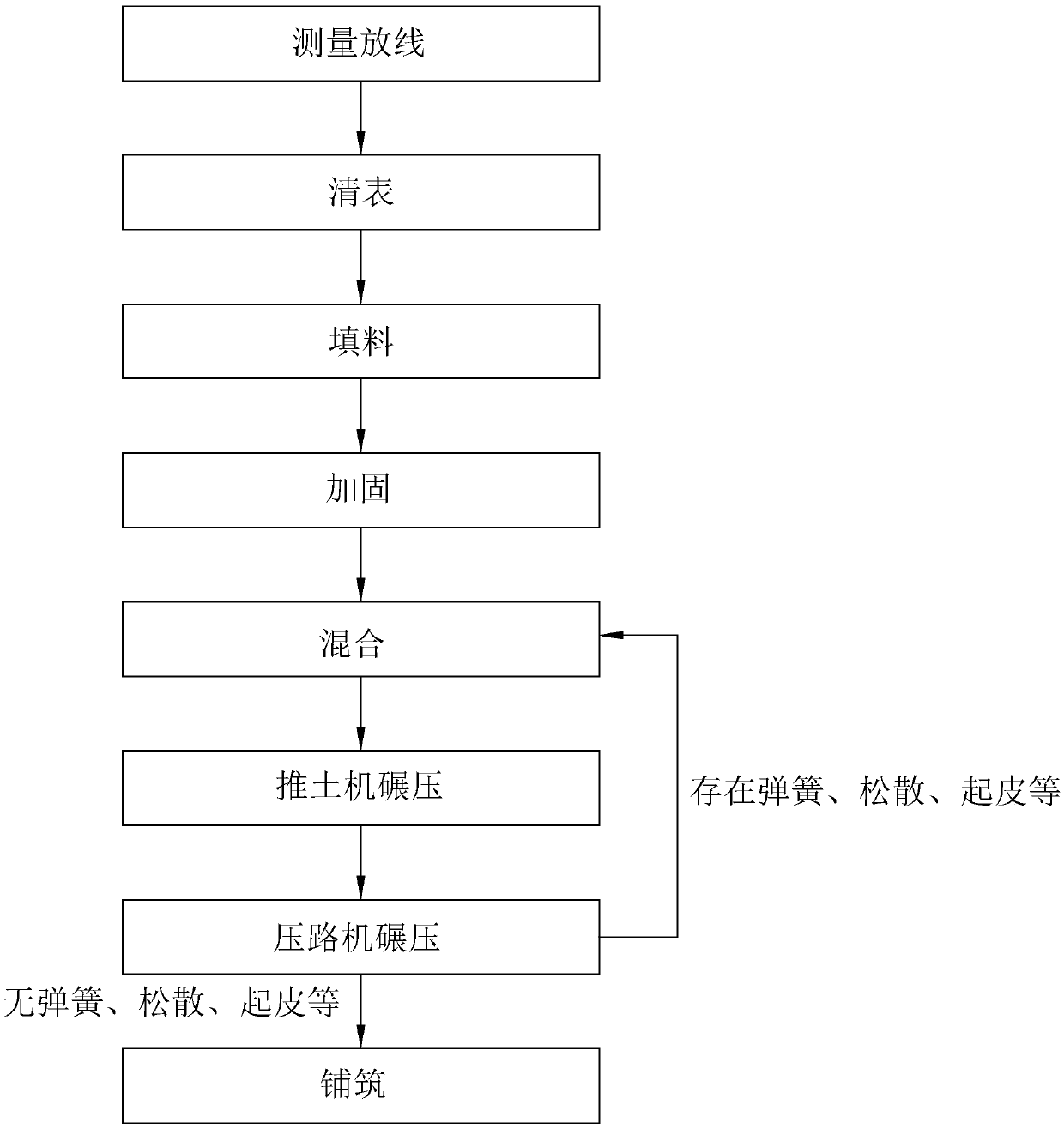

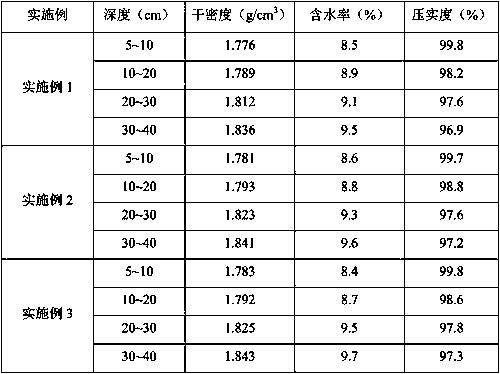

Method for constructing roadbed

InactiveCN109629361AImprove reinforcementImprove corrosion resistanceRoadwaysEngineeringRoad construction

The invention discloses a method for constructing a roadbed through sand filling, and belongs to the field of traffic construction. In the technical scheme, the method is characterized by including the steps of surveying and setting out, surface clearing, filling, reinforcing, mixing, rolling compaction of a bulldozer, rolling compaction of a road roller and paving. The method solves the technicalproblem that in the prior art, the roadbed is prone to losing stability and deforming, and is applied to road construction to enhance the effect of roadbed stability.

Owner:鼎固建安集团有限公司

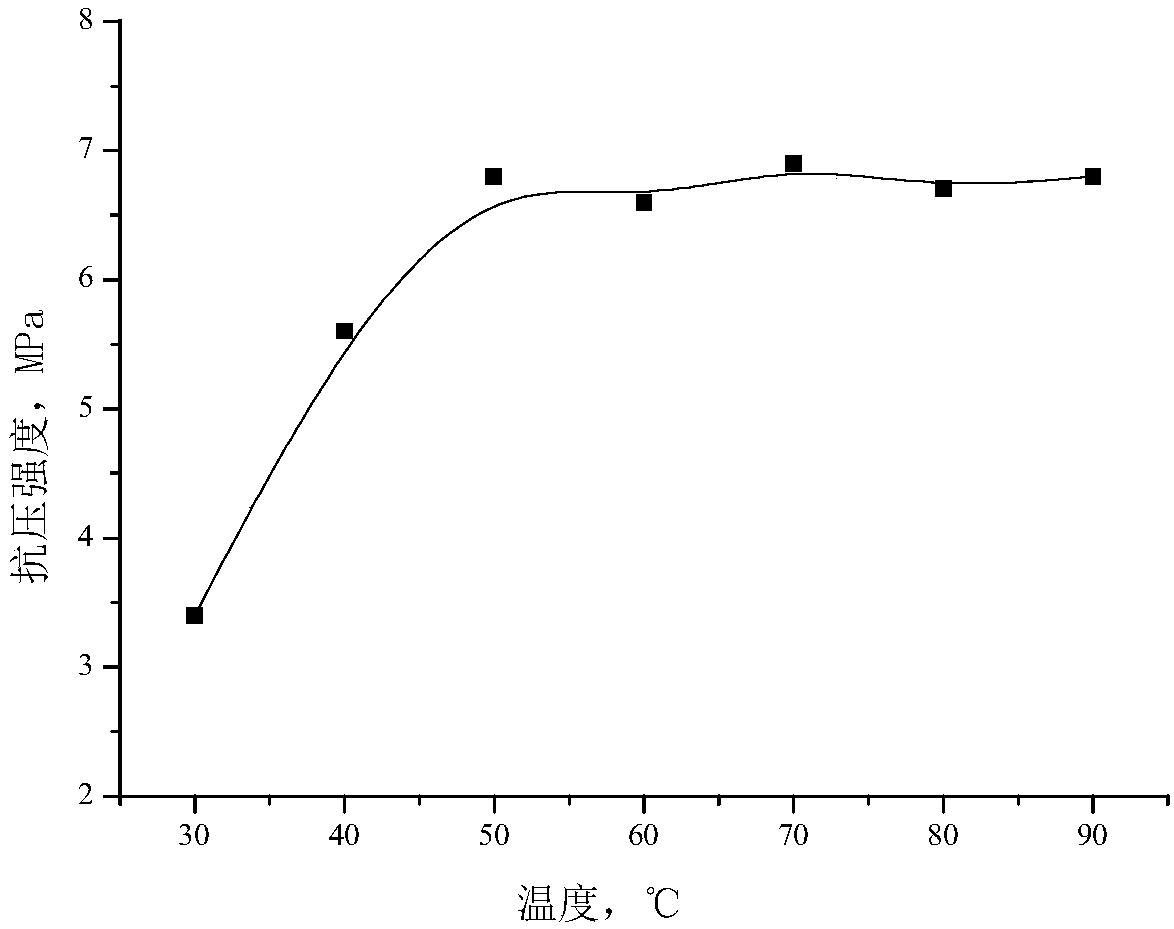

Coated sand for sand prevention in oil well and preparation method of coated sand

