Method for forming solidified filler by filling phosphorous gypsum in downhole goaf

A technology of phosphogypsum and gobs, which is applied in the direction of filling, mining equipment, earth drilling and mining, etc., can solve the problems of heavy burden on phosphate fertilizer enterprises, occupation of phosphogypsum, and environmental pollution, so as to reduce the loss rate of mining dilution and prevent Settlement, the effect of improving the ore recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

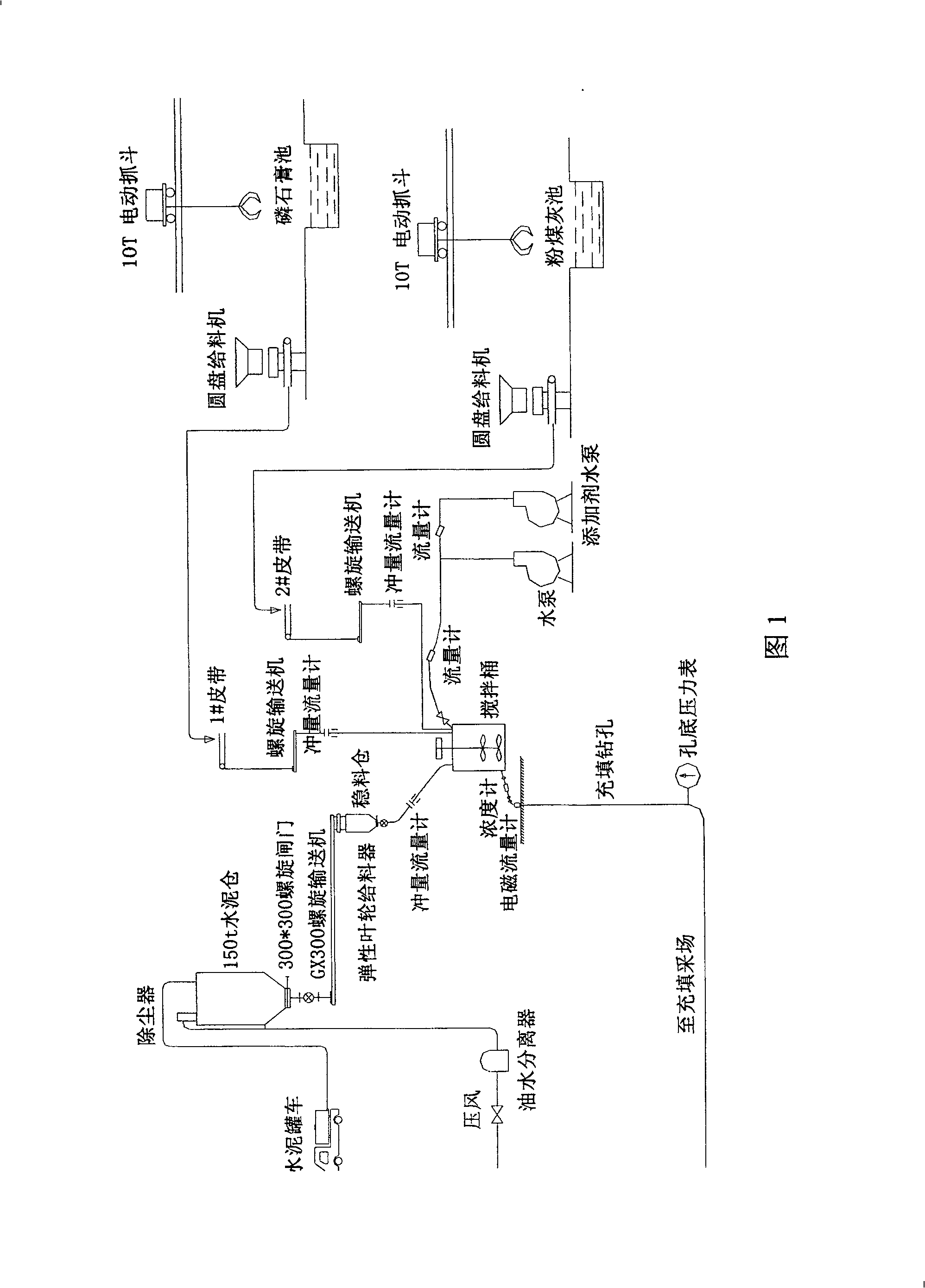

[0016] Example 1: A large amount of phosphogypsum waste is produced in the production of phosphoric acid by a phosphate rock, and a filling system is built with the process flow shown in Figure 1. Use 10 tons of cement, 10 tons of fly ash, 70 tons of phosphogypsum, and 2.1 tons of sodium sulfate additives to fill in the No. 5 underground stope, and the mass concentration of the filling slurry is 60%. After the filling slurry is filled into the stope, it solidifies to form a filling body. 10 samples are taken on site and the strength of the filling body is tested. The average strength of the filling body for 28 days is 1.08MPa, which can meet the mining technical requirements.

Embodiment 2

[0017] Example 2: The ore deposit of a certain phosphate rock is located under the road. In order to realize the safe mining of ore under the road, a filling system was built with the technological process shown in Figure 1. Fill No. 1 stope with 15 tons of cement, 15 tons of fly ash, 90 tons of phosphogypsum, and 2.5 tons of sodium sulfate additive, and the mass concentration of the filling slurry is 58%. Five samples were taken on site, and the average strength of the phosphogypsum solidified body in the test stope reached 1.28MPa in 28 days. According to research and analysis, the use of this strength phosphogypsum consolidation body to fill the goaf will not cause underground mining to damage the road.

Embodiment 3

[0018] Example 3: A certain phosphate rock resource is of high grade. It was originally mined by the caving method. The ore dilution rate reached 38%, and the mining loss rate reached 42%. In order to reduce the loss rate of dilution, a filling system is built with the technological process shown in Figure 1. Fill the test stope with 5 tons of cement, 5 tons of fly ash, 40 tons of phosphogypsum and 0.8 tons of sodium sulfate additive, and the mass concentration of the filling slurry is 58%. Five samples were taken from the filling stope, and the average strength of the phosphogypsum solidified body reached 0.81MPa after 28 days of testing. The ore is mined by the phosphogypsum consolidation filling process, the mining dilution rate is reduced to 8%, and the ore loss rate is reduced to 5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| osmotic coefficient | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com