Novel rotor type fibre filtering material

A technology of fiber filtration and rotor, applied in the direction of filtration and separation, separation methods, chemical instruments and methods, etc., can solve the problems of low filtration precision, small specific surface area, easy to fall off, etc., achieve good backwashing effect, high filtration speed, solid The effect of high knot strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

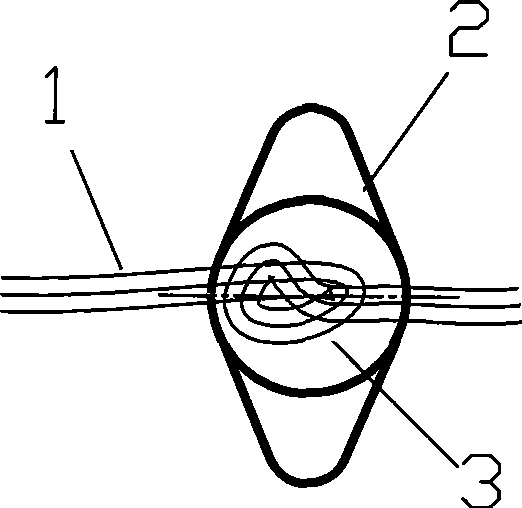

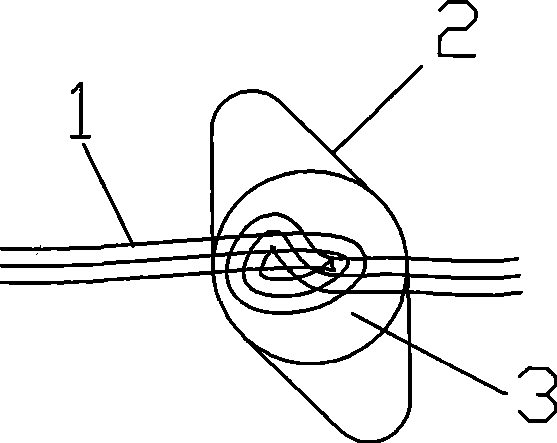

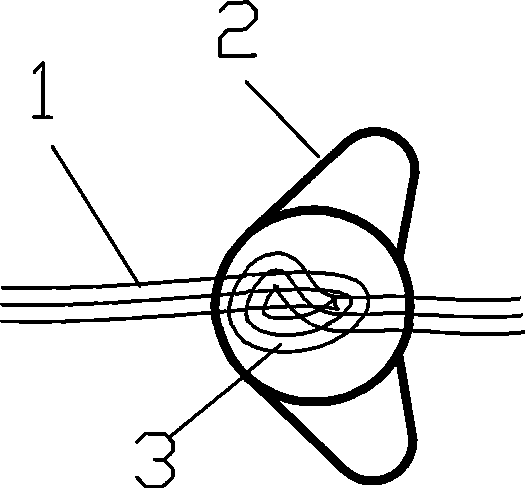

[0030] see Figure 1-Figure 3 , a novel rotor type fiber filter material of the present invention is made up of fiber bundle 1, rotor core 2, fiber section 3, wherein, the material of fiber section 3 and fiber bundle 1 is the same material or two different materials; The core of the rotor core 2 is integrated with the rotor; the fiber bundles 1 include linear distribution, several bundle plane intersection distributions or several bundle three-dimensional intersection distributions, and the distribution of the rotor core 2 on the fiber bundles 1 includes one, several A string of components, the distribution at the intersection of the plane intersection distribution or the distribution at the intersection of the three-dimensional intersection distribution; the core shape of the rotor core 2 includes spherical, ellipsoidal, and other pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com