ActiveCN105542739AGood film formingImprove liquidityDrilling compositionLow temperature curingMethyl cellulose

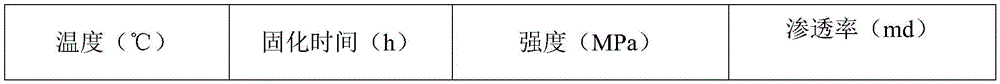

The invention discloses coated sand for sand prevention in an oil well and a preparation method of coated sand. The coated sand comprises A-type coated sand and B-type coated sand and is characterized in that the A-type coated sand is obtained by wrapping quartz sand with organosilicon-modified epoxy resin, a ketimine curing agent and external isolating agent hydroxy methyl cellulose in sequence; B-type coated sand is obtained by wrapping the surface of the quartz sand with cycloaliphatic epoxide resin, an amine curing agent and external isolating agent hydroxy methyl cellulose in sequence. The coated sand disclosed by the invention comprises the A-type coated sand and B-type coated sand, and a co-synergistic effect is generated after the A-type coated sand and the B-type coated sand are mixed, so that the requirements for low-temperature curing and high-temperature mining are met simultaneously. The coated sand disclosed by the invention meets the actual application requirements, gives consideration to low-temperature curing (a minimum temperature of 40 DEG C) to form higher strength, simultaneously is good in permeability, can stably work in a high temperature-resistant environment (about 280 DEG C), is wide in research and development scope of application, can be suitable for not only heavy oil wells, but also middle and low-temperature oil wells and water wells and is lower in comprehensive cost.

Owner:济南蓝昆新材料科技有限公司

Long-acting active sand-controlling oil washing agent and preparation method thereof

The invention relates to a long-acting active sand-controlling oil washing agent and a preparation method thereof. The sand-controlling oil washing agent is composed of the following raw materials in percent by mass: 3-5 parts of a long-chain fatty acid ammonium salt, 0.3-0.6 part of a silane coupling agent, 3-5 parts of a poly-amino compound, 1-3 parts of formaldehyde, 2-5 parts of a water soluble surfactant, 0.1-0.3 part of a hydroxide, 0.2-0.5 part of hydrochloric acid and 5-10 parts of hexane. The sand-controlling oil washing agent is synthesized by employing a three-step method. The action principle comprises that the surfactant is absorbed on rock and displaces crude oil originally attaching to rock, so that crude oil falls off from the surface of rock, and the purpose of washing oil is realized; excess ammonium ions are absorbed on the surface of clay, so that the electrostatic repulsion force on the surface of clay is counteracted and clay is stabilized; and also through the consolidation effect of generated sand-controlling oil-washing resin macro-molecules on sandstone, gravels are stabilized and consolidated.

Owner:CHINA PETROLEUM & CHEM CORP +1

Soil curing agent and application thereof

ActiveCN108277012ARealize the curing effectImprove performanceBuilding constructionsOrganic fertilisersPolyolSURFACTANT BLEND

The invention provides a soil curing agent. The soil curing agent is prepared from a component A and a component B; the component A is prepared from water, ethanol, tourmaline, a component A cationicsurfactant and low molecular polyol; the component B is prepared from polysaccharide, a component B surfactant, a biological enzyme, calcium carbonate, a complex compound, an inorganic-organic compound, water and ethanol.

Owner:宋应师

Magnesium-coal cinder based novel paving and mining filling material and preparation method thereof

InactiveCN112851277ALow costRealize the recycling of solid wasteCement productionSlagWaste treatment

The invention discloses a novel magnesium-coal cinder-based paving and mining filling material and a preparation method thereof. The material comprises the following raw materials in percentage by weight: 15-50% of a magnesium-coal cinder-based cementing material, 50-85% of aggregate and 0-5% of an additive, the magnesium-coal cinder-based cementing material is a cementing material formed by adding one or two of fly ash and coal gasification slag into magnesium slag serving as a basic raw material; the aggregate comprises one or a combination of more of construction waste, coal gangue, aeolian sand, slag and desulfurized gypsum; the additive comprises one or a combination of more of a retarder, a water reducing agent, an early strength agent and a drag reducer. The invention provides a new utilization way for solid waste treatment in the coal chemical industry and the magnesium smelting industry, and realizes solid waste recycling.

