Method for casting and solidifying end portion of fiber rope

A fiber rope and fiber technology, which is applied in the field of soft rigging manufacturing, can solve the problems of insufficient material performance, high material strength, and reduced casting consolidation strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

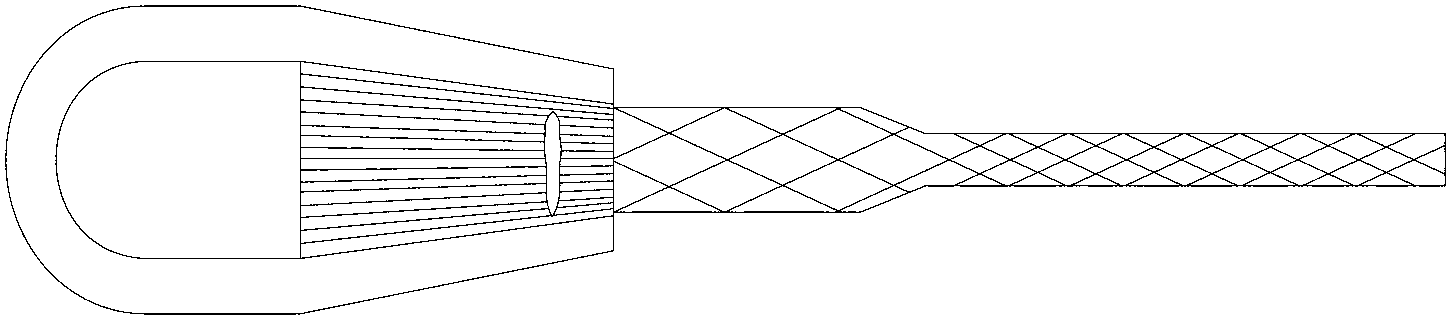

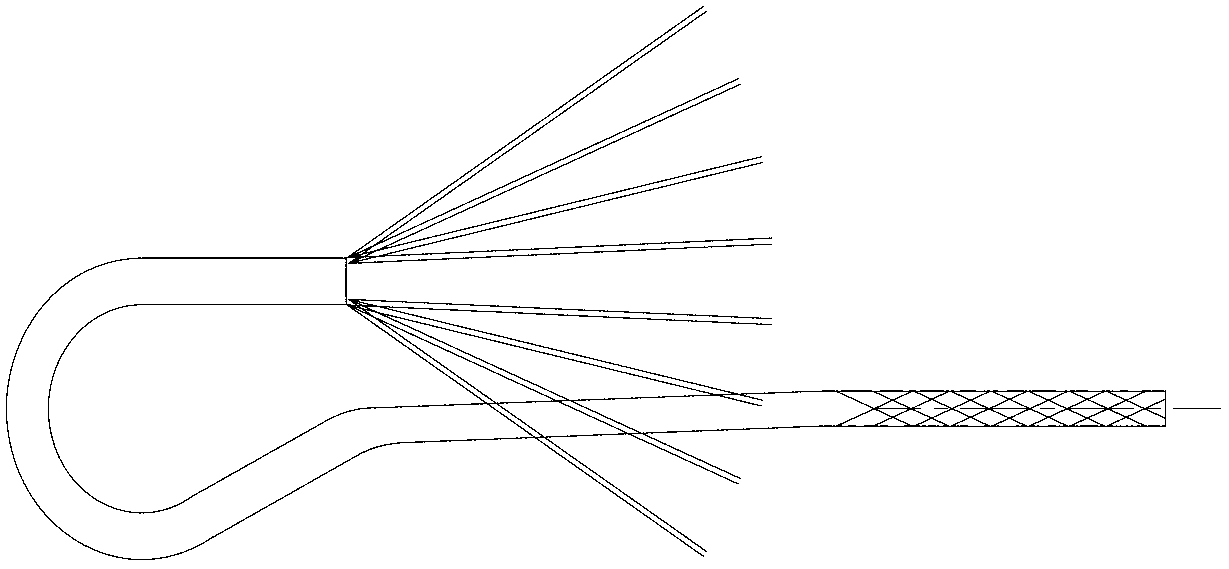

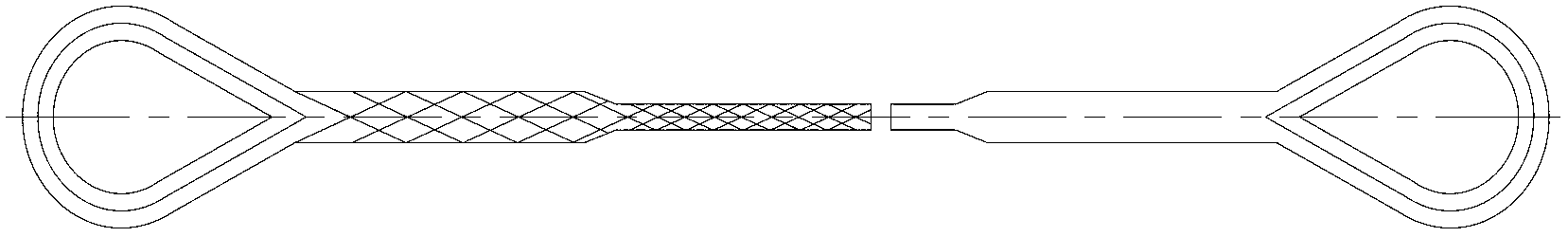

[0014] Such as figure 1 As shown, in general, the casting of fiber materials is greatly affected by factors such as the strength of the casting material. Generally, the breaking force test value of low-strength fibers has little influence, and may partially reach the strength of the cable body; while for ultra-high-strength fibers, because the material strength is much greater than that of the casting material, the fibers extend in the casting material, causing local overload, making the rope It breaks inside the cup body, thereby failing to reach the breaking strength of the rope body. For example: the UHMWPE material rope body, the breaking force of the casting cup only reaches about 70% of the breaking force of the cable body. The following is a casting test for UHMWPE material ropes:

[0015] Take an ordinary ultra-high molecular weight polyethylene material rope with a diameter of about 35mm, and its breaking force value is about 100 tons (the 100-ton breaking force rop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com