Soil curing agent

A soil stabilizer, a new type of technology, applied in the direction of soil conditioning materials, chemical instruments and methods, organic fertilizers, etc., can solve the problems of high cost, low strength, poor frost resistance, etc., to achieve small deformation, high consolidation strength, Good frost resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with the examples given by the inventor.

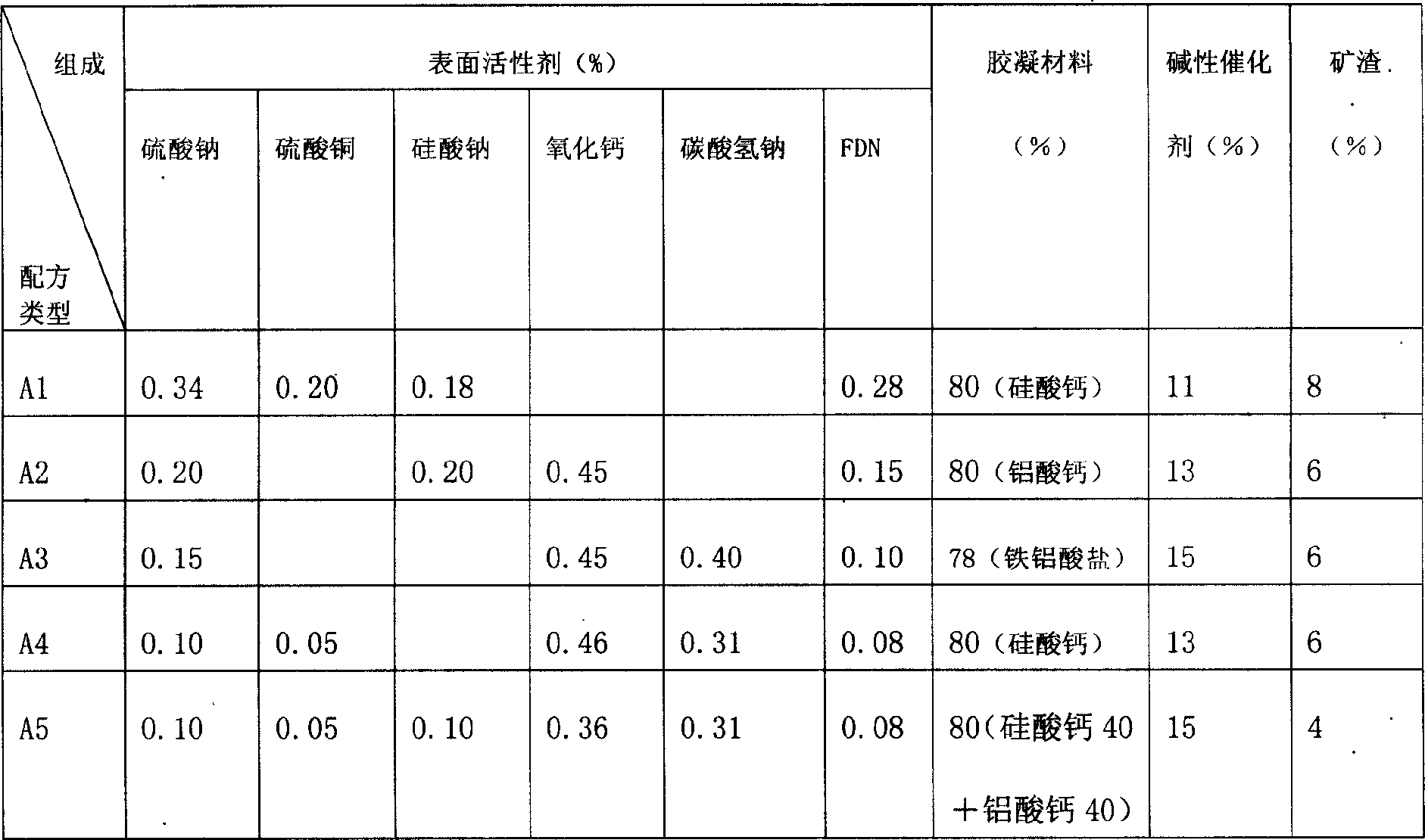

[0013] The novel soil solidifying agent of the present invention is mixed and ground to Blaine's specific surface area of 400-900m with the components of the following weight ratio 2 / kg made into:

[0014] Cementitious material: 78%~80%

[0015] Basic catalyst: 10%~15%

[0016] Surfactant: 1%~1.5%

[0017] Slag: 3.5%~11%

[0018] In each component of the material, the water content should be less than 2%;

[0019] The cementitious material includes calcium silicate, calcium aluminate, and one or more combinations of aluminoferrite;

[0020] The basic catalyst is composed of natural gypsum, fly ash. Gypsum content is measured as SO in hydraulic cementitious materials 3 The content is controlled within the range of 4.0±0.2%;

[0021] The surfactant is sodium silicate, copper sulfate, sodium sulfate and FDN raw materials, which are compounded...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com