Owner:西安弗尔绿创矿业科技有限责任公司

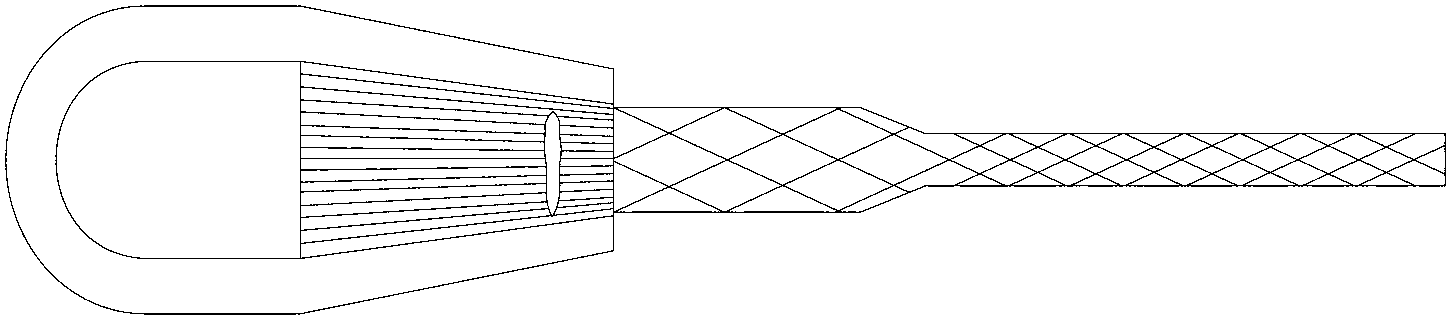

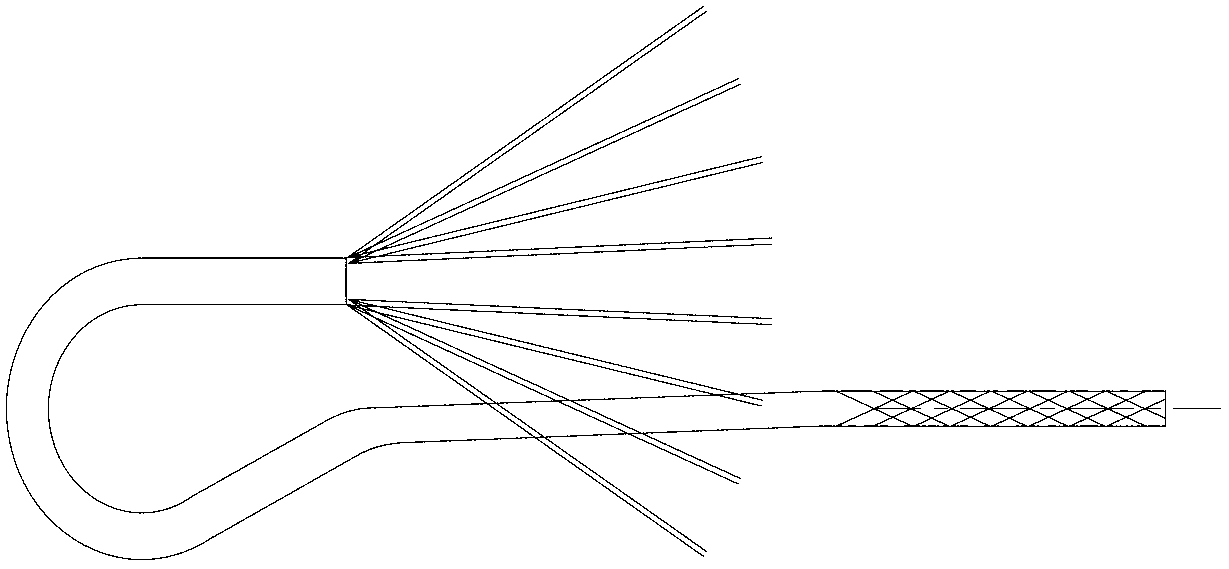

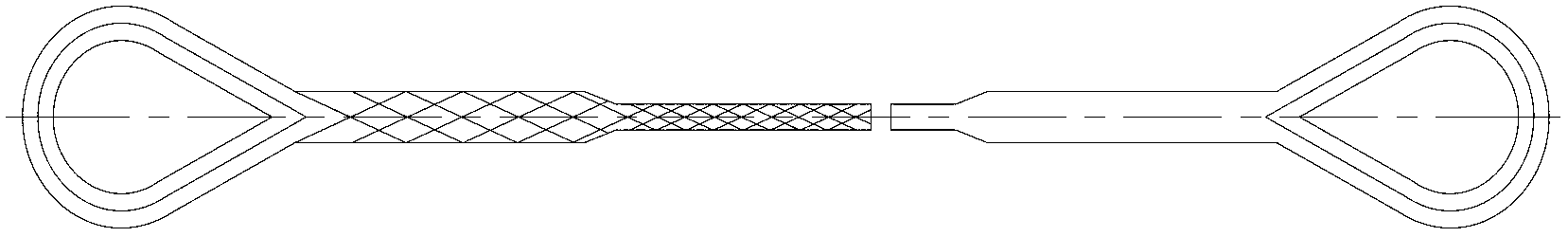

Method for casting and solidifying end portion of fiber rope

ActiveCN103255658AIncrease profitHigh consolidation strengthBinding endsFiberUltimate tensile strength

The invention discloses a method for casting and solidifying the end portion of a fiber rope. The method relates to the fiber rope and a joint. The method comprises the steps of scattering one end of the fiber rope, folding the end portion in half in an inserting and weaving mode, thickening the end portion of the fiber rope, inserting the partially thickened end portion of the fiber rope from the small-bore end of the joint, scattering fiber strands, inserted into the joint, of the fiber rope into a cone shape, allowing the fiber strands to be evenly distributed inside a casting cup, slowly pouring prepared resin into the casting cup, and allowing the end portion of the fiber rope and the joint to be solidified together. The joint and the thickening portion of the fiber rope are pre-tensioned, and fibers of the thickening portion are evenly stressed so that whole breaking force is improved. The method is used for solidification of the end portion, connected with the resin, of the fiber rope. According to the method for casting and solidifying the end portion of the fiber rope, the proper resin, the proper joint with an inverted-cone-shaped hole and a proper solidification part are selected for partial thickening and casting, solidification strength of the rope is improved so that the aim of equal strength casting of the fiber rope can be achieved, and therefore a fiber use ratio is improved.

Owner:JULI SLING

Emulsion type low-temperature sand consolidation agent and preparation method and application thereof

ActiveCN108659805AUniform and stable dispersionMeet sand control needsDrilling compositionAdhesivePickering emulsion

The invention relates to an emulsion type low-temperature sand consolidation agent and a preparation method and application thereof. The emulsion type low-temperature sand consolidation agent is characterized in that an oil-in-water type Pickering emulsion is prepared from a water phase, an oil phase and an emulsifying stabilizer; the emulsifying stabilizer is dispersed in an interface of the water phase and the oil phase; the water phase is prepared from an adhesive, a curing agent and a coupling agent. The emulsion type low-temperature sand consolidation agent has the advantages that the sand prevention requirement of low-temperature stratums can be met, the high temperature-resistant characteristic is realized, and the good water-resistant, oil-resistant, alkaline-resistant and salt-resistant properties are realized; after the resin in the emulsifier is cured, the oil phase in the emulsion system is also used as a pore expansion agent, so that the good permeability of the stratum isguaranteed, and the damage to the stratum is little; the emulsion type low-temperature sand consolidation agent is suitable for the secondary sand prevention of common straight wells, large-inclination wells and irregular well holes after failure of chemical sand prevention or mechanical sand prevention, and the application range of sand prevention is broad.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

Ultralow density plugging agent for low-pressure leaking formations and preparation method thereof

InactiveCN106281265AImprove the bearing strengthImprove suspension stabilityDrilling compositionTemperature resistanceFiber

The invention relates to an ultralow density plugging agent for low-pressure leaking formations and a preparation method thereof. According to the technical scheme, the ultralow density plugging agent is composed of, by weight, water as a continuous phase, 50-70% of a gel plugging agent, 0.1-0.3% of plugging fiber, 2.5-3.5% of a surfactant, 2-6% of a lightweight rigid plugging additive, 1-2% of polymer and 0.5-2% of water-absorbent expansion resin. the invention has the following beneficial effects: through built-in-test, the lowest density of the prepared plugging agent can reach 1.0g / cm<3>, and density is adjustable; the plugging agent has good temperature resistance which can reach 180 DEG C, and is especially suitable for plugging of deep and ultra-deep wells; bearing capability is greater than or equal to 15 MPa, and the plugging agent has characteristics of large plugging depth and good plugging effect and is applicable to various types of formation leakage such as large-sized cracks and pore-fractures, etc.

Owner:SINOPEC SSC +2

Drainage consolidation construction method for treating soft soil foundation by container stacking loading

InactiveCN101824817AImprove consistencyHigh consolidation strengthSoil preservationUltimate tensile strengthPollution

The invention relates to a drainage consolidation construction method for treating soft soil foundation by container stacking loading, belonging to the technical field of water containing soft soil foundation drainage and consolidation construction. The existing method directly takes earth and rock materials as stacking loading substances, has high transportation expenses and insufficient stacking loading pressure, and construction fails to satisfy the engineering project with higher requirements on bearing capacity required by the foundation. The method comprises the following construction steps: laying base materials, inserting drainage components, stacking and loading a box container on the base materials for prepressing, discharging ponding out of the foundation and the like. In the invention, the self weight of the box container and the weight of the stacking loading substances form a stacking loading monomer which has regular shapes, can be carried and is suitable for long distance transportation and stacking. According to the construction requirement of the foundation to be treated, the method can achieve flexible assembly, repeated use, reduced construction cost, high construction efficiency, clean process and small pollution; the stacking and unloading height significantly improves and realizes balanced stress of the foundation; and the foundation consolidated by the method has good consistency and high consolidation strength, thus facilitating to accurately calculate the stacking loading pressure of a unit area.

