Emulsion type low-temperature sand consolidation agent and preparation method and application thereof

A sand-fixing agent and emulsion-type technology, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of low compressive strength of cemented core, easy curing, and sand ejection in fracturing wells, etc., and reaches the scope of application of sand control wide, good permeability, and little formation damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

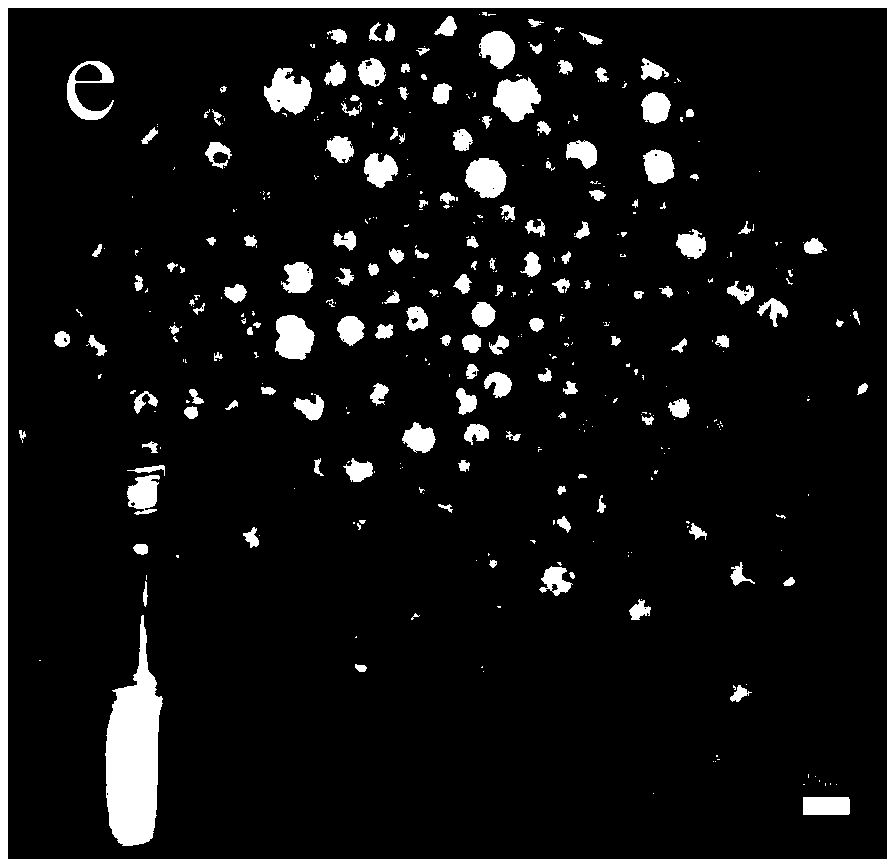

Image

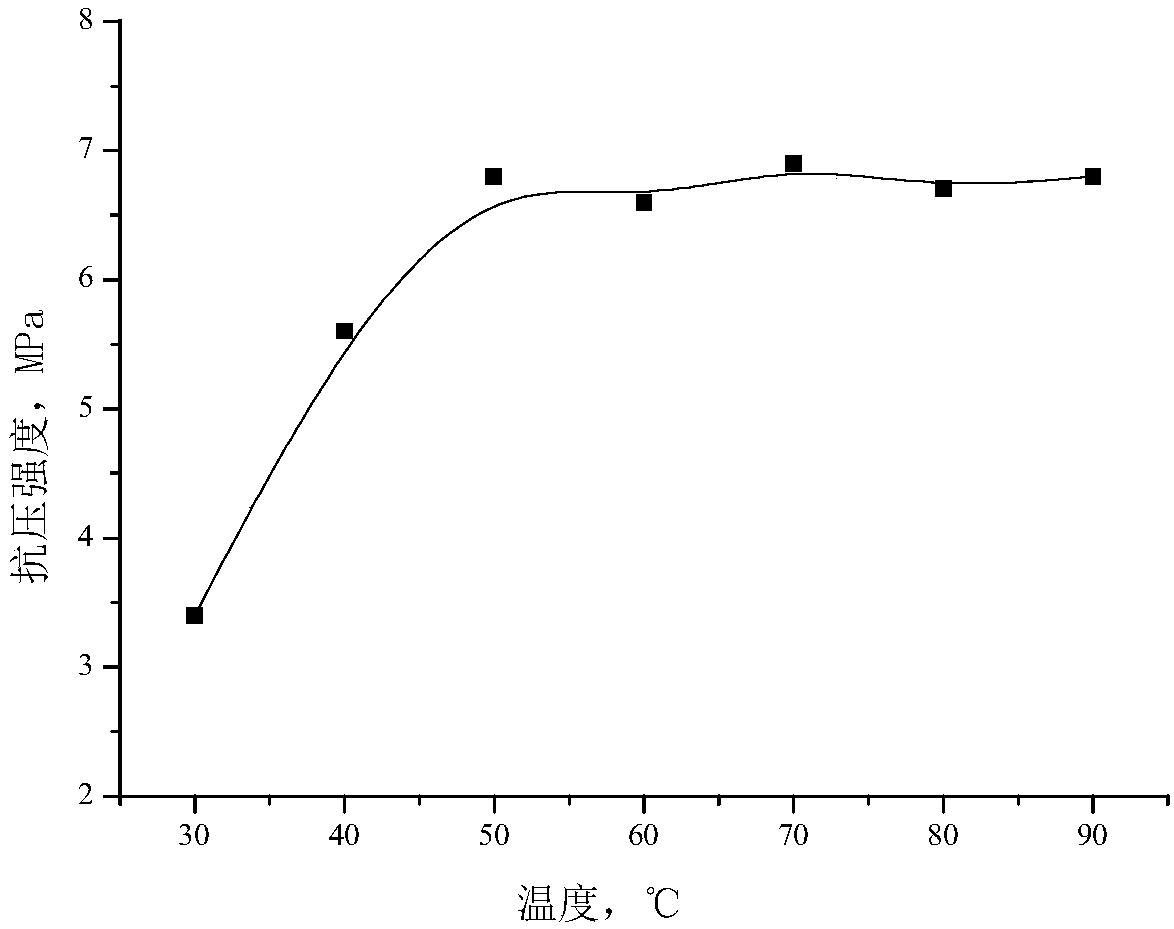

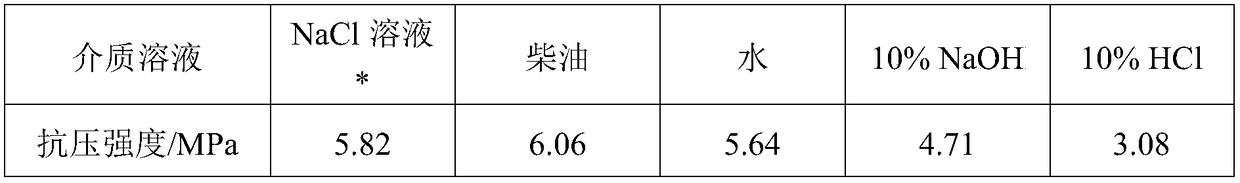

Examples

Embodiment Construction

[0012] An emulsion-type low-temperature sand-consolidating agent, the raw material components and their weight percentages are as follows:

[0013] 63-76% of cementing agent, 22-35% of oil phase, 0.9%-1.5% of emulsification stabilizer, 0.05%-0.5% of curing agent, and 0.1%-0.3% of coupling agent.

[0014] Preferably according to the present invention, the cement is a melamine-formaldehyde resin solution with a mass concentration of 35-55%, and the solvent is water.

[0015] Preferably according to the present invention, the oil phase is kerosene.

[0016] Preferably according to the present invention, the emulsification stabilizer agent is hydrophilic nano-silica particles, and the hydrophilic nano-silica particles are nano-silica particles surface-treated with a coupling agent or added Nano silica particles with particle dispersant.

[0017] Preferably according to the present invention, the curing agent is a weakly acidic curing agent.

[0018] Further preferably, the curi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com