Coated sand for sand prevention in oil well and preparation method of coated sand

A coating and oil well technology, applied in the field of coating sand for oil well sand control and its preparation, can solve the problems of insufficient solidification strength at low well temperature, broken casing pipe, overhaul of oil well, etc., so as to save sand control operation time and improve fluidity , the effect of long validity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

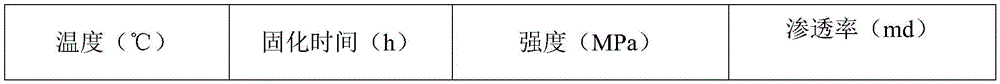

Examples

Embodiment 1

[0041] The coated sand for sand control in this embodiment includes Type A coated sand and Type B coated sand, wherein Type A coated sand is coated with silicone modified epoxy resin and ketimine curing agent in sequence on the outside of quartz sand. agent and external release agent hydroxypropyl methylcellulose; B-type coated sand is coated with alicyclic epoxy resin, molecular sieve-blocked diethylenetriamine and external release agent hydroxypropylmethyl on the surface of quartz sand in sequence. cellulose.

[0042] The particle size of the quartz sand is 0.4-0.8mm.

[0043] The preparation method of the coated sand for sand control of the oil well comprises the following steps:

[0044] The production method of component A is (at room temperature):

[0045] (1) Mix silicone-modified epoxy resin (medium-viscosity liquid) and ketimine curing agent in a mixing tank at a ratio of 5:1.

[0046] (2) Mix the quartz sand and resin / curing agent mixture in a sand mixer at a rati...

Embodiment 2

[0060] The coated sand for sand control in this embodiment includes Type A coated sand and Type B coated sand, wherein Type A coated sand is coated with silicone modified epoxy resin and ketimine curing agent in sequence on the outside of quartz sand. agent and external release agent hydroxypropyl methylcellulose; B-type coated sand is coated with alicyclic epoxy resin, molecular sieve-blocked diethylenetriamine and external release agent hydroxypropylmethyl on the surface of quartz sand in sequence. cellulose.

[0061] The particle size of the quartz sand is 0.4-0.8mm.

[0062] The preparation method of the coated sand for sand control of the oil well comprises the following steps:

[0063] The production method of component A is (at room temperature):

[0064] (1) Mix silicone-modified epoxy resin (medium-viscosity liquid) and ketimine curing agent in a mixing tank at a ratio of 4:1.

[0065] (2) Mix the quartz sand and resin / curing agent mixture in a sand mixer in a rati...

Embodiment 3

[0076] The coated sand for sand control in this embodiment includes Type A coated sand and Type B coated sand, wherein Type A coated sand is coated with silicone modified epoxy resin and ketimine curing agent in sequence on the outside of quartz sand. agent and external release agent hydroxypropyl methylcellulose; B-type coated sand is coated with alicyclic epoxy resin, molecular sieve-blocked diethylenetriamine and external release agent hydroxypropylmethyl on the surface of quartz sand in sequence. cellulose.

[0077] The particle size of the quartz sand is 0.4-0.8mm.

[0078] The preparation method of the coated sand for sand control of the oil well comprises the following steps:

[0079] The production method of component A is (at room temperature):

[0080] (1) Mix silicone-modified epoxy resin (medium-viscosity liquid) and ketimine curing agent in a mixing tank at a ratio of 6:1.

[0081] (2) Mix the quartz sand and resin / curing agent mixture in a sand mixer in a rati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com