Owner:任再永

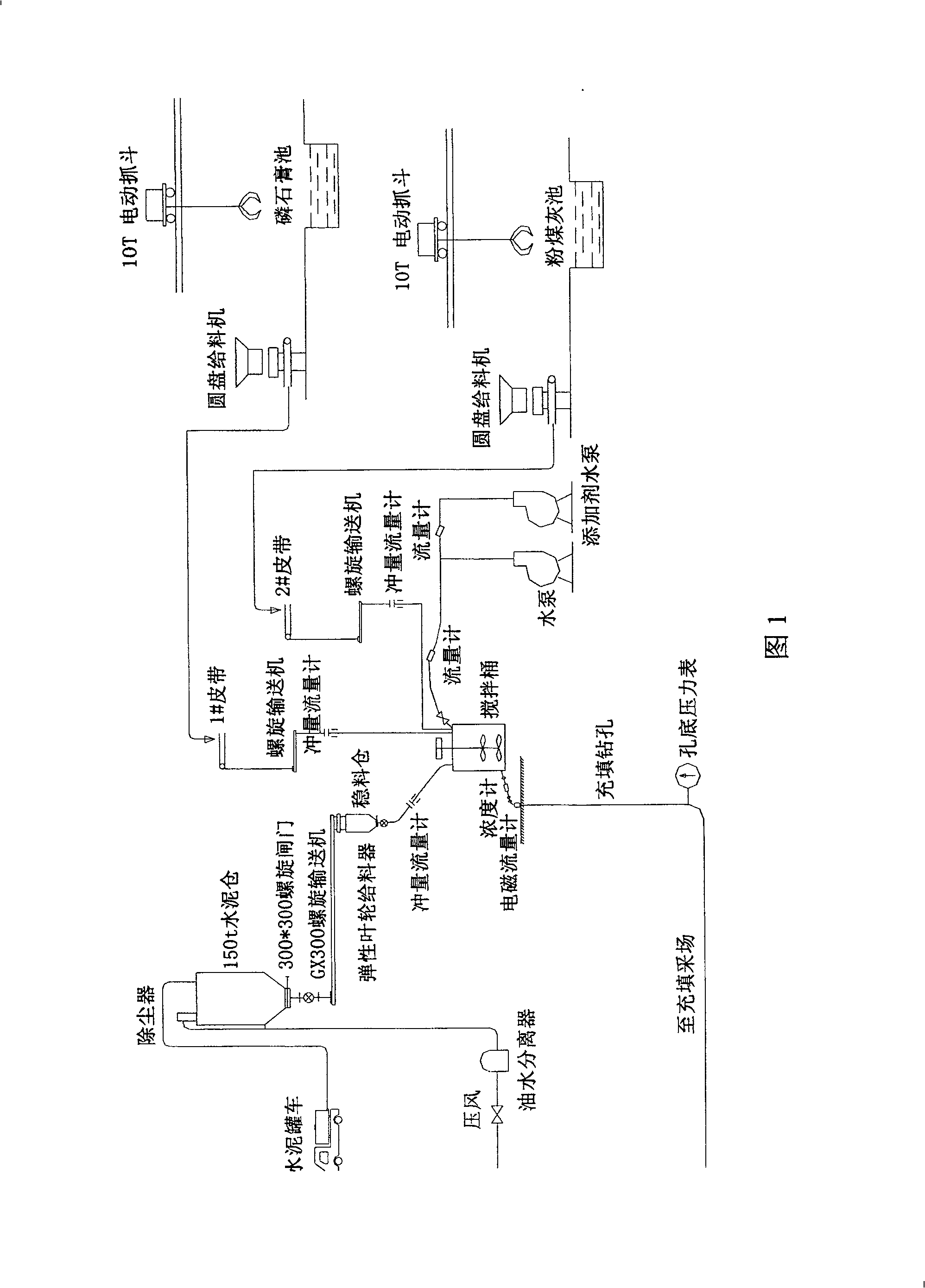

Method for forming solidified filler by filling phosphorous gypsum in downhole goaf

The method of forming solidified filler through filling ardealite in downhole goaf includes mixing cement, flyash and ardealite in the ratio of 1 to 1to 6-8; adding sodium sulfate as additive in the amount of 1.3-2.5 wt% of the foregoing three materials, mixing with water to form slurry of 57-63 wt% concentration, filling the slurry to the downhole goaf, and solidifying to form the high strength filler. The present invention can raise ore recovering rate, reduce ore loss, lower mining cost, avoid surface deposition, and utilize ardealite effectively.

Owner:CENT SOUTH UNIV

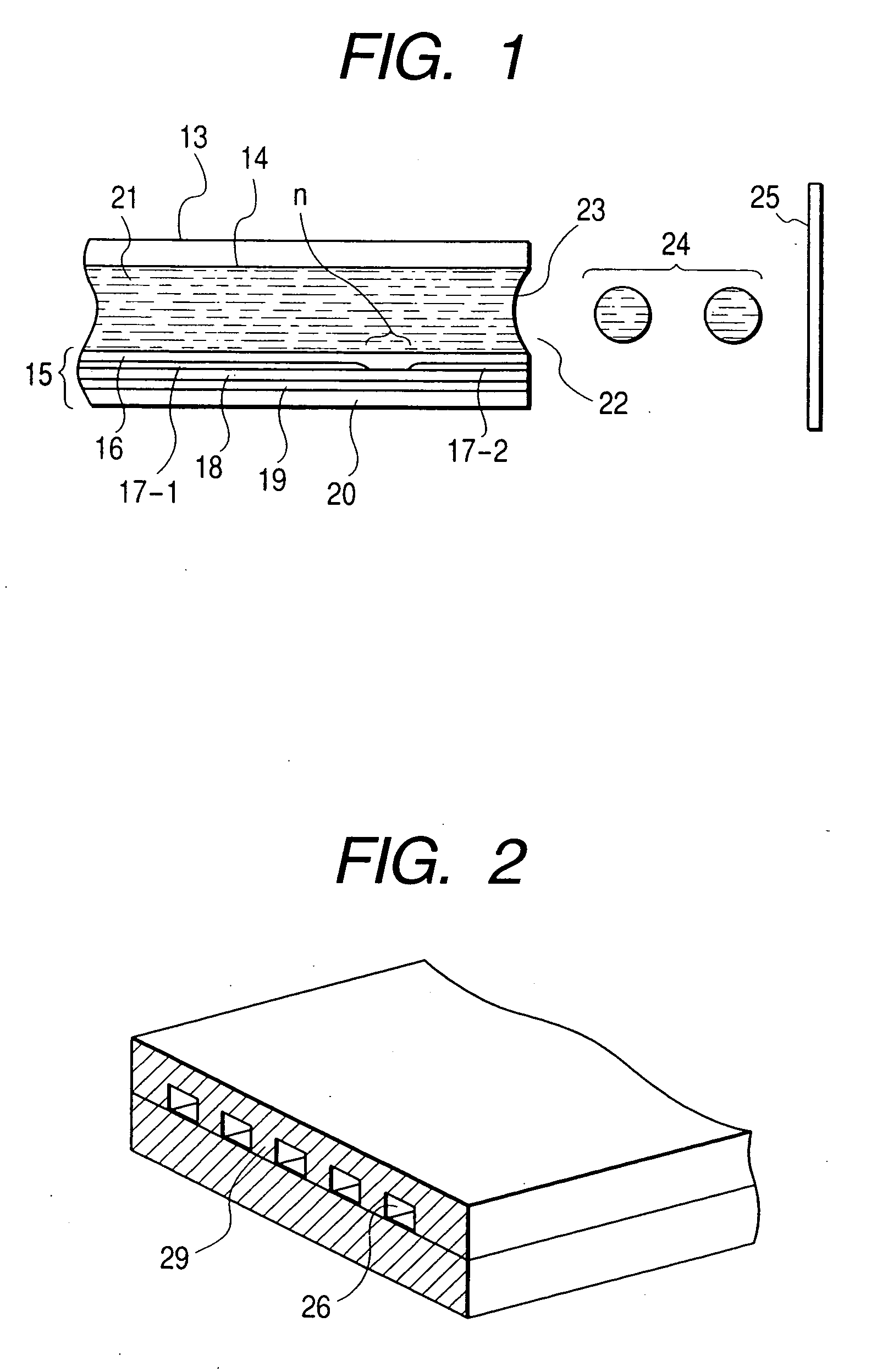

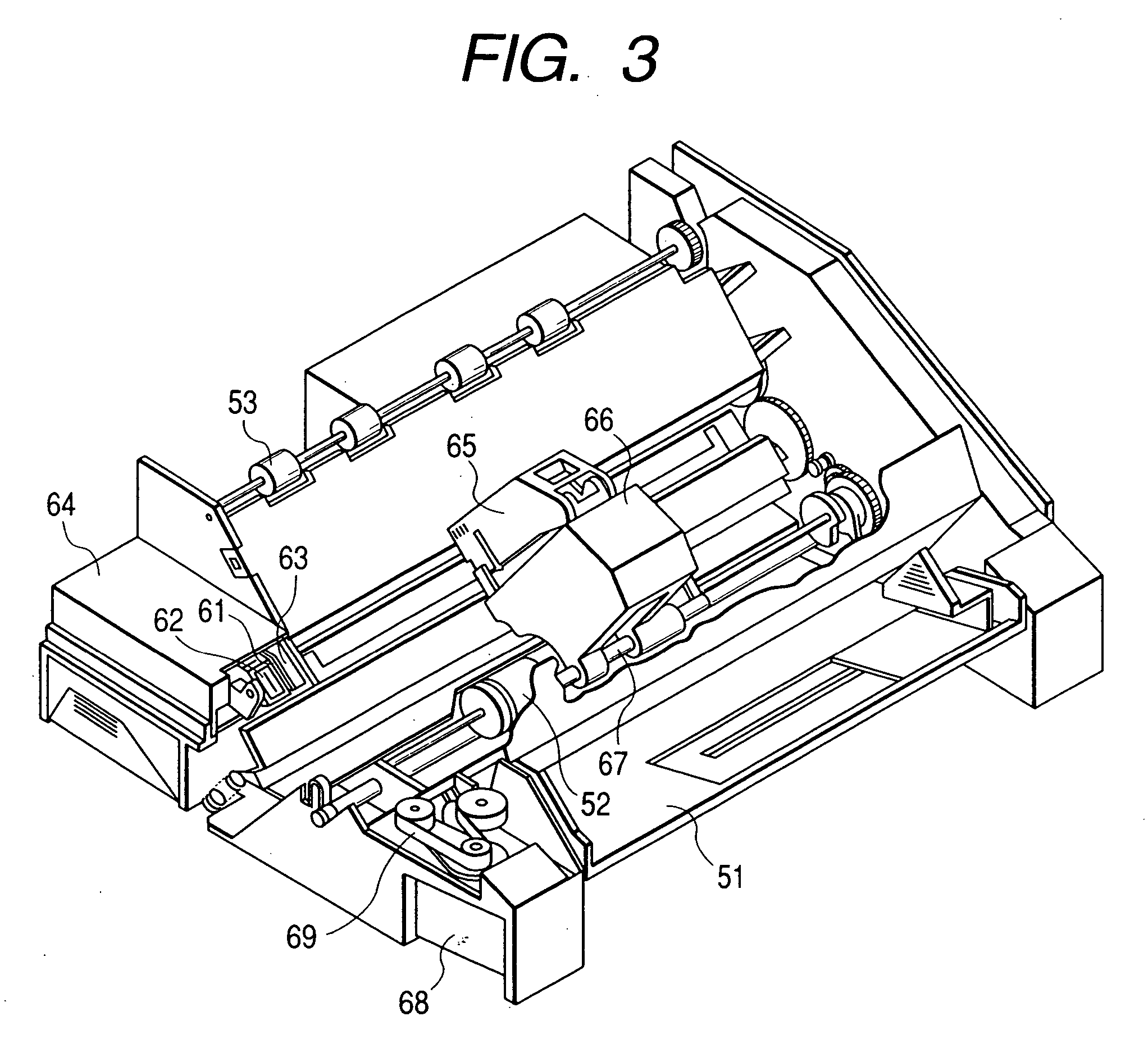

Resin-coated sand for multilayer mold

ActiveUS20080021133A1High consolidation strengthImprove gas permeabilitySynthetic resin layered productsCellulosic plastic layered productsShell moldingTar

To provide resin-coated sand for a multilayer mold in which the consolidation strength of the casting mold obtained by using it and gas permeability thereof are improved at the same time, the amount of occurrence of pyrolytic products (tar, soot and the like) derived from organic substances is effectively inhibited, when molding is performed using such a casting mold, and further, the casting mold after molding can exhibit excellent collapsibility. Disclosed is resin-coated sand for a multilayer mold, in which surfaces of refractory particles are coated with a binder composition containing a phenolic novolak resin having an ortho / para bond ratio of methylene groups of 1.5 or more and an aromatic amine as indispensable constituents, and the grain fineness number is from 80 to 150.

Owner:ASAHI YUKIZAI KOGYO CO LTD +1

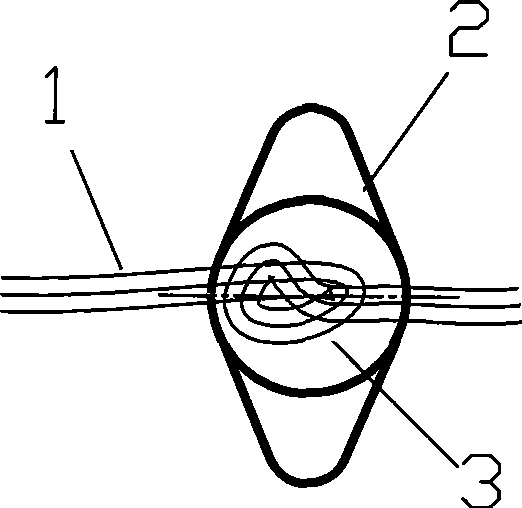

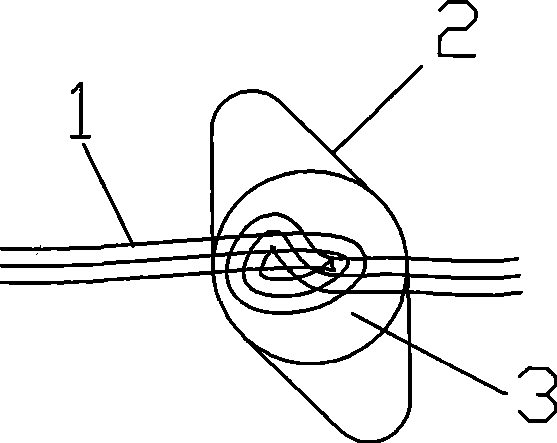

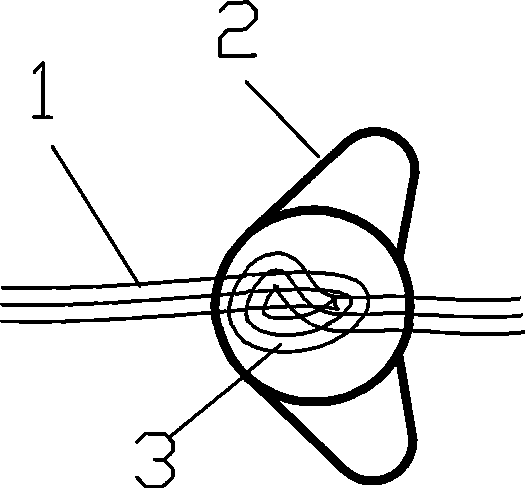

Novel rotor type fibre filtering material

InactiveCN101496972ANot easy to fall offHigh consolidation strengthWater/sewage treatmentFiltration separationFiber bundleWater filter

The invention relates to a filtering material used for water filtering. The invention discloses a novel rotary wing type fiber filtering material. The filtering material comprises fiber bundles and fiber nodes formed by fiber silks. The fiber nodes are the nodes formed by fiber silk buckles, the nodes at the cross positions of the fiber silks, the folding nodes of the fiber silks or the nodes formed by one fiber silk tied with other fiber silks. The fiber bundles and fiber nodes pass through the center of a rotary wing core; and the nodes of the fiber bundles and fiber nodes are enwrapped and bound by the rotary wing core. The filtering material has high binding strength and good back washing effects, and saves water and energy. The filtering material is suitable for the mechanized production. As the fiber bundles have a great volume ratio, the volumetric fraction of a filter bed is high and a filtering rate is high.

Owner:卢普伦

Sand-preventing method of artificial borehole wall, and material for sand prevention

ActiveCN107163926AImprove salt toleranceCalcium resistantFluid removalDrilling compositionAlkylphenolSURFACTANT BLEND

The invention discloses a sand-preventing method of an artificial borehole wall, and a material for sand prevention. The material for sand prevention comprises guide liquid, sand carrying liquid and promoting liquid which are prepared separately, wherein the guide liquid comprises the following components in percentage by weight: 0.5 to 20 percent of sodium chloride, 0.2 to 2 percent of calcium chloride, 0.1 to 1 percent of magnesium chloride, 0.2 to 4 percent of alkylphenol polyoxyethylene, 0.3 to 8 percent of an anionic surfactant capable of resisting calcium and magnesium ions and 0.01 to 6 percent of a dimethyl diallyl ammonium chloride-acrylamide-acrylic acid copolymer; the sand carrying liquid comprises the following components in percentage by weight: 0.01 to 5 percent of a dimethyl diallyl ammonium chloride-acrylamide copolymer and 0.5 to 20 percent of ammonium chloride; and the promoting liquid comprises the following components in percentage by weight: 8 to 22 percent of a penetrating agent and 18 to 35 percent of a dehydroxylation catalyst. The material for sand prevention performs sand prevention, can protect the stratum, has high sand carrying capability, reduces friction and enhances the consolidation strength, and the penetration ratio of the artificial borehole wall formed after sand prevention is more than 12 <mu>m<2>.

Owner:东营市科诺石油技术有限责任公司

Side slope protection method for arid desert area

InactiveCN102808417AEasy to fixImprove anti-kinetic effectClimate change adaptationExcavationsAridFreeze thawing

The invention discloses a side slope protection method for an arid desert area. The side slope protection method comprises the following steps of: 1) prefabricating reinforced concrete grids to form parallelogram lattice structures; 2) arranging the reinforced concrete grids on the foundation layer of a selected side slope, embedding the reinforced concrete grids into a soil body for certain depth, using long anchor bolts to closely connect intersections of the reinforced concrete grids and inserting the anchor bolts into the soil body for certain depth; 3) arranging supporting skeletons on two sides of the parallelogram grids at intervals of certain distance; 4) laying a top beam and a bottom beam through the entire structure at the tops and the bottoms of the grids; and 5) spraying organic and inorganic mixed sand stabilizing materials with certain thickness onto the foundation layer of the side slope in the grids. The side slope protection method for the arid desert area has the advantages that sand dunes can be effectively stabilized and prevented from moving forwards, the driving force resisting effect of the side slope is improved, the bonding strength and the water resistance are improved, the freeze-thaw resisting stability, the wind erosion resistance and the weather resistance are improved, and the goals of stabilizing the sand dunes and preventing sand damages are achieved.

Owner:CHINA CONSTR SIXTH ENG DIV CORP

Solidifiable flow sand bridge plugging method for shaft of oil and gas well

ActiveCN103422835AReduce the number of tripsReduce the risk of being stuckSealing/packingHigh intensityCarrier fluid

The invention discloses a solidifiable flow sand bridge plugging method for a shaft of an oil and gas well, and relating to the technical field of fracture reconstruction work and rework operation used in petroleum extraction. 2-8 percent by volume of solidifiable particles, 20-30 percent by volume of quartz stand and 60-80 percent by volume of carrier fluid are mixed on the ground and then injected into the shaft; the mixed fluid is conveyed to a perforated interval; after the carrier fluid is heated and becomes less viscous by a stratum, filtrate enters the stratum; the solidifiable particles are cemented and solidified with the quartz sand under the effects of temperature and pressure to form high-strength solid so as to realize plugging of the shaft at the perforated interval. By using the method, pipe column trip is not required, and the operation risk caused by pipe column trip is avoided; the number of isolated intervals is not limited, so that an infinite series of layered / interval reconstruction operation can be theoretically realized.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

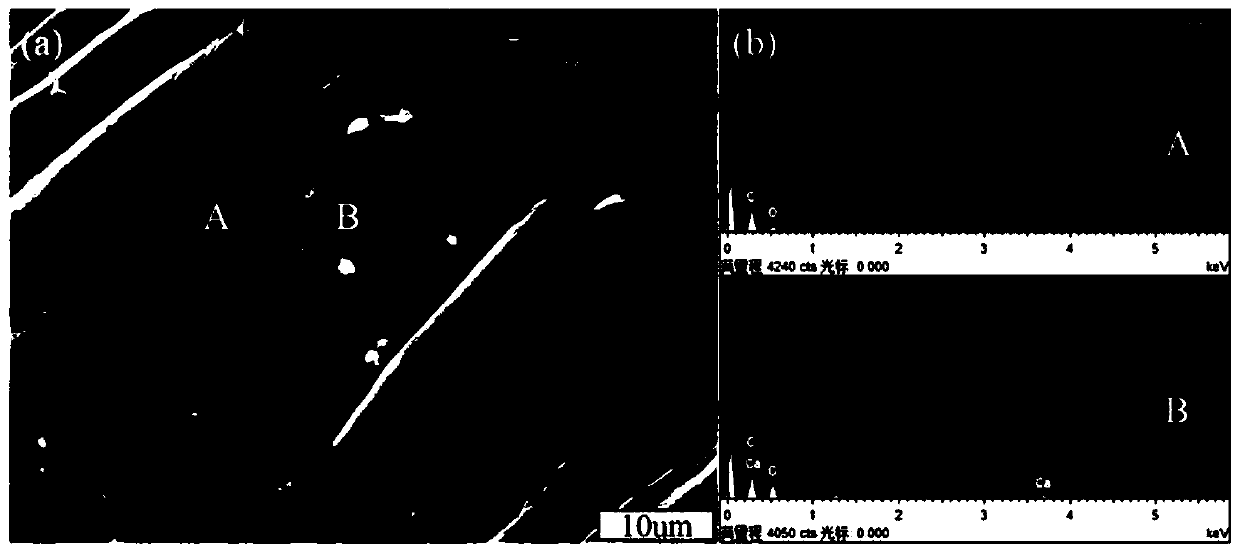

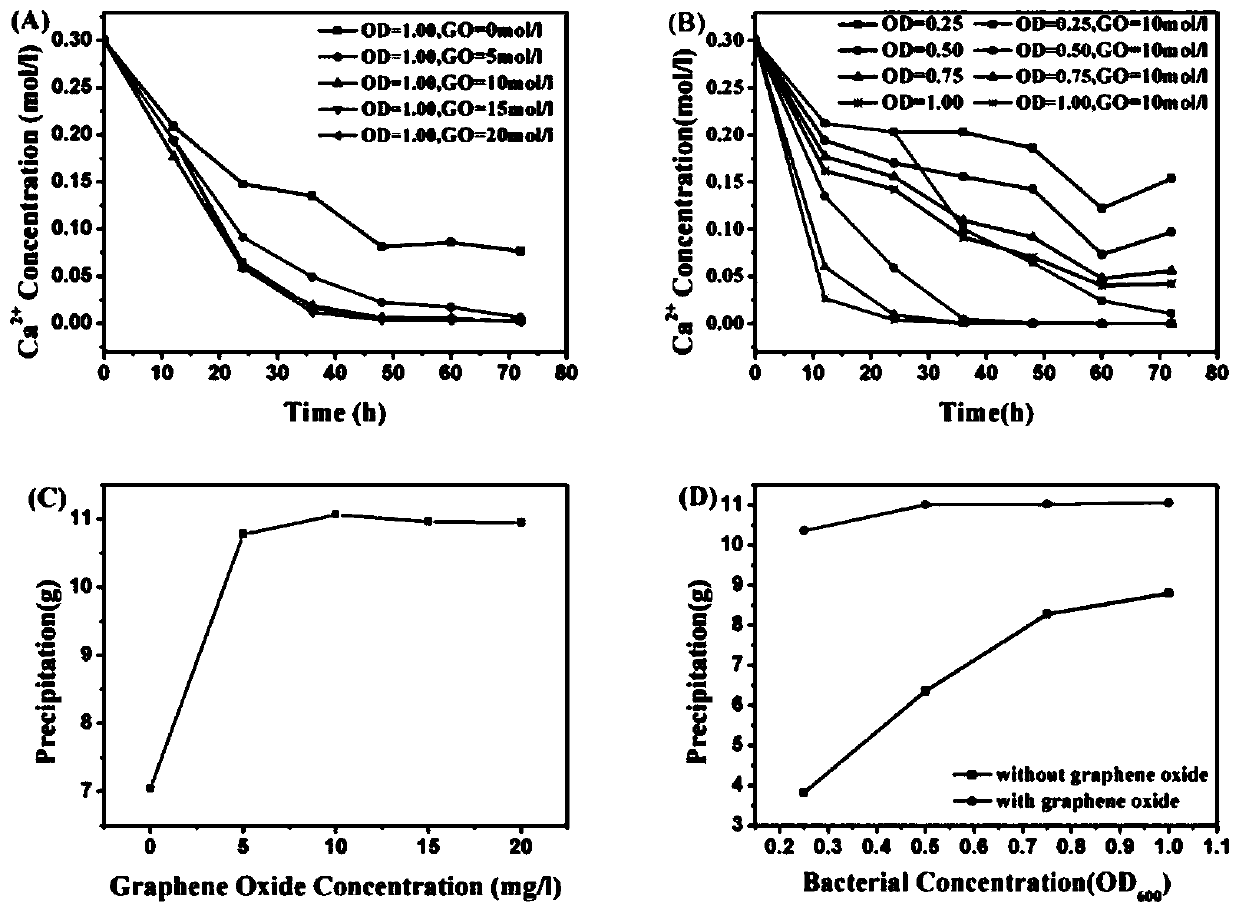

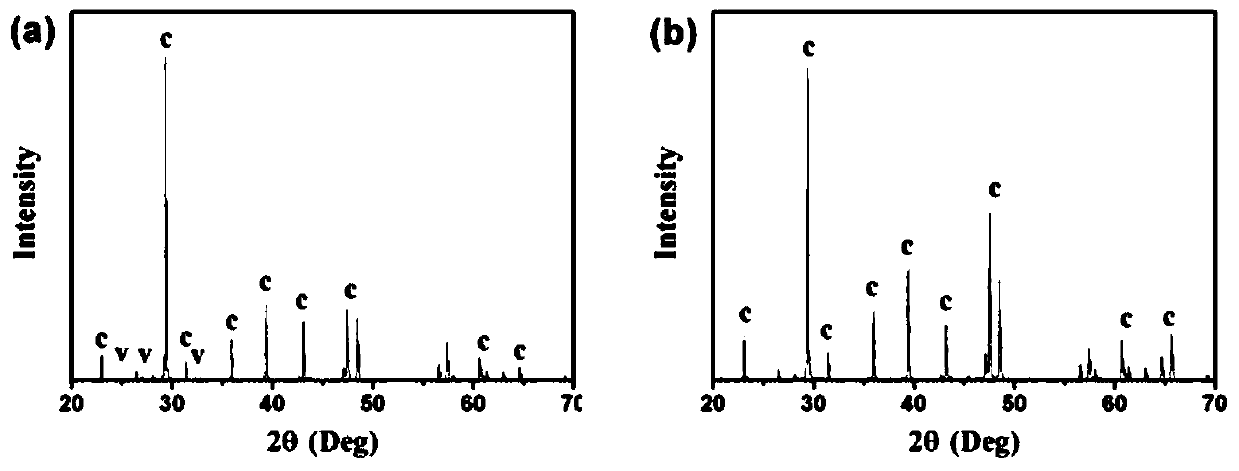

Application of graphene oxide in improving soil consolidation strength, composition and application method of composition

InactiveCN110684541AHigh consolidation strengthIncrease reaction rateContaminated soil reclamationOrganic fertilisersCalcium crystalsMicroorganism

The invention provides an application of graphene oxide in improving soil consolidation strength, a composition and an application method of the composition, and relates to the technical field of microbially induced calcium carbonate soil improvement. According to the application of graphene oxide in improving the soil consolidation strength, the composition and the application method of the composition, the graphene oxide can enable microorganisms to induce the rapid growth of calcium carbonate crystals in calcium carbonate, and the yield of the calcium carbonate is increased; and the size ofthe calcium carbonate crystals can further be changed, the consolidation of soil is facilitated, and the compressive strength of the soil is improved.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

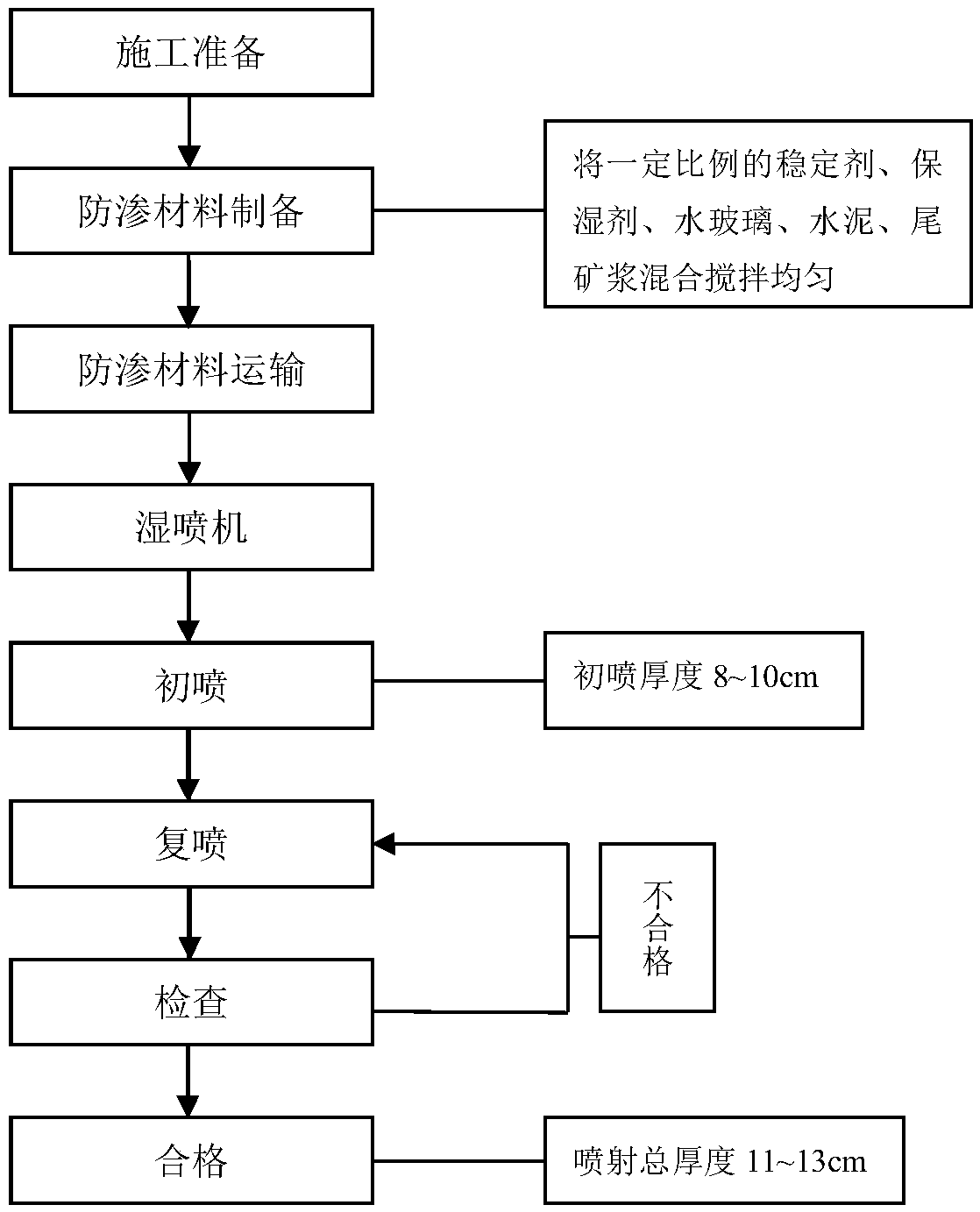

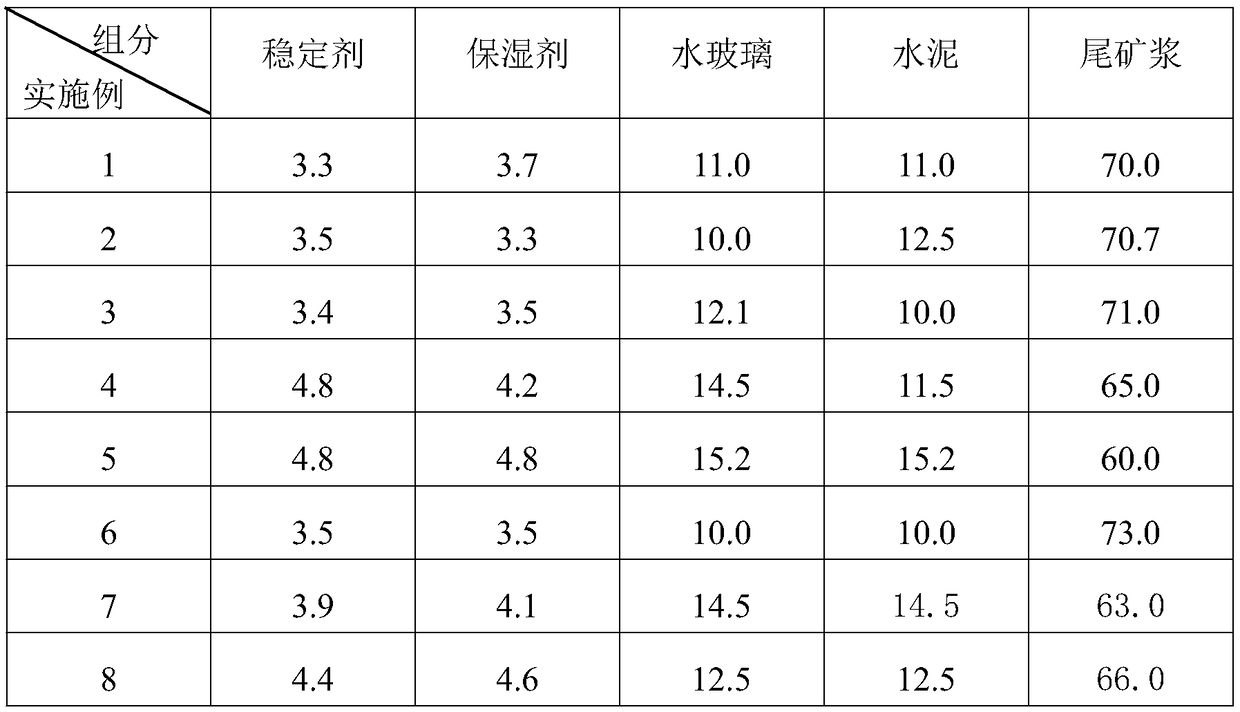

Slope, pit bottom and foundation bottom seepage preventing method based on tailings composite anti-seepage material

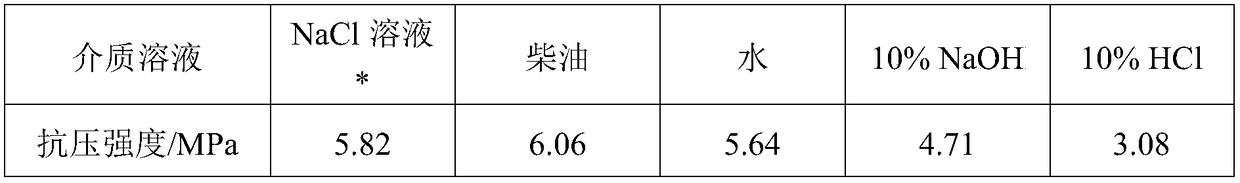

ActiveCN108867712AReduce penetrationImprove acid resistanceProtective foundationSlurryPermeability coefficient

The invention discloses a slope, pit bottom and foundation bottom seepage preventing method based on a tailings composite anti-seepage material. The used tailings composite anti-seepage material comprises, by mass percentage, 3.3-4.8% of stabilizer, 3.3-4.8% of wetting agent, 10.0-15.2% of sodium silicate, 10.0-15.2% of cement and 60.0-73.0% of tailings slurry, wherein the stabilizer is the mixture of calcium chloride and sodium borate tetrahydrate, The method includes: preparing and mixing the anti-seepage material, processing a to-be-sprayed face, conveying the mixed anti-seepage material, spraying the mixed anti-seepage material, and inspecting spraying quality. The method has the advantages that an anti-seepage material layer finally formed by the method is extremely low in permeability, the permeability of the anti-seepage material layer is only 1 / 1000 of that of high-quality clay, the permeability coefficient k of the anti-seepage material layer can reach 1*10<-9>, and the anti-seepage material layer is good in acid resistance and base resistance, high in stability, high in concretion strength and resistant to erosion.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com